Documente Academic

Documente Profesional

Documente Cultură

G. Std. ITP For Pipeline Job PDF

Încărcat de

Anonymous 4e7GNjzGWDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

G. Std. ITP For Pipeline Job PDF

Încărcat de

Anonymous 4e7GNjzGWDrepturi de autor:

Formate disponibile

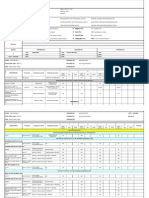

HINDUSTAN PETROLEUM CORPORATION LTD

STANDARD

INSPECTION

TEST PLAN

FOR

PIPELINE JOBS

STANDARD INSPECTION TEST PLAN FOR PIPING WORKS

PAGE: 1 of 4

HINDUSTAN PETROLEUM CORPORATION LTD

1.0

GENERAL

The enclosed ITPs shall be followed for the works to be performed by the Contractor

under this Tender. The provisions indicated for stagewise inspection by HPCL are a

minimum and the contractor shall develop a detailed ITP and obtain approval for the

same prior to commencement of work. Contractor to carry out 100% examination of all

activities.

2.0

LEGEND

HP:

W:

Hold point;

A point which requires inspection/ verification and acceptance by HPCL before

any further processing is permitted. The Contractor shall not process the

activity/ item beyond a Hold point without written approval by HPCL.

Witness Point;

An activity which requires witnessing by HPCL when the activity is performed.

Rw:

Review of Contractors documentation.

S:

Surveillance Inspection by HPCL;

Monitoring or making observations to verify whether or not materials/ items or

services conform to specified requirements. Surveillance activities may include

audit, inspections, witness of testing, review of quality documentation & records,

etc.

WC:

100% examination by Contractor.

Responsibility for execution of the inspection/testing is with the Contractor.

STANDARD INSPECTION TEST PLAN FOR PIPING WORKS

PAGE: 2 of 4

HINDUSTAN PETROLEUM CORPORATION LTD

____________________________________________________________________

S.NO.

ACTIVITY

CONTRACTOR

________________________________________________________________________

A.

HPCL

PRIOR TO FABRICATION

1.

Acceptance of the survey work prior to pipeline laying

WC

HP

2.

Acceptance of the Pipe support sleepers

WC

HP

3.

Incoming Material

Owners Supply

Contractors supply, including check testing

4.

Welding Filler Material Approval/Qualification

a) Manufacturing Test Certificate/Documents

b) Testing, if any

5.

WPS/PQR ( For Product Piping only )

a) Procedure

b) Testing

i) Carbon Steel

c) Approval of Final WPS/PQR

WC

WC

Rw

HP

WC

WC

Rw

W

WC

HP

WC

WC

HP

HP

WC

WC

W

HP

Note : Party to establish WPS/PQR within 15 days from the date of LOI

6.

a) Welder performance Qualification Test

b) Certification & Approval of welder

(For Product Piping Only)

7.

Review & approval of P&ID, GAD & Isometric drawings

WC

HP

8.

Fabrication, erection, testing procedure for job

WC

HP

B.

FABRICATION, ERECTION, WELDING & TESTING OF PIPES

1.

Blast cleaning (For Product piping only) and painting of pipes WC

2.

Pipe edge preparation, aligning over sleepers

3.

Erection & fitup of pipes including fittings, flanges etc.,

4.

Sequence of welding

WC

5.

Baking of electrodes

WC

6.

Inter-pass cleaning

WC

STANDARD INSPECTION TEST PLAN FOR PIPING WORKS

WC

WC

PAGE: 3 of 4

HINDUSTAN PETROLEUM CORPORATION LTD

7.

Visual check of welding

8.

DPT/RADIOGRAPHY of the joints

9.

Erection of valves

10.

Pipe supports welding

11.

Hydrotesting

STANDARD INSPECTION TEST PLAN FOR PIPING WORKS

WC

WC

W

HP

WC

W

WC

WC

W

HP

PAGE: 4 of 4

S-ar putea să vă placă și

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 paginiExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Welding Procedure Specification FormatDocument3 paginiWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- 27 Points of Difference Between Personnel Management & HRDDocument2 pagini27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Hydrostatic Test (Log) : Quality Control FormDocument22 paginiHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Welding Defect - MACRO PDFDocument5 paginiWelding Defect - MACRO PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Portland Cement: Standard Specification ForDocument9 paginiPortland Cement: Standard Specification ForHishmat Ezz AlarabÎncă nu există evaluări

- Ferrite Content MeasurementDocument5 paginiFerrite Content MeasurementFasil Paruvanath100% (1)

- Welding Log DW-CWDocument12 paginiWelding Log DW-CWhasan shahriarÎncă nu există evaluări

- D7029 - Inspection Release Note FormatDocument2 paginiD7029 - Inspection Release Note Formatnisha_khanÎncă nu există evaluări

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 paginiEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriÎncă nu există evaluări

- Daily Report-31 (Su Jinlong)Document3 paginiDaily Report-31 (Su Jinlong)sujinlongÎncă nu există evaluări

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 paginiA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarÎncă nu există evaluări

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 paginiItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- AKP Storage TanksDocument51 paginiAKP Storage Tankscris_2010Încă nu există evaluări

- Weld Defect Wall ChartDocument6 paginiWeld Defect Wall ChartMuhammad Attaulla KhanÎncă nu există evaluări

- Pressure Vessel ITP Rev 0Document10 paginiPressure Vessel ITP Rev 0SLC HosurÎncă nu există evaluări

- QAP For Conical StrainerDocument2 paginiQAP For Conical StrainersatishchidrewarÎncă nu există evaluări

- Specification For Visula Welding InspectionsDocument5 paginiSpecification For Visula Welding InspectionsAhmed Shaban KotbÎncă nu există evaluări

- Resume - 01.03.2016Document5 paginiResume - 01.03.2016muthuswamy77Încă nu există evaluări

- Itp TankageDocument7 paginiItp TankageIr FankovicÎncă nu există evaluări

- SAIC-W-2077 Weld Joint Identification SystemDocument1 paginăSAIC-W-2077 Weld Joint Identification Systemkarioke mohaÎncă nu există evaluări

- Asme Sec Ix (Welder Qualification)Document39 paginiAsme Sec Ix (Welder Qualification)VinodÎncă nu există evaluări

- Welder Id SampleDocument1 paginăWelder Id SampleArputharaj Maria LouisÎncă nu există evaluări

- Re-Welding, Expansion & HT ProcedureDocument6 paginiRe-Welding, Expansion & HT Proceduresuria qaqcÎncă nu există evaluări

- Welding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareDocument2 paginiWelding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareStoian ValentinÎncă nu există evaluări

- Visual Inspection ReportDocument2 paginiVisual Inspection ReportAlfian ImaduddinÎncă nu există evaluări

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 paginiBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHÎncă nu există evaluări

- Job Description NDTDocument4 paginiJob Description NDTNDTInstructorÎncă nu există evaluări

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 paginiRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Încă nu există evaluări

- Cold Tap Coating Report 2Document1 paginăCold Tap Coating Report 2Jamal BakhtÎncă nu există evaluări

- Itp Electrical SwitchgearDocument4 paginiItp Electrical SwitchgearpertmasterÎncă nu există evaluări

- Structural Steel and Pipe Work ProcedureDocument5 paginiStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Welding Inspector Job and ResponsilbilitiesDocument5 paginiWelding Inspector Job and ResponsilbilitiesFelix GomintongÎncă nu există evaluări

- ITP Heat ExchangerDocument1 paginăITP Heat Exchangersarmad009Încă nu există evaluări

- Instrumentation and ControlsDocument2 paginiInstrumentation and ControlsTrí NguyễnÎncă nu există evaluări

- Resume KunalDocument4 paginiResume KunalDevÎncă nu există evaluări

- Flash Report-2016-2-21Document3 paginiFlash Report-2016-2-21sujinlongÎncă nu există evaluări

- Pressure Vessel Dimension Inspection PDFDocument17 paginiPressure Vessel Dimension Inspection PDFEqubal KhanÎncă nu există evaluări

- Doc. No Revision No Revision DateDocument6 paginiDoc. No Revision No Revision DateShyam SinghÎncă nu există evaluări

- Receiving Material Procedure CoverDocument1 paginăReceiving Material Procedure Covergst ajahÎncă nu există evaluări

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 paginiHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdÎncă nu există evaluări

- QAP For PQR'S - For Impact TestingDocument3 paginiQAP For PQR'S - For Impact TestingDries VandezandeÎncă nu există evaluări

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 paginiElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifÎncă nu există evaluări

- PROJECT STANDARDS and SPECIFICATIONS Welding Qualification Test Procedure Rev01webDocument5 paginiPROJECT STANDARDS and SPECIFICATIONS Welding Qualification Test Procedure Rev01webhiyeonÎncă nu există evaluări

- ITP - PP Insulation Using Wire MeshDocument2 paginiITP - PP Insulation Using Wire MeshBurning TrainÎncă nu există evaluări

- PMT VQP RDocument26 paginiPMT VQP Rpvpallasigui3126Încă nu există evaluări

- 012 QualityNewsLetter - January2012Document8 pagini012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுÎncă nu există evaluări

- ACMV Inspeciton Check ListDocument22 paginiACMV Inspeciton Check ListNaing Win TunÎncă nu există evaluări

- Scope of ResponsibilitiesDocument2 paginiScope of ResponsibilitiesMuthu Srinivasan Muthu Selvam100% (1)

- Information and Inspection: Type of Test: Service Test / Leak TestDocument2 paginiInformation and Inspection: Type of Test: Service Test / Leak TestNorman MoralesÎncă nu există evaluări

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument3 paginiInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadÎncă nu există evaluări

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateDocument1 paginăDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueÎncă nu există evaluări

- Oman-India Fertilizer Project OIFDocument24 paginiOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Receiving Material Procedure (Done) (Sudah Direvisi)Document8 paginiReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangÎncă nu există evaluări

- ASME Buttweld Fittings ExplainedDocument13 paginiASME Buttweld Fittings ExplainedMarine SleimanÎncă nu există evaluări

- Material Inspection Report: Project Name Date InspDocument22 paginiMaterial Inspection Report: Project Name Date InspRafiqKuÎncă nu există evaluări

- Activity Report Running WPS & PQRDocument3 paginiActivity Report Running WPS & PQRAndre Brama AlvariÎncă nu există evaluări

- Inspection Report - ValvesDocument2 paginiInspection Report - ValvesJaspal KaurÎncă nu există evaluări

- How To Read Welding Gauges PDFDocument5 paginiHow To Read Welding Gauges PDFjimbox88Încă nu există evaluări

- D. Specs For Field & Shop PaintingDocument10 paginiD. Specs For Field & Shop PaintingrajeshÎncă nu există evaluări

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 paginiAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaÎncă nu există evaluări

- O - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationDocument8 paginiO - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationMDhana SekarÎncă nu există evaluări

- Vessel Final BoxDocument14 paginiVessel Final Boxmanoj thakkarÎncă nu există evaluări

- Lesson 14 WelderQuals - New2Document80 paginiLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- Inspection In Manufacturing A Complete Guide - 2020 EditionDe la EverandInspection In Manufacturing A Complete Guide - 2020 EditionÎncă nu există evaluări

- Name Name Name Name: To: CCDocument1 paginăName Name Name Name: To: CCAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 paginiSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 paginiSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 paginăSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWÎncă nu există evaluări

- Warrior Tech Spare Parts List 2Document1 paginăWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWÎncă nu există evaluări

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 paginiShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- Weld Joint Preparation Weld Joint PreparationDocument1 paginăWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Asme Ix QW PDFDocument183 paginiAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 paginiSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWÎncă nu există evaluări

- Kafou Health Safety Loss Prevention ProgramDocument117 paginiKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWÎncă nu există evaluări

- Bio Data-01.07.13Document2 paginiBio Data-01.07.13Anonymous 4e7GNjzGWÎncă nu există evaluări

- Numbering Format: Project DocumentationDocument1 paginăNumbering Format: Project DocumentationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Notes-Api Exams-Prathap DhasDocument7 paginiNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWÎncă nu există evaluări

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 paginiRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWÎncă nu există evaluări

- QW484Document1 paginăQW484Anonymous 4e7GNjzGWÎncă nu există evaluări

- HSMC Employee Induction Procedure (Offices)Document3 paginiHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWÎncă nu există evaluări

- Module 0-Course Orientation: Objectives OutlineDocument2 paginiModule 0-Course Orientation: Objectives OutlineEmmanuel CausonÎncă nu există evaluări

- Tripura 04092012Document48 paginiTripura 04092012ARTHARSHI GARGÎncă nu există evaluări

- ModelsimDocument47 paginiModelsimKishor KumarÎncă nu există evaluări

- MIDTERM Exam - Programming 2 - 2SEM 2020Document3 paginiMIDTERM Exam - Programming 2 - 2SEM 2020Bab bidiÎncă nu există evaluări

- Finite State MachineDocument75 paginiFinite State Machinecall_asitÎncă nu există evaluări

- EceDocument75 paginiEcevignesh16vlsiÎncă nu există evaluări

- 3D Tetris Cake Evening 2Document13 pagini3D Tetris Cake Evening 2Subham KarmakarÎncă nu există evaluări

- Stellite 6 FinalDocument2 paginiStellite 6 FinalGumersindo MelambesÎncă nu există evaluări

- BS EN 50483-6-2009 EnglishDocument27 paginiBS EN 50483-6-2009 EnglishДмитро Денис100% (2)

- IMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFDocument28 paginiIMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFNorman AinomugishaÎncă nu există evaluări

- Activity 6 Product Disassembly ChartDocument5 paginiActivity 6 Product Disassembly Chartapi-504977947Încă nu există evaluări

- PERSONAL DEVELOPMENT (What Is Personal Development?)Document37 paginiPERSONAL DEVELOPMENT (What Is Personal Development?)Ronafe Roncal GibaÎncă nu există evaluări

- Denial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Document1 paginăDenial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Gbp GbpÎncă nu există evaluări

- RRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestDocument46 paginiRRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestBharat KumarÎncă nu există evaluări

- Directorate of Technical Education, Maharashtra State, MumbaiDocument57 paginiDirectorate of Technical Education, Maharashtra State, MumbaiShubham DahatondeÎncă nu există evaluări

- The Ins and Outs Indirect OrvinuDocument8 paginiThe Ins and Outs Indirect OrvinusatishÎncă nu există evaluări

- Harish Raval Rajkot.: Civil ConstructionDocument4 paginiHarish Raval Rajkot.: Civil ConstructionNilay GandhiÎncă nu există evaluări

- Leadership Nursing and Patient SafetyDocument172 paginiLeadership Nursing and Patient SafetyRolena Johnette B. PiñeroÎncă nu există evaluări

- Python Cheat Sheet-1Document8 paginiPython Cheat Sheet-1RevathyÎncă nu există evaluări

- Supply Chain Management 101Document36 paginiSupply Chain Management 101Trần Viết ThanhÎncă nu există evaluări

- Chapter 4 Seepage TheoriesDocument60 paginiChapter 4 Seepage Theoriesmimahmoud100% (1)

- Mericon™ Quant GMO HandbookDocument44 paginiMericon™ Quant GMO HandbookAnisoara HolbanÎncă nu există evaluări

- Contract 1 ProjectDocument21 paginiContract 1 ProjectAditi BanerjeeÎncă nu există evaluări

- Citing Correctly and Avoiding Plagiarism: MLA Format, 7th EditionDocument4 paginiCiting Correctly and Avoiding Plagiarism: MLA Format, 7th EditionDanish muinÎncă nu există evaluări

- CNC Manuel de Maintenance 15i 150i ModelADocument526 paginiCNC Manuel de Maintenance 15i 150i ModelASebautomatismeÎncă nu există evaluări

- English 2 Q3 Week 7 DLLDocument7 paginiEnglish 2 Q3 Week 7 DLLEste R A BulaonÎncă nu există evaluări

- Technical Textile and SustainabilityDocument5 paginiTechnical Textile and SustainabilityNaimul HasanÎncă nu există evaluări

- Max9924 Max9927Document23 paginiMax9924 Max9927someone elseÎncă nu există evaluări