Documente Academic

Documente Profesional

Documente Cultură

1 - 201 - Steam and Water Drums

Încărcat de

yogaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 - 201 - Steam and Water Drums

Încărcat de

yogaDrepturi de autor:

Formate disponibile

Steam drum

In the early designs the drums were riveted or solid forged from a single

ingot, but for modern boilers the drum is generally fabricated from steel

plate of differing thicknesses and welded. The materials used are

governed by classification society rules. Test pieces must be provided.

The cylindrical drum is normally constructed from four plates.

Two dished End plates, a thick wall tube plate (thicker to accommodate

the holes drilled in it without increased stress) and completed with a

thinner wrapper plate.

Construction takes the form of rigidly clamping the descaled,

bent wrapper and tube plates together. In addition test pieces cut from

the original material are attached to the construction in such away that

the longitudinal weld extends either sided of the join. These pieces are

later removed and shaped test shapes cut out from specified areas

including across the weld.

The longitudinal weld is critical (taking twice the

circumferential stress) and is normally carried out by specialized

automatic machinery using submerged arc techniques.

The dished end pieces are accurately aligned and welded.

On completion the construction is cleaned and non-destructive

testing- such as x-ray photography, carried out. Final machining is

carried out and any stub pieces and doublers attached. The now

complete drum is heat treated at 600 to 650'C.

The final process is hydraulic testing to classification

requirements. Natural circulation within a boiler is due to the differing

specific gravities of the water at the differing temperatures, the steam

drum provides a reservoir of cool water to give the gravitational head

necessary for natural circulation. Cool water entering the steam drum

via the feed lines provides the motive effect for the circulation

distributing it to the downcomers.

Also the space within the drum provides for the separation of

the steam and water emulsions formed in the water walls and the

generating tubes. Water droplets entrained with the separated steam are

removed by separating components fitted in the drum as well as the

perforated baffle plates fitted at the water line.

The space above the water line provides for a reserve steam

space needed to maintain plant stability during manoeuvring conditions.

Also fitted are the chemical injection distributing pipe and the

scuming plate.

The smaller the drum is made, the less thickness of material

that is required. However, the limitation to how small is that sufficient

space must be allowed for the separation of water from the steam before

passing out to the superheater space otherwise dryers must be used.

Also, due to the smaller reserve of water, larger fluctuations in water level

occur during manoeuvring.

SAFETY VALVE CONFIGURATION

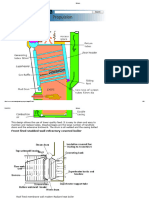

Figure 1

The internal fittings in the steam drum help distribute the water evenly

throughout the drum, separate the generated steam from the water and

remove moisture from the steam before it leaves the boiler (refer to Figure

2).

1. Lower baffle plates or apron plates Separate the incoming

feedwater and generated steam and direct the steam to the

separators.

2. Primary separators (cyclone separators) separate most of the water

from the steam by giving it a cyclone or rotary motion so that the

water particles are expelled from the steam by the centrifugal

forces. These separators are vertically mounted in the steam drum

so that the steam rises out the top and the water falls back into

the steam drum.

3. Secondary separators (chevron dryers) remove additional moisture

from the steam by changing the direction of steam flow several

times. The steam passes on but the moisture cannot make the

direction change with the steam. These separators are mounted

above the primary separators and direct steam to the dry box

which collects the steam at the top of the steam drum, directing it

to the steam outlet piping to the superheater.

4. Feedwater leaves the economizer and enters the boiler through the

internal feed pipe and becomes "boiler water." Perforations along

the side of the feed pipe allow water to be distributed evenly

throughout the steam drum (refer to Figure 2)

STEAM DRUM INTERNALS

Figure 2

5. Since suspended solids may accumulate on the surface of the

water in the steam drum, there must be means of removing them.

The surface blow pipe is used to remove these light suspended

solids from the surface of the water and to reduce the total

dissolved solid content of the boiler water. Suspended solids

usually consist of oil, salt contaminants, or excessive treatment

chemicals which can cause foaming on the water surface.

Dissolved solids usually consist of salt contaminants and

treatment chemicals that are in solution.

Water drum

Distributes feed water from the downcomers to the headers and

generating tubes. Provides a space for accumulating precipitates and

allows them to be blown down.

Water drum size is limited to that required to receive the

generating tubes, for modern radiant heat boilers with only a single bank

of screen tubes and no generating tubes between the drums, the water

drum has been replaced by a header and the downcomers fed straight to

the waterwall headers. With system blow down is done at the steam

drum. Too small a water drum can cause problems of maintaining ideal

water level and little steam reserve

S-ar putea să vă placă și

- Tray-Type Deaerator: A. Parallel DownflowDocument4 paginiTray-Type Deaerator: A. Parallel DownflowMuhammad Fakhriy IndallahÎncă nu există evaluări

- Deaerator TypesDocument4 paginiDeaerator TypesMuhammad Fakhriy Indallah0% (2)

- BoilerDocument47 paginiBoilerSahil Mishra100% (1)

- Ideal Steam DrumDocument6 paginiIdeal Steam DrumFahad RockingÎncă nu există evaluări

- Boiler Dru InternalsDocument18 paginiBoiler Dru InternalsRaghvendra Singh ShaktawatÎncă nu există evaluări

- BoilerDocument48 paginiBoilerAbdallah Mansour100% (2)

- Turbine AuxillariesDocument139 paginiTurbine AuxillariesAwez RanaÎncă nu există evaluări

- Fossil Fuel Steam GeneratorDocument33 paginiFossil Fuel Steam Generatorchaiya sonwongÎncă nu există evaluări

- Basic Boiler ConstructionDocument8 paginiBasic Boiler ConstructionLuthfi Yulian FikriÎncă nu există evaluări

- Drum Internal1Document12 paginiDrum Internal1mayurpatare100% (1)

- Basic Boiler ConstructionDocument37 paginiBasic Boiler ConstructionSudarmarine SudharÎncă nu există evaluări

- Nashik Generation Training Centre: Boiler Drum & Its InternalsDocument17 paginiNashik Generation Training Centre: Boiler Drum & Its InternalsAhemadÎncă nu există evaluări

- HRSG BoilersDocument40 paginiHRSG BoilersNadeem KhanÎncă nu există evaluări

- DeaeratorDocument3 paginiDeaeratorDHANDAPANIÎncă nu există evaluări

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Basic Boiler Construction GuideDocument8 paginiBasic Boiler Construction GuideIonescu FlorinÎncă nu există evaluări

- Modern Boiler ConstructionDocument7 paginiModern Boiler ConstructionMeghanath AdkonkarÎncă nu există evaluări

- Natural Circulation in BoilerDocument9 paginiNatural Circulation in BoilerSajjad AhmedÎncă nu există evaluări

- Boiler Drum and Its InternalDocument17 paginiBoiler Drum and Its InternalAhemad100% (1)

- Forced Air Cooled Transformer GuideDocument12 paginiForced Air Cooled Transformer GuideRizal BachtiarÎncă nu există evaluări

- PowerDocument26 paginiPowersenaÎncă nu există evaluări

- 1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeDocument21 pagini1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeAbdi samad MohamedÎncă nu există evaluări

- Blowdown Systems EG 9 - 2 PDFDocument4 paginiBlowdown Systems EG 9 - 2 PDFcvolkan1Încă nu există evaluări

- Boilers & SteamDocument25 paginiBoilers & SteamNarendra niranjan MathiyarasuÎncă nu există evaluări

- 3 Lecture 4 Steam Generator and ConditionarDocument19 pagini3 Lecture 4 Steam Generator and ConditionarHasib RyanÎncă nu există evaluări

- Boiler Feedwater DeaerationDocument5 paginiBoiler Feedwater DeaerationFA AyÎncă nu există evaluări

- Boiler and Turbine For BOE ExamDocument71 paginiBoiler and Turbine For BOE Examkeerthi dayarathnaÎncă nu există evaluări

- Report in Steam Generators: Schematic Diagram of A Boiler SystemDocument18 paginiReport in Steam Generators: Schematic Diagram of A Boiler SystemZa YonÎncă nu există evaluări

- Boiler DrumDocument8 paginiBoiler Drumvinod kumarÎncă nu există evaluări

- Blowdown ValvesDocument6 paginiBlowdown ValvesKyrie AbayaÎncă nu există evaluări

- Condenser CondenserDocument36 paginiCondenser Condenserobisonandlaw100% (1)

- Motor Ship Steam Plan1Document3 paginiMotor Ship Steam Plan1Jitendra KumarÎncă nu există evaluări

- Surface CondenserDocument7 paginiSurface Condensermhd_bashiriÎncă nu există evaluări

- Condenser Functions of Condensers: Plant Maintenance Work and Service - PracticeDocument18 paginiCondenser Functions of Condensers: Plant Maintenance Work and Service - PracticeTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- Open Feedwater Heaters Closed Feedwater HeatersDocument22 paginiOpen Feedwater Heaters Closed Feedwater HeatersM.Thirunavukkarasu100% (1)

- High Pressure Water Tube Boiler: Design, Working & AdvantagesDocument11 paginiHigh Pressure Water Tube Boiler: Design, Working & AdvantagesBien100% (1)

- Boiler Parts and FunctionsDocument35 paginiBoiler Parts and FunctionsHaseeb RazaÎncă nu există evaluări

- Steam Turbine Condenser: How it Works and TypesDocument33 paginiSteam Turbine Condenser: How it Works and TypesSatyam KumarÎncă nu există evaluări

- BoilersDocument26 paginiBoilersDeepak GawdeÎncă nu există evaluări

- Surface CondenserDocument33 paginiSurface CondensershivvaramÎncă nu există evaluări

- Boiler Preservation Methods Dry and WetDocument14 paginiBoiler Preservation Methods Dry and WetTin Aung KyiÎncă nu există evaluări

- Boiler Mountings and Accessories PDFDocument4 paginiBoiler Mountings and Accessories PDFShankar JhaÎncă nu există evaluări

- Submitted by GAURAV NETAMDocument13 paginiSubmitted by GAURAV NETAMAbhishek KumarÎncă nu există evaluări

- Wall Blowers or Water Cannon For Slagging FurnacesDocument2 paginiWall Blowers or Water Cannon For Slagging FurnacesKamal ArabÎncă nu există evaluări

- Boiler Components & Working ExplainedDocument14 paginiBoiler Components & Working Explainedavv456Încă nu există evaluări

- BoilerDocument23 paginiBoilerfaizan_3i6300Încă nu există evaluări

- DeaeratorDocument3 paginiDeaeratorfirojaga13100% (1)

- Instruction Manual Vacuum CondenserDocument12 paginiInstruction Manual Vacuum CondenserGarry BernzÎncă nu există evaluări

- Basic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerDocument12 paginiBasic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerAnand JinoÎncă nu există evaluări

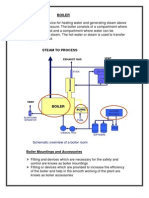

- Boiler Steam To ProcessDocument9 paginiBoiler Steam To ProcessMDR PRAPHUÎncă nu există evaluări

- Fire Water Tube BoilerDocument12 paginiFire Water Tube BoilerFatma HelalÎncă nu există evaluări

- Steam CondenserDocument53 paginiSteam CondenserGeorge Markas100% (1)

- Evaporator SDocument23 paginiEvaporator SMehwish NoorÎncă nu există evaluări

- Cooling TowersDocument35 paginiCooling Towersedbaka100% (1)

- 1 Boilers MmsDocument35 pagini1 Boilers MmsTahir MahmoodÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDe la EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshÎncă nu există evaluări

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- Scientific American Supplement, No. 446, July 19, 1884De la EverandScientific American Supplement, No. 446, July 19, 1884Încă nu există evaluări

- Adani Power's Goal of 20,000 MW by 2020Document43 paginiAdani Power's Goal of 20,000 MW by 2020Vara BikkinaÎncă nu există evaluări

- Water in Air Calculator - Version 3Document11 paginiWater in Air Calculator - Version 3yogaÎncă nu există evaluări

- Water quality monitoring in power plantsDocument13 paginiWater quality monitoring in power plantsAurenio RibeiroÎncă nu există evaluări

- PPChem 2015 17 06 342-353 NewDocument12 paginiPPChem 2015 17 06 342-353 NewyogaÎncă nu există evaluări

- PPChem 2015 17 06 342-353 NewDocument12 paginiPPChem 2015 17 06 342-353 NewyogaÎncă nu există evaluări

- Biomass Power Plant Performance ProcedureDocument67 paginiBiomass Power Plant Performance ProcedureMohd AshakriÎncă nu există evaluări

- Examples of Stator Winding Partial Dishcarge Due To Inverter DrivesDocument4 paginiExamples of Stator Winding Partial Dishcarge Due To Inverter DrivesyogaÎncă nu există evaluări

- Ae 101 GBDocument6 paginiAe 101 GBmoath1977Încă nu există evaluări

- Bohr-Sommerfeld QuantizationDocument6 paginiBohr-Sommerfeld QuantizationabihagulÎncă nu există evaluări

- DPR Nag River Volume IIIDocument290 paginiDPR Nag River Volume IIIashutosh_shahu1Încă nu există evaluări

- Alpacon Altreat 400Document12 paginiAlpacon Altreat 400EmadÎncă nu există evaluări

- TDS - RheoFIT 764Document2 paginiTDS - RheoFIT 764aahtagoÎncă nu există evaluări

- Defect SolidDocument21 paginiDefect SolidSafialMojnabin100% (1)

- Algebra:: N N N N N N 1B 2B ZoneDocument6 paginiAlgebra:: N N N N N N 1B 2B Zonevenedick sapongayÎncă nu există evaluări

- Boron Family (Exercise) Module-2-1Document11 paginiBoron Family (Exercise) Module-2-1Raju SinghÎncă nu există evaluări

- The Solar DynamoDocument29 paginiThe Solar Dynamoanizha_nÎncă nu există evaluări

- Masatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsDocument225 paginiMasatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsPo48HSDÎncă nu există evaluări

- Comparative Analysis of Sonic and Neutron-Density Logs For Porosity Determination in The South-Eastern Niger Delta Basin, Nigeria ODocument11 paginiComparative Analysis of Sonic and Neutron-Density Logs For Porosity Determination in The South-Eastern Niger Delta Basin, Nigeria OsardinetaÎncă nu există evaluări

- Gating ManualDocument84 paginiGating Manualmr.nguyenk100% (4)

- Accuracy Precision Significant Digits PDFDocument5 paginiAccuracy Precision Significant Digits PDFnkar037Încă nu există evaluări

- Material Science QuestionsDocument40 paginiMaterial Science QuestionsLucky KapoorÎncă nu există evaluări

- Gcse 239/01 Additional Science: Foundation Tier Biology 2 A.M. THURSDAY, 13 January 2011 45 MinutesDocument12 paginiGcse 239/01 Additional Science: Foundation Tier Biology 2 A.M. THURSDAY, 13 January 2011 45 MinutessureshthevanÎncă nu există evaluări

- Preservation and Conservation For Libraries and ArchivesDocument236 paginiPreservation and Conservation For Libraries and ArchivesflunkedÎncă nu există evaluări

- Earthing CalculationDocument4 paginiEarthing CalculationNipuna Thushara WijesekaraÎncă nu există evaluări

- Ball PistonDocument15 paginiBall PistonNm5793100% (1)

- Part 2 - AtmosphereDocument21 paginiPart 2 - AtmosphereMarie YabutÎncă nu există evaluări

- MIT8 02SC Notes16to18Document30 paginiMIT8 02SC Notes16to18GeorgeChangÎncă nu există evaluări

- Geotextile BookDocument63 paginiGeotextile BookIsparmoÎncă nu există evaluări

- SM ch1 Mat Meyers 2Document37 paginiSM ch1 Mat Meyers 2infinity_azÎncă nu există evaluări

- 9A03301 Materials Science and EngineeringDocument4 pagini9A03301 Materials Science and EngineeringsivabharathamurthyÎncă nu există evaluări

- Week 2 MineralsDocument23 paginiWeek 2 MineralsShuaib IsmailÎncă nu există evaluări

- Advantages and Disadvantages of Stainless Steel CookwareDocument15 paginiAdvantages and Disadvantages of Stainless Steel CookwareFaIz FauziÎncă nu există evaluări

- April 2010 One FileDocument296 paginiApril 2010 One FileSaad MotawéaÎncă nu există evaluări

- Comparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisDocument8 paginiComparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisPanagiotis GkezerlisÎncă nu există evaluări

- Acids and Alkalis Practice Test 1Document3 paginiAcids and Alkalis Practice Test 1Harry Baggaley100% (1)

- Carbohydrates OutlineDocument3 paginiCarbohydrates OutlineKalka BoroÎncă nu există evaluări

- IJCE v5n1p48 enDocument18 paginiIJCE v5n1p48 enAslam HutagiÎncă nu există evaluări