Documente Academic

Documente Profesional

Documente Cultură

Adiprene BLM 500

Încărcat de

8612106535Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Adiprene BLM 500

Încărcat de

8612106535Drepturi de autor:

Formate disponibile

Water Emulsifiable/Dispersible

Reactive Prepolymer

ADIPRENE BLM 500

PRODUCT DATA

Urethane

Prepolymers

ADIPRENE BLM 500

ADIPRENE BLM 500 is an MDI based urethane prepolymer with

blocked isocyanate curing sites, which can be activated by heating. The

blocked curing sites allow protracted storage of the polymer in the

presence of moisture and active vulcanizing agents. Diamine-cured

ADIPRENE BLM 500 yields vulcanizates having improved performance

over common TDI based urethane materials.

MDI is one of the most commonly used diisocyanates in industrial

polyurethane applications. However, blocked MDI prepolymer and its

application are very limited. Conventional MDI prepolymers generally

contain more than 10% free MDI, due to the need of using excess amount

of the diisocyanate in prepolymer preparation. Blocked prepolymers are

highly viscous and gel-like in appearance. This is from the high tendency

of crystallization of the blocked MDI.

ADIPRENE BLM 500 is a novel blocked system based on low free

isocyanate technology. With Chemturas unique process, the residual

MDI in the unblocked preoplymer is below 0.5%. The resulting blocked

prepolymer has very good processing characteristics, such as low viscosity

and melting point. Moreover, the widely used curative for conventional

MDI prepolymer is 1,4 butanediol (BDO).

Amine cured MDI

polyurethanes are preferred for many demanding applications, expecially

those requiring toughness and modulus retention at high temperature.

Thus, blocked MDI prepolymers open to the opportunity to use amine

curatives, for end-use properties not achieved by conventional MDI

urethanes.

Materials made from ADIPRENE BLM 500 have high tensile strength

and high elongation, and especially have excellent tear strength. They are

also low in viscous damping indicating low heat generation and more

durability in dynamic applications. ADIPRENE BLM 500 is well suited

as a vehicle for abrasion resistant coatings for fabric and rubber, and for

solvent-resistant adhesives.

ADIPRENE BLM 500

POLYMER PROPERTIES

TABLE I

Typical Properties of ADIPRENE BLM 500 Prepolymer

Physical form .......................................................... Viscous liquid

Color ....................................................................... Light yellow to amber

Isocyanate content, %

Blocked ............................................................. 4.17 4.63

Free ................................................................... 0.2 max.

Specific Gravity at 77F (25C).............................. 1.08

104F (40C) ........................... 1.07

Viscosity (Brookfield), cps (Pas)

@ 122F (50C) ................................................ 12,000 35,000 (12 35)

Raw prepolymer storage stability ........................... Excellent at room temperature. ADIPRENE

BLM 500 tends to freeze slowly when

stored at 75F (24C) or below. It is

unharmed by freezing and may be thawed

by storing overnight at 125F (52C). After

thawing, the liquid should be thoroughly

mixed before it is used.

Solubility................................................................. Soluble in most common solvents such as

toluene, ethyl acetate, methyl ethyl ketone,

and trichloroethylene. Solubility is limited

in aliphatic solvents and alcohols.

Handling Precautions .............................................. During heat cure, the blocking agent (methyl

ethyl ketoxime), a volatile flammable liquid

(b.p. above 302F [150C]), is evolved and

provisions must be made for removal of this

vapor. Trace amounts of diphenylmethane

diisocyanate may also be released during

cure. The blocking agent and diphenyl

methane diisocyanate are irritants and

harmful; exposure to and inhalation of their

vapors should be avoided.

Note: These data are presented to describe ADIPRENE BLM 500 and are not intended to serve as specifications.

ADIPRENE BLM 500

TYPICAL VULCANIZATE PROPERTIES

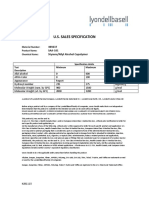

VULCANIZATE PROPERTIES

Cured films of ADIPRENE BLM 500 urethane rubber are tough, highly extensible and have a

high modulus. Table II shows the comparison of amine cured Adiprene BLM 500 and BL 16 (a

TDI based prepolymer), and BDO cured conventional MDI prepolymer. Using Lonzacure

MDEA and MDA, cured BLM 500 is tougher than BL 16/MDA, and much tougher than

conventional MDI prepolymer/BDO, in terms of higher hardness, modulus and tear strength.

Material from de-blocked/cured BLM 500 prepolymer also provides improved dynamic

performance. Figure 1 demonstrates much lower damping at both low and high temperatures of

material obtained with Adiprene BLM 500 (MDI based) vs. Adiprene BL 16 (TDI based.).

TABLE II

Property Comparison of Chain Extended

BLM 500 vs. BL 16 and conventional MDI.

Curative

B635*

BLM 500

BL 16

BDO**

MDEA*** MDA****

MDA

Hardness, Shore A .................................89........................ 95 ............. 97 .....................95

100% Modulus, psi ..............................1100.................... 2200 ......... 2100 .................1650

300% Modulus, psi ...............................----..................... 3800 ......... 2400 .................3650

Tensile, psi ...........................................6110.................... 6350 ......... 4250 .................5400

Elongation at break, %..........................390...................... 410 ........... 600 ...................455

Split Tear, pli .........................................80....................... 145 ........... 210 ...................130

Vibrathane B 635 is a conventional non blocked MDI/PTMEG prepolymer.

1,4 Butanediol.

4,4 methylene-bis-2,6 diehylaniline

4,4 methylene dianiline

Figure 1. BLM-500 vs BL-16; Damping Property Comparison

0.2

0.18

BLM-500/MDA

BL-16/MDA

0.16

0.14

0.12

Tan Delta

*

**

***

****

0.1

0.08

0.06

0.04

0.02

0

30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220

Temperature, C

ADIPRENE BLM 500

COMPOUNDING

CURING SYSTEMS

When unblocked by heat, the regenerated NCO groups in ADIPRENE BLM 500 react with any

of the materials (containing active hydrogens) normally used as isocyanate reactants. Thus

polyols and polyamines can be used as curatives. Polyols are quite slow in reacting with this

prepolymer, so the most useful curatives appear to be aromatic diamines such as 4,4 methylene

dianiline, and 4,4 methylene-bis-2,6 diethyl aniline.

ADIPRENE BLM 500 is unblocked by heating at 212 to 266F (100-130C) for a period of time

depending upon film thickness; a ten-mil (0.25mm) film of freshly mixed prepolymer and MDA

is fully cured after one hour at 266F (130C). Aged blends will cure somewhat faster.

Vulcanization of ADIPRENE BLM 500 in sections thicker than about 20 mils (0.50 mm) is

impractical because of the difficulty of removing the blocking agent from thick films without

blowing and subsequent porosity.

COMPOUNDING

Coatings and adhesives can be prepared in a wide viscosity range by diluting ADIPRENE BLM

500 with such solvents as toluene, xylene, ethyl acetate, or propylene glycol monomethyl ether

acetate. Table III shows the viscosity/solvent level relationship of a blend of ADIPRENE BLM

500 and propylene glycol monomethyl ether acetate (PMA).

TABLE III

Viscosity of Solvent Solutions of

ADIPRENE BLM 500

ADIPRENE BLM 500, 100 parts by weight

Propylene glycol monomethyl ether acetate, phr

Viscosity at 104F (40C), cps (Pas)

0............................................................................................

20..........................................................................................

40..........................................................................................

60..........................................................................................

70,000 (70)

3,000 (3.0)

650 (0.65)

250 (0.25)

A typical solvent-diluted composition is shown in Table IV. This composition can be prepared

as follows: mix ADIPRENE BLM 500 and propylene glycol monomethyl ether acetate at 104F

(40C); melt the MDA at 212F (100C) and add to the ADIRENE BLM 500 solution with

continuous stirring. MDA may also be added as a solution in solvent.

ADIPRENE BLM 500

SOLVENT INFORMATION

TABLE IV

Solvent Diluted Composition

Parts by weight:

ADIPRENE BLM 500 .............................................................................. 100

PMA (Propylene Glycol Monomethyl Ether Acetate).............................. 60

Methylene dianiline .................................................................................. 10

A substrate having a ten-mil (0.25mm) coating of the formulation in Table IV was heated at

158F (70C) for 20 - 30 minutes to drive off the solvent, followed by one hour at 266F (130C)

to cure the prepolymer. Properties of this cured coating are listed in Table II. Higher

temperature, for example 302F (150C), may shorten the time to cure the prepolymer.

Pigmented coatings can readily be prepared with ADIPRENE BLM 500.

Solventless mixtures of ADIPRENE BLM 500 and MDA can be prepared by melting the MDA

at 212F (100C) and adding it with continuous agitation to ADIPRENE BLM 500 which has

been warmed to about 158F (70C).a Viscosity vs. temperature of ADIPRENE BLM 500 is

given in Table V. Storage life will be reduced if ADIPRENE BLM 500 is heated above 176F

(80C). It may be necessary to heat solventless blends during application to achieve a workable

viscosity. A blend of ADIPRENE BLM 500 and 10 phr MDA will remain fluid at 158F (70C)

for more than one hour.

ADIPRENE BLM 500 should also be considered in adhesive applications. The ability to be

applied without solvents is a desirable feature in such applications. The cured film has a high

degree of resistance to dry cleaning solvents and provides a flexible bond to fabric-to-fabric and

flock bonding applications.

TABLE V

Viscosity of Adiprene BLM 500

Temperature, F (C)

122 (50)

140 (60)

158 (70)

Viscosity

13600 cps

6700 cps

510 cps

If the ADIPRENE BLM 500 or the agitator is not warm, molten MDA will crystallize before going into

solution. The resulting crystals will dissolve at an extremely slow rate.

5

REV: 12/04dd:7/05dd

S-ar putea să vă placă și

- Self-Adhesive Materials For Plastic Surfaces: Technical Info #7Document2 paginiSelf-Adhesive Materials For Plastic Surfaces: Technical Info #78612106535Încă nu există evaluări

- Surfactants Emulsion PolymersDocument2 paginiSurfactants Emulsion Polymers8612106535100% (2)

- Acrylol SynthesisDocument2 paginiAcrylol Synthesis8612106535Încă nu există evaluări

- 15885Document1 pagină158858612106535Încă nu există evaluări

- 1K Blocked Series BULLETIN PDFDocument1 pagină1K Blocked Series BULLETIN PDF8612106535Încă nu există evaluări

- Phenolic Resins Specification: Condition ConditionDocument1 paginăPhenolic Resins Specification: Condition Condition8612106535Încă nu există evaluări

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document9 paginiEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535Încă nu există evaluări

- EDTA Manganese Sodium (EDTA-MnNa2)Document2 paginiEDTA Manganese Sodium (EDTA-MnNa2)8612106535Încă nu există evaluări

- Morpholine PDFDocument2 paginiMorpholine PDF8612106535Încă nu există evaluări

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 paginiDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535Încă nu există evaluări

- EDTA Magnesium Sodium (EDTA-MgNa2)Document2 paginiEDTA Magnesium Sodium (EDTA-MgNa2)8612106535Încă nu există evaluări

- Morpholine PDFDocument2 paginiMorpholine PDF8612106535Încă nu există evaluări

- 3D Formpress Technologie GB US PDFDocument2 pagini3D Formpress Technologie GB US PDF8612106535Încă nu există evaluări

- Difference Ether Ester - 111010Document1 paginăDifference Ether Ester - 1110108612106535Încă nu există evaluări

- Desmocoll 400-1Document3 paginiDesmocoll 400-18612106535Încă nu există evaluări

- Sales Specification - US - 2Document1 paginăSales Specification - US - 28612106535Încă nu există evaluări

- TDS SR238 2Document1 paginăTDS SR238 28612106535Încă nu există evaluări

- HI-THANE A-3310D: Technical InformationDocument1 paginăHI-THANE A-3310D: Technical Information8612106535Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Carbon Fibre ReportDocument14 paginiCarbon Fibre ReportyoyotoyoÎncă nu există evaluări

- Steam Tracing Excel 2007Document74 paginiSteam Tracing Excel 2007cybermineÎncă nu există evaluări

- Electric FiringDocument146 paginiElectric FiringStefan Van Cleemput91% (11)

- Saf T Lok 2010 LiteratureDocument32 paginiSaf T Lok 2010 LiteratureNahbi Emilio PerezÎncă nu există evaluări

- Schaeffler DiagramDocument9 paginiSchaeffler DiagramAji Ashiq75% (4)

- Heat Treatment of Carbon SteelDocument10 paginiHeat Treatment of Carbon SteelPrasanna RajaÎncă nu există evaluări

- Galvany Shopprimer IZ182 (N) (Two-Component) : Product DescriptionDocument2 paginiGalvany Shopprimer IZ182 (N) (Two-Component) : Product DescriptionTrịnh Minh Khoa100% (1)

- 1-01 How To Use SSPCDocument7 pagini1-01 How To Use SSPCPratyush MylaÎncă nu există evaluări

- Investment MaterialsDocument191 paginiInvestment MaterialsPriyanka SetiaÎncă nu există evaluări

- Pipe SupportsDocument4 paginiPipe Supportsbabmech6007Încă nu există evaluări

- 04b Concrete Repair MethodsDocument37 pagini04b Concrete Repair MethodsUbaid Mazhar Abidi Syed80% (5)

- 5-ITP-Concrete Works PDFDocument4 pagini5-ITP-Concrete Works PDFShivarajJadhavÎncă nu există evaluări

- L25 Waterproofing of Walls, Beams, Columns, Slabs, Retaining Walls PDFDocument43 paginiL25 Waterproofing of Walls, Beams, Columns, Slabs, Retaining Walls PDFarancyppÎncă nu există evaluări

- FRP Rods For Brittle Fracture ResistantDocument9 paginiFRP Rods For Brittle Fracture Resistantdmsoares1989Încă nu există evaluări

- Centrifugal CastingDocument3 paginiCentrifugal Castingdurim-fcb4435Încă nu există evaluări

- P01 - PT in Building & Its AdvantagesDocument11 paginiP01 - PT in Building & Its AdvantagesPartha Pratim RoyÎncă nu există evaluări

- Pernos UNF UNCDocument14 paginiPernos UNF UNCEvelin MamaniÎncă nu există evaluări

- Special ConcreteDocument2 paginiSpecial ConcreteRamprasad KadaliÎncă nu există evaluări

- Borates in Gypsum BoardDocument2 paginiBorates in Gypsum BoardChetan PatelÎncă nu există evaluări

- Aci Code ListDocument2 paginiAci Code ListMohammed Ansar A MÎncă nu există evaluări

- TL - 260 - en 2015Document11 paginiTL - 260 - en 2015hand42100% (1)

- Silicone Rubber White PaperDocument6 paginiSilicone Rubber White PaperRahul YadavÎncă nu există evaluări

- IK Module 6 Easa Part 66Document246 paginiIK Module 6 Easa Part 66Hamzeh Al-Qaisi100% (1)

- Comparison of Jute Fiber Over Glass FibeDocument5 paginiComparison of Jute Fiber Over Glass FibeBobby LupangoÎncă nu există evaluări

- A Botany Lesson With Clay and UnderglazesDocument2 paginiA Botany Lesson With Clay and UnderglazesarianamoonÎncă nu există evaluări

- 3 CoatingDocument17 pagini3 CoatingChau NhiÎncă nu există evaluări

- Mechanical SealDocument64 paginiMechanical SealKhoh Kai ShengÎncă nu există evaluări

- HDPE DrainageDocument48 paginiHDPE DrainageKarthikeyan SankarrajanÎncă nu există evaluări

- BOQ For Civil-BhatindaDocument19 paginiBOQ For Civil-BhatindaRajesh ChowhanÎncă nu există evaluări

- Engineering MaterialsDocument29 paginiEngineering MaterialsSyed Waqar AhmedÎncă nu există evaluări