Documente Academic

Documente Profesional

Documente Cultură

Manual Viscosímetro

Încărcat de

luigi_mazzuccoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual Viscosímetro

Încărcat de

luigi_mazzuccoDrepturi de autor:

Formate disponibile

Operating Instructions

Automated Viscosity

Analyzer

HVB

U 480, HVU481 und HVU482

Walter Herzog GmbH

Testing Equipment for Petroleum Products

Badstrae 3-5

D-97912 Lauda-Knigshofen, P.O.Box 1241

Germany

Telefax

++49 ()9343 / 640-101

Internet: www.Walter-Herzog.com

Sales department:

Telephone: ++49 (0)9343 / 640-0

E-Mail: Sales@Walter-Herzog.com

Service:

Telephone:++49 (0)9343 / 640-181

E-Mail: HSC@Walter-Herzog.com

Automated Viscosity Analyzer HVU 480/481/482

Copyright

The Automatic Viskosimeter HVU481/482 and this manual are protected by copyright.

Reproduction of the unit will result in prosecution.

All rights to the manual are reserved. Reproduction in any form, including in the form of

excerpts, shall require written permission from the copyright holder.

We reserve the right to make technical and content changes including without prior notice.

Liability

The manual was carefully checked prior to issue. However, no express or implicit liability

whatsoever is assumed for losses or consequential losses arising from the use of this manual.

Claims for damages are excluded unless gross negligence, deliberate action or errors in the

assured properties of the unit can be proved against the company Walter Herzog GmbH.

We accept no liability for losses arising from the improper use of the unit or use other than as

intended.

Great care was taken on the development of the software program. But neither Walter Herzog

GmbH nor the Licensor will take upon any guarantee, juridical responsibility or liability for

any consequences arising by the use of the program, above all for lacking economical success,

missed earnings, consequential damages and deficiently consequential damages.

According to the current state of engineering it is not possible to develop computer software

in such a way that it will work faultlessly under any applicability and combination. This is

mostly the result of the large number of the various hardware configurations.

All brand names and product names mentioned are trademarks or registered trademarks of the

relevant companies or organizations.

Copyright 1996 WALTER HERZOG GmbH,

D-97922 Lauda-Knigshofen

Doc.- Nr.: 820-087

Introduction

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Contents

1

2

5

6

Introduction ........................................................................................................................ 7

1.1

General ....................................................................................................................... 7

1.2

Amendment to Operating Instructions ....................................................................... 8

Technical Specifications.....................................................................................................9

2.1

Unit Values HVU 480/481 ......................................................................................... 9

2.2

Unit Values HVU 482 ..............................................................................................10

2.3

Ambient and Operation Conditions.......................................................................... 11

HVU 480/481/482 Configuration..................................................................................... 13

3.1

General ..................................................................................................................... 13

3.2

Ordering information:............................................................................................... 14

3.3 ......................................................................................................................................... 15

3.4

Accessories specific for HVU481 ............................................................................ 17

3.5

Accessories specific for HVU482: ........................................................................... 18

3.6

Accessories for HVU481 and HVU482: ..................................................................20

3.7

HVU 482 NTC Capillaries (Sensor B) ..................................................................... 25

3.8

HVU 482 with capillaries from the HVU480/481....................................................25

HVU 480/481/482 Installation ......................................................................................... 27

4.1

General ..................................................................................................................... 27

4.2

HVU 480/481 Installation Procedure ....................................................................... 28

4.2.1 Cleaning Solvents for HVU 480/481 ......................................................................29

4.3

HVU 482 Installation Procedure .............................................................................. 29

4.3.1 Solvents for HVU 482 ............................................................................................. 30

4.3.2 Filling of the drying tubes ....................................................................................... 31

4.3.3 Installation of the drying tubes ................................................................................ 32

4.3.4 Installation of the cold trap...................................................................................... 32

4.4

Connection of a slop sensor (Accessory) ................................................................. 33

4.4.1 Not networked units with slop sensor ..................................................................... 33

4.4.2 Several units with one common used slop sensor ................................................... 33

4.4.3 Networked units with own slop sensor.................................................................... 33

4.5

Coding of the measurement points ........................................................................... 34

4.6

Connection between HVU 480/481/482 and printer ................................................ 34

4.7

Connection of several HVU 480/481/482 units to one printer................................. 35

4.8

Connection of several HVU 480/481/482 units to a PC........................................... 35

HVU 480/481/482 Operation ........................................................................................... 37

5.1

Menu Range.............................................................................................................. 37

Program Measurement...................................................................................................... 39

6.1

General ..................................................................................................................... 39

6.2

Sample Identification................................................................................................ 40

6.3

Programming of parameters ..................................................................................... 40

6.4

Bath heating? ............................................................................................................41

6.5

Start of testing procedure.......................................................................................... 41

6.6

Aborting the viscosity measurement ........................................................................ 41

6.7

Viscosity measurement procedure............................................................................ 42

6.8

End of test................................................................................................................. 42

6.8.1 Display of viscosity and flow periods ..................................................................... 42

6.8.2 Printing test results .................................................................................................. 43

6.9

Program Overview.................................................................................................... 44

Version 21.1B/14.1B

Introduction

Automated Viscosity Analyzer HVU 480/481/482

Parameter Program ........................................................................................................... 47

7.1

General information.................................................................................................. 47

7.2

Standard/non-standard .............................................................................................. 48

7.3

Left Capillary............................................................................................................ 48

7.4

Right Capillary ......................................................................................................... 48

7.5

Programming Analysis Tolerance ............................................................................ 48

7.6

Cleaning.................................................................................................................... 49

7.7

Pre-flush ................................................................................................................... 50

7.8

Solvent 1 ................................................................................................................... 50

7.9

Solvent 2 ................................................................................................................... 51

7.10 Drying....................................................................................................................... 51

7.11 Sample Measurement ............................................................................................... 52

7.12 Equilibration time ..................................................................................................... 52

7.13 Equilibration type ..................................................................................................... 52

7.14 Temperature Units (C/F) ....................................................................................... 53

7.15 Bath Temperature ..................................................................................................... 53

7.16 Bath calibration ........................................................................................................ 54

7.17 Cooling valve temperature........................................................................................ 55

7.18 Acceleration due to gravity ...................................................................................... 55

7.19 Slop sensor connected?............................................................................................. 56

7.20 Data transfer ............................................................................................................. 56

7.21 Printer ....................................................................................................................... 57

7.22 Print .......................................................................................................................... 57

7.23 Printing Viscosity Results ........................................................................................ 57

7.24 Capillary Calibration ................................................................................................ 58

7.25 Text Language .......................................................................................................... 58

7.26 Interval air dryer ....................................................................................................... 59

7.27 Bath heating? ............................................................................................................59

7.28 Parameter Print-out................................................................................................... 60

7.29 Change Password...................................................................................................... 61

7.30 Parameter Overview ................................................................................................. 62

8

Viscosity measurements ................................................................................................... 67

8.1

General ..................................................................................................................... 67

8.2

Drying of the viscometers for the HVU 482 ............................................................ 67

8.2.1 Bath temperature above the dew point .................................................................... 67

8.2.2 Bath temperature below the dew point .................................................................... 68

8.3

HVU482 and Viscometer with hose connection ...................................................... 68

8.4

Preparation and execution of viscosity measurements ............................................. 68

8.5

Measuring result deviations with the HVU 482 .......................................................69

9

Diagnostic Program .......................................................................................................... 71

9.1

General ..................................................................................................................... 71

9.2

Check the Reference Resistors ................................................................................. 71

9.3

Bath Temperature Display........................................................................................ 72

9.4

NIR detection left .....................................................................................................72

9.5

NIR detection right ................................................................................................... 72

9.6

NTC detection left .................................................................................................... 73

9.7

NTC detection right .................................................................................................. 73

9.8

Bath Cooling Valve .................................................................................................. 73

9.9

Bath Heaters ............................................................................................................. 74

Introduction

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

9.10

9.11

9.12

9.13

9.14

9.15

9.16

9.17

9.18

9.19

9.20

9.21

9.22

9.23

9.24

9.25

9.26

Slop Tank Level ....................................................................................................... 74

Solvent left................................................................................................................ 75

Solvent right .............................................................................................................75

Solenoid Valves Left ................................................................................................ 75

Solenoid Valves Right .............................................................................................. 76

Air Pressure Pump .................................................................................................... 76

Vacuum Pump .......................................................................................................... 76

Detection Left ........................................................................................................... 76

Detection Right......................................................................................................... 77

Buzzer (acoustic signal)............................................................................................ 77

Set the Clock 24/12 Hour Mode ............................................................................... 77

Set the Clock Time ................................................................................................... 78

Date Programming.................................................................................................... 78

Inspek air dryer in..................................................................................................... 78

Bath Circulation Values............................................................................................ 79

HVU 480/481/482 Software (manufacturer use only) ............................................. 80

Diagnostic Overview ................................................................................................ 81

10

Messages....................................................................................................................... 85

10.1 Messages of the HVU 480/481/482 ......................................................................... 85

10.1.1 Error numbers 1.................................................................................................. 86

10.1.2 Error numbers 10................................................................................................88

10.1.3 Error numbers 20................................................................................................91

10.1.4 Error numbers 30................................................................................................94

10.1.5 Error numbers 40................................................................................................94

10.1.6 Error numbers 60................................................................................................94

10.1.7 Error numbers 90................................................................................................95

10.1.8 Error messages that are coded into the flow out times .......................................... 96

11

Cleaning Cycle ............................................................................................................. 97

11.1 General information.................................................................................................. 97

11.2 Initial flushing ..........................................................................................................99

11.3 Flushing .................................................................................................................... 99

11.4 Drying..................................................................................................................... 100

11.5 Cleaning Program Overview .................................................................................. 101

12

HVU 480/481/482 Construction Overview................................................................ 102

12.1 HVU 480/481/482 Mechanics Overview ............................................................... 102

12.2 HVU 480/481/482 Electronics Overview .............................................................. 103

13

HVU 480/481/482 Serial Output................................................................................106

13.1 General ................................................................................................................... 106

13.2 Protocol Capillary Left ........................................................................................... 107

13.3 Protocol Capillary Right......................................................................................... 108

13.4 Protocol Example: .................................................................................................. 110

14

HVU 480/481/482 Calibration ................................................................................... 112

14.1 General ................................................................................................................... 112

14.2 Available mercury thermometers ........................................................................... 113

14.3 Check of Time Measurement ................................................................................. 113

15

Spare Parts .................................................................................................................. 115

15.1 HVU 480 Spare Parts ............................................................................................. 115

15.2 Recommended spare parts for appr. 2 years of operation for HVU481+482......... 118

15.3 Recommended spare parts for appr. 2 years of operation specific for HVU481....121

Version 21.1B/14.1B

Introduction

Automated Viscosity Analyzer HVU 480/481/482

15.4 Recommended spare parts for appr. 2 years of operation specific for HVU482....122

15.5 Other spare parts for HVU481 + HVU482............................................................. 123

15.6 Configuration of the Measurement Unit................................................................. 128

15.7 CPU with keyboard and display controller 607-252 .............................................. 129

15.7.1 Configuration Master/Slave................................................................................. 129

15.7.2 Configuration Display controller.........................................................................130

16

Peculiarities ................................................................................................................ 131

16.1 Viscosity Determination acc. to DIN 51 562 ......................................................... 131

17

Maintenance ............................................................................................................... 133

17.1 Maintenance work for HVU 482 ............................................................................ 133

17.1.1 Maintenance of the drying tubes (optional)......................................................... 133

17.1.2 Maintenance of cold trap (optional) .................................................................... 134

17.1.3 Removal of the moisture in the thermostated bath by heating ............................ 134

18

HVU 480/481/482 Documentation............................................................................. 135

18.1 General ................................................................................................................... 135

18.2 Resistance Table ..................................................................................................... 136

18.3 Drawings and wiring diagrams............................................................................... 137

18.4 HVU 480/481/482 Identification Diagrams ...........................................................137

Introduction

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

1 Introduction

1.1

General

The viscosity determination for mineral oils, hydrocarbons and other transparent or

non-transparent liquids that behave like Newton's fluid represents a testing method

often required by the mineral oil industry. The product specifications define the

respective allowable viscosity range. Within the allowable limit ranges, it is thus

particularly important to achieve accurate measurements with an extremely high

reproducibility. This requires the use of a highly accurate viscometer, a viscosity

bath with an extremely high temperature stability and an accurate time measurement.

A number of glass viscometers are available to determine the kinematic viscosity.

The Ubbelohde viscometer with a suspended sphere level has proven to be a device

producing the most accurate measurements. Due to the design features of the unit,

the coefficient of expansion exhibited by the glass at different temperatures has such

a minor effect that it can be neglected.

The Herzog HVU 480/481/482 is based on this Ubbelohde viscometer and uses a

fourth glass tube to obtain an automatic cleaning phase; it is available in two

versions.

With NIR - Can be used for transparent to very dark samples (order no.

04805-000-XX). When the meniscus is no longer operative due to the low

transparency exhibited by the sample, the HVU 480/481/482 program switches

automatically to the through-view mode.

With NTC - Used for non-transparent samples or for samples that absorb NIR

(near infrared) or reflect through solid bodies (order no. 04806-000-XX).

NIR and NTC viscometers can be used simultaneously in a HVU 480/481/482

bath.

The Herzog HVU 480/481/482 is fitted with a viscosity bath to receive 2 HVU

480/481/482 Ubbelohde viscometers yielding a measurement range of between +20

C and +150 C, with an automatic washing and drying device, electronic time

measurement unit and a program that meets the requirements of our world-wide

clients (manufacture and supply of viscometers since 1977). A special silicon oil is

required as the bath liquid. The unit was designed such that it includes features to

protect the environment (small solvent quantity for cleaning purposes).

Version 21.1B/14.1B

Introduction

Automated Viscosity Analyzer HVU 480/481/482

The Herzog HVU 480/481/482 viscometers can be used as individual units or with

the VISNET data bank software (optional) with a personal computer using Windows.

It is possible to control up to 16 HVU 480/481/482 testing units with up to 32

measurement points by means of one serial interface of a central PC and to

automatically transfer the data to the VISNET data bank. Automatic viscosity index

calculations as well as statistical evaluations can be executed by means of the data

bank.

To obtain testing protocols from a joint printer (optional), it is possible to link up to

16 HVU 480/481/482 units without the need to operate a PC.

1.2

Amendment to Operating Instructions

This Operating Instructions (Version 21.1B) describe the functions of the instruments

with HLIS-Versions:

HLIS16

unit version 14.1B

HLIS32

unit version 21.1B

Introduction

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

2 Technical Specifications

2.1

Unit Values HVU 480/481

Standard methods

DIN 51562

ASTM D 445

IP 71

Mains voltage

230 V

Mains frequency

50 or 60 Hz

Power rating (Watt)

1200 Watt

Dimensions (WxDxH)

350x500x900 mm

Weight

88 kg (HVU480)

100kg (HVU481)

Temperature indication

Sample volume

C / F

20ml

Viscosity range

1-50 000 mm2/s

Temperature range

20-150 C

68-302 F

Detection system

NIR or NTC

Consumption of cleaning solvent

10 ml per cycle

Text language

German/English

Cooling of the temperature regulated bath below ambient air temperature can be

achieved with a independent cooling system.

Output of viscosity measurement can be seen on the HVU 480/481 display and/or with a

PC.

HVU 480/481 results can be printed out with a printer

Version 21.1B/14.1B

Technical Specifications

Automated Viscosity Analyzer HVU 480/481/482

2.2

Unit Values HVU 482

Standard methods

DIN 51562

ASTM D 445

IP 71

Mains voltage

230 V 10 %

Mains frequency

50 or 60 Hz

Power rating (Watt)

1200 Watt

Dimensions (WxDxH)

350x515x900 mm

Weight

102 kg

Temperature indication

C / F

Sample volume

20 ml

Viscosity range

1-50 000 mm2/s

Temperature range

-40 to +100 C

-40 to +212 F

Detection system

+100C

Sensor A from -40C to

Sensor B from +20C to

+100C

Required cooler power at HVU 482 bathtemp.

-20 C ==> 150 Watt

-40 C ==> 200 Watt

Cooling valve

optional, external

Consumption of cleaning solvent

10 ml per cycle

Text language

German/English

Cooling of the temperature regulated bath below ambient air temperature can be

achieved with a independent cooling system.

Output of viscosity measurement can be seen on the HVU 482 display and/or with a

PC.

HVU 482 results can be printed out with a printer

10

Technical Specifications

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

2.3

Ambient and Operation Conditions

For the operation of the HVU 480/481/482 the following conditions must be

fulfilled. If the instrument is used for other purposes or is operated without fulfilling

these conditions, the producer will take no liability.

The HVU 480/481/482 is a viscosity automate for the detection of viscosity

according to ASTM 445.

The permissible location of use is the industry sector.

The instrument is constructed according to safety class 1 and may therefore

only be operated at a grounded plug (with safety contact).

The voltage fluctuations of the power supply net may not exceed 10 % of the

nominal value.

The external connection cables RS232, Centronics and HTR must be shielded.

The instrument should only be operated at ambient temperatures between 10C

and 35C. The best results are achieved between 15C and 25C.

The storage temperatures should not exceed the range of -15C to +55C.

The relative air humidity may be maximum 60 % at temperatures up to 35C

The initial boiling point from the solvent, for cleaning the capillaries should be

distinct higher as the bath temperature.

Version 21.1B/14.1B

Technical Specifications

11

Automated Viscosity Analyzer HVU 480/481/482

12

Technical Specifications

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

3 HVU 480/481/482

Configuration

3.1

General

The HVU 480/481/482 Viscometer is an integrated unit. The main components

include:

Electronic controller

Temperature regulated bath and fixtures for two Ubbelohde capillaries

Color coded connectors to the capillaries

Three bottles are needed; two to store cleaning solvents and the other bottle for slop

which is generated from the cleaning cycle.

The HVU 480/481/482 arrives with 20 liters of manufacturer specified silicone oil.

Sample material used for viscosity analysis is filled into the capillary with a

disposable hypodermic syringe. The available Ubbelohde capillaries along with their

part numbers are listed here.

Version 21.1B/14.1B

HVU 480/481/482 Configuration

13

Automated Viscosity Analyzer HVU 480/481/482

3.2

Ordering information:

Order No.

Description

Picture

04811-000-00

Herzog Automated HVU 481 Viscometer acc.

To ASTM D 445, complete with integrated

keypad, display, temperature bath, 2

Ubbelohde style NIR capillary tubes as

specified below (NTC detection on request)

timing and cleaning systems.

Bath temperature range +20 to +150 C.

Up to 16 viscometers baths may be connected

to a PC for data acquisition, test program

setting and results management with HLIS-32

(Herzog Laboratory Information System).

Order this instrument is at some future time

you may want to upgrade to use the MP491

sample changers.

For 230 V +/- 10%, 50 Hz. Power cord with

Continental European IEC/DIN plug.

Capillaries

Standard Supply are 2 NIR viscometer

capillaries with constants 0.1 and 1.0

otherwise please select 2 capillaries from the

accessory list below.

Accessories included:

04831-000-00 Silicone bath oil, can of 20 liters

1 x 414-143 Solvent supply and slop

disposal hose; Teflon, 6 m,

6mm x 7mm x 0.5 mm

2 x 370-323 Solvent pre-filter 45m mesh

1 x 626-082 Connection cable for HTR

communication, instrument to

instrument, short, 0,8 m

1 x 101-052 Cord with Continental European

IEC/DIN plug. DIN mains

connector

1 x 412-221 Set of hexagonal wrenches:

1.5; 2; 2.5; 3; 4; 5mm.

04811-000-60

Herzog Automated HVU 481 Viscometer acc.

To ASTM D 445 as above but

for 230 V +/- 10%, 60 Hz

625-113

Transformer 1380W; In 115V, out 230V,

With 2 sockets for Continental European

IEC/DIN plug.

625-116

Transformer 1380W; In 208V, out 230V,

With 2 sockets for Continental European

IEC/DIN plug.

14

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

3.3

Order No.

Description

04821-000-01

Herzog Automated HVU 482 Viscometer,

operating normal and low bath temperatures,

acc. to ASTM D 445, complete with integrated

keypad, display, temperature bath, 2

Ubbelohde style NIR capillary tubes.

Bath temperature range: -40 to +100C

(-20 to -40C 8 hours only)

-without external cooling:

+50 to +100C

Bath temp. Stability:

+/- 0,01C

Temperature indication:

C or F

Required cooler power: -20C = 150 Watt

-40C = 200 Watt

Meniscus detection: NIR from -40 to +100C

NTC from +20 to +100C

Viscometer cleaning: automatically

Air drier:

Molecular sieve

Up to 16 viscometers baths may be connected

to a PC for data acquisition, test program

setting and results management with HLIS-32

(Herzog Laboratory Information System).

For 230 V +/- 10%, 50 Hz. Power cord with

Continental European IEC/DIN plug.

Capillaries

Standard Supply are 2 NIR viscometer

capillaries with constants 0.1 and 1.0

otherwise please select 2 capillaries from the

accessory list below.

Accessories included:

04341-000-00 Silicone bath oil, can of 20

liters

2 x 108-286 Drying tube for capillaries

(filled with molecular sieve)

and connection hose

1 x 108-315 Drying tube for bath (filled with

molecular sieve) and

connection hose

1 x 414-143 Solvent supply and slop

disposal hose; Teflon, 6 m,

6mm x 7mm x 0.5 mm

2 x 370-323 Solvent pre-filter 45m mesh

1 x 626-082 Connection cable for HTR

communication, instrument to

instrument, short, 0,8 m

1 x 101-052 Cord with Continental

European IEC/DIN plug. DIN

mains connector

1 x 412-221 Set of hexagonal wrenches:

1.5; 2; 2.5; 3; 4; 5mm.

04821-000-61

Herzog Automated HVU 482 Viscometer,

operating normal and low bath temperatures

as above but:, 230V +/- 10%, 60Hz.

Version 21.1B/14.1B

Picture

HVU 480/481/482 Configuration

15

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

Picture

625-113

Transformer 1380W; In 115V, out 230V,

With 2 sockets for Continental European

IEC/DIN plug.

625-116

Transformer 1380W; In 208V, out 230V,

With 2 sockets for Continental European

IEC/DIN plug.

16

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

3.4

Accessories specific for HVU481

Order No.

Description

Picture

110-141

Kit to Upgrade from HVU481 to HVU490 in

order to use MP491 sample changers

04911-000-02

Automatic Sample Changer MP491 for 2

converted HVU481 baths with a 48 samples

capacity.

Complete with a set of 48 sample beakers.

For 230 V +/- 10%, 50 or 60 Hz (please specify

in your order).

04911-000-04

Automatic Sample Changer MP 491 for a 4bath capacity with a 96 sample capacity.

Complete with a set of 96 sample beakers.

For 230 V +/- 10 %, 50 Hz or 60 Hz (please

specify in your order).

08283-000-00

External circulation cooler obtains bath

temperatures from 20 . 40C.

Cooler must be positioned on the bench level

of the viscometer. Max. pump pressure 0.15

bar.

For 230 VAC, 50 Hz, 300 W .

Power cord with Continental European IEC/DIN

plug.

Dimensions 200 x 350 x 500 mm (w x d x h)

08290-000-00

External circulation cooler obtains bath

temperatures from 20C 40C.

With powerful pump, cooler can be placed

under the bench on floor level. Max. pump

pressure 0.4bar.

Working temperature -10 to +120C,

Cooling Power: 150 W at 20C

Bath volume3 - 4,5 ltr.

For 230VAC, - 50 Hz, 300W.

Power cord with Continental European IEC/DIN

plug.

Dimensions 200 x 350 x 550 mm

301-047

Silicone connection hose in8x2mm with

out 32mm Armaflex isolation for connection

of cooler to viscometer (2 m)

Version 21.1B/14.1B

No picture

HVU 480/481/482 Configuration

17

Automated Viscosity Analyzer HVU 480/481/482

3.5

Accessories specific for HVU482:

Order No.

Description

04825-000-01

Low temp. NIR-Ubbelohde Viscometer capillary

for HVU 482 , with NIR meniscus detection,

ready mounted in holder, with engraved

capillary constant and color coding for

connection to hoses,

Constancy "C" appr. 0,001 mm2/s2

range 0,2 to 1,2 mm2/s.

04825-000-02

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,003, range 0,6 to 3,0 mm2/s

04825-000-03

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,005 range 1,0 to 5,0 mm2/s

04825-000-04

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,01, range 2,0 to 10,0 mm2/s

04825-000-05

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,03, range 6,0 to 30,0 mm2/s

04825-000-06

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,05, range 10,0 to 50,0 mm2/s

04825-000-07

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,1, range 20,0 to 100,0 mm2/s

04825-000-08

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,3, range 60,0 to 300 mm2/s

04825-000-09

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 0,5, range 100 to 500 mm2/s

04825-000-10

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 1,0 range 200 to 1000 mm2/s

04825-000-11

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 3,0, range 600 to 3000 mm2/s

04825-000-12

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 5,0, range 1000 to 5000 mm2/s

04825-000-13

Low temp. NIR Ubbelohde Viscometer for HVU

482, c = appr. 10, range 2000 to 10.000

mm2/s

08301-000-00

Circulation cooler recommended for Viscosity

determinations down to -20C

Working Temp. range:45 to +150C

Temperature control:

0.02C

Resolution of indication:

0.1C

Bath volume:

5.5.8 l

Dimensions (WxDxH):

40 x 50 x 78 cm

Voltage:

230V, 50Hz

Power

2 kW

Power cord with Continental European

IEC/DIN plug.

18

Picture

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

08284-000-00

Circulation cooler recommended for

Viscosity determinations down to -40C

Continuous cooling by operation with max.

cooling capacity, depending on load, up to -80

degree C.

With air-cooled compressors, floor-mounted

unit with grips and 4 castors.

Temp-adjustment/display: digital red LED

Display resolution:

1 degr. C

Flow rate:

22 l/min. max.

Max. feed pressure:

0,5 bar

Bath Volume:

11 ltr. appr.

Cooling capacity:

450 W at 20 C

90 W at -80 C

Cooling medium:

R 404 a/TP5R3

-free of CFCDimensions (WxDxH):

50x62x75 cm

Voltage:

230V, 50Hz,

Power:

1,1 kW max.

Power cord with Continental European IEC/DIN

plug.

301-047

Silicone connection hose in8x2mm with

out 32mm Armaflex isolation for connection

of cooler to viscometer (2 m)

101-173

Isolation valve, isolates the external chiller

when cooling is not necessary and prevents

excessive bath heating against the cooler.

24 V, 12 W, ND 6 mm

01000-445-51

Certified Reference Material for viscosity verification

and calibration, at low temperature, 500ml, with

Certificate stating result and accuracy

2

JF1, 3.7 mm /s @ -20C

108-332

Adaptor set to connect HVU481 NIR capillaries

of the 04805 type and NTC capillaries of

the04806 type to the thread couplings of the

HVU482.

Attention: Only for use above +20C

Version 21.1B/14.1B

Picture

No picture

HVU 480/481/482 Configuration

19

Automated Viscosity Analyzer HVU 480/481/482

3.6

Order No.

Accessories for HVU481 and HVU482:

Description

Picture

04805-000-01 NIR-Ubbelohde Viscometer capillary for

HVU 480 / HVU481, with NIR meniscus

detection, ready mounted in holder, with

engraved capillary constant and color coding for

connection to hoses,

Constancy c = appr. 0.001 mm2/s2

range 0,2 to 1,2 mm2/s.

04805-000-02

NIR-Ubbelohde Viscometer c = appr. 0,003

HVU 480/481, range 0,6 to 3,0 mm2/s

04805-000-03

NIR-Ubbelohde Viscometer c = appr. 0,005

HVU 480/481, range 1,0 to 5,0 mm2/s

04805-000-04

NIR-Ubbelohde Viscometer c = appr. 0,01

HVU 480/481, range 2,0 to 10,0 mm2/s

04805-000-05

NIR-Ubbelohde Viscometer c = appr. 0,03

HVU 480/481, range 6,0 to 30,0 mm2/s

04805-000-06

NIR-Ubbelohde Viscometer c = appr. 0,05

HVU 480/481, range 10,0 to 50,0 mm2/s

04805-000-07

NIR-Ubbelohde Viscometer c = appr. 0,1

HVU480/481, range 20,0 to 100,0 mm2/s

04805-000-08

NIR-Ubbelohde Viscometer c = appr. 0,3

HVU480/481, range 60,0 to 300,0 mm2/s

04805-000-09

NIR-Ubbelohde Viscometer c = appr. 0,5

HVU480/481, range 100,0 to 500,0 mm2/s

04805-000-10

NIR-Ubbelohde Viscometer c = appr. 1,0

HVU480/481, range 200,0 to 1000,0 mm2/s

04805-000-11

NIR-Ubbelohde Viscometer c = appr. 3,0

HVU480/481, range 600,0 to 3.000,0 mm2/s

04805-000-12

NIR-Ubbelohde Viscometer c = appr. 5,0

HVU480/481, range 1.000,0 to 5.000,0 mm2/s

04805-000-13

NIR-Ubbelohde Viscometer c = appr. 10,0

HVU480/481, range 2.000,0 to 10.000, 0

mm2/s

04805-000-14

NIR-Ubbelohde Viscometer c = appr. 30,0

HVU480/481, range 6.000,0 to 30.000,0 mm2/s

04805-000-15

NIR-Ubbelohde Viscometer c = appr. 50,0

HVU480/481, range 10.000,0 to 50.000,0

mm2/s

04805-000-16

NIR-Ubbelohde Viscometer c = appr. 2,0

HVU480/481, range 400,0 to 2.000,0 mm2/s

20

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

Picture

04806-000-01

NTC-Ubbelohde Viscometer capillary for

HVU480/HVU481 with NTC meniscus

detection for opaque samples, ready mounted

in holder, with engraved constant and color

coding for connection to hoses.

c= 0.001 mm2/s2

Range 0,2 to 1,2 mm2/s

04806-000-02

NTC Ubbelohde Viscometer C = 0.003

HVU 480/ 481, range 0,6 to 3,0 mm2/s

04806-000-03

NTC Ubbelohde Viscometer C = 0.005

HVU 480/481, range 1,0 to 5,0 mm2/s

04806-000-04

NTC Ubbelohde Viscometer C = 0.01

HVU 480/481, range 2,0 to 10,0 mm2/s

04806-000-05

NTC Ubbelohde Viscometer C = 0.03

HVU 480/481, range 6,0 to 30,0 mm2/s

04806-000-06

NTC Ubbelohde Viscometer C = 0.05

HVU 480/481, range 10,0 to 50,0 mm2/s

04806-000-07

NTC Ubbelohde Viscometer C = 0.1

f HVU 480/481, range 20,0 to 100,0 mm2/s

04806-000-08

NTC Ubbelohde Viscometer C = 0.3

HVU 480/481, range 60,0 to 300,0 mm2/s

04806-000-09

NTC Ubbelohde Viscometer C = 0.5

HVU 480/481, range 100,0 to 500,0 mm2/s

04806-000-10

NTC Ubbelohde Viscometer C = 1.0

HVU 480/481, range 200,0 to 1.000,0 mm2/s

04806-000-11

NTC Ubbelohde Viscometer C = 3,0

HVU 480/481, range 600,0 to 3.000,0 mm2/s

04806-000-12

NTC Ubbelohde Viscometer C = 5.0

MP 480, range 1.000,0 to 5.000,0 mm2/

04806-000-13

NTC Ubbelohde Viscometer C = 10.0

HVU 480/481, range 2.000,0 to 10.000,0

mm2/s

04806-000-14

NTC Ubbelohde Viscometer C = 30.0

HVU 480/481, range 6.000,0 to 30.000,0

mm2/s

04806-000-15

NTC Ubbelohde Viscometer C = 50,0

HVU 480/481, range 10.000 to 50.000 mm2/s

04806-000-16

NTC Ubbelohde Viscometer C = 2.0

HVU 480/481, range 400,0 to 2.000,0 mm2/

108-247

Slop container for 6 liter waste solvent. Ready

to connect the slop sensor 638-031 and 2

Teflon slop hoses. Has a drain nozzle where

a vacuum pump may be connected.

Version 21.1B/14.1B

HVU 480/481/482 Configuration

21

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

108-331

Capillary adjustment tool to verify the

perpendicular adjustment of the capillary in the

holder in order to assure the D445

requirements

638-040

Picture

Timing device check tool for HVU480,

HVU481, HVU482, HVU490 clocks.

Plugged into the NTC meniscus sensor socket,

it will give a light signal enduring 600 seconds.

Use a precision stop watch to verify the HVUs

internal clock

638-031

Slop sensor for HVM472/ HVU480, HVU481,

HVU482, HVU490, detects a full slop

container, preventing overflow. Ready to be

placed in 108-247 slop container.

110-084

Slop sensor with weight for non Herzog origin

containers

04841-000-01

HLIS-32 Windows PC Program

(English edition)

; Herzog Laboratory Information System,

PC based Windows program

; Operates up to 10 analyzers HVU 480,

HVU 481 or HVU 482 with material

based individual measurement

programs

; Calculates VI and other derived data

; Storage and database management

; Customized output data format for a

transfer to an external LIMS

22

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Order No.

01061-481-02

Description

Picture

PC with LCD display

; 15.1" TFT LCD

; Vivid Screen offers natural colors

; Hard-Disk-Drive

; Floppy-Disk-Drive

; CD-ROM-Drive

626-072

Connection cable PC to instrument (RS 232)

2,5 m

101-137

Ink jet printer with English and German

manual, ASCII compatible, for 100 - 230VAC.

Power cord with Continental European IEC/DIN

plug.

626-053

Connection cable printer to PC

(CENTRONICS)

101-214

Matrix dot printer, 40 columns, using endless

paper roll of 76mm width, Centronics interface,

Dimensions: 156 mm (W) x 248 mm (D) x 132

mm (H).

230 VAC, 24W, Power cord with Continental

European IEC/DIN plug.

Centronics Printer cable not included

101-212

Ink ribbon for Matrix dot printer 101-214

No Picture

101-184

Ink ribbon for Matrix dot printer 101-175 and

101-176

No Picture

101-185

Paper rolls (10 pcs.) for Matrix dot printer 101175, 101-176 and 101-214

76 mm x 60 x 12mm

Version 21.1B/14.1B

HVU 480/481/482 Configuration

23

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

626-029

Connection cable Printer (Centronics) to

HVU481/482. This is a special wired cable for

certain Herzog instruments only.

105-094

Space saving base to have printer above PC

01000-445-01

Certified Reference Material for viscosity

verification and calibration,

500ml, with Certificate, stating results and

accuracy of density @ 20C and

viscosity @ 20, 25, 40, 50 and 100C

S1, 2.9 mm2/s @40C; 1.2 mm2/s @ 100C

01000-445-11

D5, 4.0 mm2/s @40C; 1.4 mm2/s @ 100C

01000-445-02

S6, 5.7 mm2/s @40C; 1.8 mm2/s @ 100C

01000-445-12

D10, 7.5 mm2/s @40C; 2.2 mm2/s @ 100C

01000-445-03

S20, 18 mm2/s @40C; 3.9 mm2/s @ 100C

01000-445-13

D50, 30 mm2/s @40C; 5.2 mm2/s @ 100C

01000-445-04

S60, 54 mm2/s @40C; 7.7 mm2/s @ 100C

01000-445-09

P1/13, 114 mm2/s @40C; 13 mm2/s @ 100C

01000-445-05

S200, 180 mm /s @40C; 17 mm /s @ 100C

01000-445-15

D500, 225 mm2/s @40C; 20 mm2/s @ 100C

01000-445-19

D750, 323 mm2/s @40C; 26 mm2/s @ 100C

01000-445-16

D1000, 420 mm2/s @40C; 31 mm2/s @ 100C

01000-445-06

S600, 522 mm2/s @40C; 36 mm2/s @ 100C

01000-445-20

P4/1000, 1004 mm2/s @40C; 59 mm2/s @ 100C

01000-445-07

S2000, 1700 mm2/s @40C; 84 mm2/s @ 100C

01000-445-17

D5000, 1850 mm2/s @40C; 88 mm2/s @ 100C

01000-445-18

D10000, 3500 mm2/s @40C; 143 mm2/s @ 100C

01000-445-08

S8000, 6700 mm2/s @40C; 236 mm2/s @ 100C

01000-445-10

P1/600, 22020 mm2/s @40C; 600 mm2/s @ 100C

505-001

Control thermometer +18 +22C:0.01C res.

505-003

Control thermometer +38 +42C:0.01C res.

505-004

Control thermometer +48 +52C:0.01C res.

505-005

Control thermometer +98 .. +102C:0.01C res

24

Picture

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Order No.

Description

505-006

Control thermometer +96+103 F:0,02F res.

505-007

Control thermometer +206..+214F:0,02F res.

505-008

Control thermometer +68.+72C:0,01C res.

506-051

Certified thermometer +18 +22C:0,01C res.

506-053

Certified thermometer +38+42C:0,01C res.

506-054

Certified thermometer +48+52C:0,01C res.

506-055

Certified thermometer +68+72C:0,01C res.

506-056

Certified thermometer +98..+102C:0,01C res.

506-057

Certified thermometer +96..+103F:0,02F res.

506-058

Certified thermometer +206+214F:0,02F res.

506-121

Certified thermometer +148+152C:0,01C res

506-122

Certified thermometer +133+137C:0,01C res

626-082

Connection cable for HTR communication,

instrument to instrument, short 0,8 m

626-138

Connection cable for HTR, instrument to

instrument long 2,5 m

3.7

Picture

HVU 482 NTC Capillaries (Sensor B)

For the moment there are no special NTC capillaries available for the HVU 482. You

can use the NTC capillaries produced for the HVU 480/481 with an adapter (Order

No.: 108-332).

Note:

Only suitable for bath temperatures higher than +20C.

3.8

HVU 482 with capillaries from the

HVU480/481

At bath temperatures higher than +20C, it is also possible to use NIR or NTC

capillaries of the HVU480/481, with an adapter(Order No.: 108-332).

Version 21.1B/14.1B

HVU 480/481/482 Configuration

25

Automated Viscosity Analyzer HVU 480/481/482

26

HVU 480/481/482 Configuration

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

4 HVU 480/481/482 Installation

4.1

General

Place the HVU 480/481/482 on a stable laboratory bench. The sample flow in the

viscometer depends on gravity. Therefore the capillaries must be in a vertical

position (90).

Before putting the HVU 480/481/482 into service, check the data for voltage,

frequency and power rating. The socket for the HVU 480/481/482 must be fused

accordingly. If the supply corresponds with the values on the rating plate, plug in the

unit.

Volt 230

Hertz 50

Watt 1200

FABR. NR.

93480079

Volt 230

Hertz 60

Watt 1200

FABR. NR.

Version 21.1B/14.1B

93480079

HVU 480/481/482 Installation

27

Automated Viscosity Analyzer HVU 480/481/482

4.2

HVU 480/481 Installation Procedure

Before the HVU 480/481 can be put into service, please follow these installation

procedures:

Note:

Be careful not to drop screws into the bath compartment during

installation procedures.

1. Unscrew the knurl screws and remove the silver bath cover plate (4 screws).

Upon removing this plate you will see screws that secure the plastic collars

used to secure the glass baffle tubes.

2. With a screw driver, unscrew and remove the plastic collars (2 screws).

3. Carefully place the glass baffle tubes into position. The glass tube should be

centred above circulation holes and in the middle of the metal stabilising studs

on bath floor.

4. With a screw driver, secure the plastic collars fitting them over the glass tubes.

Make sure that the capillary key slot on the collar is mounted so that it points to

the left. This is essential for lining up the colour coded capillary connection

tubes.

5. Replace and secure the silver bath cover plate.

6. Connect all coloured hoses to the corresponding colour shown on HVU

480/481 diagram (see chapter HVU 480/481 Identification Diagrams). Slop

bottle must be atmospheric allowing air displacement when slop is discharged

into the bottle.

7. Volume of the slop bottle must be larger than solvent 1 and solvent 2 bottles

combined (ex. solvent 1 and solvent 2 bottles are one liter each for a total of 2

liters. Slop bottle needs to be 2.5 to 3 liters).

If fast cooling of the regulated bath is needed or the bath temperature must be lower

than ambient air temperature, a cooling system should be connected to the connectors

at the rear of the HVU 480/481 (see chapter HVU 480/481 Identification Diagrams).

To insure meaningful results when using the HVU 480/481 without a cooling system,

the ambient air temperature must be at least 15K lower than the bath temperature. To

maintain a constant HVU 480/481 bath temperature, when using a cooling system,

the cooling system set temperature should be 10K below the required bath

temperature ( ex. HVU 480/481 bath temperature = 20C, Cooling system = 10C).

When using common water cooling, it must be kept at a constant temperature and

flow rate to maintain satisfactory HVU 480/481 bath regulation.

Fill the bath with silicone oil up to 2 cm below the top of the glass window. The

glass viscometer is completely immersed in bath oil because of special construction.

28

HVU 480/481/482 Installation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

Note: Do not fill above the level. Bath overflow can occur at high temperatures.

If the bath temperature is not stable, it could be that there is water in the

siliconoil. The water could be evaporated if the bath is heated to 130 C for

3 hours.

4.2.1 Cleaning Solvents for HVU 480/481

Do not use acetone as a cleaning solvent. Acetone destroys the Viton seals used in

the HVU 480/481. In concentrations of 50% or less, aromatics can be used for

cleaning solvent material. We recommend 50% aromatic (ex. Toluene) mixed with

cleaning solvent. The IBP for cleaning solvent should be higher than the HVU

480/481 bath temperature.

4.3

HVU 482 Installation Procedure

Before the HVU 482 can be put into service, please follow these installation

procedures:

Note:

Be careful not to drop screws into the bath compartment during

installation procedures.

1. Unscrew the four knurled screws holding the heat exchanging tubes and

remove the transport safety devices.

2. Connect the solvent and slop vessel according to the HVU 480/481 diagram

(refer to chapter Hardware documentation). Connect the Solvent-filter (370323) in the Solvent-hospipe. The slop vessel must be atmospheric so that the

air can escape when the cleaning solvent drains into the vessel.

3. Volume of the slop bottle must be larger than solvent 1 and solvent 2 bottles

combined (ex. solvent 1 and solvent 2 bottles are one liter each for a total of 2

liters. Slop bottle needs to be 2.5 to 3 liters).

If fast cooling of the regulated bath is needed or the bath temperature must be lower

than 60C, a cooling system should be connected to the connectors at the rear of the

HVU 482 (see chapter Hardware documentation).

To insure meaningful results when using the HVU 482 without a cooling system, the

ambient air temperature must be at least 55C lower than the bath temperature. To

maintain a constant HVU 482 bath temperature, when using a cooling system, the

cooling system set temperature should be 15C below the required bath temperature

(ex. HVU 482 bath temperature = -20C, Cooling system = -35C) and the cooling

liquid flow should be constant.

When using common water cooling, it must be kept at a constant temperature and

flow rate to maintain satisfactory HVU 482 bath regulation.

Version 21.1B/14.1B

HVU 480/481/482 Installation

29

Automated Viscosity Analyzer HVU 480/481/482

Fill the bath with silicone oil up to 1.5 to 1 cm below the top of the glass heat

exchanger tube. Oil may spill over at a bath temperature of +100C when more oil is

filled in.

The glass viscometer is completely immersed in bath oil because of special

construction.

Note: Do not fill above the level. Bath overflow can occur at high temperatures.

Despite extensive constructional measurements it is not possible to avoid that the

silicone oil will absorb humidity. Therefore it is necessary to heat up the bath to

100C after about 40 operation hours (depending on the bath temperature and the

atmospheric humidity) refer to chapter Removal of the humidity in the

thermostated bath by heating.

4.3.1 Solvents for HVU 482

The IBP for cleaning solvent should be higher than the HVU 482 bath temperature.

The materials which are in contact with the solvent are brass, Kalrez and Teflon.

Therefore nearly every solvent is possible.

e.g. Aceton, Toluol, n-Heptan, benzine

Note: Humidity (water) in the solvent can settle in the capillary such leading to

unprecise measuring results. Therefore make sure that either dry solvent is used or

the solvent is dryed with a molecular sieve.

30

HVU 480/481/482 Installation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

4.3.2 Filling of the drying tubes

To fill the drying tubes with the drying beads loosen the knurled nut and take out the

disk and the filter.

Drying

Filter

Disk

Knurled nut

Then fill the drying tube with the drying beads and remove the filter, the disk and the

nut.

As the drying beads have only a certain absorbing capacity, it is necessary to

exchange them once in a while (refer to chapter Maintenance of the drying tubes).

Note:

Version 21.1B/14.1B

There are drying beads of different qualities on the market. If the

water absorbing capacity of the drying beads is not sufficient, ice

will form in the thermostated bath and the capillary tube. Ice in the

capillary tube will lead to deviations in the measuring results.

HVU 480/481/482 Installation

31

Automated Viscosity Analyzer HVU 480/481/482

4.3.3 Installation of the drying tubes

Install the dry tubes as shown in the picture.

4.3.4 Installation of the cold trap

Connect the cold trap in the preflow area, i.e. between the outflow of the cooler and

the inflow of the HVU 482.

The cold trap will loose its power when there is ice at the cooling tube. For

maintenance of the cold trap refer to chapter :Maintenance of cold trap.

32

HVU 480/481/482 Installation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

4.4

Connection of a slop sensor

(Accessory)

To prevent an overflow of the slop container it is neccessary to use a slop sensor. The

plug for the slop sensor is at the rear panel of the unit.

4.4.1 Not networked units with slop sensor

After the connection of the slop sensor the last step is to change the parameter Slop

Sensor to Yes.

4.4.2 Several units with one common used slop sensor

Are several units supposed to use one slop sensor, the slop sensor is connected to the

Master unit. The other units have to be configured as slave and networked with the

Master (see chapter 4.6).

Afterwards it is necessary to change the parameter Slop Sensor to Yes.

4.4.3 Networked units with own slop sensor

Are networked units supposed to use own slop sensors, it is necessary to make a

hardware modification.

This modification is to be done by an service engineer. The modification is to

connect by an wire Pin 4 and Pin 33 of the 37 Pin plug to the CPU board 607-084.

Afterwards it is necessary to change at all units the parameter Slop Sensor to

Yes.

Attention:

Version 21.1B/14.1B

All units which have not the modification will use the information

of the slop sensor which is connected to the master unit !

HVU 480/481/482 Installation

33

Automated Viscosity Analyzer HVU 480/481/482

4.5

Coding of the measurement points

As delivered, the testing units are coded as measurement point 1 and master.

To change the coding, simply disconnect the power from the HVU 480/481/482 and

remove the hood of the electronics unit. The DIL switch (S1) and the wrap pins

(WP1 and WP2) are located on circuit board 607-13 or 607-84 adjacent to the 9-pole

plug (see drawing in the hardware instructions).

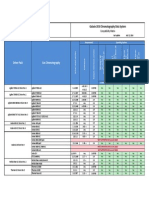

S

W

I

T

C

H

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

0

On

On

On

On

On

On

On

X

UNIT NUMBER

1

2

3

4

off on off on

on off off on

on on on off

on on on on

on on on on

on on on on

on on on on

X X X X

5

off

on

off

on

on

on

on

X

6

on

off

off

on

on

on

on

X

7

off

off

off

on

on

on

on

X

8

on

on

on

off

on

on

on

X

9

off

on

on

off

on

on

on

X

10

on

off

on

off

on

on

on

X

11

off

off

on

off

on

on

on

X

12

on

on

off

off

on

on

on

X

13

off

on

off

off

on

on

on

X

14

on

off

off

off

on

on

on

X

15

off

off

off

off

on

on

on

X

Switch 1.8 X = off = Master

Switch 1.8 X = on = Slave

Note: When a unit is to be changed from "master" to "slave" (or vice-versa), it will

be necessary to change the jumpers accordingly. In the master mode, the 3

jumpers must bridge the pins WP1; pins WP2 are thus bridged for the slave

operation. Please make sure that only one testing unit is coded as "master"

when several linked testing units are used.

4.6

Connection between HVU 480/481/482

and printer

A printer can be connected to the analysis unit HVU 480/481/482 to print the test

results. This requires only a standard printer with a parallel printer connection and

the expanded IBM character set.

The connection between the printer and the parallel interface (D-SUB 25P) at the

back of the HVU 480/481/482 must be made using cable no. 626-029. (The

centronics cable usually used for PCs cannot be used to connect the printer to the

HVU 480/481/482).

34

HVU 480/481/482 Installation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

4.7

Connection of several HVU 480/481/482

units to one printer

When several testing units (up to 16 HVU 480/481/482) must be connected to one

printer, it is necessary to link them to the HTR plug (on the back of the testing unit)

by means of the enclosed cable no. 626-082.

Gert 2 / Unit 2

Gert 1 / Unit 1

Kabel Nr. 626-082

Master

Gert 3 / Unit 3

Kabel Nr. 626-082

Slave

Slave

Kabel Nr. 626-029

Drucker / Printer

It should be noted that the printer must be connected to the "master" testing unit and

that the other testing units are linked as "slaves".

Furthermore, each testing unit must have a different equipment number (equipment

numbers 0-15).

4.8

Connection of several HVU 480/481/482

units to a PC

It is possible to connect up to 16 viscometers of the type HVU 480/481/482 to one

PC.

Cable no. 626-072 is used to connect the analysis unit defined as "master" to the PC.

With the help of cable no. 626-082, the "master" and the maximum of 15 "slaves"

shall be connected to the lower HTR plug (D-Sub 9P) on the back of the HVU

480/481/482 (see chapter HVU 480/481/482 Identification Diagrams) and shall be

coded as indicated in chapter Coding of the measurement points

Furthermore, each testing unit must have a different equipment number (equipment

numbers 0 - 15).

The syntax of the data transfer is described in chapter HVU 480/481/482 Serial

Output.

Version 21.1B/14.1B

HVU 480/481/482 Installation

35

Automated Viscosity Analyzer HVU 480/481/482

36

HVU 480/481/482 Installation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

5 HVU 480/481/482 Operation

5.1

Menu Range

PROGRAM

This menu is used to start the viscosity measurement. It is

possible to enter a sample number and to change specific

parameters for this viscosity determination.

DIAGNOSTIC

Program to check functions: when this menu is called, instrument

functions can be released and checked. During a viscosity

analysis the diagnostic menu is a function indication window

only. The program run can ONLY be observed (see chapter

Diagnostic Program).

PARAMETER

This menu is used to enter the parameters. With this menu, it is

possible to program the parameters required for the execution of

the viscosity test. Four freely programmable parameter programs

are available. To prevent unauthorised changes, the parameters

can be protected by a password (see chapter Parameter Program).

MESSAGES

Program for error message indication: in this menu, errors and

messages are displayed (see chapter Error messages).

HVU 480/481/482 Keyboard and Display (see chapter Identification Diagrams) for

identification)

PROGRAM 1

PROGRAM 2

PROGRAM 3

PROGRAM 4

CLEANING

Version 21.1B/14.1B

HVU 480/481/482 Operation

37

Automated Viscosity Analyzer HVU 480/481/482

38

HVU 480/481/482 Operation

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

6 Program Measurement

6.1

General

After switching on the HVU 480/481/482, the manufacturer, model number, unit

number and the software version of the Display-Slave (Slave 0) are displayed.

HERZOG HVU 480

Version

#.##

Press the "start" button and the display will show the approximate calibration factor

of the left (L > K = ..) and right capillary (R > K = ....) along with the bath

temperature. A flashing bath temperature display indicates that the programmed bath

temperature has not been reached.

To program a viscosity analysis, the operator must choose to program either the right

or left capillary. Designate a capillary by pushing the "right" arrow key (right

capillary) or the "left" arrow key (left capillary).

Choose the viscosity analysis program that you need with the "P" key. Press the

"start" key to initiate the test.

L>K~0.03

Bathtemp.

Version 21.1B/14.1B

R>K~1

40.00 C

Program Measurement

39

Automated Viscosity Analyzer HVU 480/481/482

6.2

Sample Identification

Alphanumeric signs can be entered to identify sample tests. The keyboard is

constructed in such a way that numbers can be entered directly while letters must be

selected with the "up" and "down" arrow keys (see chapter Identification Diagrams)).

The "up" and "down" arrow keys scroll through all possible letters. Pressing the

arrow "right" key enters the selected letter and moves the cursor one step to the right.

When numbers are keyed in, the cursor automatically moves to the right. Characters

can be deleted with the arrow "left" key. Up to 14 characters can be entered.

Example: Input "Tank 1520" as the sample number.

The letters for "Tank" are selected by scrolling through all the letters with the "up"

and "down" arrow keys. After each individual character the arrow "right" key is

pressed to enter data and move the cursor to the next position.

The numbers are entered directly by pressing them on the numeric keypad.

Incorrect characters can be deleted by using the arrow "left" key.

Activation of the "start" key will move to the next parameter.

L>K=0.02916

Pr-No TANK 1520

6.3

Programming of parameters

This program is used to determine the need to change any of the specific parameters.

These changed parameters are valid only for one test. All program parameters return

to their original values, when the operator leaves the program menu or presses the

STOP key. In other words, the parameters must be programmed again in the program

menu.

Since there is no need to change these parameters often, they are listed in a submenu. The right-arrow key must be used to move to "Yes" to activate said sub-menu.

Thereafter, the arrow-up key can be moved to reach the sub-menu. The definitions of

the parameters are given in chapter xx.

Parameter

Yes

40

Program Measurement

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

6.4

Bath heating?

Only important for the HVU 482!!

When the bath temperature is below the dew point there is the risk of water

formation. As long as the HVU 482 is switched on, the dewiness can be avoided.

Therefore it is recommended to heat the thermostated bath above the dew point

before it is switched off.

If the question displayed is answered with yes, the thermostated bath is heated

automatically at the end of the measuring cycle.

You can choose in the parameter program whether this question shall be displayed in

the start menu.

6.5

Start of testing procedure

Press the START key again.

The testing process does not begin right away; the question "Start Test?" is displayed

first. Press the STOP key to abort the starting procedure.

L>K=0.02916

Test start ?

Press the START key again, when the testing is to be carried out without checking

the programming. The display shows the capillary constants and the status for the left

and the right measurement station as well as the bath temperature. A blinking bath

temperature light indicates that the programmed bath temperature has not yet been

reached. The measurement procedure (tempering, measuring) begins only after the

proper bath temperature has been reached.

6.6

Aborting the viscosity measurement

The measurement procedures of the HVU 480/481/482 can be aborted any time

during the viscosity analysis by pressing the STOP key. The display shows "Abort

test?". The display itself does not abort the test; this is achieved by pressing the

STOP key again. When it is nevertheless necessary to test the sample again, it will be

necessary to remove the capillary tube connection hoses to provide a fluid level

balance for the sample to be tested.

When the test was aborted during the cleaning cycle, the solvent located in the

system is piped under pressure to the slop container. However, the capillary tubes as

well as the cleaning system are not clean. Accordingly, the cleaning phase must be

activated prior to the next measurement.

Version 21.1B/14.1B

Program Measurement

41

Automated Viscosity Analyzer HVU 480/481/482

Test Stop?

Pr. No. TANK 1520

Press the START key, when the measurement is to be continued.

6.7

Viscosity measurement procedure

The bath temperature stabilizes at the earlier established value after the viscosity

measurement has been started. The capillary tube type (sensor A or B) is recognized

automatically. As soon as the bath temperature is reached, the tempering period

begins to adjust the sample to the bath temperature. To obtain a faster tempering of

the sample, the sample can be moved during the tempering period; this is called the

"Dynamic tempering type". Particle deposits on the capillary tube can lead to

erroneous measurement results; this applies in particular to black samples. It will be

necessary to use the static tempering type in this case.

The measurement cycle is repeated until two sequential measurement results are

within the programmed tolerance (see chapter Programming Analysis Tolerance).

The flushing and drying process begins after the viscosity measurement. The

cleaning of the capillary tubes can be programmed such that two different solvents

are used sequentially. Air is used for the drying process.

The cleaning system consists of 14 solenoid valves, one vacuum pump and a compressed air pump (see chapter Cleaning Cycle).

6.8

End of test

After the viscosity has been measured, it will be possible to display the viscosity of

the sample as well as all flow periods and to print a test protocol.

These functions are available prior to the start of a new measurement phase.

6.8.1 Display of viscosity and flow periods

he already concluded flow periods can still be indicated on the display during other

measurements or after the measurement. The flow periods can only be displayed,

when the program is in the PROGRAM mode.

1. Activate "PROGRAM" by pressing the "M" key.

2. Select the right or left capillary tube by pressing the left-arrow or right-arrow

key.

3. To display other flow periods, press the up-arrow or down-arrow key.

42

Program Measurement

Version 21.1B/14.1B

Automated Viscosity Analyzer HVU 480/481/482

6.8.2 Printing test results

The test results can be printed on a printer either automatically or on request by the

operator (see chapter Printer up to chapter Printing Viscosity Results). It is also

possible to print several copies, if required. The operator can choose between a

"standard protocol" and an "expanded protocol" (see chapter Print). The expanded

protocol is used automatically and "*" is printed after the word viscosity, when no

measurement value met the tolerance requirements. This indicates that the viscosity