Documente Academic

Documente Profesional

Documente Cultură

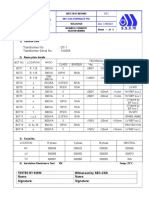

Tan Delta Test For Transformer

Încărcat de

mayur3dhande0 evaluări0% au considerat acest document util (0 voturi)

208 vizualizări3 paginiTan Delta Test

Titlu original

Tan Delta Test for Transformer

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTan Delta Test

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

208 vizualizări3 paginiTan Delta Test For Transformer

Încărcat de

mayur3dhandeTan Delta Test

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

Tan Delta Test for Transformer

In a pure capacitor current leads the voltage by 90 degrees. When a

r e s i s t o r i s introduced in between the current leads an angle less than 90 degrees.

Similarly in a Dielectric material when a cavity or deterioration starts,

the life of them a t e r i a l s t a r t s d e t e r i o r a t i n g , a s t h e r e i s a r e s i s t a n c e g

e t t i n g a d d e d a n d h e n c e leakage current increases.In tan Delta we find the difference in the

angle and periodically note down the pace at whichdeterioration takes place.Tan Delta is also known

as the 'loss angle' or 'dissipation factor'.It is used to test the level of degradation in insulation

materials of electrical machines and power cables.Tan Delta, also called Loss Angle or

Dissipation Factor testing, is a diagnostic method of testing electrical equipment to

determine the integrity of the insulation. This is done to try topredict the remaining life expectancy of the

equipment

.

The winding insulation of an electrical machine, or a cable free from defects, will act

as aperfect capacitor, that is, it will only store energy and not dissipate it.In an ideal capacitor, the

voltage and current are out of phase by 90 degrees and the currentflowing through the insulation is

purely capacitive Ic.However, dielectric losses within the insulation due to deterioration or other

factors, will resultin the reduction of the resistance in the insulation. This will in turn

increase the resistivecurrent Ir.The phase angle between the current and voltage is now

less than 90 degrees, and the extent to which this is less than 90 degrees gives the level of

degradation in the insulation.So this 'loss angle' is required to be measured.If the angle is Delta, then

the tangent of Delta can be calculated by dividing is 'opposite over adjacent', which is Ir/Ic.There are

various methods of how this is tested and industrial standards, such as the IEC provide

acceptable values of Tan-delta for different types of insulation.

Tan Delta, also called Loss Angle or Dissipation Factor testing, is a diagnostic method

of testing electrical equipment to determine the integrity of the insulation. This is done to try to predict

the remaining life expectancy of the equipment.If the insulation free from defects, it approaches the properties

of a perfect capacitor. It is very similar to a parallel plate capacitor with the conductor and the neutral

being the two platesseparated by the insulation material.In a perfect capacitor, the voltage and current

are

phase

shifted

90

degrees

and

the

current through the

insulation is capacitive. If there are impurities in the insulation,for example,moisture,

the resistance of the insulation decreases, resulting in an increase in resistive current

through the insulation. It is no longer a perfect capacitor. The current and voltage will no longer be

shifted 90 degrees. It will be something less than 90 degrees. The extent to w h i c h t h e

phase shift is less than 90 degrees is indicative of the

level

o f i n s u l a t i o n contamination, hence quality/reliability. This "Loss Angle" is measured and

analyzed.Below is a representation of an insulation. The tangent of the angle is measured. This

will indicate the level of resistance in the insulation. By measuring IR/IC (opposite over adjacent

the tangent), we can determine the quality of the insulation. In a perfect insulation, the anglewould be

nearly zero. An increasing angle indicates an increase in the resistive

current through the insulation, meaning contamination. The greater the angle, the

worse is the insulation.

Insulation power factor is the angle

90 . I f t h e i n s u l a t i o n i s e x c e l l e n t , t h e t a n d e l t a o r dissipation factor is equal to the

power factor. Essentially, both tan delta and power factor are just the same.

Method

of Testing

The cable

or winding

whose

insulation

is to be

tested is

first

disconnected

and

isolated.

The

test

voltagei s a p p l i e d

f r o m t h e Ver y L o w

Frequency power source and

t h e T a n d e l t a c o n t r o l l e r t a k e s t h e measurements.

The test voltage is increased in steps upto the rated voltage of the cable. The readingsare plotted in

a graph against the applied voltage and the trend is studied. A healthy insulation

wouldproduce a straight line.The test should be continued only if the graph is a straight

line. A rising trend would indicate weak i n s u l a t i o n w h i c h m a y

fail if the

test voltage is increased beyond the rated voltage of the cable.

Interpretation of the test data

There are not standard formulae or benchmarks to ascertain the success of a tan delta test. The

healthof the insulation which is measured is obtained by observing the nature of the trend which is

plotted.

As t e a d y, s t r a i g h t t r e n d w o u l d i n d i c a t e a h e a l t h y i n s u l a t i o n , w h i l e a r i s i n g t r

e n d w o u l d i n d i c a t e a n insulation that has been contaminated with water and other impurities

S-ar putea să vă placă și

- Transformer Cooling System and MethodsDocument4 paginiTransformer Cooling System and Methodsmayur3dhandeÎncă nu există evaluări

- Site Testing Pre Commissioning PDFDocument2 paginiSite Testing Pre Commissioning PDFadi nugrohoÎncă nu există evaluări

- ABB Test Report For Bcu Relay: P A N e LD e T A Il SDocument3 paginiABB Test Report For Bcu Relay: P A N e LD e T A Il SJayamkondanÎncă nu există evaluări

- Site Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsDocument2 paginiSite Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsGajendran SriramÎncă nu există evaluări

- Testing of BushingDocument8 paginiTesting of BushingAmir Ali khanÎncă nu există evaluări

- How To Test Distance Relay 7SA522 PDFDocument55 paginiHow To Test Distance Relay 7SA522 PDFBalaji100% (1)

- Short Circuit TestDocument1 paginăShort Circuit TestFatima MirÎncă nu există evaluări

- Scope: Transformer Winding Resistance MeterDocument4 paginiScope: Transformer Winding Resistance MeterL Adly100% (1)

- Effect Residual Magnetism On The Magnetic Core of A TransformerDocument4 paginiEffect Residual Magnetism On The Magnetic Core of A Transformerhendro suprianto nugrohoÎncă nu există evaluări

- Transformer Testing GuideDocument9 paginiTransformer Testing GuideShravan RawalÎncă nu există evaluări

- Magnetizing CurrentDocument4 paginiMagnetizing CurrentSureshraja9977Încă nu există evaluări

- VT Secondary Injection FormatDocument3 paginiVT Secondary Injection FormatDanish AfzalÎncă nu există evaluări

- Relay Symbols and Fuction NumDocument14 paginiRelay Symbols and Fuction NumPrasanna DharmapriyaÎncă nu există evaluări

- 4.various Tests Part 1Document69 pagini4.various Tests Part 1Rohit JoshiÎncă nu există evaluări

- Routine Tests For Oil Immersed TransformersDocument14 paginiRoutine Tests For Oil Immersed TransformersFreddie Asiedu LarbiÎncă nu există evaluări

- Thrust Block DesignDocument8 paginiThrust Block Designsoma_sharad8507Încă nu există evaluări

- Sizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableDocument9 paginiSizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableNeomax BuildersÎncă nu există evaluări

- ISA Introduction To The Test of Protection RelaysDocument23 paginiISA Introduction To The Test of Protection RelaysCata CatalinÎncă nu există evaluări

- Tan Delta Test For TransformerDocument2 paginiTan Delta Test For TransformerInayat Hathiari85% (13)

- TR Differential Ret670Document19 paginiTR Differential Ret670Mahdi AlamriÎncă nu există evaluări

- Tan Delta TestingDocument2 paginiTan Delta TestingNillutpal BoruahÎncă nu există evaluări

- Testing NotesDocument12 paginiTesting NotesJigar TakoliaÎncă nu există evaluări

- Sop HT SWGR MeggeringDocument3 paginiSop HT SWGR MeggeringLincoln DsouzaÎncă nu există evaluări

- GT - 1 Bushing Current Transformer Ir Test ReportDocument5 paginiGT - 1 Bushing Current Transformer Ir Test ReportPrathap KumarÎncă nu există evaluări

- TX Stability CurrentDocument2 paginiTX Stability Currentykh92167Încă nu există evaluări

- Grounding Resistance MeasurementsDocument13 paginiGrounding Resistance MeasurementskishansaiÎncă nu există evaluări

- 1.3 Series and Parallel Resistance NewDocument32 pagini1.3 Series and Parallel Resistance Newnandhakumarme64% (11)

- Magnetic Balance Test On Transformers PDFDocument3 paginiMagnetic Balance Test On Transformers PDFDhinesh KumarÎncă nu există evaluări

- Principle of Tan Delta TestDocument12 paginiPrinciple of Tan Delta TestDeal Achmad FadealÎncă nu există evaluări

- Testing Procedure For Switch Yard Equipments 1Document9 paginiTesting Procedure For Switch Yard Equipments 1d_kabulpuria100% (2)

- CT-VT Testing PDFDocument9 paginiCT-VT Testing PDFusmanÎncă nu există evaluări

- Commissioning Numerical RelaysDocument24 paginiCommissioning Numerical Relayslankesh_db100% (1)

- Temperature Rise Test of TransformerDocument4 paginiTemperature Rise Test of Transformermayur3dhandeÎncă nu există evaluări

- 7 Transformer-ProtectionDocument42 pagini7 Transformer-Protectionmuaz_aminu1422Încă nu există evaluări

- Transformer Stability Test Short Circuit CalculatiosDocument1 paginăTransformer Stability Test Short Circuit CalculatiosElsayed Abdelmagid MohamedÎncă nu există evaluări

- 4.various Tests Part 1Document53 pagini4.various Tests Part 1Rohit JoshiÎncă nu există evaluări

- Volt::Ch: Voltech Engineers Pvt. LTDDocument32 paginiVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- Testing of Power TransformerDocument55 paginiTesting of Power TransformerDiego Betancourt MejiaÎncă nu există evaluări

- Testing of InsulationDocument27 paginiTesting of Insulationகவி பாரதி முத்துசாமிÎncă nu există evaluări

- Uss 105Document12 paginiUss 105Soumya BhowmickÎncă nu există evaluări

- Temperature Indicator of TransformerDocument4 paginiTemperature Indicator of Transformermayur3dhande100% (1)

- 2.u#1 11KV Switchgear Testing Book-2 PDFDocument219 pagini2.u#1 11KV Switchgear Testing Book-2 PDFSabyasachi PatraÎncă nu există evaluări

- TAN DELTA PrincipleDocument3 paginiTAN DELTA PrincipleRahul PhadakeÎncă nu există evaluări

- Manual CMC 356 OMICRONDocument12 paginiManual CMC 356 OMICRONRusber Michel Llama FloresÎncă nu există evaluări

- Transformer WorkshopDocument44 paginiTransformer Workshopniyaz100% (3)

- Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document2 paginiPower Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PÎncă nu există evaluări

- L5 Buck - Boost Converter Analysis and DesignDocument14 paginiL5 Buck - Boost Converter Analysis and DesignKarthickÎncă nu există evaluări

- Transformer Testing PDFDocument40 paginiTransformer Testing PDFrajabharath12100% (1)

- Restricted Earth Fault Relay-AHQDocument4 paginiRestricted Earth Fault Relay-AHQEnpak ArsalanÎncă nu există evaluări

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 paginiTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun AhsanÎncă nu există evaluări

- ASR StarterDocument2 paginiASR Starterrajan_2002eee100% (3)

- Baur PGK25 Cable Test Set User ManualDocument1 paginăBaur PGK25 Cable Test Set User ManualKuyan LesmanaÎncă nu există evaluări

- Testing Procedure For Transformer Differential Protection Relay Using Conventional KitDocument14 paginiTesting Procedure For Transformer Differential Protection Relay Using Conventional KitRavi MehroliyaÎncă nu există evaluări

- Electrical Testing Method Statement PDFDocument1 paginăElectrical Testing Method Statement PDFKamal LatifÎncă nu există evaluări

- Testing Procedures: CT Test FormatDocument2 paginiTesting Procedures: CT Test FormatEngr Zainulabidin KaimkhaniÎncă nu există evaluări

- Distance Protection Relay of LineDocument11 paginiDistance Protection Relay of LineYahya DarÎncă nu există evaluări

- Aux Transformer TestDocument4 paginiAux Transformer TestEngr Fahimuddin QureshiÎncă nu există evaluări

- Tan Delta On CablesDocument4 paginiTan Delta On Cablesrabka001Încă nu există evaluări

- Need of Tan Delta Test in Power SystemsDocument3 paginiNeed of Tan Delta Test in Power SystemsJohn Swamidoss J100% (1)

- Tan Delta Test - Loss Angle Test - Dissipation Factor TestDocument2 paginiTan Delta Test - Loss Angle Test - Dissipation Factor TesthusnainyasirÎncă nu există evaluări

- Tan DeltaDocument1 paginăTan DeltaHamayoun MurtazaÎncă nu există evaluări

- Tan Delta FAQDocument6 paginiTan Delta FAQDev SwainÎncă nu există evaluări

- DC Voltage TestingDocument44 paginiDC Voltage TestingAdriel BayÎncă nu există evaluări

- Data Demonstration: The Van de Graaff GeneratorDocument5 paginiData Demonstration: The Van de Graaff GeneratorPanha SethyÎncă nu există evaluări

- Exp1,2,3 2K20CO153Document9 paginiExp1,2,3 2K20CO153divye guptaÎncă nu există evaluări

- Measurement of Insulation Resistance IR Part 1Document5 paginiMeasurement of Insulation Resistance IR Part 1hafizg100% (1)

- Strata: Stratovolcanoes or Composite Volcanoes Are Tall Conical Mountains Composed of LavaDocument1 paginăStrata: Stratovolcanoes or Composite Volcanoes Are Tall Conical Mountains Composed of Lavamayur3dhandeÎncă nu există evaluări

- Hurricane Irene Was A Large and DestructiveDocument1 paginăHurricane Irene Was A Large and Destructivemayur3dhandeÎncă nu există evaluări

- GIRISH Space Heaters & Thermostats PDFDocument2 paginiGIRISH Space Heaters & Thermostats PDFmayur3dhandeÎncă nu există evaluări

- TornadoDocument1 paginăTornadomayur3dhandeÎncă nu există evaluări

- Hurricane KatrinaDocument2 paginiHurricane Katrinamayur3dhandeÎncă nu există evaluări

- VolcanoDocument1 paginăVolcanoRaj KumarÎncă nu există evaluări

- Cycloconvertor ApplicationsDocument1 paginăCycloconvertor Applicationsmayur3dhandeÎncă nu există evaluări

- NPWR201644 - Volume 3 - Schedules of PricesDocument10 paginiNPWR201644 - Volume 3 - Schedules of Pricesmayur3dhandeÎncă nu există evaluări

- Power InverterDocument1 paginăPower Invertermayur3dhandeÎncă nu există evaluări

- 3 PH RectifierDocument1 pagină3 PH Rectifiermayur3dhandeÎncă nu există evaluări

- High VoltageDocument6 paginiHigh Voltagemayur3dhandeÎncă nu există evaluări

- Sweep Frequency Response Analysis TestDocument4 paginiSweep Frequency Response Analysis Testmayur3dhandeÎncă nu există evaluări

- Rect FierDocument1 paginăRect Fiermayur3dhandeÎncă nu există evaluări

- Shielding ElementsDocument2 paginiShielding Elementsmayur3dhandeÎncă nu există evaluări

- PDFDocument115 paginiPDFmayur3dhandeÎncă nu există evaluări

- 2 ACTS12kPLUSDocument4 pagini2 ACTS12kPLUSmayur3dhandeÎncă nu există evaluări

- High VoltageDocument4 paginiHigh Voltagemayur3dhandeÎncă nu există evaluări

- Liquid Rotor Resistance Starter Conventional LrsDocument3 paginiLiquid Rotor Resistance Starter Conventional Lrsmayur3dhandeÎncă nu există evaluări

- Details of Resistors of Impulse GeneratorDocument1 paginăDetails of Resistors of Impulse Generatormayur3dhandeÎncă nu există evaluări

- 28Document2 pagini28mayur3dhandeÎncă nu există evaluări

- Installation of Power TransformerDocument8 paginiInstallation of Power Transformermayur3dhandeÎncă nu există evaluări

- Silica Gel BreatherDocument3 paginiSilica Gel Breathermayur3dhandeÎncă nu există evaluări

- Radiator of TransformerDocument3 paginiRadiator of Transformermayur3dhandeÎncă nu există evaluări

- Magnetic Oil Gauge or MOGDocument2 paginiMagnetic Oil Gauge or MOGmayur3dhandeÎncă nu există evaluări

- Experience With In-Field Assessment of Water Contamination ofDocument19 paginiExperience With In-Field Assessment of Water Contamination ofmayur3dhandeÎncă nu există evaluări

- 7.1.eddy Current Testing-Part-1Document15 pagini7.1.eddy Current Testing-Part-1Mohanad AlmalahÎncă nu există evaluări

- CIE O LEVEL SYLLABUS Physics 5054Document40 paginiCIE O LEVEL SYLLABUS Physics 5054Sakib Ex-rccÎncă nu există evaluări

- Psycho Metric ChartDocument3 paginiPsycho Metric ChartAparajita MalhotraÎncă nu există evaluări

- Major Class Work 2Document8 paginiMajor Class Work 2Aloysi DelouizaÎncă nu există evaluări

- Dielectric Materials PDFDocument157 paginiDielectric Materials PDFsharon blushteinÎncă nu există evaluări

- 1502 00502 PDFDocument15 pagini1502 00502 PDFƩńg Mễdĥàť ẌƿÎncă nu există evaluări

- Electricity Worksheet 1Document2 paginiElectricity Worksheet 1JashÎncă nu există evaluări

- Power Supplies: Types of Power SupplyDocument8 paginiPower Supplies: Types of Power SupplySireesh YeshwantapurÎncă nu există evaluări

- Kinetics of A Particle: Force and Acceleration (II) : by Dr. Toh Hoong ThiamDocument19 paginiKinetics of A Particle: Force and Acceleration (II) : by Dr. Toh Hoong Thiamnadia syahiraÎncă nu există evaluări

- A Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDocument4 paginiA Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDaniel CannywoodÎncă nu există evaluări

- Physical Symbols MeaningDocument5 paginiPhysical Symbols MeaningSrijna SahniÎncă nu există evaluări

- Slurry. Basic Calculations. Examples 1 To 13 - Equations and Figures - Bingham FluidsDocument265 paginiSlurry. Basic Calculations. Examples 1 To 13 - Equations and Figures - Bingham Fluidskeiko davilaÎncă nu există evaluări

- Data AnalysisDocument8 paginiData AnalysisJosline MuriikiÎncă nu există evaluări

- Understanding Differentiation: Bridge CourseDocument7 paginiUnderstanding Differentiation: Bridge CourseAZTECIANO SORCERERÎncă nu există evaluări

- AP Physics B - Electromagnetic InductionDocument20 paginiAP Physics B - Electromagnetic InductionMarin CvitanÎncă nu există evaluări

- PDFDocument58 paginiPDFSyed MuneebÎncă nu există evaluări

- Equation of Motion PDFDocument2 paginiEquation of Motion PDFMazvita TakawiraÎncă nu există evaluări

- 13.parallel Plate CapacitorDocument3 pagini13.parallel Plate CapacitorShubhamÎncă nu există evaluări

- Physics Principles With Applications 6th Edition Giancoli Solutions ManualDocument35 paginiPhysics Principles With Applications 6th Edition Giancoli Solutions Manualstringy.devest4avfbk100% (24)

- Handbook of Electronics Tables and Formulas.6-Th EdDocument276 paginiHandbook of Electronics Tables and Formulas.6-Th Edpacot24100% (2)

- Accelerate 2E Unit 7 INT - Consumerism - Teacher - S Notes - Edited 17.02.20Document10 paginiAccelerate 2E Unit 7 INT - Consumerism - Teacher - S Notes - Edited 17.02.20Trevor AndersonÎncă nu există evaluări

- Homework Solutions Chapter 11 2nd AssignmentDocument4 paginiHomework Solutions Chapter 11 2nd AssignmentLija BinuÎncă nu există evaluări

- Figuring It OutDocument77 paginiFiguring It OutGoranÎncă nu există evaluări

- Evsjv ' K Ebwewei C RV: Gkwu We Kly Mvi Ms C: Gynvt Avãyjvn Avj Gvngy'Document44 paginiEvsjv ' K Ebwewei C RV: Gkwu We Kly Mvi Ms C: Gynvt Avãyjvn Avj Gvngy'Abdullah Al MahmudÎncă nu există evaluări

- Thermodynamics MRCP 2017Document47 paginiThermodynamics MRCP 2017Calvin LabialÎncă nu există evaluări

- Fundamentals of Power Electronics - Unit 9 - Week 7 - DC-DC SWITCHED CONVERTERSDocument3 paginiFundamentals of Power Electronics - Unit 9 - Week 7 - DC-DC SWITCHED CONVERTERSRakib BiswasÎncă nu există evaluări