Documente Academic

Documente Profesional

Documente Cultură

D12A Valve and Injector Pre Loads

Încărcat de

Sherzad ChemDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

D12A Valve and Injector Pre Loads

Încărcat de

Sherzad ChemDrepturi de autor:

Formate disponibile

IMPACT 3.

13 February 2008

Printed by:BILLYROWAN

Service

Chassis ID

Path

214/Repair/D12A420 VEB/Valves and

unit injectors, adjust. Valve cover

removed

Model

Identity

FH12

39052968

Publish date

Operation No.

21 February 2006

21414-3

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

1 / 15

IMPACT 3.0

13 February 2008

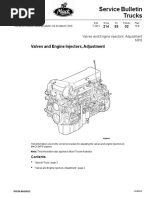

21414-3 Valves and unit injectors, adjusting

Special tools: 9996956, 9998390

Other special equipment: 9989876, 9999696

Setting marks for engines with VEB

General

1

Setting marks for valves and unit injector

1. Exhaust valves for no. 6 cylinder (VEB)

2. Intake valves and unit injector, no. 5 cylinder

In addition to TDC-top dead centre marking on no. 1 cylinder, there are 12 marks on the camshaft

(2 for each cylinder).

Each marking consists of a number (1-6) and a line marking.

The letter V is stamped in front of six of the number markings.

Only a number marking indicates that the rocker arms for the intake valves and the unit injector, on

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

2 / 15

IMPACT 3.0

13 February 2008

the cylinder which corresponds to the number marking is in the position for adjusting when the line

marking on the camshaft is opposite the setting mark on the bearing cap.

The stamped V, together with a number marking indicates that the exhaust valve rocker arm is in

position for adjusting.

Note: If is very important that the line marking on the camshaft is exactly opposite the setting mark on the bearing cap

(tolerance 2 mm) when the valves are being adjusted. Otherwise there is a risk that the rocker arm roller may not lie

against the camshaft basic circle.

Setting mark, bearing cap

2

On later design engines, the camshaft bearing cap has two marks, approx. 5 mm apart.

The camshaft line marking should be between the marks on the bearing cap when carrying out

adjustments on these engines.

Adjusting, general

3

The procedures for adjusting valves and unit injectors deal with the adjustment in the following

order:

Exhaust valves, VEB, adjusting

Intake valves, adjusting

Unit injector, adjusting pre-loading

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

3 / 15

IMPACT 3.0

13 February 2008

Note that valves and unit injectors should be adjusted in the order according to the camshaft

marking when the engine is turned over in the direction of rotation.

By adjusting in this order, the crankshaft need not be rotated more than two turns for adjusting all

the valves and unit injectors.

A felt-tip pen can be used to mark the rocker arms that have been checked, alternatively adjusted.

4

Note: If the work is carried out in the truck, make sure that the gear lever is in neutral, the parking brake applied and

that the starting key is in the Off position.

5

Alternative 1. Remove the inspection cover underneath the flywheel and fit cranking tool 9996956.

Special tools: 9996956

6

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

4 / 15

IMPACT 3.0

13 February 2008

Alternative 2. Remove the fuses for the engine control system and connect up the equipment to

turn over the engine with the starter motor, refer to Procedures when turning the engine over with

the starter motor.

Exhaust valves, VEB, adjusting

7

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

5 / 15

IMPACT 3.0

13 February 2008

Turn the engine over with the starter motor according to the instructions, or crank the flywheel with

tool 9996956, tuntil the nearest line marking for the exhaust valve on the camshaft is opposite the

setting mark on the bearing cap, tolerance 2 mm (alternatively betwen the marks).

Check, via the number marking on the camshaft on which cylinder adjustment is to be carried out.

Note: If tool 9996956 is used to crank the flywheel, make sure that the tool is removed if the engine is to be turned over

with the starter motor.

Special tools: 9996956

8

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

6 / 15

IMPACT 3.0

13 February 2008

Make sure that the camshaft marking which is opposite the setting mark on the bearing cap

concerns the adjustment of the exhaust valves, for example V5.

Adjust to zero clearance on the valve caliper by slackening the adjustment screw so that it does not

lie against the valve stem.

Then screw down the adjustment screw so that it lies against the valve stem, then tighten it a

further flat edge (60). Do not tighten the lock nut.

10

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

7 / 15

IMPACT 3.0

13 February 2008

Note: When screwing down the adjustment screw, press the valve caliper down against the valve spindles at the same

time.

It is very important to press on the caliper as near as possible to the adjustment screw, see arrow in the sketch.

11

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

8 / 15

IMPACT 3.0

13 February 2008

Press the rocker arm downwards as shown in the sketch. If there is a springing movement felt in the

rocker arm, pull the rocker arm plunger spring outwards at the same time as the rocker arm is

pressed down to make contact against the valve spindles.

The oil film which may remain behind the plunger is punctured when the plunger lightens from the

seating and the setting will be more accurate.

Use a thick piece of wire or a bent screwdriver to pull out the spring.

Note: Make sure that the wire or screwdriver is properly cleaned before being used.

Dirt between the rocker arm plunger and rocker arm can cause the plunger to fasten resulting in a loss of braking

function on the cylinder.

Make sure that the plunger sliding surface in the rocker arm is not damaged.

12

Measure the valve clearance with a feeler gauge, note the value and compare it with the value in

the specifications.

Note: Turn the rocker arm pressure sleeve so that it does not tip over when carrying out the measurement.

If the valve clearance corresponds with the specifications, torque-tighten the lock nut according to

the specifications.

13

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

9 / 15

IMPACT 3.0

13 February 2008

If it is necessary to adjust the valve clearance, remove the lock nut and shims, but do not move the

adjustment screw out of position.

Calculate, on the basis of the value, the thickness for the new shims.

Max. two shims may be used.

(Select the shims so that they are both approx. the same thickness, if it is necessary to use two

shims.)

Note: The shims are available in thickness intervals of 0.05 mm and the thickness is stamped on the shims.

14

Make sure that the shims and the valve caliper are well cleaned. Fit the shims and torque-tighten

the adjustment screw lock nut according to the specifications.

Note: Make sure that the adjustment screw is not moved out of position when tightening the nut.

15

Re-check the valve clearance.

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

10 / 15

IMPACT 3.0

13 February 2008

16

Adjust the other exhaust valves for VEB in the same manner.

Intake valves, adjusting

17

The intake valves on all engines, both with and without VEB, are adjusted in the same way as the

exhaust valves on engines not equipped with VEB.

Note: Make sure that the marking on the bearing cap is opposite the line marking on the camshaft which indicates

adjustment of intake valves and unit injectors on engines equipped with VEB.

Unit injectors

18

Note: The unit injectors are supplied by two different manufacturers.

Check the manufacture of the unit injectors in the engine in question as the adjusting procedures differ between the

injectors from the different manufacturers.

Unit injector, adjusting pre-loading

19

Check that the camshaft line marking for adjusting the intake valves and unit injector are opposite

the marking on the bearing cap, tolerance 2 mm (alternatively between the marks).

Check, via the number marking on the camshaft on which cylinder unit injector pre-loading is to be

adjusted.

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

11 / 15

IMPACT 3.0

13 February 2008

Note: If tool 9996956 is used to crank the flywheel, make sure that the tool is removed if the engine is to be turned over

with the starter motor.

20

Slacken the adjustment screw and adjust the unit injector rocker arm to zero play against the

crankshaft.

21

Note: Step 21 only applies to Lucas unit injectors.

Preload the unit injector by screwing down the adjustment screw 3-4 flats , (180- 240).

Torque-tighten the lock nut according to the specifications.

22

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

12 / 15

IMPACT 3.0

13 February 2008

Note: Steps 22 and 23 only apply to Bosch unit injectors.

Place gauge 9998390 on a dial indicator together with a magnetic foot.

Position the dial indicator so that the gauge flange rests against the unit injector spring disc and the

probe is directed towards the flat surface between the spring seat and the fuel valve.

Special tools: 9998390

Other special equipment: 9989876 9999696

23

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

13 / 15

IMPACT 3.0

13 February 2008

Preload the dial indicator 2-3 mm.

Preload the unit injector by screwing down the adjustment screw until the gauge bottoms against

the flat surface and the dial indicator pointer has stopped.

Torque-tighten the lock nut according to the specifications.

24

Adjust the other unit injectors in the same way.

Function check

25

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

14 / 15

IMPACT 3.0

13 February 2008

Carry out a function check by starting the engine and letting it run until it reaches normal working

temperature.

Then allow the engine to idle for a further 4-10 minutes.

When the idle speed is even, the cylinder balancing system has set the correct fuel volume for the

unit injectors.

Note: Cylinder balancing can only take place as long as no power consuming components, for example a pto, are

engaged.

The exhaust pressure governor must not be activated.

(Remove the el. connection from the solenoid valve if the parking brake is applied.)

If the parking brake is not applied, make sure in some other way that the truck cannot move.

26

Check that no fault codes have been generated. If fault codes have been generated, note the codes

and then erase them. Check that the fault codes are not generated again.

Copyright Volvo Parts Corporation

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are

uncontrolled.

15 / 15

S-ar putea să vă placă și

- Veb PDFDocument11 paginiVeb PDFIzz BaharÎncă nu există evaluări

- Valves & Unit Injectors AdjustingDocument14 paginiValves & Unit Injectors AdjustingZibao JumaÎncă nu există evaluări

- 2 Valves and Injectors Adjustment VEBDocument21 pagini2 Valves and Injectors Adjustment VEBRuju RujuÎncă nu există evaluări

- Actuator Variable Geometry Turbocharger ReplacementDocument11 paginiActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- 450 Dxi Rocker Arms Adjustment PDFDocument12 pagini450 Dxi Rocker Arms Adjustment PDFvaleriy89% (9)

- Remove and install timing assembly in 7 stepsDocument48 paginiRemove and install timing assembly in 7 stepsMirek100% (1)

- Valve and Injector Adjustment With EPG D12, D12A, D12B, D12CDocument9 paginiValve and Injector Adjustment With EPG D12, D12A, D12B, D12CRioga Rioga100% (1)

- Valves and JAK, AdjustDocument6 paginiValves and JAK, AdjustSherzad ChemÎncă nu există evaluări

- Volvo FH12 With Engine D12A Fault Codes PDFDocument4 paginiVolvo FH12 With Engine D12A Fault Codes PDFShadreck Takudzwa Ngwerume100% (1)

- Motor Volvo PDFDocument16 paginiMotor Volvo PDFdilsoclarinet100% (1)

- Delphi Volvo D11K PDFDocument3 paginiDelphi Volvo D11K PDFMas Inyeccion Electronica100% (2)

- Injection Pump, Setting On EngineDocument2 paginiInjection Pump, Setting On EngineSherzad Chem86% (7)

- 221-42 Oil Pressure Fault-TracingDocument8 pagini221-42 Oil Pressure Fault-TracingElio Custodio HuachacaÎncă nu există evaluări

- Pneumatic Diagram FH, FM, CHID E730001 - English (United Kingdom) 362 KB 2007-08-21Document26 paginiPneumatic Diagram FH, FM, CHID E730001 - English (United Kingdom) 362 KB 2007-08-21MTK2016Încă nu există evaluări

- Adjust Valves and Unit InjectorsDocument4 paginiAdjust Valves and Unit InjectorsSherzad Chem100% (3)

- Control Housing, Overhaul PDFDocument23 paginiControl Housing, Overhaul PDFEsam PhlipeÎncă nu există evaluări

- Camshaft Wear, CheckDocument4 paginiCamshaft Wear, CheckIzz BaharÎncă nu există evaluări

- Engine 1 TrainingDocument238 paginiEngine 1 TrainingSherzad Chem100% (13)

- General Manual: Electronic Unit Pump (Eup) - Daf - MX DDNX303 (EN)Document185 paginiGeneral Manual: Electronic Unit Pump (Eup) - Daf - MX DDNX303 (EN)Carl Anthony Chamberlain100% (9)

- Volvo Truck Fuel Bleeding GuideDocument2 paginiVolvo Truck Fuel Bleeding GuideSherzad Chem100% (1)

- Volvo FH4 D13K500 Cylinder HeadDocument98 paginiVolvo FH4 D13K500 Cylinder HeadGregg BaffledonÎncă nu există evaluări

- Field Service Tips: Fault tracing on D6B enginesDocument3 paginiField Service Tips: Fault tracing on D6B enginesyazeed naibanÎncă nu există evaluări

- enDocument17 paginienRegistr Registr60% (5)

- 2016ENG-01 Eng 01 307895096 PDFDocument60 pagini2016ENG-01 Eng 01 307895096 PDFjames100% (1)

- ZF Double - H Shift PatternDocument4 paginiZF Double - H Shift Patternnamduong3680% (1)

- 431-228 I-Shift Generation C Design and Function PDFDocument31 pagini431-228 I-Shift Generation C Design and Function PDFJosiney Hungaro CardosoÎncă nu există evaluări

- Volvo d12d Valve AdjustmentDocument7 paginiVolvo d12d Valve Adjustmentali78% (9)

- Basic Engine D12DDocument11 paginiBasic Engine D12DHamilton Miranda100% (7)

- Compressor FHDocument5 paginiCompressor FHomaralihas100% (1)

- ESPECIFICACIONES D12C Motor VolvoDocument44 paginiESPECIFICACIONES D12C Motor VolvoErika Salinas100% (4)

- FM, FH - Gearbox RemovedDocument41 paginiFM, FH - Gearbox RemovedSlVÎncă nu există evaluări

- FFL Ken CM CGMDocument44 paginiFFL Ken CM CGMكـروري كـشخةة100% (1)

- DC16 Cylinder SequenceDocument1 paginăDC16 Cylinder Sequencejengandxb100% (1)

- Adblue FH4 PDFDocument45 paginiAdblue FH4 PDFAhmad BaharÎncă nu există evaluări

- BooksrvtDocument27 paginiBooksrvtGabriel Balcazar100% (4)

- F2be0681a F3a F3beDocument478 paginiF2be0681a F3a F3bejvega_534120100% (2)

- Fault Codes 11 and 12 - Accelerator Pedal Sensor and Idling Contact IssuesDocument40 paginiFault Codes 11 and 12 - Accelerator Pedal Sensor and Idling Contact IssuesIzz BaharÎncă nu există evaluări

- 17071-02 B13R D13C CHN 125761-132856 PDFDocument120 pagini17071-02 B13R D13C CHN 125761-132856 PDFAnonymous EDNsviÎncă nu există evaluări

- Cajas en InglesDocument25 paginiCajas en InglesJose sQ100% (1)

- Fuel System Issue 6 1Document20 paginiFuel System Issue 6 1Ririn Dwi100% (1)

- I-Shift Calibration Operation Number 40070 Fails at Calibration of The "Stroke Length"Document4 paginiI-Shift Calibration Operation Number 40070 Fails at Calibration of The "Stroke Length"Tun Tun Win KseÎncă nu există evaluări

- d2676 Regulacja ZaworówDocument10 paginid2676 Regulacja ZaworówLUKAS100% (3)

- Volvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionDocument3 paginiVolvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionMohammad Saleh AbbasiÎncă nu există evaluări

- Volvo Control System System DescriptionDocument11 paginiVolvo Control System System DescriptionTun Tun Win KseÎncă nu există evaluări

- Service Bulletin Trucks: Lubrication Service and Oil ChangesDocument47 paginiService Bulletin Trucks: Lubrication Service and Oil ChangesBismarck Roberto Rojas Duran92% (12)

- FM PDFDocument660 paginiFM PDFEngkus KuswayaÎncă nu există evaluări

- Air Supply Description and FunctionDocument12 paginiAir Supply Description and Functionirfan100% (1)

- Lubrication and Oil System: GeneralDocument6 paginiLubrication and Oil System: Generalgustavo100% (2)

- Low Compression, Fault TracingDocument8 paginiLow Compression, Fault TracingIzz Bahar100% (2)

- Hpi Work DescriptionDocument32 paginiHpi Work DescriptionHari100% (7)

- Cylinder Compression, Manual Test D12DDocument16 paginiCylinder Compression, Manual Test D12DHamilton Miranda100% (1)

- PV776-20 006218Document9 paginiPV776-20 006218Benjamin Miranda FloresÎncă nu există evaluări

- 2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Document13 pagini2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Ricardo75% (4)

- Assambly Procedure For Connecting Rod Big EndDocument16 paginiAssambly Procedure For Connecting Rod Big EndMiguel Carpio100% (6)

- Gearbox OverhaulDocument80 paginiGearbox OverhaulMurniansyah AnsyahÎncă nu există evaluări

- TSB Ajuste Válvulas e InyectorDocument13 paginiTSB Ajuste Válvulas e InyectorMASTERTECH_01100% (1)

- Calibre Valvulas MP8 s34-5116Document20 paginiCalibre Valvulas MP8 s34-5116Jose AGÎncă nu există evaluări

- Injector Stainless & CopperDocument31 paginiInjector Stainless & CopperHamish Schnuriger100% (1)

- Service Bulletin Trucks: SRS, AirbagDocument43 paginiService Bulletin Trucks: SRS, AirbagSherzad ChemÎncă nu există evaluări

- D12A Refit Cylinder HeadDocument26 paginiD12A Refit Cylinder HeadSherzad ChemÎncă nu există evaluări

- Service Bulletin Trucks: Microwave Oven Rear, ReplaceDocument3 paginiService Bulletin Trucks: Microwave Oven Rear, ReplaceSherzad ChemÎncă nu există evaluări

- Service Bulletin Trucks: SRS, AirbagDocument43 paginiService Bulletin Trucks: SRS, AirbagSherzad ChemÎncă nu există evaluări

- FLC Wiring Diagram UpdateDocument1 paginăFLC Wiring Diagram UpdateSherzad Chem100% (1)

- D12A Valve and Injector Pre LoadsDocument15 paginiD12A Valve and Injector Pre LoadsSherzad Chem100% (2)

- Abs Section 59 TSP 25096 11.86Document14 paginiAbs Section 59 TSP 25096 11.86Sherzad ChemÎncă nu există evaluări

- D12A Valve and Injector Pre LoadsDocument15 paginiD12A Valve and Injector Pre LoadsSherzad Chem100% (2)

- SRS Repair Version 2Document17 paginiSRS Repair Version 2Sherzad ChemÎncă nu există evaluări

- Training Tips & Tactics: Module 1-FoundationDocument124 paginiTraining Tips & Tactics: Module 1-FoundationSherzad ChemÎncă nu există evaluări

- SRS Repair Version 2Document17 paginiSRS Repair Version 2Sherzad ChemÎncă nu există evaluări

- D12A Refit Cylinder HeadDocument26 paginiD12A Refit Cylinder HeadSherzad ChemÎncă nu există evaluări

- Camshift ReplaceDocument13 paginiCamshift ReplaceSherzad ChemÎncă nu există evaluări

- Truck Tralkkiuf PDFDocument134 paginiTruck Tralkkiuf PDFfrank mutaleÎncă nu există evaluări

- FM9, VT2206PTDocument6 paginiFM9, VT2206PTSherzad Chem67% (3)

- Electronically Controlled Brake System (EBS)Document18 paginiElectronically Controlled Brake System (EBS)Sherzad Chem100% (4)

- Training Tips and Tactics: Transmissions - ManualDocument190 paginiTraining Tips and Tactics: Transmissions - ManualSherzad Chem100% (2)

- Central Locking System PDFDocument5 paginiCentral Locking System PDFSherzad Chem0% (1)

- Valves and JAK, AdjustDocument6 paginiValves and JAK, AdjustSherzad ChemÎncă nu există evaluări

- VolvoDocument130 paginiVolvorepro3k85% (26)

- Injection Pump, Setting On EngineDocument2 paginiInjection Pump, Setting On EngineSherzad Chem86% (7)

- Vehicle ECU FunctionsDocument2 paginiVehicle ECU FunctionsSherzad Chem0% (1)

- Airdry Version2Document5 paginiAirdry Version2Sherzad Chem100% (2)

- Main Switch: CHID-A573694 and CHID-B353886Document2 paginiMain Switch: CHID-A573694 and CHID-B353886Sherzad ChemÎncă nu există evaluări

- Vehicle Control UnitDocument1 paginăVehicle Control UnitSherzad ChemÎncă nu există evaluări

- Central Locking SystemDocument5 paginiCentral Locking SystemSherzad ChemÎncă nu există evaluări

- Volvo Tad941ge OperationDocument76 paginiVolvo Tad941ge OperationSherzad Chem100% (1)

- 3736a G9T Common Rail SystemDocument180 pagini3736a G9T Common Rail Systemplamenvp21100% (1)

- I-Shift, Design and FunctionDocument59 paginiI-Shift, Design and FunctionSherzad Chem94% (17)

- Ebs STD, Ebs Med, Ebs HigDocument15 paginiEbs STD, Ebs Med, Ebs HigSherzad ChemÎncă nu există evaluări

- Guru Mann's Dumbbell Home Workout SplitDocument5 paginiGuru Mann's Dumbbell Home Workout Splitashish chopraÎncă nu există evaluări

- Mercury Outboard Replacement Lower UnitsDocument7 paginiMercury Outboard Replacement Lower UnitsMarine Parts ChinaÎncă nu există evaluări

- Acrosport - EnglishDocument20 paginiAcrosport - EnglishFranÎncă nu există evaluări

- 7 In. 29.000 LB/FT 0.408 In. L80 6.059 In. Vam® 21 HT: OD Weight Wall Th. Grade API Drift ConnectionDocument1 pagină7 In. 29.000 LB/FT 0.408 In. L80 6.059 In. Vam® 21 HT: OD Weight Wall Th. Grade API Drift ConnectionBalkis FatihaÎncă nu există evaluări

- Heavy Duty Tow Tractor Moves Up To 120,000 LbsDocument2 paginiHeavy Duty Tow Tractor Moves Up To 120,000 Lbsvitor rodriguesÎncă nu există evaluări

- Cunningham & Turner, 2016Document38 paginiCunningham & Turner, 2016Ratu SetiawanÎncă nu există evaluări

- DREAMCAST GAMESDocument162 paginiDREAMCAST GAMESOla EmanÎncă nu există evaluări

- Hydraulic and Steering System Training for 1107EX ProductDocument35 paginiHydraulic and Steering System Training for 1107EX ProductJUNA RUSANDI SÎncă nu există evaluări

- Swadesi Vs Videshi Products - EnglishDocument4 paginiSwadesi Vs Videshi Products - EnglishOmkar MungurdekarÎncă nu există evaluări

- Link Volkswagen GolDocument11 paginiLink Volkswagen GolDiego De La Fuente0% (1)

- Dungeon Alliance SupplementDocument12 paginiDungeon Alliance SupplementmhamlingÎncă nu există evaluări

- Amber Alert: Issued by Texas Dept. of Public SafetyDocument2 paginiAmber Alert: Issued by Texas Dept. of Public SafetyBrandon ScottÎncă nu există evaluări

- The Winning Edge: "This Is The Next Evolution of Football"Document27 paginiThe Winning Edge: "This Is The Next Evolution of Football"mathwhiz81Încă nu există evaluări

- DPWH Weather ChartDocument3 paginiDPWH Weather ChartRessa Acuin85% (13)

- Power 100 Heat Map: PostingsDocument1 paginăPower 100 Heat Map: Postingsjotham_sederstr7655Încă nu există evaluări

- STLTKD HandbookDocument34 paginiSTLTKD HandbookMark De JesusÎncă nu există evaluări

- Yoga SequenceDocument12 paginiYoga Sequenceअखिलेश कुमार पांडेयÎncă nu există evaluări

- Runningback DrillsDocument41 paginiRunningback DrillsJustin100% (3)

- s570 t4 Maintenance ChartDocument1 paginăs570 t4 Maintenance ChartEd VanegasÎncă nu există evaluări

- NCERT Books Mathematics Class IVDocument171 paginiNCERT Books Mathematics Class IVnikhilam.com88% (8)

- Clay Therapy PDFDocument12 paginiClay Therapy PDFIin WahyuniÎncă nu există evaluări

- DW01 PDFDocument2 paginiDW01 PDFLucca ZanettiÎncă nu există evaluări

- Table Tennis: History & DevelopmentDocument5 paginiTable Tennis: History & DevelopmentRyle ArbonÎncă nu există evaluări

- WP Nav RTEDocument1.753 paginiWP Nav RTEErick AvendañoÎncă nu există evaluări

- Listado de Juegos para PC Con EmuladorDocument5 paginiListado de Juegos para PC Con EmuladorMarcelo IbañezÎncă nu există evaluări

- Sutton Grammar School For Boys 1Document1 paginăSutton Grammar School For Boys 1wizardzx2Încă nu există evaluări

- Issue of Shares Questions With SolutionsDocument4 paginiIssue of Shares Questions With SolutionsSumiran BansalÎncă nu există evaluări

- EVOBET88 Situs Judi Slot Online Gacor Dan Agen Judi Bola PDFDocument1 paginăEVOBET88 Situs Judi Slot Online Gacor Dan Agen Judi Bola PDFArrafi FahrezaÎncă nu există evaluări

- Super Mario RPG Legend of The Seven Stars - Guide PDFDocument225 paginiSuper Mario RPG Legend of The Seven Stars - Guide PDFSamuel MoireÎncă nu există evaluări

- Kai Biceps Compressed PDFDocument17 paginiKai Biceps Compressed PDFGermanas Gureckis50% (2)