Documente Academic

Documente Profesional

Documente Cultură

ZTT Ficha Tecnica FFOO

Încărcat de

José Luis Franco Calderón BartraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ZTT Ficha Tecnica FFOO

Încărcat de

José Luis Franco Calderón BartraDrepturi de autor:

Formate disponibile

Spec No.

: ZTT 59600-1

Revision: 1

Date: Mar. 7, 2016

TECHNICAL SPECIFICATION

All-Dielectric Self-Supporting Fiber Cable

Designer

Senior Technical Man ager

Approver

Chief Technical Engineer

Jiangsu Zhongtian Technology Co., Ltd.

No. 5 Zhongtian Road, NEATA, Nantong City, Jiangsu province, China Tel: +86-513-8919 1138 Fax: +86-513- 8359 9670

1. General

1.1 Scope

This listed specification covers the design requirements and performance standard for the supply of

optical fiber cable in the industry. It also includes ZTT premium designed cable with optical,

mechanical and geometrical characteristics.

Cable type Application

OFC-48G.652D-FASA-S1 Self-supporting aerial installation cable

1.2 Cable Description

ZTT cable possesses high tensile strength and flexibility in compact cable sizes. At the same time, it

provides excellent optical transmission and physical performance.

1.3 Quality

Excellent quality control is achieved through intense in-house quality check and stringent audit

acceptance by ISO 9001.

1.4 Reliability

Initial and periodic product qualification tests for performance and durability are performed rigorously

to ensure product reliability.

1.5 Reference

The cable which ZTT offered are designed, manufactured and tested according to international

standards as follows:

IEC 60793-1 Optical fiber Part 1: Generic specifications

IEC 60793-2 Optical fiber Part 2: Product specifications

Standard for testing and performance for All-Dielectric Self-Supporting (ADSS)

IEEE P1222

fiber optic cable for use on electric utility power lines

ITU-T G.650 Definition and test methods for the relevant parameters of single-mode fibers

ITU-T G.652 Characteristics of a single-mode optical fiber and cable

EIA/TIA 598 Color code of fiber optic cables

www.zttcable.com ALL Rights Reserved Copyright 2016 page 1 of 11

2. Optical Fiber

The optical fiber is made of high pure silica and germanium doped silica. UV curable acrylate material

is applied over fiber cladding as optical fiber primary protective coating. The detail data of optical fiber

performance are shown in the following table.

G.652D Fiber

Specifications

Category Description

Before cabling After cabling

Attenuation @1310 nm 0.34 dB/km 0.35 dB/km

Attenuation @1550 nm 0.20 dB/km 0.25 dB/km

Zero Dispersion Wavelength 1300~1324 nm

Zero Dispersion Slope 0.092 ps/nm 2km

Optical

PMD 0.1 ps/km

Specifications

Cable Cutoff Wavelength (cc) 1260 nm

Macro bending Loss

(100 turns; 50 mm) @1550 nm 0.05 dB

(100 turns; 50 mm) @1625 nm 0.10 dB

Mode Field Diameter @1310 nm 9.20.4m

Cladding Diameter 125 1m

Dimensional

Core/clad concentricity error 0.6m

Specifications

Cladding Non-Circularity 1.0%

Mechanical

Proof stress 0.69Gpa

Specifications

www.zttcable.com ALL Rights Reserved Copyright 2016 page 2 of 11

3. Cable Structure

3.1 Cable Type: OFC-48G.652D-FASA-S1 (200m Span)

1

2

3

4

5

6

7

8

Picture is only for reference 9

Technical Characteristics Construction

The unique extruding technology provides 1. Outer sheath (PE, anti-UV)

the fibers in the tube with good flexibility and 2. Strength member (Aramid yarns)

bending endurance 3. Loose tube

The unique fiber excess length control 4. Fiber and jelly

method provides the cable with excellent 5. Central strength member (FRP)

mechanical and environmental properties 6. Water blocking yarns

Multiple water blocking material filling 7. Water blocking tape

provides dual water blocking function 8. Inner sheath (PE, anti-UV)

Provide good tension performance 9. Rip cords

Dimension and Properties

Fiber count 48 G.652D

No of loose tube / filler 4/2

Fiber No. per tube 12

Cable OD 12.5mm5%

Physical

Cable weight 122kg/km15%

Operation temperature range -40 deg C to + 70 deg C

Installation temperature range -30 deg C to + 70 deg C

Transport and storage temperature range -40 deg C to + 70 deg C

Max. tensile load 5.73KN

Crush resistance 3000 N/10cm

Mechanical

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown gray white red black yellow violet pink aqua

Tube color blue orange green brown / / / / / / / /

Remark: 1. The sheath thickness is not including the ripcord.

www.zttcable.com ALL Rights Reserved Copyright 2016 page 3 of 11

3.2 Cable Type: OFC-48G.652D-FASA-S1 (300m Span)

1

2

3

4

5

6

7

8

Picture is only for reference 9

Technical Characteristics Construction

The unique extruding technology provides 1. Outer sheath (PE, anti-UV)

the fibers in the tube with good flexibility and 2. Strength member (Aramid yarns)

bending endurance 3. Loose tube

The unique fiber excess length control 4. Fiber and jelly

method provides the cable with excellent 5. Central strength member (FRP)

mechanical and environmental properties 6. Water blocking yarns

Multiple water blocking material filling 7. Water blocking tape

provides dual water blocking function 8. Inner sheath (PE, anti-UV)

Provide good tension performance 9. Rip cords

Dimension and Properties

Fiber count 48 G.652D

No of loose tube / filler 4/2

Fiber No. per tube 12

Cable OD 12.8mm5%

Physical

Cable weight 128kg/km15%

Operation temperature range -40 deg C to + 70 deg C

Installation temperature range -30 deg C to + 70 deg C

Transport and storage temperature range -40 deg C to + 70 deg C

Max. tensile load 8.5KN

Crush resistance 3000 N/10cm

Mechanical

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown gray white red black yellow violet pink aqua

Tube color blue orange green brown / / / / / / / /

Remark: 1. The sheath thickness is not including the ripcord.

www.zttcable.com ALL Rights Reserved Copyright 2016 page 4 of 11

3.3 Cable Type: OFC-48G.652D-FASA-S1 (400m Span)

1

2

3

4

5

6

7

8

Picture is only for reference 9

Technical Characteristics Construction

The unique extruding technology provides 1. Outer sheath (PE, anti-UV)

the fibers in the tube with good flexibility and 2. Strength member (Aramid yarns)

bending endurance 3. Loose tube

The unique fiber excess length control 4. Fiber and jelly

method provides the cable with excellent 5. Central strength member (FRP)

mechanical and environmental properties 6. Water blocking yarns

Multiple water blocking material filling 7. Water blocking tape

provides dual water blocking function 8. Inner sheath (PE, anti-UV)

Provide good tension performance 9. Rip cords

Dimension and Properties

Fiber count 48 G.652D

No of loose tube / filler 4/2

Fiber No. per tube 12

Cable OD 12.8mm5%

Physical

Cable weight 126kg/km15%

Operation temperature range -40 deg C to + 70 deg C

Installation temperature range -30 deg C to + 70 deg C

Transport and storage temperature range -40 deg C to + 70 deg C

Max. tensile load 10.79KN

Crush resistance 3000 N/10cm

Mechanical

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown gray white red black yellow violet pink aqua

Tube color blue orange green brown / / / / / / / /

Remark: 1. The sheath thickness is not including the ripcord.

www.zttcable.com ALL Rights Reserved Copyright 2016 page 5 of 11

3.4 Cable Type: OFC-48G.652D-FASA-S1 (600m Span)

1

2

3

4

5

6

7

8

Picture is only for reference 9

Technical Characteristics Construction

The unique extruding technology provides 1. Outer sheath (PE, anti-UV)

the fibers in the tube with good flexibility and 2. Strength member (Aramid yarns)

bending endurance 3. Loose tube

The unique fiber excess length control 4. Fiber and jelly

method provides the cable with excellent 5. Central strength member (FRP)

mechanical and environmental properties 6. Water blocking yarns

Multiple water blocking material filling 7. Water blocking tape

provides dual water blocking function 8. Inner sheath (PE, anti-UV)

Provide good tension performance 9. Rip cords

Dimension and Properties

Fiber count 48 G.652D

No of loose tube / filler 4/2

Fiber No. per tube 12

Cable OD 13.4mm5%

Physical

Cable weight 137kg/km15%

Operation temperature range -40 deg C to + 70 deg C

Installation temperature range -30 deg C to + 70 deg C

Transport and storage temperature range -40 deg C to + 70 deg C

Max. tensile load 15.34KN

Crush resistance 3000 N/10cm

Mechanical

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown gray white red black yellow violet pink aqua

Tube color blue orange green brown / / / / / / / /

Remark: 1. The sheath thickness is not including the ripcord.

www.zttcable.com ALL Rights Reserved Copyright 2016 page 6 of 11

3.5 Cable Type: OFC-48G.652D-FASA-S1 (1000m Span)

1

2

3

4

5

6

7

8

Picture is only for reference 9

Technical Characteristics Construction

The unique extruding technology provides 1. Outer sheath (PE, anti-UV)

the fibers in the tube with good flexibility and 2. Strength member (Aramid yarns)

bending endurance 3. Loose tube

The unique fiber excess length control 4. Fiber and jelly

method provides the cable with excellent 5. Central strength member (FRP)

mechanical and environmental properties 6. Water blocking yarns

Multiple water blocking material filling 7. Water blocking tape

provides dual water blocking function 8. Inner sheath (PE, anti-UV)

Provide good tension performance 9. Rip cords

Dimension and Properties

Fiber count 48 G.652D

No of loose tube / filler 4/2

Fiber No. per tube 12

Cable OD 14.5mm5%

Physical

Cable weight 160kg/km15%

Operation temperature range -40 deg C to + 70 deg C

Installation temperature range -30 deg C to + 70 deg C

Transport and storage temperature range -40 deg C to + 70 deg C

Max. tensile load 24.29KN

Crush resistance 3000 N/10cm

Mechanical

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown gray white red black yellow violet pink aqua

Tube color blue orange green brown / / / / / / / /

Remark: 1. The sheath thickness is not including the ripcord.

www.zttcable.com ALL Rights Reserved Copyright 2016 page 7 of 11

4. Test Requirements

Approved by various professional optical and communication product institution, ZTT also conduct

various in-house testing in its own Laboratory and Test Center. She also conduct test with special

arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical

Communication Products (QSICO). ZTT possess the technology to keep its fiber attenuation loss within

Industry Standards.

The cable is in accordance with applicable standard of cable and requirement of customer. The following

test items are carried out according to corresponding reference.

Routine tests of optical fiber

Mode field diameter IEC 60793-1-45

Mode field Core/clad concentricity IEC 60793-1-20

Cladding diameter IEC 60793-1-20

Cladding non-circularity IEC 60793-1-20

Attenuation coefficient IEC 60793-1-40

Chromatic dispersion IEC 60793-1-42

Cable cut-off wavelength IEC 60793-1-44

www.zttcable.comALL Rights Reserved Copyright 2016 page 8 of 11

Test List

4.1Tension Loading Test

Test Standard IEC 60794-1-2 E1

Sample length No less than 50 meters

Load Max. working tensile load

Duration time 1 minute

Fiber strain:0.33%

Test results Additional attenuation:0.1dB

No damage to cable elements

4.2 Crush/Compression Test

Test Standard IEC 60794-1-2 E3

Load Crush load

Duration time 10 minutes

Test number 1

Additional attenuation:0.1dB

Test results

No damage to cable elements

4.3 Impact Resistance Test

Test Standard IEC 60794-1-2 E4

Impact energy 4.5J

Radius 12.5mm

Impact points 3

Impact number 1

Additional attenuation:0.1dB

Test result

No damage to cable elements

4.4 Repeated Bending Test

Test Standard IEC 60794-1-2 E6

Bending radius 20 X diameter of cable

Cycles 25 cycles

Additional attenuation:0.1dB

Test result

No damage to cable elements

www.zttcable.comALL Rights Reserved Copyright 2016 page 9 of 11

4.5 Torsion/Twist Test

Test Standard IEC 60794-1-2 E7

Sample length 2m

Angles 180 degree (load 50N)

cycles 10

Additional attenuation:0.1dB

Test result

No damage to cable elements

4.6 Bend Test

Test Standard IEC 60794-1-2 E11B

Mandrel diameter 20 X diameter of cable

Turn number 4

Number of cycles 3

Additional attenuation: 0.1dB

Test result

No damage to cable elements

4.7 Temperature cycling Test

Test Standard IEC 60794-1-2 F1

Temperature step +20 -40 +70+20

Time per each step 12 hrs

Cycles 2

Attenuation variation for reference value (the attenuation to be measured

Test result before test at +203) 0.1dB/km

4.8 Water penetration Test

Test Standard IEC 60794-1-2 F5

Height of water column 1m

Sample length 1m

Test time 1h

Test result No water leakage from the opposite of the cable core

4.9 Drip Test

Test Standard IEC 60794-1-2 E14

Sample length 0.3m (5 samples)

Temperature 65

Duration 24 hrs

Test result No filling compound shall drip from tubes

www.zttcable.comALL Rights Reserved Copyright 2016 page 10 of 11

5. Packing and Drum

5.1 ZTT cables are packed in carton, coiled on Bakelite & wooden drum. During transportation, right tools

should be used to avoid damaging the package and to handle with ease. Cables should be protected

from moisture; kept away from high temperature and fire sparks; protected from over bending and

crushing; protected from mechanical stress and damage.

Wooden strip seal

Wooden flange

Inner tub

Cable fixing point

Axle hole

Cable trough

5.2 The color of cable marking is white. (The printing shall be carried out at interval of 1 meter on the

outer sheath of cable) The inner end of cable is then sealed with heat shrinkable end cap to prevent

ingress of water and is made available for testing. The outer end of cable is equipped with heat

shrinkable end cap. Outer sheath marking legend can be changed according to users requests.

5.3 Outdoor cable packing

Bakelite & wooden drum

Strong wooden batten protection

www.zttcable.comALL Rights Reserved Copyright 2016 page 11 of 11

S-ar putea să vă placă și

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDe la EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsÎncă nu există evaluări

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pagini2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayÎncă nu există evaluări

- ZTT Adss 20-113931 - BDocument11 paginiZTT Adss 20-113931 - BervanÎncă nu există evaluări

- 0.9. OPGW - Tech - Discription For OPGWDocument12 pagini0.9. OPGW - Tech - Discription For OPGWgiorgis072Încă nu există evaluări

- Wire Products: Alumoweld Wire and StrandDocument8 paginiWire Products: Alumoweld Wire and StrandAndres FrancoÎncă nu există evaluări

- P59x en 0814b PDFDocument4 paginiP59x en 0814b PDFLa Picarona del PeruÎncă nu există evaluări

- Test and Diagnosis System: VLF Sinus 45 KVDocument2 paginiTest and Diagnosis System: VLF Sinus 45 KVNur FajarÎncă nu există evaluări

- EDC-DTS-LV002 - Electrical Accessories For LV ABCDocument34 paginiEDC-DTS-LV002 - Electrical Accessories For LV ABCJoe bilouteÎncă nu există evaluări

- Generic Specification: Optical Ground Wire Cables (OPGW) For Installation On High Voltage Power LinesDocument15 paginiGeneric Specification: Optical Ground Wire Cables (OPGW) For Installation On High Voltage Power LinesKy TaÎncă nu există evaluări

- National Electric Safety Code Ansi c2 NescDocument44 paginiNational Electric Safety Code Ansi c2 NescLenin NateraÎncă nu există evaluări

- Adss 24 Hilos Span 100 - Life FiberDocument2 paginiAdss 24 Hilos Span 100 - Life FiberDiego FigueroaÎncă nu există evaluări

- Sudkabel Garnituren ENGDocument20 paginiSudkabel Garnituren ENGShin Hye ParkÎncă nu există evaluări

- Of Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetDocument4 paginiOf Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetShubhranshu SumanÎncă nu există evaluări

- Products:, 2016. JSHP Delivered On Schedule Without Surprise !Document1 paginăProducts:, 2016. JSHP Delivered On Schedule Without Surprise !Isaac SternÎncă nu există evaluări

- Sol Sdm02 SK Pe Ele FD 061 r01Document9 paginiSol Sdm02 SK Pe Ele FD 061 r012D EngenhariaÎncă nu există evaluări

- Dimensiuni TrafoDocument2 paginiDimensiuni TrafoGorgan BogdanÎncă nu există evaluări

- An Introduction To Test CablesDocument5 paginiAn Introduction To Test CablesArun KumarÎncă nu există evaluări

- Pesos y Dimensiones Columnas y Elementos HºAº (CIMALCO)Document1 paginăPesos y Dimensiones Columnas y Elementos HºAº (CIMALCO)Marcelo Aldao100% (1)

- 6 GFMF 150 DatasheetDocument2 pagini6 GFMF 150 DatasheetHamad YousafaniÎncă nu există evaluări

- Opgw CatalogDocument14 paginiOpgw CatalogSeptimiu Bota100% (2)

- Optical Joint Box EWMJ: Outside PlantDocument3 paginiOptical Joint Box EWMJ: Outside PlantvgskarÎncă nu există evaluări

- RV Al - U-1000 AR2V Eng - Rev5 PDFDocument4 paginiRV Al - U-1000 AR2V Eng - Rev5 PDFjarias-solarpackÎncă nu există evaluări

- CSE-A 12-24 KV - 250 - 400 - 630 A - English 2010Document2 paginiCSE-A 12-24 KV - 250 - 400 - 630 A - English 2010ruimauricioferreiraÎncă nu există evaluări

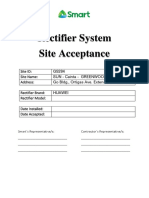

- Rectifier System Site AcceptanceDocument7 paginiRectifier System Site Acceptancearcue quirozÎncă nu există evaluări

- WhatsMinerTool Operating GuideDocument19 paginiWhatsMinerTool Operating GuideRicardo Jose FuenmayorÎncă nu există evaluări

- Datasheet Ion 8650Document10 paginiDatasheet Ion 8650Angelo Rivera Paredes100% (1)

- NA2XS FL 2Y RM 18 30 KV PDFDocument2 paginiNA2XS FL 2Y RM 18 30 KV PDFSid Ali RABEHIÎncă nu există evaluări

- Siprotec 7sl86 v6 ProfileDocument2 paginiSiprotec 7sl86 v6 ProfileproteccionesÎncă nu există evaluări

- Aislador Estacion NPP20XG27SDocument1 paginăAislador Estacion NPP20XG27SSaúl Gómez RobinsónÎncă nu există evaluări

- Line Installation and Protective Equipment Overhead Specifiers Guide Br100008enDocument120 paginiLine Installation and Protective Equipment Overhead Specifiers Guide Br100008enPolano SpiridionÎncă nu există evaluări

- CIGRE Vol2Document64 paginiCIGRE Vol2reinscÎncă nu există evaluări

- 24 Fiber OPGW ANDES PDFDocument7 pagini24 Fiber OPGW ANDES PDFMAN TÎncă nu există evaluări

- Licensed by Information Handling ServicesDocument11 paginiLicensed by Information Handling ServicesCristian SnchezÎncă nu există evaluări

- Power Transmission Over Long Distances With CablesDocument8 paginiPower Transmission Over Long Distances With CablesramsesiÎncă nu există evaluări

- Optical Ground Wire: Fiber Optic Cable Used For Providing A Grounding Path For Transmission SystemsDocument4 paginiOptical Ground Wire: Fiber Optic Cable Used For Providing A Grounding Path For Transmission SystemsTheoVarneyÎncă nu există evaluări

- Manual 850Document290 paginiManual 850niravÎncă nu există evaluări

- Norma Canadiense Interferencia (CAN3-C108 3 1-M84)Document26 paginiNorma Canadiense Interferencia (CAN3-C108 3 1-M84)Pancho RomanÎncă nu există evaluări

- Heatshrink Joints PDFDocument24 paginiHeatshrink Joints PDFMonish KrishnaÎncă nu există evaluări

- Aislador Espiga, Caract. TécnicasDocument1 paginăAislador Espiga, Caract. TécnicasEduardo Rivas CéspedesÎncă nu există evaluări

- Product Catalogue: Power CablesDocument54 paginiProduct Catalogue: Power CablesBrion Bara IndonesiaÎncă nu există evaluări

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pagini(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinÎncă nu există evaluări

- Reconectador Cooper Power SystemsDocument16 paginiReconectador Cooper Power SystemsAdonis Alexander Sfakianakis MaurokefalidisÎncă nu există evaluări

- Manual de Pararrayos ABBDocument24 paginiManual de Pararrayos ABBLuisAlbertoAlvaradoMontesÎncă nu există evaluări

- Instruction Sheet D3208 MANUALDocument48 paginiInstruction Sheet D3208 MANUALscalariÎncă nu există evaluări

- 560CMU02 EnglishDocument4 pagini560CMU02 EnglishfrixiofrixioÎncă nu există evaluări

- IEEE Standards Interpretations For IEEE STD 605 ™ - 1998 IEEE Guide For Design of Substation Rigid-Bus StructuresDocument5 paginiIEEE Standards Interpretations For IEEE STD 605 ™ - 1998 IEEE Guide For Design of Substation Rigid-Bus StructuresRayzwanRayzmanÎncă nu există evaluări

- Aero-Z Reference ListDocument5 paginiAero-Z Reference ListPablo CondoriÎncă nu există evaluări

- WGR 273 1Document5 paginiWGR 273 1jan rogerÎncă nu există evaluări

- Raychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingDocument4 paginiRaychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingGIBUÎncă nu există evaluări

- TA314 enDocument56 paginiTA314 enIonescu Gheorghe100% (1)

- Siemens DTC PresentationDocument8 paginiSiemens DTC Presentationgiolgau01Încă nu există evaluări

- HiTemp® Series Accessories For ACCC® ConductorsDocument32 paginiHiTemp® Series Accessories For ACCC® ConductorsAndre Luis Fontes FerreiraÎncă nu există evaluări

- SBEC4000 Parts NumbersDocument88 paginiSBEC4000 Parts NumbersRyan WilsonÎncă nu există evaluări

- Optical Fiber Transmission Media (Opgw) For A Reliable Operation of The Telecommunication and Protection System On Hvac SystemDocument25 paginiOptical Fiber Transmission Media (Opgw) For A Reliable Operation of The Telecommunication and Protection System On Hvac SystemCarlos Alberto Di PalmaÎncă nu există evaluări

- Products l3 Oskf Ansi 71503 v1 enDocument4 paginiProducts l3 Oskf Ansi 71503 v1 enSergiu Aparatu100% (2)

- 36kV GISDocument19 pagini36kV GISNiket GuptaÎncă nu există evaluări

- Département Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual InstallationDocument26 paginiDépartement Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual Installationjrsk638742Încă nu există evaluări

- ZTT Duct Cable 17-70971 - KAI - 210420 - 195939Document12 paginiZTT Duct Cable 17-70971 - KAI - 210420 - 195939Soebangkit TvÎncă nu există evaluări

- ZTT Anti-Rodent Cable Cfs02752+cad0171Document8 paginiZTT Anti-Rodent Cable Cfs02752+cad0171Marcelo VenegasÎncă nu există evaluări

- ZTT Duct Cable 20-109788-2-ADocument8 paginiZTT Duct Cable 20-109788-2-AVictor DoyoganÎncă nu există evaluări

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocument2 paginiExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanÎncă nu există evaluări

- British Army Vehicles Equipment LKDocument35 paginiBritish Army Vehicles Equipment LKLIVE3ORDIEÎncă nu există evaluări

- UME in Brief 2008 - SSDocument44 paginiUME in Brief 2008 - SSapi-3772864Încă nu există evaluări

- Semiconductor Optical AmplifierDocument40 paginiSemiconductor Optical AmplifierVikas ThakurÎncă nu există evaluări

- Food Quiz Test 1Document3 paginiFood Quiz Test 1robymecÎncă nu există evaluări

- Acme Screw AssembliesDocument51 paginiAcme Screw Assemblies1940LaSalleÎncă nu există evaluări

- Radio Theory: Air Waves in AviationDocument16 paginiRadio Theory: Air Waves in Aviationchand_basha_8Încă nu există evaluări

- Lecture Notes On DryingdsgaaaaaaaaaaDocument15 paginiLecture Notes On DryingdsgaaaaaaaaaaSaumith DahagamÎncă nu există evaluări

- 711 Sokkia Manualset130rDocument182 pagini711 Sokkia Manualset130rjose antonio carazoÎncă nu există evaluări

- Arduino 3 Axis Mini Lazer Paper CutterDocument14 paginiArduino 3 Axis Mini Lazer Paper CutterMarius DanilaÎncă nu există evaluări

- Leica DISTO D8: The Original Laser Distance MeterDocument24 paginiLeica DISTO D8: The Original Laser Distance MeterserddsÎncă nu există evaluări

- Modules Computer 2 QTR 3Document24 paginiModules Computer 2 QTR 3dr.cie27Încă nu există evaluări

- 5.4.5 Reflection Feedback and Noise: F F F F F FDocument2 pagini5.4.5 Reflection Feedback and Noise: F F F F F FNovi Sebtian AmeliaÎncă nu există evaluări

- Headland Laser TechnologyDocument40 paginiHeadland Laser TechnologyshrusÎncă nu există evaluări

- Transline Part 2Document97 paginiTransline Part 2Haw-ChyunÎncă nu există evaluări

- Lab 3-EllipsometerDocument5 paginiLab 3-EllipsometerSam StideÎncă nu există evaluări

- Epson K100 K200 EPIL BrochureDocument2 paginiEpson K100 K200 EPIL BrochurevelsÎncă nu există evaluări

- Ultrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Document8 paginiUltrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Saeed AshaÎncă nu există evaluări

- Measuring Control of Construction MaterialsDocument7 paginiMeasuring Control of Construction MaterialsYOLO crapperÎncă nu există evaluări

- Process TablesDocument43 paginiProcess TablesmonkeydluffyÎncă nu există evaluări

- Speed /frequency / Wavelength: EquationDocument3 paginiSpeed /frequency / Wavelength: Equationsansay cagaananÎncă nu există evaluări

- Array Waveguide Gratings (AWG)Document15 paginiArray Waveguide Gratings (AWG)Mukunda Saiteja AnnamÎncă nu există evaluări

- 10.energy Band Gap Behavior of Binary OxidesDocument24 pagini10.energy Band Gap Behavior of Binary OxidesWan HafizaÎncă nu există evaluări

- Muhammad Zulkarnain Bin Abdul Rahman: Mobile: 019-7565446 EmailDocument5 paginiMuhammad Zulkarnain Bin Abdul Rahman: Mobile: 019-7565446 EmailAsma AmalinaÎncă nu există evaluări

- Toshiba - E STUDIO - 350 352 353 450 452 453Document302 paginiToshiba - E STUDIO - 350 352 353 450 452 453asirirÎncă nu există evaluări

- AC Checklists Posted On JAQG WebDocument2 paginiAC Checklists Posted On JAQG WebDaniel SanchezÎncă nu există evaluări

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDocument34 paginiSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaÎncă nu există evaluări

- 03-Xray FilmDocument50 pagini03-Xray FilmReza Apa Ja'er100% (1)

- Understanding OTDRDocument10 paginiUnderstanding OTDRAnonymous 6PurzyegfXÎncă nu există evaluări

- 5W Emitter Led DatasheetDocument15 pagini5W Emitter Led DatasheetAlércio RosaÎncă nu există evaluări