Documente Academic

Documente Profesional

Documente Cultură

MYOLA Feedlot W

Încărcat de

Najeeb EMhaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MYOLA Feedlot W

Încărcat de

Najeeb EMhaDrepturi de autor:

Formate disponibile

MYOLA feedlot was built by a consortium of local northern NSW cotton and grain

farmers and Sydney investors in 1993.

Moree grain and cotton farmers, James and Andrea Mulligan and family, one of the

major original investors, now own the business outright.

Historically, Myola feedlots heavy reliance on custom-feeding exposed it to the

ebbs and flows in demand for feedlot space, caused by seasonal conditions.

However a greater emphasis now in longer-term program type custom-feeding

relationships, rather than casual spot feeding work, has been a significant and

successful strategy.

Myola was always intended primarily as a custom-feedyard, and underwent a series

of expansions from around 2001 when it was at 5000 head to its current capacity of

20,000 head.

The effects of the recent drought, firstly in Queensland and then NSW have added

to the capacity pressure on Myola. The biggest proportion of custom-fed cattle tend

to come from NSW, but when circumstances and seasons dictate, its not

uncommon to see Queensland cattle in the pens.

With Elders Killara feedlot taking on more principal positions in their cattle, Myola is

now clearly the largest custom-feed service-provider in NSW.

The feedlot itself holds a Coles contract for supply of a B-double each fortnight of

trade heifers to Australian Country Choice in Brisbane and the rest of the pens are

occupied with custom-feeding clients cattle. Another regular custom-feeding client

also holds a supermarket supply contract.

Major feeder clients include supply chains like James Macleans Allied Beef program,

and end-users with grainfed branded beef programs including several large beef

processors.

While the proportions change a little over time, currently the greatest proportion of

custom-fed cattle are 70-day steers and heifers, with fewer cattle destined for

export programs.

The focus on building relationships with dedicated supply chains to deliver

program type custom-feeding, as opposed to relying solely on spot market

feeding has paid off for Myola, allowing it to avoid some of the inevitable occupancy

peaks and troughs that custom feedyards historically tended to be exposed to.

Its about building that surety of supply, week-in, week-out, that the branded beef

business delivers, that underpins our business these days, feedlot manager Jeff

Dight said.

A new feedmill (a whopping big

Ferrell Ross 24 x 56 unit was installed about six years ago. Myola has always used

steamflaking for grain processing due to its improved digestibility and resultant

cattle performance.

The surrounding farming country grows silage and roughage to meet some of the

feedlots requirements, with the balance sourced from the surrounding area.

Cropping internally this year included both an annual summer and winter program.

Silage production this year exceeded 8000 tonnes including summer silage of

irrigated corn and winter silage of barley and wheat a recipe which has proven

very successful over the past couple of years.

The yard features shade access in all pens, with first pens covered way back in the

late 1990s. Both shadecloth and corrugated iron-based shade systems are used.

Convenient access to grain, cottonseed and other feedstuffs is one of Myolas

biggest competitive advantages, followed by good access to a wide range of

NSW/Qld abattoirs chasing grainfed cattle.

Feed and inventory management aids like Digi-Star, FY3000, and Stockaid have all

contributed to the operational efficiency and reporting systems used by the yard

S-ar putea să vă placă și

- Profitable PoultryDocument16 paginiProfitable PoultryJaba de SojaÎncă nu există evaluări

- Asset and Liability ManagementDocument57 paginiAsset and Liability ManagementMayur Federer Kunder100% (2)

- Grazing Animal Nutrition PDFDocument46 paginiGrazing Animal Nutrition PDFPaulo Junior100% (1)

- Beef Feedlot Management Guide: Inma Agribusiness Program - USAID/IraqDocument38 paginiBeef Feedlot Management Guide: Inma Agribusiness Program - USAID/IraqJhon Oleg RamosÎncă nu există evaluări

- Beef Feedlot Management GuideDocument38 paginiBeef Feedlot Management GuideHassan Ali Khalid100% (1)

- Corporate Finance MCQDocument35 paginiCorporate Finance MCQRohan RoyÎncă nu există evaluări

- Business PlanDocument16 paginiBusiness PlanFrank Donald SasaÎncă nu există evaluări

- Growing Cattle Feed Hydroponically PDFDocument30 paginiGrowing Cattle Feed Hydroponically PDFJob Mateus100% (1)

- Beef Cattle Management - With Information on Selection, Care, Breeding and Fattening of Beef Cows and BullsDe la EverandBeef Cattle Management - With Information on Selection, Care, Breeding and Fattening of Beef Cows and BullsÎncă nu există evaluări

- Aged Swine Student Ref.Document23 paginiAged Swine Student Ref.Charlotte AcayanÎncă nu există evaluări

- Aquaponics: Fish and Crop Plants Share The Same Recycled Water in LaosDocument1 paginăAquaponics: Fish and Crop Plants Share The Same Recycled Water in LaosAquaponicsÎncă nu există evaluări

- Introduction To Dairy Farming PPT 1114fcdDocument24 paginiIntroduction To Dairy Farming PPT 1114fcdShubham JaiswalÎncă nu există evaluări

- Hydroponic FourrageDocument12 paginiHydroponic FourrageSalman LabiadhÎncă nu există evaluări

- The Formation of Pure-Bred Flocks and Their Subsequent ManagementDe la EverandThe Formation of Pure-Bred Flocks and Their Subsequent ManagementÎncă nu există evaluări

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument22 paginiStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceRohit RajagopalÎncă nu există evaluări

- Offtake Agreement For Maize: WHEREAS The Seller Has Offered To Supply The Buyer and The Buyer Has Agreed To PurchaseDocument3 paginiOfftake Agreement For Maize: WHEREAS The Seller Has Offered To Supply The Buyer and The Buyer Has Agreed To PurchaseChiccoe Joseph100% (1)

- Statement of The ProblemDocument86 paginiStatement of The ProblemMedini Chippali100% (2)

- Dairy Farming Project 2019 PDFDocument2 paginiDairy Farming Project 2019 PDFeric omoloÎncă nu există evaluări

- Pembrokeshire FarmerDocument32 paginiPembrokeshire FarmerDigital MediaÎncă nu există evaluări

- High Welfare Milk Production IndiaDocument4 paginiHigh Welfare Milk Production Indiaarpit85Încă nu există evaluări

- Factory Farms in North CarolinaDocument2 paginiFactory Farms in North CarolinaFood and Water WatchÎncă nu există evaluări

- CC F4P Newletter April 2018Document7 paginiCC F4P Newletter April 2018Laura LakeÎncă nu există evaluări

- May 2013 Mundika Farm UpdateDocument4 paginiMay 2013 Mundika Farm UpdateStichting Oud in Afrika (Old in Africa Foundation)Încă nu există evaluări

- Dairy Cattle: Dairy Cattle (Also Called Dairy Cows or Milk Cows) AreDocument11 paginiDairy Cattle: Dairy Cattle (Also Called Dairy Cows or Milk Cows) AreZerotheoryÎncă nu există evaluări

- Case 3.philosophers Wool Business Case StudyDocument12 paginiCase 3.philosophers Wool Business Case StudytrucnguyenÎncă nu există evaluări

- Statement of The ProblemDocument35 paginiStatement of The Problempradeepkallur100% (3)

- Australia, The Dairy CountryDe la EverandAustralia, The Dairy CountryÎncă nu există evaluări

- Rice News - 13 April 2022Document25 paginiRice News - 13 April 2022Mujahid AliÎncă nu există evaluări

- Alternative Enterprises: Economic Performance and ViabilityDocument35 paginiAlternative Enterprises: Economic Performance and ViabilityGiovanniSyaputraÎncă nu există evaluări

- Milk ProsessDocument3 paginiMilk Prosessvector dairyÎncă nu există evaluări

- Hunter Grain, Swap and RD1 On A ShipDocument1 paginăHunter Grain, Swap and RD1 On A ShipRichardÎncă nu există evaluări

- The Irish Dairy IndustryDocument3 paginiThe Irish Dairy Industryapi-180658041Încă nu există evaluări

- Cargill A Threat To FoodDocument16 paginiCargill A Threat To FoodrikcaptÎncă nu există evaluări

- Dairy FarmingDocument8 paginiDairy FarmingGeoffrey TanuiÎncă nu există evaluări

- Livestock Fact Cards v1 WebDocument28 paginiLivestock Fact Cards v1 Webgw23shewardgeorginaÎncă nu există evaluări

- Beef CattleDocument25 paginiBeef CattleJomel Paul PalmaÎncă nu există evaluări

- Factory Farms in MichiganDocument2 paginiFactory Farms in MichiganFood and Water Watch100% (1)

- Dairy Farming 00 Mich RichDocument316 paginiDairy Farming 00 Mich Richrajatgupta9155Încă nu există evaluări

- Warehouse Report FinalDocument38 paginiWarehouse Report FinalZardar WaseemÎncă nu există evaluări

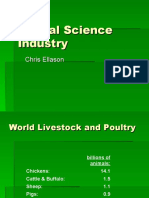

- Animal Science IndustryDocument44 paginiAnimal Science IndustryRamadhan Ghinan NafsiÎncă nu există evaluări

- Vermeer Making Hay Volume1 Summer 2013Document12 paginiVermeer Making Hay Volume1 Summer 2013woodfordequipmentÎncă nu există evaluări

- Tef Pitch (Tejuvic Farms)Document3 paginiTef Pitch (Tejuvic Farms)D J Ben UzeeÎncă nu există evaluări

- Proposals For Development of Non-Profitable Livestock Farms of The NLDBDocument9 paginiProposals For Development of Non-Profitable Livestock Farms of The NLDBMark WuÎncă nu există evaluări

- Diversifying Cropping SystemsDocument20 paginiDiversifying Cropping SystemsmutazsalihÎncă nu există evaluări

- Amul-Avertising and Sales PromotionDocument30 paginiAmul-Avertising and Sales PromotionShalini_Pandey_23190% (1)

- Factory Farms in PennsylvaniaDocument2 paginiFactory Farms in PennsylvaniaFood and Water WatchÎncă nu există evaluări

- Factory Farms in IowaDocument3 paginiFactory Farms in IowaFood and Water WatchÎncă nu există evaluări

- Chimzis Dairy Farm BPDocument26 paginiChimzis Dairy Farm BPdala.dishesÎncă nu există evaluări

- Bowen J Ryan - Research Essay 1Document8 paginiBowen J Ryan - Research Essay 1api-735950405Încă nu există evaluări

- Trends in Dairy Goat FarmingDocument5 paginiTrends in Dairy Goat FarmingmutegiÎncă nu există evaluări

- WIYLS Visits A Beef Finishing ShedDocument7 paginiWIYLS Visits A Beef Finishing ShedGalani MothobiÎncă nu există evaluări

- 9 Baked Goods and Cereal Products: Andrew WhitleyDocument14 pagini9 Baked Goods and Cereal Products: Andrew WhitleyRaga BhavaÎncă nu există evaluări

- Flying High With RabbitsDocument5 paginiFlying High With RabbitsjopiougÎncă nu există evaluări

- Factory Farms in CaliforniaDocument2 paginiFactory Farms in CaliforniaFood and Water WatchÎncă nu există evaluări

- Napier Proposal PerlisDocument7 paginiNapier Proposal PerlisMr. KÎncă nu există evaluări

- Queensland Fresh ProduceDocument20 paginiQueensland Fresh Produceyeetamus407Încă nu există evaluări

- Direct Market Beef AgPlan SampleDocument14 paginiDirect Market Beef AgPlan SampleMichael ZibaÎncă nu există evaluări

- Brochure06 enDocument8 paginiBrochure06 enNilamdeen Mohamed ZamilÎncă nu există evaluări

- CafiDocument18 paginiCafiapi-437138926Încă nu există evaluări

- Sheep Cop ReportDocument20 paginiSheep Cop ReportnoureddinÎncă nu există evaluări

- School ReportDocument18 paginiSchool ReportAbhinayaa BalajiÎncă nu există evaluări

- IUF AusDocument15 paginiIUF AusIqbal ArrasyidÎncă nu există evaluări

- Cargill SummaryDocument19 paginiCargill SummaryNISREEN WAYA100% (1)

- Olam Invests $150M in Nigerian Poultry, Feed Sectors - Feed StrategyDocument3 paginiOlam Invests $150M in Nigerian Poultry, Feed Sectors - Feed StrategyakuabataÎncă nu există evaluări

- Wales Farmer Feb 2014Document28 paginiWales Farmer Feb 2014Digital MediaÎncă nu există evaluări

- Chapter 2 Test BankDocument7 paginiChapter 2 Test Bankrajalaxmi rajendranÎncă nu există evaluări

- Impact 2020 Agenda-C667Document3 paginiImpact 2020 Agenda-C667Edwards TranÎncă nu există evaluări

- Poverty and Human Development Report 2011Document184 paginiPoverty and Human Development Report 2011Repoa TanzaniaÎncă nu există evaluări

- Green HRM - Issues & Challenges: Mrs. Pallavi KumariDocument21 paginiGreen HRM - Issues & Challenges: Mrs. Pallavi KumariAbida SultanaÎncă nu există evaluări

- Essay Dev Econ Kalihputro Fachriansyah 30112016 PDFDocument7 paginiEssay Dev Econ Kalihputro Fachriansyah 30112016 PDFKalihÎncă nu există evaluări

- Blue Nile GooodDocument67 paginiBlue Nile GooodKamil Jagieniak100% (1)

- Patton and Littleton EnglishDocument3 paginiPatton and Littleton EnglishAyu Ratih KusumadewiÎncă nu există evaluări

- Capacity ManagementDocument16 paginiCapacity ManagementHitesh BabbarÎncă nu există evaluări

- 1992 ColwellDocument20 pagini1992 ColwellBhagirath BariaÎncă nu există evaluări

- Working Capital Management at BEMLDocument20 paginiWorking Capital Management at BEMLadharav malikÎncă nu există evaluări

- Question CAP III AND CA MEMBERHSIP New OneDocument17 paginiQuestion CAP III AND CA MEMBERHSIP New OneSuraj ThapaÎncă nu există evaluări

- FM - Kelompok 4 - 79D - Assignment CH9, CH10Document8 paginiFM - Kelompok 4 - 79D - Assignment CH9, CH10Shavia KusumaÎncă nu există evaluări

- KaleeswariDocument14 paginiKaleeswariRocks KiranÎncă nu există evaluări

- An Introduction To Supply Chainmanagement: William J. StevensonDocument7 paginiAn Introduction To Supply Chainmanagement: William J. StevensonpraveenÎncă nu există evaluări

- UCD2F1209Document17 paginiUCD2F1209sharvin05Încă nu există evaluări

- Inv TG B1 88173907 101003789746 January 2023 - 1 PDFDocument4 paginiInv TG B1 88173907 101003789746 January 2023 - 1 PDFVara Prasad dasariÎncă nu există evaluări

- Process Costing Tutorial SheetDocument3 paginiProcess Costing Tutorial Sheets_camika7534Încă nu există evaluări

- L01B Topic 2Document39 paginiL01B Topic 2Emjes GianoÎncă nu există evaluări

- The Fundamental Concepts of Macroeconomics: Erandathie PathirajaDocument69 paginiThe Fundamental Concepts of Macroeconomics: Erandathie PathirajaDK White LionÎncă nu există evaluări

- GMR Infrastructure LimitedDocument35 paginiGMR Infrastructure LimitedAmrut BhattÎncă nu există evaluări

- Topic Selection: by Tek Bahadur MadaiDocument24 paginiTopic Selection: by Tek Bahadur Madairesh dhamiÎncă nu există evaluări

- Accounting Activity 4Document2 paginiAccounting Activity 4Audrey Janae SorianoÎncă nu există evaluări

- DigitalDocument4 paginiDigitalideal assignment helper 2629Încă nu există evaluări

- Chipotle 2013 Organizational AnalysisDocument7 paginiChipotle 2013 Organizational Analysistarawneh92Încă nu există evaluări

- Tan VS CirDocument3 paginiTan VS CirJani MisterioÎncă nu există evaluări