Documente Academic

Documente Profesional

Documente Cultură

Welding Recommendation TS890

Încărcat de

mpedraza-1Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Welding Recommendation TS890

Încărcat de

mpedraza-1Drepturi de autor:

Formate disponibile

1. Steel grades 3.

Workpiece temperature

during welding

1.1 Chemical analysis

The following table shows the chemical analysis in

percentage of TS890 Every time that structural and wear resistant steel To calculate the heat input could be used this following TIG MMA SAW MAG MAG

are welded it is very important to minimize the risks formula: EN Designation EN ISO 636-A2008 EN 757 EN 756 EN ISO 16834-A EN ISO 16834-A

of cold cracking ( also known as hydrogen cracking or W2Mo E894 Mn2Ni CrMo B67 H5 SZ 3Ni 2,5Cr Mo G89 6 M Mn4Ni2CrMo G89 6 M Mn4Ni2CrMo

delayed cracking) . The main cause of cold cracking is h* U* I* 60 Size (mm) 2,4 3,25 - 4 2,5 1 1,2

CHEMICAL ANALYSIS

the presence of hydrogen together with the stress in the Q=

n* 1000 AWS Class AWS A5.28-05 ER70S-A1 AWS A5.5-06 E12018-M AWS A5.28: E120S-G AWS A5.28: E120S-G

welded joint.

GRADE C Mn Si P S Ni V Cr Mo The risk of cracking is minimized by:

TS890 0.20 1.50 0.50 0.020 0.010 0.30 0.10 0.80 0.70 preheating the parent material before welding; Where :

guaranteeing that the joint surface are perfectly clean

Other element like Nb and Ti might be added in order to increase hardenability and improve mechanical properties up to a total combined of 0.10 % max.

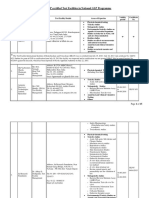

and dry; Q = Heat input [kJ/mm] Welding Filler Metal Current Run-out lenght Trav

Voltage (V) Heat Input (KJ/mm)

minimizing the shrinkage stresses, which could be U = Voltage [V] Process Electrode size (mm) Type & Polarity Ampers (A) Speed (mm;mm/min)

reached by a good fit between the workpieces and I = Current [A] TIG 2,4 DC (-) 145 - 155 13 - 14 55 - 65 1,044 - 1,420

1.2 Weldability (see point 3) determined, based on the cast analysis, by this a well planned sequences of weld runs (balanced V = Welding speed [mm/min]

h = Arc efficiency factor MMA 3,24 DC (+) 130 - 140 22,5 - 23,5 85 - 95 1,478 - 1,858

Weldability is a key factor for the tubes in structural and following formula (according to the IIW): welding);

MMA 4 DC (+) 160 - 170 23,5 - 24,5 110 - 120 1,504 - 1,717

engineering applications. selecting a filler material with low hydrogen content.

Tenaris guarantees the good weldability of the product Description and product application field SAW 2,5 DC (-) 270 - 290 25,5 - 26,5 410 - 430 0,961 - 1,125

Mn Cr+ Mo+V Ni+Cu

thanks to its controlled chemical composition with low CEV= C + + + 3.1 Preheating MAG 1 DC (+) 185 - 205 15 - 16 160 - 180 0,527 - 0,656

carbon equivalent. 6 5 15

Preheating is very important in tack welding and in Welding Method Arc efficiency factory h

MAG 1,2 DC (-) 220 - 240 19 - 20 300 - 320 0,560 - 0,672

welding of the root pass.

MAXIMUM CEV

1.3 Carbon Equivalent Value (CEV) The higher the temperature during and after welding, Manual Metal Arc (MMA) 0.8

A steel with a low carbon equivalent has a better GRADE TS890 the easier it will be for the hydrogen to escape from Gas Metal Arc (MAG) 0.8 0.9

weldability than a steel with a high value. CEV % max 0,70 the steel. The need for preheating increases with the Submerged Arc (SAW) 1.0 INTERPASS for all welding process

The Maximum Carbon Equivalent Value (CEV) is plate thickness to compensate for the faster cooling

TIG (GTAW) 0.7

of thick plate, and because thick plate has a higher TS 890

CEV value than a thinner plate. If the ambient is rich Thickness mm 5,6 >5,6 12 >12 25 >25 40

Value of Arc efficiency factory considering the different welding process

of humidity and / or the temperature is below 5 C, it Temperature C 20 - 75 100 - 150 150 - 175 175 - 250

occurs to increase the temperatures standards and also

2. Mechanical Properties and Impact test the temperature should be increased if the workpiece

welded is rigidly restrained.

3.4 Selection of filler material

The choice of filler material is in function with the

Thickness inch

Temperature F

0,22

68 - 167

>0,22 0,79

212 - 302

>0,79 0,98

302 - 347

>0,98 1,57

347 - 482

demanded made on the mechanical properties of the

TS 890 welded joints in the different cases. Also it is important

2.1 MECHANICAL PROPERTIES to choose a filler material which allows to keep an

Thickness (mm) 5,6 >5,6 12 >12 25 >25 40

hydrogen content of 5 ml /100 g in the weld metal.

Minimum Yield strength (MPa) WT (mm) Tensile Strength (MPa) Minimum Elongation Long Temperature (C) 20 100 150 175

GRADE The main benefits of choosing low-strength filler

20 >20 40 >40 20 >20 40 >40 All % Thickness (inch) 0,22 >0,22 0,79 >0,79 0,98 >0,98 1,57 material rather than high-strength filler material (yield

TS890 890 850 820 960 - 1130 920 - 1090 870 - 1040 14 Temperature (F) 68 212 302 347 strength in excess of 500 N/mm2) are:

Major toughness of the weld metal;

Preheating values (mm-inch / C - F)

Improved ductility of the welded joint;

Reduce sensitivity to cracking.

2.2 IMPACT TEST PROPERTIES IN LONGITUDINAL The TS890 steel grade is weldable with traditional

welding procedures, given observance of the generally 3.2 Post heating And finally for fillet welds, it is always recommendable

DIRECTION accepted technical rules. Post heating of welded joint normally for this steel to select under-matching filler material.

Charpy V - notch 10 x 10 at - 40 C (*) - Minimum Average Energy (J) grade is not performed.

Grade WT (mm) Joule It is very important to define a welding procedure which

takes into account the following conditions: 3.3 Selection of heat input

40 45

TS890 Thickness of the base material TS890 could be subjected to the following welding

> 40 40 Specific heat input (specially for HAZ) process:

Design requirements (for join preparation) MMA (Manual Metal Arc)

Welding method used MAG (Gas Metal Arc)

Weld material characteristics SAW (Submerged Arc)

2.3 IMPACT TEST PROPERTIES IN TRANSVERSAL TIG (Tungsten Inert Gas)

DIRECTION Special attention is taken towards cracks susceptibility, It is important to establish the correct value of heat

which is more likely to happen with high thickness and input to obtain a satisfactory combination of toughness,

Charpy V - notch 10 x 10 at - 40 C (*) - Minimum Average Energy (J)

high resistance. strength and preserve hardness of the heat affected zone

Grade WT (mm) Joule

(HAZ).

40 30 This particularity is connected to the following factors:

TS890 Chemical analysis (by means CEV)

> 40 27

The amount of diffusible hydrogen in the weld

material

HAZ micro - structure This catalog was produced in collaboration with IIS Progress S.r.l.

company of the Italian Institute of Welding Group.

(*) Other test temperature may be performed upon agreement Tensile stress concentrations at the weld joints The Italian Institute of Welding is a Founder Member of International Institute

Value of toughness in ZF and ZTA after welding of Welding (IIW) and European Welding Federation (EWF) and IIS Progress S.r.l.

is an Authorized Training Body of IIW and EWF.

process

4WELDING.indd 2 14/06/13 12:03

Description and product application field www.tenaris.com

Welding Recommendation

TS890

Tenaris has developed the following steel grades, Reference Standards

supplied in quenched and tempered condition: The specification PSP 00148 is based on EN 10210-1/2

and SEW 090 t.2 standards.

- TS590 For the purpose of this specification based on means

- TS690 that these standards are only taken as reference, but full

- TS770 compliance with those documents is not envisaged.

- TS890

EN 10210-1

The main characteristics of these products, with respect Hot finished structural hollow sections of non-alloy and

to traditional steel grades, are elevated yield strength fine grain steels Part 1: Technical delivery conditions.

and very good toughness at low temperature, with a

chemical composition that guarantees an optimum EN 10210-2

weldability. Hot finished structural hollow sections of non-alloy and

fine grain steels Part 2: Tolerances, dimensions and

High strength seamless steel tubes used for structural sectional properties.

and engineering purposes are produced according to

Tenaris Specification PSP 00148. In all cases latest SEW 090 t.2

edition of this specification shall be used. Liquid quenched and tempered high-resistance fine

grained steels General technical delivery conditions for

These tubes are used in steel construction for civil and tubes and hollow sections.

engineering purposes where the relationship between

mass and space occupied is specially critical.

Welding Recommendation TS890 - Rev. 00 - May 2013

Tenaris has produced this catalogue for general information only. While every effort has been made to ensure the accuracy of the information contained within this

publication, Tenaris does not assume any responsibility or liability for any loss, damage, injury resulting from the use of information and data herein. Tenaris products and

services are only subject to the Companys standard Terms and Conditions or otherwise to the terms resulting from the respective contracts of sale, services or license, as the

case may be. The information in this publication is subject to change or modification without notice. For more complete information please contact a Tenariss representative or

visit our website at www.tenaris.com. Tenaris 2013. All rights reserved.

IP

4WELDING.indd 3 14/06/13 12:03

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Mpaps D 7130Document4 paginiMpaps D 7130mpedraza-1Încă nu există evaluări

- Mpaps S B 4.101 Gs PLDocument6 paginiMpaps S B 4.101 Gs PLmpedraza-1Încă nu există evaluări

- Qs865atez Data GR&RDocument2 paginiQs865atez Data GR&Rmpedraza-1Încă nu există evaluări

- Bernoulli PDFDocument19 paginiBernoulli PDFmpedraza-1Încă nu există evaluări

- Auditoria Por CapasDocument23 paginiAuditoria Por Capasmpedraza-1Încă nu există evaluări

- CEMS G-5 Part 1ADocument7 paginiCEMS G-5 Part 1Ampedraza-1Încă nu există evaluări

- RequirementsDocument18 paginiRequirementsmpedraza-1Încă nu există evaluări

- E-Coating Process FinalDocument1 paginăE-Coating Process Finalmpedraza-1Încă nu există evaluări

- Corporate Standard CPS0098: 1 ScopeDocument11 paginiCorporate Standard CPS0098: 1 Scopempedraza-1Încă nu există evaluări

- CD6 Prototype Control PlanDocument3 paginiCD6 Prototype Control Planmpedraza-1Încă nu există evaluări

- CD6 Prototype PFMEADocument4 paginiCD6 Prototype PFMEAmpedraza-1Încă nu există evaluări

- DOE Paint Pops On Seam: CMT Columbus, OHDocument13 paginiDOE Paint Pops On Seam: CMT Columbus, OHmpedraza-1Încă nu există evaluări

- Guideline APQP Workbook Rev DDocument19 paginiGuideline APQP Workbook Rev Dmpedraza-1100% (1)

- AtlasDocument44 paginiAtlasmpedraza-1Încă nu există evaluări

- English Grammar: Prepositions of TimeDocument3 paginiEnglish Grammar: Prepositions of Timempedraza-1Încă nu există evaluări

- 5 Fases Del Apqp (Core)Document5 pagini5 Fases Del Apqp (Core)mpedraza-1Încă nu există evaluări

- Adverbs That Tell Us For How LongDocument2 paginiAdverbs That Tell Us For How Longmpedraza-1Încă nu există evaluări

- Doe Imc 1 - October 2007Document9 paginiDoe Imc 1 - October 2007mpedraza-1Încă nu există evaluări

- Prepositions of Place: At, In, On: at For A POINT in For An Enclosed Space On For A SURFACEDocument4 paginiPrepositions of Place: At, In, On: at For A POINT in For An Enclosed Space On For A SURFACEmpedraza-1Încă nu există evaluări

- Expressing The Date: For Single Days and Dates We Use OnDocument2 paginiExpressing The Date: For Single Days and Dates We Use Onmpedraza-1Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Systemic FluoridesDocument58 paginiSystemic FluoridesShalakha BhardwajÎncă nu există evaluări

- Pcac - Ucm486146Document429 paginiPcac - Ucm486146leoncioÎncă nu există evaluări

- Question Paper SSC 32Document18 paginiQuestion Paper SSC 32Tarun BediÎncă nu există evaluări

- Poro Die Casting MethologyDocument3 paginiPoro Die Casting Methologypurushothaman1234566Încă nu există evaluări

- Student Exploration: Collision Theory: NCVPS Chemistry Fall 2014Document7 paginiStudent Exploration: Collision Theory: NCVPS Chemistry Fall 2014erwin golovashkin0% (1)

- Chapter 10Document42 paginiChapter 10Teddy Matthew AudleyÎncă nu există evaluări

- Protein Structure Function and Uses WorksheetDocument3 paginiProtein Structure Function and Uses WorksheetAngelon UdaniÎncă nu există evaluări

- WPS (Gtaw)Document2 paginiWPS (Gtaw)Ramadhan AdityaÎncă nu există evaluări

- Astm d1752Document2 paginiAstm d1752Whitebeard RagnarokÎncă nu există evaluări

- Journal of Molecular Structure: Yasushi Numata, Hayato Kobayashi, Norihiko Oonami, Yuki Kasai, Hiroyuki TanakaDocument5 paginiJournal of Molecular Structure: Yasushi Numata, Hayato Kobayashi, Norihiko Oonami, Yuki Kasai, Hiroyuki TanakaIoana AlexandraÎncă nu există evaluări

- PresentationDocument14 paginiPresentationshu-sunanÎncă nu există evaluări

- Durometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDocument2 paginiDurometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDarwin_Sidney100% (1)

- Tallentex Class 10 # 2022-23Document20 paginiTallentex Class 10 # 2022-23Sreeja SujithÎncă nu există evaluări

- 3d Printing Materials PropertiesDocument51 pagini3d Printing Materials PropertiesAmy GaoÎncă nu există evaluări

- M 29-03 Fine Aggregate For Bituminous Paving Mix PDFDocument3 paginiM 29-03 Fine Aggregate For Bituminous Paving Mix PDFWalticoZegarraHerreraÎncă nu există evaluări

- Trislot Reactor Internal Part PDFDocument12 paginiTrislot Reactor Internal Part PDFjonathanÎncă nu există evaluări

- BV 300 Layer Management Guide: Types of HousingDocument20 paginiBV 300 Layer Management Guide: Types of HousingBINAY KUMAR YADAV100% (1)

- ConcreteDocument23 paginiConcreteHein ZanÎncă nu există evaluări

- Manual de RadioisotoposdDocument257 paginiManual de RadioisotoposdNorma Mendoza GonzálezÎncă nu există evaluări

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 paginiANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezÎncă nu există evaluări

- Blast FurnaceDocument28 paginiBlast Furnaceavanisharma_1991Încă nu există evaluări

- Theory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence TimeDocument5 paginiTheory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence Timeiko856Încă nu există evaluări

- Soyaben ProjectDocument66 paginiSoyaben ProjectAmeshe Moges100% (1)

- ReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryDocument396 paginiReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryyulliarperezÎncă nu există evaluări

- Wafer Biscuit PlantDocument9 paginiWafer Biscuit Planttechnocrat_vspÎncă nu există evaluări

- Measurements of Surface TensionDocument11 paginiMeasurements of Surface TensionHema ParasuramanÎncă nu există evaluări

- 2021 Raptor CatalogDocument12 pagini2021 Raptor CatalogLoc BuiÎncă nu există evaluări

- Have You Ever Imagined An Environment That Is Not GreenDocument2 paginiHave You Ever Imagined An Environment That Is Not GreenGeorge Anderson Loza FloresÎncă nu există evaluări

- New List of GLP Approved LabsDocument15 paginiNew List of GLP Approved LabsMulayam Singh YadavÎncă nu există evaluări

- Geotechnical EngineeringDocument5 paginiGeotechnical EngineeringNicole ForrosueloÎncă nu există evaluări