Documente Academic

Documente Profesional

Documente Cultură

PROGRAM SUPPLY PLANNING

Încărcat de

Non Etabas GadnatamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PROGRAM SUPPLY PLANNING

Încărcat de

Non Etabas GadnatamDrepturi de autor:

Formate disponibile

PROGRAM SUPPLY PLAN

During the pre-FEED Phase, the Program Procurement Management Team (PPMT) in cooperation with the

Envelope Management Teams and other Company stakeholders, developed an overall Program Supply

Plan, which was further developed during the FEED Phase.

The driving force behind the plan is to establish the Vendor selection and management process and

determine the level of Company engagement preceding and during the EPC Phase by addressing the

following areas:

(a) Optimum number of Vendors available, or required, to address the extensive and diverse RTIP scope

of supply.

(b) Procurement strategies for key commodities based upon the overall RTIP contracting strategy and

schedule considerations, available supply sources, technology requirements, potential risks and rewards,

local content, total cost of ownership and similar requirements.

(c) Need to negotiate and award Program Leveraged Agreements (PLAs) to support standardization

initiatives, and to reduce cost and schedule.

(d) Optimum level of consolidation of Vendors, and equipment / material models and types to enable

effective site standardization, including spare parts, and operations and maintenance requirements.

(e) Optimum levels of expediting and inspection to be imposed upon the individual Contractors.

The Program Supply Plan can be thought of as the repository for the "Program Approved Vendors List" and

all procurement strategies developed during FEED as part of the following independent activities:

Program Contracting Strategy

Equipment and Materials Standardization Plan

Procurement Market Studies and Selected Sourcing Strategies

Local Content Plan

Main elements of the finalized plan include estimated quantities and cost by equipment / material groupings

(on the project level - see Project Supply Plan), approved Vendors, negotiation elements, timing, expediting

and inspection requirements, and procurement strategies and their implementation elements, etc. A

classification for Equipment and Bulk materials will identify the approach for obtaining market pricing to

support the estimate.

PROJECT SUPPLY PLANS

Specific Project Supply Plans for each unit were developed by the responsible FEED / PMC Contractors in

cooperation with the Envelope Management Teams by incorporating relevant elements from the Program

Supply Plan and increasing the level of detail to include item specific requirements / strategies. In addition,

the Project Supply Plans will include all Licensor mandated proprietary Vendors to comply with performance

and warranty obligations. These plans will be the controlling document for the supply of all equipment and

materials, related services and standardization by the Contractors, and issued as part of the EPC Invitation to

Bid (ITB). Company Project Procurement Leads (PPLs) will provide required direction and oversight for the

Project Supply Plans with final approval by the PPMT.

Doc. No: A554-K-PRG-PU-LIS-DOC-009 Contains Confidential Information of Date: 29 July 2011

(Introduction) Both Dow and Saudi Aramco Revision: 04

EQUIPMENT AND MATERIAL CLASSIFICATIONS

For the FEED Estimate, Company has directed the FEED / PMC Contractors to obtain Vendor

budget quotations for eighty percent (80%) of the Total Equipment Cost per unit. Equipment

being defined as all "tagged" process equipment (mainly mechanical and process containing

equipment - PCE). The bulk materials are addressed differently (a mix of market data and

statistical modeling).

Recommendation:

The budget quotes should cover more than just the Process Equipment, as many other major

equipment items may have a very high value and therefore an impact on the estimate accuracy.

Request:

The FEED / PMC Contractor is requested to review the attached list of equipment and materials

categories and comment on the selected classification: Bulk or Equipment. An Equipment

identifier ("E") indicates that item will be added to the equipment list, and consequently covered

by budget quotes, provided the cost is of sufficient magnitude to influence the eighty percent

(80%) requirement. An identifier "B" means it has been classified as a Bulk item. Note that

some "Critical Equipment" may require a "purchase quality" inquiry perhaps - to be indentified in

the Estimating Plan.

Doc. No: A554-K-PRG-LIS-DOC-009 Contains Confidential Information of Date: 29 July 2011

(Classifications) Both Dow and Armaco Revision: 04

STANDARDIZATION CATEGORY DEFINITIONS

Depending on the final selection of the product categories to be standardized

(outcome of the workshops, benefit / cost evaluations) Company will use the

following means of achieving standardization / variability minimization.

Category A - PLAs: Where functionality of the whole Complex or safety is

concerned, or a significant impact on total cost of ownership is identified, one (1) or

a limited number of Vendors will be selected by Company to supply Program-wide

equipment and/or materials. Alternatively, such Vendors may be selected by

Company to supply a given site area or envelope. During the Design Phase,

Company will competitively bid and enter into Program-wide PLAs with Category A

Vendors.

Category B - Company Directed Materials: Where Company wishes to direct

Vendor selection due to total cost of ownership considerations or any other reason,

Company may request Contractor to utilize a Vendor other than the one selected by

Contractor from the Project Supply Plan. Such Company direction may give rise to

a Change Order under paragraph 10 of Schedule A.

Category C - Matching Vendor Materials: Where Company does not wish to

influence Vendor selection, Contractor shall conduct the procurement process in

accordance with the Vendor selection requirements set out in Schedule G. Once a

Vendor has been selected, Contractor must source items within its scope of Work

from the same Vendor to achieve a level of standardization.

Category D - Commodity Materials: For certain high volume, low impact materials

and low unit cost items (including components of a larger item or package typically

purchased by the main Equipment manufacturer) where standardization is required

but it is not economically advantageous to develop a PLA, Contractor must procure

only from Vendors listed in the Project Supply Plan or designated within the

technical package (datasheets/specifications contained in the Project Design Basis).

Category E - Critical Equipment: For Critical Equipment that requires special

attention in the procurement process. In some cases the Company may have

started the formal requisition process prior to the Effective Date. Contractor shall

assume responsibility for completing the procurement whether or not already

initiated by Company.

Category F - Licensor Directed Materials: For Equipment that must be procured

from a specific Vendor as required by a License Agreement.

Doc. No: A554-K-PRG-PU-LIS-DOC-009 Contains Confidential Information of Date: 29 July 2011

(Standardization) Both Dow and Saudi Aramaco Revision: 04

EXPEDITING LEVEL GUIDELINES

Typical Organization and Reporting Structure

An Expediting Coordinator shall be assigned to each individual Engineering, Procurement

and Construction (EPC) project by the EPC contractor and have responsibility for providing

oversight, supervision and coordination of all expediting activities both in the EPCs home

office and in the field, including all worldwide support locations and 3rd Party Agencies. The

Expediting Coordinator shall also be responsible for establishing and maintaining all project

expediting plans, procedures, work processes and related documentation for implementation

across the project to ensure maximum standardization of approach, reporting and control.

During EPC execution the Expediting Coordinator, working within the parameters as

established by these Expediting Level Guidelines, will determine the level and type (Home

Office and / or Field) of expediting required depending upon the complexity of the equipment

/ material, delivery criticality (interdependency, high impact on the project construction

schedule), field required date and / or previous history with the vendor, subject to

reassessment as circumstances dictate and Owner approval. After the appropriate level of

expediting has been established, the order is then assigned to the responsible Home Office

Expediter.

Home Office Expediters, reporting to the Expediting Coordinator, will be assigned to perform

desk expediting as outlined below and to provide oversight, supervision and coordination of

all expediting activities performed by Field Expediters, where required.

If field expediting is required, the assigned Home Office Expediter shall be responsible for

completing and forwarding all assignment details to the Field Expediter. The Home Office

Expediter shall determine which Field Expediter is best suited for a particular assignment

(considering cost, availability and experience).

Upon completion of each expediting visit, the Field Expediter shall complete the appropriate

expediting report and forward to the Home Office Expediter for further action and / or

distribution. Any back-up documents referred to in the report, such as production schedules,

photographs, etc. may be forwarded separately.

Home Office (Desk) Expediting

Home Office Expediters responsibilities and duties include: Verify receipt of order and

request return of signed order acknowledgement; confirm order has been entered into

vendor's system; confirm primary point of contact; review and confirm documentation

requirements; and establish a contact schedule to monitor the progress of milestones,

manufacturing schedules, sub-vendor orders, inspection witness points, and delivery.

Contains Confidential Information of Date: 29 July 2011

A554-K-PRG-PU-LIS-DOC-009 (Expediting) Both Dow and Aramco Revision: 04

Field Expediting

The Field Expediters responsibilities and duties shall be parallel to the duties of the Home

Office Expediter, regarding established level of communication with the manufacturer;

maintaining the timely submittal of drawings; confirming receipt of suborder equipment and

materials; and measuring the progress in the shop against the fabrication schedule.

Expediting Levels

The Expediting Levels outlined below (and incorporated within the Program Supply Plan) are

established based upon the complexity and criticality of equipment and materials as defined

herein. These levels reflect the minimum criteria for expediting coverage.

Level 1: Refers to industry standard equipment and materials purchased from vendors who

have demonstrated reliability in meeting standard delivery schedules. Usually no Field

Expediting is required. Home Office Expediting by telephone and email is required once a

month, as a minimum.

Level 2: This refers to equipment or materials with limited sources, large quantities and / or

schedule sensitive. Field Expediting is required and coverage ranges from once a month to

twice a month, or more frequently as required. Home Office Expediting is still required by

telephone and email twice a month, as a minimum.

Level 3: This refers to equipment and materials involving complex manufacturing steps, large

quantities, exotic materials, and / or is schedule critical. Field Expediting is required and

coverage normally ranges from twice a month to weekly visits. Home Office Expediting is still

required by telephone and email twice a month, as a minimum.

Level 4: This refers to equipment or materials with the highest priority considering delivery

time, vendor performance, the overall construction schedule and / or on the critical path.

These items are considered to be of prime importance to the successful and timely execution

of the project. Field Expediting coverage ranges from weekly visits to resident expediter.

Home Office Expediting is still required by telephone and email as required.

NOTE: Owner reserves the right to change the Expediting Levels (to a higher or lower level

or frequency based upon current performance and conditions) and also reserves the right to

accompany field expediters on visits to vendors and sub-vendors offices and manufacturing

facilities as Owner deems necessary.

Contains Confidential Information of Date: 29 July 2011

A554-K-PRG-PU-LIS-DOC-009 (Expediting) Both Dow and Aramco Revision: 04

INSPECTION LEVEL GUIDELINES

Level 0 Documentation requirements only; no equipment vendor inspection required

Level 1 Only final inspection is required prior to shipping

Includes as a minimum, pre-inspection meetings, one or more unspecified in

Level 2 progress surveillance visits, all witness and hold points, final inspection, and

release for shipment.

Same as level 2, except that in progress surveillance inspections shall be on a

Level 3

regular basis ( daily, weekly or bi-weekly)

Level 4 Resident inspector continually monitoring the work.

Contains Confidential Information of Date: 29 July 2011

A554-K-PRG-PU-LIS-009 (Inspection) Both Dow and Saudi Aramco Revision: 04

Program Supply Plan

Revision Record - Rev. 04

4 GEN ALL APPLICABLE CATEGORIES Indicated PLA Categories and Vendors where applicable

4 GEN ALL APPLICABLE CATEGORIES Deleted Spacing and Formatted where necessary

4 LABORATORY ALL CATEGORIES Revised entire section with the most recent changes

4 A4.7 ANALYZER, INFRARED (IR) - GAS CORRELATION Perkin-Elmer Deleted

ANALYZER, TOTAL ORGANIC CARBON (TOC) - ONLY FOR PROCESS WATER

4 A1.12 CONDENSATE STREAMS WITHOUT PARTICLES (CLEAN STREAM) "Pollution Control Systems (Biotector)" changed to "Biotector Analytical Systems Ltd."

ANALYZER, TOTAL ORGANIC CARBON (TOC) - ONLY FOR PROCESS WATER

4 A1.12 CONDENSATE STREAMS WITHOUT PARTICLES (CLEAN STREAM) Vendor Changed from Shimadzu to Biotector Analytical Systems Ltd.

ANALYZER, TOTAL ORGANIC CARBON (TOC) - ALL APPLICATIONS EXCEPT

FOR CLEAN PROCESS WATER CONDENSATE AND WATER WITH

4 A1.13 MONOMERS (DIRTY STREAM) "Pollution Control Systems (Biotector)" changed to "Biotector Analytical Systems Ltd."

4 A8.15 ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION VALVES (BELLOWS) Circo Instrumentation Technologies (HOKE) Deleted

4 A8.16 ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION VALVES (BALL) Circo Instrumentation Technologies (HOKE) Deleted

4 A8.19 ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION VALVES (O-RING) Circo Instrumentation Technologies (HOKE) Deleted

ANALYZER, SAMPLE SYSTEMS - ANALYZER SYSTEM PACKAGER Computer System Protection Chambers and Integrated Communications Co LTD (CPIC)

4 A8.23 (INTEGRATION) (SA) Added

4 A8.38 ANALYZER, SAMPLE SYSTEMS - TUBING FITTINGS Circo Instrumentation Technologies (HOKE) Deleted

Category Description Revised to Read "ANALYZER, SAMPLE SYSTEMS - HEAT

4 A8.39 ANALYZER, SAMPLE SYSTEMS - HEAT TRACED BUNDLES TRACED, PRE-INSULATED AND/OR JACKETED TUBING OR TUBING BUNDLES"

4 A8.43 ANALYZER, PROCESS SAMPLING Biar Inc. Added

4 A8.43 ANALYZER, PROCESS SAMPLING Phoenix Precision Added

4 B1.1 BATTERY, CHARGERS Special Considerations Added

4 B1.2 BATTERY, FLOODED ELECTROLYTE STA. STORAGE BATTERY Special Considerations Added

4 B2.0 BUS DUCT Category Deleted

4 B2.1 BUS DUCT, 18 kV ISO-PHASE Category and Vendors Deleted in their entirety

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B4.1

B4 1 CABLE POWER

CABLE, POWER, 1KV THROUGH 35 KV Ne ans Deleted

Nexans

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV Oman Cables Industry (SA) Deleted

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV Prysmian Cables & Systems SRL Deleted

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV "Riyadh Cable" Added to Saudi Modern Company for Cable (SA)

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV The Okonite Company Deleted

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV Gulf Cable & Electrical Industries Co KSC Added

4 B4.2 CABLE, < 1000 V "Power" Added to Category Description

4 B4.2 CABLE, POWER, < 1000 V Draka Cableteq Deleted

4 B4.2 CABLE, POWER, < 1000 V Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B4.2 CABLE, POWER, < 1000 V Oman Cables Industry (SA) Deleted

4 B4.2 CABLE, POWER, < 1000 V Prysmian Cables & Systems SRL Deleted

4 B4.2 CABLE, POWER, < 1000 V "Riyadh Cable" Added to Saudi Modern Company for Cable (SA)

4 B4.2 CABLE, POWER, < 1000 V "Gulf Cable - Kuwait" changed to "Gulf Cable & Electrical Industries Co KSC"

4 B4.3 CABLE, INSTRUMENTATION & CONTROL Special Considerations Added to Belden Wire & Cable

4 B4.3 CABLE, INSTRUMENTATION & CONTROL Special Considerations Added to Kerpenwerk GMBH

4 B4.3 CABLE, INSTRUMENTATION & CONTROL Okazaki Manufacturing Company Deleted

4 B4.3 CABLE, INSTRUMENTATION & CONTROL TE Wire and Cable Company Deleted

4 B4.3 CABLE, INSTRUMENTATION & CONTROL Special Consideration Added to the Okonite Company

4 B4.3 CABLE, INSTRUMENTATION & CONTROL Special Considerations Added to Northwire

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

Moved Saudi Cable Company (SA) from B4.4 to B4.3 and combined Category B4.4 with

B4.3, since vendors are identical for both categories. Equipment Description of B4.3 now

4 B4.3 CABLE, INSTRUMENTATION, CONTROL , & THERMOCOUPLE reads "Cable, Instrumentation, Control, & Thermocouple"

4 B4.5 CABLE, COMMUNICATIONS, FIBER OPTIC Standardization Category C Added

4 B4.12 CABLE, HV (230kV) New Category Added - Vendors not yet approved

4 B5.1 CABLE TRAY, CHANNEL, ALUMINUM Cooper B-Line Deleted

4 B5.1 CABLE TRAY, CHANNEL, ALUMINUM M.P. Husky Deleted

4 B5.1 CABLE TRAY, CHANNEL, ALUMINUM Wahah Electric Supply Company of Saudi Arabia (SA) Deleted

4 B5.1 CABLE TRAY, CHANNEL, ALUMINUM Adhwa Al Rawafid Electric Industries Added

4 B5.2 CABLE TRAY, TYPE FRP M.P. Husky Deleted

4 B5.2 CABLE TRAY, TYPE FRP Abahsain-Cope Saudi Arabia Limited (SA) Added

4 B5.2 CABLE TRAY, TYPE FRP Adhwa Al Rawafid Electric Industries Added

4 B8.3 ENGINE, STANDBY DIESEL, FOR STANDBY GENERATORS Doosan Added

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Rockwell Automation (Allen Bradley) Added

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW ABB Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Arabia Electric Limited (SA) Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Arabian Point Eight Power Company (SA) Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Electrical Power Distribution Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW General Electric Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Siemens Energy & Automation Deleted

4 B12.1 MOTOR CONTROL CENTERS, 1000 V AND BELOW Square D Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V ABB Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Arabia Electric Limited (SA) Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Arabian Point Eight Power Company (SA) Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Electrical Power Distribution Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Siemens Power Transmission & Distribution Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Square D Deleted

4 B12.2 MOTOR CONTROL CENTERS, > 1000 V Eaton / Cuttler Hammer Added

4 B13.2 MOTOR, FORM-WOUND IND., ABOVE 250 HP, HORIZONTAL Schorch Deleted

4 B14.2 PANELBOARD, ELECTRICAL, LOW VOLTAGE Kinney Electrical Manufacturing Company Deleted

4 B14.2 PANELBOARD, ELECTRICAL, LOW VOLTAGE Eaton (Cutler Hammer) Added

4 B14.3 PANELBOARD, FUSED, ELECTRICAL, LOW VOLTAGE New Category Added

4 B14.3 PANELBOARD, FUSED, ELECTRICAL, LOW VOLTAGE Kinney Electrical Manufacturing Company Added

4 B14.3 PANELBOARD, FUSED, ELECTRICAL, LOW VOLTAGE Eaton / Cuttler Hammer Added

4 B14.3 PANELBOARD, FUSED, ELECTRICAL, LOW VOLTAGE Cooper Bussman Added

4 B16.3 POWER SYSTEM, FUSES, < 1000 V Electromec Deleted

4 B16.3 POWER SYSTEM, FUSES, < 1000 V Changed Shawmut to Ferraz Shawmut (Mersen)

4 B16.3 POWER SYSTEM, FUSES, < 1000 V Siemens Energy & Automation Deleted

4 B16.4 POWER SYSTEM, FUSES, 1000 V AND ABOVE Electromec Deleted

4 B16.4 POWER SYSTEM, FUSES, 1000 V AND ABOVE GEC Deleted

4 B16.4 POWER SYSTEM, FUSES, 1000 V AND ABOVE Changed Shawmut to Ferraz Shawmut (Mersen)

4 B16.4 POWER SYSTEM, FUSES, 1000 V AND ABOVE Inepar Deleted

4 B18.2 GROUNDING, HARDWARE & CONNECTIONS "Use In-Kingdom Suppliers Approved by Owner" Comment Deleted

4 B22.1 MOTOR CONTROL STATION, NON CLASSIFIED, DIVISION 2, ZONE 2 "Use In-Kingdom Suppliers Approved by Owner" Comment Deleted

4 B22.1 MOTOR CONTROL STATION, NON CLASSIFIED, DIVISION 2, ZONE 2 CEAG Deleted

4 B22.1 MOTOR CONTROL STATION, NON CLASSIFIED, DIVISION 2, ZONE 2 Crouse Hinds Added

4 B22.1 MOTOR CONTROL STATION, NON CLASSIFIED, DIVISION 2, ZONE 2 Appleton Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

4 B22.2 MOTOR CONTROL STATION, HAZARDOUS AREA, DIVISION 1, ZONE 1 CAEG Deleted

4 B22.2 MOTOR CONTROL STATION, HAZARDOUS AREA, DIVISION 1, ZONE 1 "Use In-Kingdom Suppliers Approved by Owner" Comment Deleted

4 B24.1 SWITCHGEAR, METAL-CLAD, LV, INDOOR Arabian Point Eight Power Company (SA) Deleted

4 B24.1 SWITCHGEAR, METAL-CLAD, LV, INDOOR Electrical Power Distribution Deleted

4 B24.1 SWITCHGEAR, METAL-CLAD, LV, INDOOR Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B24.1 SWITCHGEAR, METAL-CLAD, LV, INDOOR Siemens Energy & Automation Deleted

4 B24.1 SWITCHGEAR, METAL-CLAD, LV, INDOOR Eaton Added

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED ABB Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Arabia Electric Limited (SA) Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Arabian Point Eight Power Company (SA) Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Electrical Power Distribution Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Gulf International Electric Distribution Apparatuses Co LTD (SA) Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Siemens Energy & Automation Deleted

4 B24.2 SWITCHGEAR, METAL-CLAD, INDOOR 1-38 KV AIR INSULATED Eaton Added

4 B24.5 SWITCHGEAR, (GAS INSULATED) - 230K New Category Added - Vendors not yet approved

4 B27.1 TRANSFORMER, POWER DRY TYPE 150 KVA AND LARGER Areva Deleted

4 B27.1 TRANSFORMER, POWER DRY TYPE 150 KVA AND LARGER Square D Added

4 B27.2 TRANSFORMER, POWER, LIQUID 250 KVA - 50 MVA Saudi Transformers Company (SA) Deleted

4 B29.2 UPS SYSTEM, INDUSTRIAL, ABOVE 10 TO 200KVA Amatek Deleted

4 B30.0 & B30.1 POWER FACTOR CORRECTION CAPACITORS New Category Added - Vendors not yet approved

4 B31.0 & B31.1 ELECTRICAL POWER MANAGEMENT SYSTEM New Category Added - Vendors not yet approved

4 B32.0 & B32.1 CABLE MANAGEMENT New Category Added - Vendors not yet approved

INSTRUMENT TUBE FITTINGS, SMALL VALVES (TUBING AND THREADED

4 C2.8 ENDS) Circo Instrumentation Technologies (HOKE) Deleted

INSTRUMENT TUBE FITTINGS, SMALL VALVES (TUBING AND THREADED

4 C2.8 ENDS) Hy-Lok Deleted

4 C5.1 MONITORING VIBRATION, TRANSMITTERS -NON-CRITICAL SKF Deleted

4 C5.1 MONITORING VIBRATION, TRANSMITTERS -NON-CRITICAL GE Energ

Energyy (Bently

(Bently Nevada)

Nevada) Added

4 C6.2 PRESSURE MEASUREMENT, MANIFOLDS Hy-Lok Deleted

4 C6.2 PRESSURE MEASUREMENT, MANIFOLDS Circo Instrumentation Technologies (HOKE) Deleted

4 C6.15 FIBERGLASS FLUSH RINGS Brazosport Plastics, Inc. Added

4 C6.15 FIBERGLASS FLUSH RINGS Pfeiffer Chemie-Armatureb GmbH (a member of The Samson Group) Added

ALL CATEGORIES BELOW WERE DELETED FROM GENERAL TRANSMITTER

CATEGORY(C9.0) AND RE-CATEGORIZED FOR SPECIFIC PROCESS

FUNCTIONS (PRESSURE, LEVEL AND TEMPERATURE)

TRANSMITTER, TEMPERATURE ELECTRONIC - FIELD MOUNTED -

4 C9.1 STANDARD ACCURACY Re-categorized to C8.6

TRANSMITTER, TEMPERATURE ELECTRONIC - FIELD MOUNTED - HIGH

4 C9.2 PRECISION Re-categorized to C8.7

4 C9.3 TRANSMITTER TEMPERATURE ELECTRONIC - DIFFERENTIAL Re-categorized to C8.8

4 C9.4 TRANSMITTER, PRESSURE - PRESSURE AND DIFFERENTIAL PRESSURE Re-categorized to 6.16

4 C9.5 TRANSMITTER, FLOW - PRESSURE AND DIFFERENTIAL PRESSURE Re-categorized to 6.17

4 C9.6 TRANSMITTER, ABSOLUTE OR GAUGE - EXTRUDER MELT (PLASTICS) Re-categorized to 6.18

4 C9.7 TRANSMITTER, STANDARD P AND D/P CELL Deleted in its entirety

4 C9.8 TRANSMITTER, REMOTE OR DIRECT MOUNT SEAL SYSTEM Re-categorized to 6.19

4 C9.9 TRANSMITTER - SUBMERGE ELEMENT (POND) - LEVEL MEASUREMENT Re-categorized to 4.21

4 C9.11 TRANSMITTER, SERVO DISPLACER (CUSTODY TRANSFER / ACCOUNTING) Re-categorized to 4.22

4 C9.12 TRANSMITTER, CAPACITANCE (RADIO FREQUENCY) Re-categorized to 4.23

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

4 C9.13 TRANSMITTER, LEVEL - RADAR Re-categorized to 4.24

4 C9.14 TRANSMITTER, FREE SPACE RADAR (CUSTODY TRANSFER/ACCOUNTING) Re-categorized to 4.25

4 C9.15 TRANSMITTER, GUIDED WAVE RADAR (TDR) (PROCESS CONTROL) Re-categorized to 4.26

4 C9.16 TRANSMITTER, INDUCTIVE / MAGNETOSTRICTIVE FLOAT Re-categorized to 4.27

4 C9.17 TRANSMITTER, ULTRASONIC Re-categorized to 4.28

4 C9.18 TRANSMITTER, NUCLEAR Re-categorized to 4.29

4 C9.19 TRANSMITTER, LIQUID LEVEL; DISPLACER Re-categorized to 4.30

4 C10.6 VALVE, CONTROL, ROTARY, BALL, CERAMIC BALL Changed Model in Special Considerations to 300CL to 300ZL

4 C11.18 FIELDBUS INDICATORS New Category Added and Vendors ABB, Rosemount, and Yokogawa Added

4 Various ALL APPLICABLE CATEGORIES Name Change from Bumwoo to BHI

4 D1.6 MIXERS, REACTION MIXERS Category Added

4 D1.6 MIXERS, REACTION MIXERS Sebewaing Tool & Engineering Added

4 D8.1 COMPRESSOR, API - 617 CENTRIFUGAL Inspection Level Changed from 4 to 3

4 D8.12 COMPRESSOR, FLOODED SCREW - PROCESS & REFRIGERATION GEA Added

4 D10.1 COOLING TOWER, WATER SPIG Added

Revised Category Description to read "Desuperheaters, Eductors, Steam Ejectors, and

4 D16.0 DESUPERHEATERS Venturis"

4 D16.1 DESUPERHEATER Tyco (Narvik Yarway) Added

4 D16.1 DESUPERHEATERS, GENERAL Revised Category Description to read "Desuperheaters"

4 D16.2 DESUPERHEATERS, EDUCTORS Revised Category Description to read "Eductors"

4 D16.3 DESUPERHEATERS, STEAM EJECTORS Revised Category Description to read "Steam Ejectors"

4 D16.4 DESUPERHEATERS, VENTURIS Revised Category Description to read "Venturis"

4 D17.1 DRYER, SKID INSTRUMENT AIR & COMPRESSED Van Air Inc Added

4 D17.1 DRYER, SKID INSTRUMENT AIR & COMPRESSED Ingersoll Rand Added

4 D23.4 FILTER, LIQUIDE SERVICE (BAG / BASKET / CARTRIDGE) Calgon Carbon Corporation Added

FLARES, COMBUSTION CONTROLS INCLUDING IGNITERS AND FLAME

4 D24.1 FRONT GENERATORS Calgon Carbon Corporation Added

4 D25.1 FURNACE, CRACKING Maritime Industrial Service Added

4 D25.2 FURNACE, TUBE SUPPORTS Faser Added

4 D25.2 FURNACE, TUBE SUPPORTS Fias Added

4 D35.1 LUBRICATION, API - 614 OIL SYSTEMS Changed Category Description to "Lubrication, Special Purpose Oil System"

PUMP, CENTRIFUGAL: API-610, OVERHUNG, SINGLE STAGE HORIZONTAL

4 D39.1 (TYPE OH) Flowserve Al Rushaid (SA) Added

PUMP, CENTRIFUGAL: API-610, SINGLE STAGE VERTICAL IN-LINE (TYPE

4 D39.4 OH3) Flowserve Al Rushaid (SA) Added

PUMP, CENTRIFUGAL: BETWEEN BEARING DOUBLE SUCTION, SINGLE

4 D39.9 STAGE CENTRIFUGAL (API-610) (TYPE BB1/BB2) Flowserve Al Rushaid (SA) Added

PUMP, CENTRIFUGAL: BETWEEN BEARING DOUBLE SUCTION

4 D39.8 CENTRIFUGAL (NON-API COOLING TOWER) Flowserve Al Rushaid (SA) Added

PUMP, CENTRIFUGAL: BETWEEN BEARING DOUBLE SUCTION

4 D39.8 CENTRIFUGAL (NON-API COOLING TOWER) ITT Saudi Company Added

PUMP, CENTRIFUGAL: BETWEEN BEARING DOUBLE SUCTION

4 D39.8 CENTRIFUGAL (NON-API COOLING TOWER) Sulzer Pumps Added

4 D39.10 PUMP, CENTRIFUGAL; MAGNETIC DRIVE; HORIZONTAL (ASME B73.3) Flowserve Al Rushaid (SA) Added

4 D39.10 PUMP, CENTRIFUGAL; MAGNETIC DRIVE; HORIZONTAL (ASME B73.3) (Goulds)

PUMP, CENTRIFUGAL: NON-API SEALED HORIZONTAL END SUCTION

4 D39.13 (ASME B73.1 AND PULP AND PAPER) Flowserve Al Rushaid (SA) Added

4 D39.14 PUMP, CENTRIFUGAL: NON-API SEALED VERTICAL INLINE; ASME B73.2 Flowserve Al Rushaid (SA) Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

4 D39.16 PUMP, CENTRIFUGAL: INTEGRALLY GEARED (TYPE OH6) Removed Comment "Not Anticipated For RTIP - Sole Source" and "Nikkiso"

4 D39.25 PUMP, ROTARY POS. DISPLACEMENT - SCREW TYPE API-676 Imo Pumps Added

4 D40.4 REFRIGERATION UNIT, SAFETY SHOWER WATER SKIDS Category Added

4 D40.4 REFRIGERATION UNIT, SAFETY SHOWER WATER SKIDS HydroThrift Corporation Added

SEALS AND PACKING, MECHANICAL SEALS FOR PUMPS (LIQUID AND DRY

4 D42.1 GAS) Flowserve Abahsain (SA) Added

4 D42.2 SEALS AND PACKING, SEAL POTS Flowserve Abahsain (SA) Added

SEALS AND PACKING, MECHANICAL SEALS FOR PUMPS (LIQUID AND DRY

4 D42.1 GAS) John Crane Saudi Arabia Added

4 D42.2 SEALS AND PACKING, SEAL POTS John Crane Saudi Arabia Added

4 D45.5 TURBINE, SPECIAL PURPOSE STEAM (API - 612) GE Oil & Gas Added

WATER TREATMENT SYSTEM, SANITARY WASTEWATER MEMBRANE BIO

4 D48.11 REACTOR GE Power and Water Added

WATER TREATMENT SYSTEM, SANITARY WASTEWATER MEMBRANE BIO

4 D48.11 REACTOR Koch Membrane Added

COUPLINGS, GENERAL PURPOSE, ELASTOMERIC FLEXIBLE SLEEVE

4 D50.1 SPACER OR FLEXIBLE PIN John Crane Deleted

4 D50.2 COUPLING, GENERAL PURPOSE, METALLIC FLEXIBLE ELEMENT John Crane Deleted

4 D50.3 COUPLING, FLEXIBLE API-671 John Crane Deleted

4 D52.0 & 52.1 MAN LIFT, ARIEL WORK PLATFORM New Category Added and Genie JLG Added

4 D53.0 & 53.1 SEPARATORS, VENDOR DESIGNED CARBON STEEL New Category Added and Peerless Added

4 E1.1 VESSELS, PRES.; CS; MAX. WALL THK OF 19 MM Aguilar & Salas Added

4 E1.1 VESSELS, PRES.; CS; MAX. WALL THK OF 19 MM Maritime Industrial Service Added

4 E1.1 VESSELS, PRES.; CS; MAX. WALL THK OF 19 MM Sungjin Geotec Deleted

4 E1.2 VESSELS, PRES.; CS; WALL THK OF 38 MM Sungjin Geotec Deleted

4 E1.3 VESSELS, PRES.; CS; WALL THK FROM 38 TO 76MM Aguilar & Salas Added

4 E1.3 VESSELS, PRES.; CS; WALL THK FROM 38 TO 76MM Maritime Industrial Service Added

4 E1.3 VESSELS,, PRES.;; CS;; WALL THK FROM 38 TO 76MM gj Geotec Deleted

Sungjin

4 E1.4 VESSELS, PRES.; CS; WALL THK MORE THAN 76 MM Maritime Industrial Service Added

Al Zamil Heavy Industries Ltd.; Zamil Steel Industries Structural Steel Division; Al Saghyir

Boilers and Pressure Vessel; Geyad Factory for Pressure Vessels and Steel Buildings

Limited; Hidada Limited; Yanbu Steel Company, Saudi Arabian Fabricated Metals

4 E1.4 VESSELS, PRES.; CS; WALL THK MORE THAN 76 MM Industry Company Limited - Added

4 E1.5 VESSELS, CARBON STEEL (SMALL UP TO 24" DIAMETER) CBC Industrias Pesadas SA Deleted

4 E1.5 VESSELS, CARBON STEEL (SMALL UP TO 24" DIAMETER) Dacro Industries Deleted

4 E1.6 VESSELS, CARBON STEEL (SMALL UP TO 60" DIAMETER) Dacro Industries Deleted

4 E1.6 VESSELS, CARBON STEEL (SMALL UP TO 60" DIAMETER) Zhangjiagang Furui Boiler & Pressure Vessel Mfg. Added

4 E1.7 VESSELS, CARBON STEEL (LARGE OVER 60" DIAMETER) CBC Industrias Pesadas SA Deleted

4 E1.7 VESSELS, CARBON STEEL (LARGE OVER 60" DIAMETER) Sungjin Geotec Deleted

4 E1.7 VESSELS, CARBON STEEL (LARGE OVER 60" DIAMETER) Dacro Industries Deleted

4 E1.7 VESSELS, CARBON STEEL (LARGE OVER 60" DIAMETER) Zhangjiagang Furui Boiler & Pressure Vessel Mfg. Added

4 E1.8 VESSELS, STAINLESS STEEL Zhangjiagang Furui Boiler & Pressure Vessel Mfg. Added

4 E1.8 VESSELS, STAINLESS STEEL Sungjin Geotec Deleted

4 E1.8 VESSELS, STAINLESS STEEL Maritime Industrial Service Added

4 E1.8 VESSELS, STAINLESS STEEL CBC Industrias Pesadas SA Deleted

4 E1.8 VESSELS, STAINLESS STEEL Dacro Industries Deleted

4 E1.8 VESSELS, STAINLESS STEEL Sewon Cellontech Co. Ltd. Added

4 E1.8 VESSELS, STAINLESS STEEL Shanghai Morimatsu Pressure Vessel Co. Ltd. Added

4 E1.8 VESSELS, STAINLESS STEEL Shanghai Tonghua Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) Dacro Industries Deleted

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) CBC Industrias Pesadas SA Deleted

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) Maritime Industrial Service Added

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) Al-Zamil Company for Heavy Steel Added

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) Biffal Heavy Industries Added

4 E1.9 VESSELS, ALLOY & CLAD (NICKEL BASED) Gulf Heavy Industries Added

4 E1.10 VESSELS, TITANIUM AND SUPER ALLOY CBC Industrias Pesadas SA Deleted

4 E2.2 TANKS, SHOP; ATMOSPHERIC PRESSURE; CS & SS, (API-620 and API-650) CBC Industrias Pesadas SA Deleted

4 E2.3 TANKS, FIELD, ATMOSPHERIC PRESSURE; CS, (API-620 and API-650) CBC Industrias Pesadas SA Deleted

4 E2.4 TANKS, FIELD, ATMOSPHERIC PRESSURE; SS, (API-620 and API-650) CBC Industrias Pesadas SA Deleted

4 E2.5 TANKS, LOW TEMPERATURE; (API-620) Biffal Heavy Industries Added

4 E4.1 BLENDERS, STATIC - SILO CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; CS (Small and Medium up to 60"

4 E5.1 Diameter) CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; CS (Small and Medium up to 60"

4 E5.1 Diameter) Maritime Industrial Service Added

HEAT EXCHANGERS, SHELL & TUBE; CS (Small and Medium up to 60"

4 E5.1 Diameter) Sungjin Geotec Deleted

4 E5.2 HEAT EXCHANGERS, SHELL & TUBE; CS (Large over 60" Diameter) Maritime Industrial Service Added

4 E5.2 HEAT EXCHANGERS, SHELL & TUBE; CS (Large over 60" Diameter) Sungjin Geotec Deleted

4 E5.2 HEAT EXCHANGERS, SHELL & TUBE; CS (Large over 60" Diameter) CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; STAINLESS AND ALLOY STEEL (Small

4 E5.3 up to 24" Diameter) CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; STAINLESS AND ALLOY STEEL

4 E5.4 (Medium up to 60" Diameter) CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; STAINLESS AND ALLOY STEEL

4 E5.4 (Medium up to 60" Diameter) Gulf Heavy Industries Added

HEAT EXCHANGERS,, SHELL & TUBE;; STAINLESS AND ALLOY STEEL ((Large

g

4 E5.5 over 60" Diameter) CBC Industrias Pesadas SA Deleted

HEAT EXCHANGERS, SHELL & TUBE; STAINLESS AND ALLOY STEEL (Large

4 E5.5 over 60" Diameter) Shanghai Tonghua Added

4 E5.6 HEAT EXCHANGERS, SHELL & TUBE; HIGH ALLOY CBC Industrias Pesadas SA Deleted

4 E5.8 HEAT EXCHANGERS, SURFACE CONDENSERS CBC Industrias Pesadas SA Deleted

4 E5.8 HEAT EXCHANGERS, SURFACE CONDENSERS Ilsung Added

4 E5.9 HEAT EXCHANGERS, MULTI-PIPE; DOUBLE-PIPE; HAIRPIN CBC Industrias Pesadas SA Deleted

4 E5.9 HEAT EXCHANGERS, MULTI-PIPE; DOUBLE-PIPE; HAIRPIN Sungjin Geotec Deleted

4 E5.14 HEAT EXCHANGERS, AIR COOLED Deleted Category in its entirety

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 New Category Added with Purchasing Strategy B

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 Jord International PTE (Malaysia Only) Added

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 FMB-KNM FZCO Remained from Category E5.14

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 Hudson Products Remained from Category E5.14

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 GEA BTT (France and Qatar Only) Added

4 E5.16 HEAT EXCHANGERS, AIR COOLED, BARE TUBE AREA OVER 139.4 Zamil Hudson (SA) Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW New Category Added with Purchasing Strategy B

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW Hamon D'Hondt (SA) Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW Abahsain Specialized Industrial Co (ASIC) (SA) Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW GEA BTT (France and Qatar Only) Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW FMB-KNM FZCO Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW Hudson Products Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW Jord International PTE (Malaysia Only) Added

AIR COOLED HEAT EXCHANGERS, BARE TUBE AREA OF 139.4 SQ.M AND

4 E5.17 BELOW Zamil Hudson (SA) Added

4 E7.1 TRANSFER LINE EXCHANGERS, PRIMARY Olmi SPA Added

4 E7.2 TRANSFER LINE EXCHANGERS, SECONDARY CBC Industrias Pesadas SA Deleted

4 E8.1 REACTORS, CUSTOM CBC Industrias Pesadas SA Deleted

4 E8.1 REACTORS, CUSTOM Dacro Industries Deleted

4 E8.1 REACTORS, CUSTOM Mitternight Boiler Works Inc Deleted

4 E15.1 SPHERES, ASME Sungjin Geotec Deleted

4 E15.1 SPHERES, ASME Maritime Industrial Service Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Special Considerations Added to entire section

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS ArcelorMittal Stainless Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Butting Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS North American Stainless Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Jindal Group Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Rolled Alloys Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Taiyuan Iron and Steel Group Co Ltd (TISCO) Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Shanghai Baosteel (No. 3 Mill) Added

4 E16.1

E16 1 ALLOY APPROVED MILLS

ALLOY MILLS, AUSTENITIC & DUPLEX STAINLESS

STAINLESS STEELS Kunshan Daekyung Steel Co Ltd (KDKC)

(KDKC) Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Changshu Walsin Specialty Steel Co Ltd Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS RathGibson Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Bruck Group Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Creusot Forge Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS POSCO E&C, Korea Added

4 E16.1 ALLOY APPROVED MILLS, AUSTENITIC & DUPLEX STAINLESS STEELS Salzgitter Mannesmann International GmbH Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS Special Considerations Added to entire section

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS ArcelorMittal Stainless Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS Butting Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS Rolled Alloys Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS RathGibson Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS Bruck Group Added

4 E16.2 ALLOY APPROVED MILLS, NI-BASE ALLOYS G.O. Carlson Added

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Special Considerations Added to entire section

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Butting Added

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Rolled Alloys Added

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Loterios Added

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) TIMET Added

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Listed UNITI and TICO seperately

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) Sandvik Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Program Supply Plan

Revision Record - Rev. 04

4 E16.3 ALLOY APPROVED MILLS, REACTIVE METALS (ZR, TI, TA, NB, ALLOYS) ATI Alleggheny Ludlum Added

4 E16.4 EXPLOSION CLADDING MATERIAL Special Considerations Added to entire section

4 E16.4 EXPLOSION CLADDING MATERIAL SMT Shockwave Metalworking Technologies Added

4 E16.5 ROLL BONDED CLAD PLATE AND SHEET Special Considerations Added to entire section

4 E16.5 ROLL BONDED CLAD PLATE AND SHEET New Category Added

4 E16.5 ROLL BONDED CLAD PLATE AND SHEET Voestalpine Grobblech GmbH Added

4 F1.2 PIPE, CARBON STEEL - WELDED AZIZ European Pipe Company (SA) Added

4 F1.4 PIPE, STAINLESS STEEL - SEAMLESS Jubail Energy Services (JESCO) Added

4 F1.4 PIPE, STAINLESS STEEL - SEAMLESS Davis Pipe Deleted

4 F1.4 PIPE, STAINLESS STEEL - SEAMLESS Pusan Pipe Deleted

4 F3.1 PIPE SPOOL FABRICATION - METALLIC Aasia Steel Factory Co Ltd (SA). Added

Al-Rashed Fasteners and Engineering (SA), Al-Rashid Fasteners and Engineering (SA),

Arabian Fasteners and Engineering (SA), and Saudi BEA Fasteners Manufacturing (SA)

4 H8.1 FASTENERS Added

4 H8.2 FLUROPOLYMER COATED FASTENERS New Category Added

Al-Rashed Fasteners and Engineering (SA), Al-Rashid Fasteners and Engineering (SA),

Arabian Fasteners and Engineering (SA), BEA SRL, Lone Star Fasteners LP, OME,

4 H8.2 FLUROPOLYMER COATED FASTENERS Takenaka Seisakusho Co Ltd, Triplefast Middle East Ltd Added

4 H16.0 & H16.1 PIPELINE SCRAPER TRAPS TO ASME B3.4/B31.B (Inlet Area Only) New Category Added

4 H16.1 PIPELINE SCRAPER TRAPS TO ASME B3.4/B31.B (Inlet Area Only) Glapwell Contracting Services, FAI Carvico, and Pipeline Engineering Services Added

4 H17.0 & H17.1 DISMANTLING JOINTS New Category Added

4 H17.1 DISMANTLING JOINTS Klamex Pipe Couplings and Viking Johnson Added

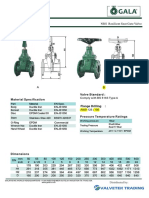

4 I1.3 PIPING VALVES, BUTTERFLY Saudi Valve Manufacturing Co Ltd Deleted

4 I1.4 PIPING VALVES, CHECK Saudi Valve Manufacturing Co Ltd Deleted

4 I1.7 PIPING VALVES, GATE Saudi Valve Manufacturing Co Ltd Deleted

4 I1.8 PIPING VALVES, GLOBE Saudi Valve Manufacturing Co Ltd Deleted

4 I1.12 PIPING VALVES, PLUG Fluroseal Added

4 J6.1 POST INDICATING VALVES American Flow Control Added

4 J9.0 FIRE PROTECTION SYSTEMS INTEGRATOR New Category Added

REDA Fire, Saudi Factory for Fire Equipment, Tyco Fire & Integrated Solutions, and

4 J9.1 FIRE PROTECTION SYSTEMS INTEGRATOR Williams Fire & Hazard Control Added

4 K1.1 STRUCTURE, STEEL Aasia Steel Factory Co Ltd.(SA) Added

Date: 29 July 2011

Contains Confidential Information of Both Dow and Saudi Aramco Rev. 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Analytical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification

Special

PAVL B= Bulk Item Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Field Need Dwg Lead Delivery Lead

Pkg. No. Revision Equipment Description Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Special Considerations

CODE E= Suffix US$ Strategy Level Level Weight Volume Date Date Date Time (weeks) Time (weeks)

Requirements

Equipment

ELECTROCHEMICAL MEASUREMENT: Ph,

2 A 1.0 CONDUCTIVITY, OXIDATION REDUCTION POTENTIAL

(ORP)

Standardization -

2 A1.1 ANALYZER, LOWER EXPLOSIVE LIMIT (LEL) - PORTABLE B DRAEGERWERK AG 1 0

Category B

INDUSTRIAL SCIENTIFIC CORP

A1.1

(MSA)

Standardization -

2 A1.2 ANALYZER, LOWER EXPLOSIVE LIMIT (LEL) - FIXED B DRAEGERWERK AG 1 0

Category B

A1.2 GENERAL MONITORS

Standardization -

2 A1.3 ANALYZER, CONDUCTIVITY B ENDRESS+HAUSER 1 0

Category B

EMERSON PROCESS

A1.3 MANAGEMENT (ROSEMOUNT

ANALYTICAL)

YOKOGAWA CORPORATION

A1.3

OF AMERICA

YOKOGAWA CORPORATION

2 A1.4 ANALYZER, OXIDATION REDUCTION POTENTIAL (ORP) B 1 0

OF AMERICA

Standardization -

2 A1.5 ANALYZER, pH ELECTRODES - CL2 APPLICATIONS B METTLER - TOLEDO (INGOLD) 1 0

Category B

EMERSON PROCESS

Standardization -

2 A1.6 ANALYZER,, pH

p ELECTRODES - ALL OTHER APPLICATIONS B MANAGEMENT

G ((ROSEMOUNT

OS OU 1 0

Category B

ANALYTICAL)

A1.6 ENDRESS+HAUSER

YOKOGAWA ELECTRIC

A1.6

CORPORATION

EMERSON PROCESS

Standardization -

2 A1.7 ANALYZER, pH TRANSMITTERS B MANAGEMENT (ROSEMOUNT 1 0

Category B

ANALYTICAL)

A1.7 ENDRESS+HAUSER

YOKOGAWA ELECTRIC

A1.7

CORPORATION

2 A1.8 ANALYZER, SPECIFIC ION - ELECTRODES B METTLER - TOLEDO (INGOLD) 1 0

A1.8 THERMO SCIENTIFIC (ORION)

YOKOGAWA CORPORATION

A1.8

OF AMERICA

2 A1.9 ANALYZER, SPECIFIC ION - TRANSMITTERS B METTLER - TOLEDO (INGOLD) 1 0

A1.9 THERMO SCIENTIFIC (ORION)

YOKOGAWA CORPORATION

A1.9

OF AMERICA

ANALYZER, PHOTO-IONIZATION DETECTOR (PID) -

2 A1.10 B PHOTOVAC 1 0

PORTABLE

A1.10 PID ANALYZERS (HNU)

2 A1.11 ANALYZER, TAPE TYPE B GASTRONICS (GMD 1 0

A1.11 HONEYWELL

Standardization -

ANALYZER, TOTAL ORGANIC CARBON (TOC) - ONLY FOR Category A,

BIOTECTOR ANALYTICAL

4 A1.12 PROCESS WATER CONDENSATE STREAMS WITHOUT E Biotector is the 1 0

SYSTEMS LTD.

PARTICLES (CLEAN STREAM) selected PLA

Vendor

Standardization -

ANALYZER, TOTAL ORGANIC CARBON (TOC) - ALL

ANALYZER

Category A,

APPLICATIONS EXCEPT FOR CLEAN PROCESS WATER BIOTECTOR ANALYTICAL

4 A1.13 E Biotector is the 1 0

CONDENSATE AND WATER WITH MONOMERS (DIRTY SYSTEMS LTD.

selected PLA

STREAM)

Vendor

A1.14 ANALYZER, BIOLOGICAL OXYGEN DEMAND (BOD) 1 1

A1.15 ANALYZER, CHEMICAL OXYGEN DEMAND (COD) B 1 1

2 A1.16 ANALYZER, TOTAL HYDROCARBON (THC) B ABB INC 1 0

ANLYZER, TOTOAL HYDROCARBON (THC) - TUEV

A1.17 B SICK MAIHAK

APPROVED

ANALYZER, NITROGEN OXIDES (NOX) -

2 A1.18 B 1 0

CHEMILUMINESCENCE

Standardization -

2 A1.19 ANALYZER, TOXIC DETECTORS (ALL) B DRAEGERWERK AG (FIXED) 1 0

Category B

A1.19 GENERAL MONITORS

A1.20 ANALYZER, TITRATOR - WET CHEMISTRY B APPLIKON 1 1

A1.21 ANALYZER, AMMONIA OR PHOSPHATE IN WASTE WATER APPLIKON 1 1

2 A2.0 CHROMATOGRAPH

Standardization -

Category A,

SIEMENS ENERGY &

4 A2.1 ANALYZER, GAS CHROMATOGRAPHY (GC) - GENERAL E Siemens is the 1 1

AUTOMATION

selected PLA

Vendor

A2.2 ANALYZER, GAS CHROMATOGRAPHY (GC) - MICRO E 1 1

A2.3 ANALYZER, ION CHROMATOGRAPHY E DIONEX 1 1

A2.4 ANALYZER, SUPER CRITICAL FLUID CHROMATOGRAPHY E ABB INC 1 1

THERMO SCIENTIFIC ((FLUID

2 A2.5

A2 5 ANALYZER,

ANALYZER HYDROCARBON SPILL DETECTOR E 1 0

DATA)

2 A3.0 MOISTURE, HUMIDITY, DEWPOINT

GE SENSING (GENERAL

2 A3.1 ANALYZER, ELECTRONIC / CHEMICAL - ALUMINUM OXIDE B 1 0

EASTERN)

A3.1 GE SENSING (PANAMETRICS)

ANALYZER, ELECTRONIC / CHEMICAL - P250 - FIXED AND DUMAT ANALYTICAL

2 A3.2 B 1 0

PORTABLE ENGINEERING GMBH

A3.2 MEECO

ANALYZER, ELECTRONIC / CHEMICAL - PHYSICAL - OSC. Standardization -

2 A3.3 B AMETEK 1 0

CRYSTAL Category B

ANALYZER, ELECTRONIC / CHEMICAL - PHYSICAL - CHILLED

2 A3.4 B 1 0

MIRROR

OPTICAL: INFRARED, ULTRA-VIOLET,

2 A4.0 SPECTROSCOPIC, REFRACTOMETER, PHOTOCELL, X-

RAY, TDL

2 A4.1 ANALYZER, CHEMICAL FLUORESCENCE B 1 0

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Analytical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Analytical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification

Special

PAVL B= Bulk Item Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Field Need Dwg Lead Delivery Lead

Pkg. No. Revision Equipment Description Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Special Considerations

CODE E= Suffix US$ Strategy Level Level Weight Volume Date Date Date Time (weeks) Time (weeks)

Requirements

Equipment

2 A4.2 ANALYZER, SPECTROSCOPY OPTICAL FIBER B OFS 1 0

2 A4.3 ANALYZER, COLORIMETER, EXTRACTIVE SAMPLE B ENDRESS+HAUSER 1 0

A4.3 SIGRIST - PHOTOMETER AG

ANALYZER, FOURIER TRANSFORM INFRARED (FTIR) / Standardization -

3 A4.4 B ABB INC 1 2

FOURIER TRANSFORM NEAR INFRARED (FTNIR) Category B

HAMILTON SUNDSTRAND

A4.4 (APPLIED INSTRUMENT

TECHNOLOGIES

ANALYZER, FILTER PHOTOMETER - INFRARED (IR) / NEAR Standardization -

3 A4.5 B ABB INC 1 1

INFRARED (NIR) Category B

A4.5 SERVOMEX

A4.6 ANALYZER, INFRARED (IR) - LUFT DETECTOR B ABB INC 1 1

SIEMENS ENERGY &

A4.6

AUTOMATION

A4.7 ANALYZER, INFRARED (IR) - GAS CORRELATION B SERVOMEX 1 1

ANALYZER, ULTRA-VIOLET (UV) / VISIBLE - SINGLE

A4.8 B ABB INC 1 1

COMPONENT, FILTER, EXTRACTIVE SAMPLE

A4.8 SERVOMEX

ANALYZER, ULTRA-VIOLET (UV) / VISIBLE - SINGLE

GALVANIC APPLIED

A4.9 COMPONENT, FILTER, IN-LINE MEASUREMENT (INCLUDING B 1 1

SCIENCES (MONITEK)

COLORIMETERS)

A4.9 OPTEK

A4.10 ANALYZER - ULTRA-VIOLET (UV) - DIODE ARRAY B 1 1

Standardization -

Category A,

YOKOGAWA CORPORATION

4 A4.11 ANALYZER, TUNED DIODE LASER (TDL) B Yokogawa is the 1 1

OF AMERICA

selected PLA

Vendor

Standardization -

Category A,

ANALYZER, INTEGRATED CAVITY OUTPUT SPECTROMETER YOKOGAWA CORPORATION

4 A4.12 B Yokogawa is the

(ICOS) OF AMERICA

selected PLA

Vendor

GUIDED WAVE

ANALYZER, FILTER PHOTOMETER - INFRARED (IR) / NEAR Standardization -

3 A4.13 (APPLICATIONS USING FIBER

INFRARED (NIR), MULTIWAVE Category B

OPTIC PROBES ONLY)

2 A5.0 OXYGEN (O2)

EMERSON PROCESS

2 A5.1 ANALYZER, DISSOLVED OXYGEN (O2) - FIXED B MANAGEMENT (ROSEMOUNT 1 0

ANALYTICAL)

A5.1 METTLER-TOLEDO (IN-GOLD)

ANALYZER, DISSOLVED OXYGEN (02) - EFFLUENT/WASTE

2 A5.2 B HACH COMPANY 1 0

WATER APPLICATIONS

ANALYZER, OXYGEN (O2) FUEL CELL - INCLUDES

2 A5.3 B DELTA F 1 0

PORTABLES

TELEDYNE ANALYTICAL

A5.3

INSTRUMENTS

ANALYZER, OXYGEN (O2) DEFICIENCY - ENCLOSED AREA Standardization -

2 A5.4 B DRAEGERWERK AG 1 0

MONITORS Category B

SIEMENS ENERGY &

2 A5.5 ANALYZER, OXYGEN (O2) - PARAMAGNETIC B 1 0

AUTOMATION

ANALYZER, OXYGEN (O2) - POLARAGRAPHIC/ELECTRO- EMERSON PROCESS

2 A5.6 B 1 0

CHEMICAL MANAGEMENT

A5.6 TELEDYNE

Standardization -

2 A5.7 ANALYZER, ZIRCONIA OXIDE (ZR O2) B AMETEK 1 0

Category B

EMERSON PROCESS

A5.7 MANAGEMENT (ROSEMOUNT

ANALYTICAL)

A5.7 SERVOMEX

2 A6.0 CONTINUOUS EMISSION MONITORS (CEMs)

Standardization -

ANALYZER, CEMs - EXTRACTIVE SYSTEMS - CO/O2/NOX - Category A, ABB

4 A6.1 B ABB INC 1 2

COLD/DRY SAMPLE is the selected

PLA Vendor

ANALYZER, CEMs - EXTRACTIVE SYSTEMS - CO/O2/NOX -

A6.2 B 1 1

HOT/WET SAMPLE

2 A7.0 PHYSICAL PROPERTIES

2 A7.1 ANALYZER, CALORIMETER (BTU OR WOBBE INDEX) B 1 0

OPTICAL CONTROL SYSTEMS

2 A7.2 ANALYZER, CAST FILM B 1 2

(OCS)

EMERSON PROCESS

2 A7.3 ANALYZER, OPACITY - EXTRACTIVE B MANAGEMENT (ROSEMOUNT 1 0

ANALYTICAL)

A7.3 ENDRESS+HAUSER

A7.3 SIGRIST - PHOTOMETER AG

2 A7.4 ANALYZER, OPACITY - IN LINE/STACK B DURAG GMBH 1 0

A7.4 SICK MAIHAK

2 A7.5

A7 5 ANALYZER,

ANALYZER PARTICLE SIZE B 1 0

2 A7.6 ANALYZER, REFRACTOMETER (IN LINE & DIFFERENTIAL) B 1 0

MESA LABORATORIES

2 A7.7 ANALYZER, SONIC VELOCITY B 1 0

(NUSONICS DIVISION)

ANALYZER, TURBIDITY (TOTAL SUSPENDED SOLIDS) - NON- GALVANIC APPLIED

2 A7.8 B 1 0

WASTE WATER APPLICATIONS SCIENCES (MONITEK)

A7.8 OPTEK

ANALYZER, TURBIDITY (TOTAL SUSPENDED SOLIDS) -

2 A7.9 B ENDRESS+HAUSER 1 0

WASTE WATER APPLICATIONS

A7.9 HACH

2 A7.10 ANALYZER, SLUDGE LEVEL MONITORING B ENDRESS+HAUSER 1 0

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Analytical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Analytical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification

Special

PAVL B= Bulk Item Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Field Need Dwg Lead Delivery Lead

Pkg. No. Revision Equipment Description Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Special Considerations

CODE E= Suffix US$ Strategy Level Level Weight Volume Date Date Date Time (weeks) Time (weeks)

Requirements

Equipment

2 A7.11 ANALYZER, THERMAL CONDUCTIVITY B ABB INC 1 0

A7.11 LFE

TELEDYNE ANALYTICAL

A7.11

INSTRUMENTS

2 A7.12 ANALYZER, RHEOMETER B THERMO SCIENTIFIC 1 2

2 A7.13 ANALYZER, VAPOR PRESSURE B 1 0

2 A7.14 ANALYZER, DUST B DURAG GMBH 1 0

A7.14 SIGRIST - PHOTMETER AG

2 A7.15 ANALYZER, FLAME IONISATION DETECTORS (FIDs) B 1 0

2 A7.16 ANALYZER, VISCOSITY - VIBRATION METHOD B HYDRAMOTION 1 0

2 A7.17 ANALYZER, VISCOSITY - ROTATING CUP METHOD B 1 0

2 A8.0 AUXILIARY SYSTEMS

Standardization -

2 A8.1 ANALYZER, DATA ACQUISITION - CLASSIFIED AREAS B DAISY DATA 1 0

Category B

SHI (PANASONIC Standardization -

2 A8.2 ANALYZER, DATA ACQUISITION - NON-CLASSIFIED AREAS B 1 0

TOUGHBOOK) Category B

HEADLINE FILTERS

2 A8.3 ANALYZER, SAMPLE SYSTEMS - FILTERS (GAS) B 1 0

(PROCESS ANAYLYTICAL)

M&C PRODUCTS

A8.3

ANALYSENTECHNIK GMBH

A8.3 PARKER HANNIFIN (BALSTON)

ANALYZER, SAMPLE SYSTEMS - FILTERS (LIQUID/GAS

2 A8.4 B A+ CORPORATION (GENIE) 1 0

SEPARATION)

A8.4 PERMA PURE PRODUCTS

2 A8.5 ANALYZER, SAMPLE SYSTEMS - FILTERS (LIQUID) B A+ CORPORATION 1 0

M&C PRODUCTS

A8.5

ANALYSENTECHNIK GMBH

ANALYZER, SAMPLE SYSTEMS - PRESSURE REGULATORS

2 A8.6 B BOC 1 0

(CYLINDERS)

A8.6 DRUVA

A8.6 MATHESON/TESCOM

A8.6 PARKER (VERIFLO)

A8.6 PRAXAIR

A8.6 SCOTT

ANALYZER, SAMPLE SYSTEMS - PRESSURE REGULATORS

2 A8.7 B DRUVA 1 0

(CARRIER GAS)

EMERSON PROCESS

A8.7 MANAGEMENT (BROOKS

PROCESS ANALYTICAL)

A8.7 PORTER INSTRUMENT

A8.7 PRAXAIR

ANALYZER, SAMPLE SYSTEMS - PRESSURE REGULATORS

2 A8.8 B DRUVA 1 0

(PROCESS)

A8.8 PARKER HANNIFAN (VERIFLO)

EMERSON PROCESS

A8.8

MANAGEMENT (TESCOM)

2 A8.9 ANALYZER,, SAMPLE SYSTEMS - ROTOMETERS (ALL)

( ) B 1 0

2 A8.10 ANALYZER, SAMPLE SYSTEMS - ENCLOSURE HEATERS B INTERTEC 1 0

A8.10 O'BRIEN

ANALYZER, SAMPLE SYSTEMS - SAMPLE COOLERS (AIR

2 A8.11 B EXAIR 1 0

OPERATED)

ITW AIR MANAGEMENT

A8.11

VORTEC

ANALYZER, SAMPLE SYSTEMS - SAMPLE COOLERS (SOLID M&C PRODUCTS

2 A8.12 B 1 0

STATE) ANALYSENTECHNIK GMBH

A8.12 PERMA PURE (BALDWIN)

A8.12 UNIVERSAL ANALYZERS

ANALYZER, SAMPLE SYSTEMS - SAMPLE COOLERS-

2 A8.13 B LYTRON 1 0

REFRIG, LIQUID SAMPLE

ANALYZER, SAMPLE SYSTEMS - SAMPLE COOLERS- HEAT

2 A8.14 B ALFA LAVAL 1 0

EXCHANGERS

A8.14 SENTRY

ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION

4 A8.15 B SWAGELOK 1 0

VALVES (BELLOWS)

ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION

4 A8.16 B SWAGELOK 1 0

VALVES (BALL)

ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION EM - TECHNIK GMBH

2 A8.17 B 1 0

VALVES, DIAPHRAGM, NON - METALLIC ARMATURENBAU

SAINT-GOBAIN

A8.17 PERFORMANCE PLASTICS

MICROELECTRONICS

(FURON)

A8.17 ENTEGRIS

ANALYZER, SAMPLE SYSTEMS - STREAM SELECT,

2 A8.18 B PARKER HANNIFAN (VERIFLO) 1 0

DIAPHRAGM, METALLIC

A8.18 SWAGELOK

ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION

4 A8.19 B SWAGELOK 1 0

VALVES (O-RING)

ANALYZER, SAMPLE SYSTEMS - MULTIPLE STREAM

A8.20 B PARKER HANNIFAN 1 0

SELECTION VALVE SWITCHING ASSEMBLY

A8.20 SWAGELOK

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Analytical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Analytical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification

Special

PAVL B= Bulk Item Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Field Need Dwg Lead Delivery Lead

Pkg. No. Revision Equipment Description Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Special Considerations

CODE E= Suffix US$ Strategy Level Level Weight Volume Date Date Date Time (weeks) Time (weeks)

Requirements

Equipment

ANALYZER, SAMPLE SYSTEMS - STREAM SELECTION

2 A8.21 B ASCO 1 0

VALVES, SOLENOID

A8.21 BURKERT

PARKER HANNIFIN

A8.21 CORPORATION (FLUID

CONTROL DIVISION)

ANALYZER, PROCESS ANALYTICAL ENGINEERING

2 A8.22 B ABB INC 1 3

CONTRACTOR (PAEC)

SIEMENS ENERGY &

A8.22

AUTOMATION

YOKOGAWA CORPORATION

A8.22

OF AMERICA

ANALYZER, SAMPLE SYSTEMS - ANALYZER SYSTEM

2 A8.23 B ABB INC (SHANGHIA) 1 3

PACKAGER (INTEGRATION)

COMPUTER SYSTEM Must have Sample

PROTECTION CHAMBERS Systems Fabrication by

4 A8.23 AND ITEGRATED 1 3

an external source

COMMUNICATIONS CO LTD acceptable to RTIP

(CPIC) (SA)

A8.23 SIEMENS AG (KARLSRUHE)

SIEMENS PROCESS

A8.23

ANALYTICS (SHANGHAI)

SIEMENS PTE LTD - PASI

A8 23

A8.23

(SINGAPORE)

SIEMENS ENERGY &

A8.23

AUTOMATION (HOUSTON)

YOKOGAWA CORPORATION

A8.23

OF AMERICA

See Analyzer - sample systems -

ANALYZER, SAMPLE SYSTEMS - ANALYZER SYSTEM

2 A8.24 B analyzer system packager 1 3

FABRICATOR

(Integration)

A8.24

See Analyzer - sample systems -

2 A8.25 ANALYZER, SAMPLE SYSTEMS - ENCLOSURES B analyzer system packager 1 0

(Integration)

2 A8.26 ANALYZER, SAMPLE SYSTEMS - PUMPS (LIQUIDS - PISTON) B FLUID METERING INC (FMI) 1 0

ANALYZER, SAMPLE SYSTEMS - PUMPS (LIQUIDS -

2 A8.27 B ISMATEC SA 1 0

PERISTALTIC)

A8.27 MASTERFLEX

A8.27 WATSON-MARLOW BREDEL

2 A8.28 ANALYZER, SAMPLE SYSTEMS - PUMPS (GASES) B AIR DIMENSIONS INC (ACI) 1 0

A8.28 KNF NEUBERGER

M&C PRODUCTS

A8.28

ANALYSENTECHNIK GMBH

ANALYZER, SAMPLE SYSTEMS - PUMPS (HIGH

2 A8.29 B BUEHLER TECHNOLOGIES 1 0

TEMPERATURE, >150 DEG C)

A8.29 KNF NEUBERGER

M&C PRODUCTS

A8.29

ANALYSENTECHNIK GMBH

ANALYZER, SAMPLE SYSTEMS - PUMP, LIQUID, SUNDYNE CORPORATION

2 A8.30 B 1 0

MAGNETICALLY COUPLED (CASTER)

ANALYZER, SAMPLE SYSTEMS - VACUUM PUMPS, ALCATEL VACUUM

2 A8.31 B 1 0

ROUGHING PRODUCTS

A8.31 EDWARDS

2 A8.32 ANALYZER, SAMPLE SYSTEMS - VACUUM PUMPS, TURBO B EDWARDS 1 0

PFEIFFER VACUUM GMBH

A8.32

(BALZERS)

ANALYZER, SAMPLE SYSTEMS - VACUUM PUMPS, HIGH GARDNER DENVER (ELMO

2 A8.33 B 1 0

FLOW, NON - CORROSIVE REITCHER)

ANALYZER, SAMPLE SYSTEMS - VACUUM PUMPS, MEDIUM

2 A8.34 B METAL BELLOWS 1 0

FLOW, NON - CORROSIVE

ANALYZER, SAMPLE SYSTEMS - VACUUM PUMPS, HIGH

2 A8.35 B AIR DIMENSIONS 1 0

TEMP, CORROSIVE

BRONKHORST HIGH-TECH

2 A8.36 ANALYZER, SAMPLE SYSTEMS - FLOW CONTROLLERS B 1 0

B.V.

EMERSON PROCESS

A8.36 MANAGEMENT (BROOKS

PROCESS ANALYTICAL)

ANALYZER, SAMPLE SYSTEMS - FLOW CONTROLLERS BRONKHORST HIGH-TECH

2 A8.37 B 1 0

(THERMAL) B.V. (PROCESS ANALYTICAL)

EMERSON (BROOKS

A8.37

PROCESS ANALYTICAL)

Standardization -

Category A,

4 A8.38 ANALYZER, SAMPLE SYSTEMS - TUBING FITTINGS B SWAGELOK Swagelok is the 1 0

selected PLA

Vendor

ANALYZER, SAMPLE SYSTEMS - HEAT TRACED, PRE-

Standardization -

4 A8.39 INSULATED AND/OR JACKETED TUBING OR TUBING B O'BRIEN 1 0

Category B

BUNDLES

A8.39 THERMON

SIEMENS ENERGY & Standardization -

2 A8.40 ANALYZER, PAMC MONITOR SYSTEM B 1 0

AUTOMATION (AWC) Category D

ANALYZER, SAMPLE SYSTEMS - PUMPS (LIQUID - PROMINENT FLUID

2 A8.41 1 0

DIAPHRAM) CONTROLS

A8.41 PULSAFEEDERS

ANALYZER, SAMPLE SYSTEMS - FILTER (WASTEWATER -

2 A8.42 HACH ENVIRONMENTAL 1 0

BLOWBACK)

4 A8.43 ANALYZER, PROCESS SAMPLING BIAR, INC 1 0

4 A8.43 PHOENIX PRECISION

2 A9.0 BOILING RANGE AND FREEZING POINT

2 A9.1 ANALYZER, FLASH POINT B 1 0

2 A9.2 ANALYZER, BOILING POINT B ABB INC 1 0

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Analytical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Electrical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification Special

PAVL Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Dwg Lead Time Delivery Lead Special

Pkg. No. Revision Equipment Description B= Bulk Item Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Field Need Date

CODE Suffix US$ Strategy Level Level Weight Volume Date Date (weeks) Time (weeks) Considerations

E= Equipment Requirements

2 B 1.0 BATTERIES & CHARGERS

Standardization - AEG Power Solutions is

Category A, AEG the PLA Vendor and

4 B1.1 BATTERY, CHARGERS B AEG POWER SOLUTIONS Power Solutions is 1 0 single point of contact for

the selected PLA chargers, batteries, and

Vendor UPS Systems.

AMETEK SOLIDSTATE

B1.1

CONTROLS

2 B1.1 C&D TECHNOLOGIES

2 B1.1 ENERSYS

2 B1.1 HINDEL

B1.1 SAFT POWER SYSTEMS

Standardization - AEG Power Solutions is

Category A, AEG the PLA Vendor and

BATTERY, FLOODED ELECTROLYTE STA. STORAGE

4 B1.2 B AEG POWER SOLUTIONS Power Solutions is 1 0 single point of contact for

BATTERY

the selected PLA chargers, batteries, and

Vendor UPS Systems.

2 B1.2 C & D TECHNOLOGIES

2 B1.2 ENERSYS

HOPPECKE BATTERIEN GMBH

B1.2

& CO. KG

2 B1.3 O USED

NOT S

2 B1.4 NOT USED

4 B2.0 NOT USED

4 B2.1 NOT USED 2 N/A

2 B3.0 LARGE DC SYSTEMS (FOR CHLORINE UNIT ONLY)

Standardization -

B3.1 LARGE DC SYSTEM, RECTIFIERS E FUJI ELECTRIC 2 2

Category E

B3.2 LARGE DC SYSTEM, RECTIFIERS - POLARIZATION E NOT A TECHNOLOGY DRIVEN SINGLE SOURCE RAPID POWER 2 2

Standardization -

B3.3 LARGE DC SYSTEM, BUS BAR - INSULATORS B NOT A TECHNOLOGY DRIVEN SINGLE SOURCE INTREPID INDUSTRIES 1 2

Category D

LARGE DC SYTEM, BUS BAR - DESIGN, FABRICATION & AMEC SPIE ZUIDWEST

2 B3.4 E 2 2

TURNKEY INSTALLATION (ELECTRON)

B3.4 FLOHE GMBH

B3.4 VISION ELECTRIC

B3.4 W.D. WHINERY

AMEC SPIE ZUIDWEST

3 B3.5 LARGE DC SYTEM, DC BUSSES - FLEXES (COPPER) B 1 2

(ELECTRON)

B3.5 FLOHE GMBH

B3.5 VISION ELECTRIC

B3.5 WATEREDGE

LARGE DC SYSTEM, BUSSES - TRANSITIONS - EXPLOSION DYNAMIC MATERIAL

3 B3.6 B NOT A TECHNOLOGY DRIVEN SINGLE SOURCE 1 2

BONDED ALUMINUM TO COPPER CORPORATION

LARGE DC SYSTEM, BUSSES - ALUMINUM FLEXES & AMEC SPIE ZUIDWEST

3 B3.7 1 2

SPLICE PLATES (ELECTRON)

B3.7 FLOHE GMBH

B3.7 Q GROUP

B3.7 VISION ELECTRIC

B3.7 W.D. WHINERY

3 B3.8 LARGE DC SYSTEM, SWITCHES B FERRAZ 1 2

B3.8 RITTER

3 B3.9 LARGE DC SYSTEM, METERING E ABB INC 2 2

B3.9 DYNAMP LLC (HALMAR/LEM)

2 B4.0 CABLE & ACCESSORIES

Technically acceptable

for Medium Voltage Multi-

Core cables per RT7D-

0447-00.

Technically Acceptable

for Medium Voltage

Single Core cables per

RT7D-0450-00 with the

following voltage ratings:

U0/U (Um) = 6/10 (12)

GULF CABLE & ELECTRICAL kV

4 B4.1 CABLE, POWER, 1KV THROUGH 35 KV B 1 1

INDUSTRIES CO KSC U0/U (Um) = 8.7/15

(17.5) kV

NOT technically

acceptable for Medium

Voltage Single Core

cables per RT7D-0450-

00 with the following

voltage ratings:

U0/U (Um) = 26/45 (52)

kV

U0/U (Um) = 20/35 (40)

4 B4.1 ( )

SAUDI CABLE COMPANY (SA)

SAUDI MODERN COMPANY

4 B4.1

FOR CABLE (RIYADH CABLE)

GULF CABLE & ELECTRICAL

4 B4.2 CABLE, POWER, < 1000 V B 1 1

INDUSTRIES CO KSC

B4.2 SAUDI CABLE COMPANY (SA)

SAUDI MODERN COMPANY

4 B4.2 FOR CABLE (RIYADH CABLE)

(SA)

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Electrical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Electrical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification Special

PAVL Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Dwg Lead Time Delivery Lead Special

Pkg. No. Revision Equipment Description B= Bulk Item Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Field Need Date

CODE Suffix US$ Strategy Level Level Weight Volume Date Date (weeks) Time (weeks) Considerations

E= Equipment Requirements

Technically acceptable

ONLY for the following

RTIP instrumentation

cable:

specification RT7D-0461-

02 (ITC)

4 B4.3 CABLE, INSTRUMENTATION, CONTROL , & THERMOCOUPLE B BELDEN WIRE & CABLE 1 1

specification RT7D-0461-

04 (non-jacketed)

specification RT7D-0462-

01 (ITC)

specification RT7D-0468-

01 (TC)

B4.3 DEKORON WIRE AND CABLE

Technically acceptable

for instrumentation cable

EXCEPT for the

following RTIP

instrumentation cable:

4 B4.3 KERPENWERK GMBH specification RT7D-0461-

01 (ITC-ER)

specification RT7D-0461-

06 (Fieldbus ITC ER)

ITC-ER)

specification RT7D-0463-

01 (ITC-ER)

Technically acceptable

ONLY for the following

MIDDLE EAST SPECIALIZED RTIP instrumentation

4 B4.3

CABLES COMPANY (SA) cable (one type):

specification RT7D-0468-

01 (TC)

Technically acceptable

for instrumentation cable

EXCEPT for the

following RTIP

instrumentation cable:

4 B4.3 NORTHWIRE specification RT7D-0466-

01 (single pair

thermocouple extension)

specification RT7D-0466-

02 (multi-pair

thermocouple extension)

Technically acceptable

for instrumentation cable

EXCEPT for the

following RTIP

instrumentation cable:

4 B4.3 THE OKONITE COMPANY specification RT7D-0461-

01 (ITC-ER)

specification RT7D-0461-

06 (Fieldbus ITC-ER)

specification RT7D-0463-

01 (ITC-ER)

Technically acceptable

for instrumentation cable

EXCEPT for the

following RTIP

instrumentation cable:

4 B4.3 SAUDI CABLE COMPANY (SA) specification RT7D-0461-

01 (ITC-ER)

specification RT7D-0461-

06 (Fieldbus ITC-ER)

specification RT7D-0463-

01 (ITC-ER)

4 B4.4 COMBINED WITH B4.3 B 1 1

Standardization -

4 B4.5 CABLE, COMMUNICATIONS, FIBER OPTIC B CORNING CABLE SYSTEMS 1 1

Category C

B4.5 DRAKA COMTEQ

MIDDLE EAST FIBER CABLE

B4.5

(SA)

OMAN FIBER OPTIC COMPANY

B4.5

(SA)

B4.5 SAUDI CABLE COMPANY (SA)

SAUDI MODERN COMPANY

B4.5

FOR CABLE (SA)

CABLE, ELECTRICAL, CATHODIC PROTECTION TURNKEY CATHODIC PROTECTION Standardization -

3 B4.6 E 1 1

SYSTEMS COMPANY Category C

CORRPRO ARABIA GROUND

B4.6

(SA)

B4.6 THREE LIONS FACTORY (SA)

3 B4.7 NOT USED B

Standardization -

3 B4.8 CABLE, GLANDS B CEAG 0 0

Category C

B4.8 CROUSE-HINDS

B4.8 HAWKE

B4.8 HUMMEL

THOMAS & BETTS (T&B

B4.8

CONDUIT FITTINGS)

Standardization -

3 B4.9 CABLE, LUGS & SPLICING SLEEVES B FCI BURNDY 0 0

Category C

B4.9 KLAUKE

B4.9 PFISTERER

B4.9 THOMAS & BETTS

B4.9 TYCO (RAYCHEM)

Standardization -

3 B4.10 CABLE, TERMINATIONS & SPLICES B 3M 0 0

Category C

PRYSMIAN CABLES &

B4.10

SYSTEMS SRL

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Electrical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Electrical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification Special

PAVL Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Dwg Lead Time Delivery Lead Special

Pkg. No. Revision Equipment Description B= Bulk Item Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Field Need Date

CODE Suffix US$ Strategy Level Level Weight Volume Date Date (weeks) Time (weeks) Considerations

E= Equipment Requirements

SIEMENS ENERGY &

B4.10

AUTOMATION

B4.10 TYCO (RAYCHEM)

EGS ELECTRICAL GROUP Standardization -

3 B4.11 CABLE, FIRE BARRIER B 0 0

(NELSON FIRESTOP) Category B

B4.11 ROXTEC (FRAME & BLOCKS)

4 B4.12 CABLE, HV (230kV) B

2.0 B5.0 CABLE TRAY

Standardization -

Category A,

ABAHSAIN-COPE SAUDI

4 B5.1 CABLE TRAY, CHANNEL, ALUMINUM B Abahsain-Cope is 1 2 1

ARABIA LIMITED (SA)

of 2 selected PLA

Vendors

ADHWA AL RAWAFID

4 B5.1

ELECTRIC INDUSTRIES

ALLIED TUBE & CONDUIT (T. J.

COPE)

Standardization -

Category A, Saudi

SAUDI ELECTRIC INDUSTRIES

4 B5.1 Electric is 1 of 2

COMPANY (SA)

selected PLA

Vendors

ALLIED TUBE & CONDUIT (T. J. Standardization -

4 B5.2 CABLE TRAY, TYPE FRP B 2 1

COPE) Category A

ABAHSAIN-COPE SAUDI

4 B5.2

ARABIA LIMITED (SA)

ADHWA AL RAWAFID

4 B5.2

ELECTRIC INDUSTRIES

Standardization -

ENDURO SYSTEMS Category A, Enduro

4 B5.2

INCORPORATED (ESI) is the selected PLA

Vendor

CIRCUIT BREAKERS (SEE SWITCHGEAR SEE SWITCHGEAR

B6.0

CATEGORIES FOR VENDORS) CATEGORIES FOR VENDORS

2 B7.0 DRIVES

Standardization -

DRIVE, VARIABLE (ADJUSTABLE) FREQUENCY LESS THAN Category A, ABB is

4 B7.1 E ABB INC 2 0

1KV the selected PLA

Vendor

ROCKWELL AUTOMATION

B7.1

(ALLEN BRADLEY)

SIEMENS ENERGY &

B7.1

AUTOMATION

WEG EQUIPAMENTOS

B7.1

ELETRICOS S.A.

DRIVE, VARIABLE (ADJUSTABLE) FREQUENCY 1KV AND Standardization -

4 B7.2 E ABB INC 2 1

ABOVE Category A

Standardization -

Category A,

SIEMENS ENERGY &

4 B7.2 Siemens is the

AUTOMATION (ROBICON)

selected PLA

Vendor

WEG EQUIPAMENTOS

B7.2

ELETRICOS S.A.

DRIVE, VERY LARGE MOTOR / VFD COMBINATIONS (>10 Standardization -

3 B7.3 E ABB INC 3 2

MW) Category B

B7.3 AREVA

SIEMENS ENERGY &

B7.3

AUTOMATION (ROBICON)

2 B8.0 GENERATORS

Standardization -

3 B8.1 GENERATOR, SYNCHRONOUS E ALSTOM ELECRIC 3 3

Category E

2 B8.1 BRUSH TURBOGENERATORS

B8.1 GE

SIEMENS ENERGY &

B8.1

AUTOMATION

ATLAS INDUSTRIAL Standardization -

4 B8.2 GENERATOR, STANDBY DIESEL E 3 1

EQUIPMENT Category A

B8.2 CATERPILLAR - ELECTRICAL

B8.2 CUMMINS (ONAN)

B8.2 F G WILSON (ENGINEERING)

B8.2 INTERGEN SRL

B8.2 KOHLER COMPANY

B8.2 MUSTANG

Standardization

Standardi ation -

Category A, SAB is

4 B8.2 S.A.B.

the selected PLA

Vendor

SAUDI DIESEL GENERATORS

3 B8.2

COMPANY

ZAHID TRACTOR

3 B8.2

(CATERPILLAR)

3 B8.3 ENGINE, STANDBY DIESEL, FOR STANDBY GENERATORS E CATERPILLAR 3 1

3 B8.3 CUMMINS

3 B8.3 DEUTZ

3 B8.3 DETROIT DIESEL/MTU

4 B8.3 DOOSAN

3 B8.3 PERKINS

2 B9.0 HEAT TRACING

Standardization -

2 B9.1 HEAT TRACING, DESIGN AND TURNKEY PROJECTS E THERMON ELECTRIC 2 1

Category C

B9.1 TYCO THERMAL CONTROLS

Date: 29 July 2011

Doc. No: A554-K-PRG-PU-LIS-DOC-009 (Electrical) Contains Confidential Information of Both Dow and Saudi Aramco Revision: 04

Ras Tanura Integrated Project (RTIP)

Program Supply Plan

Electrical

Project No: Owner to COMPLETE

Project Name: FEED / PMC Contractor to COMPLETE

Last Revised: EPC Contractor to COMPLETE

Classification Special

PAVL Tag Number / Estimate 1000 Purchasing Expediting Inspection Estimated Total Estmated Total Planned Inquiry Planned PO Dwg Lead Time Delivery Lead Special

Pkg. No. Revision Equipment Description B= Bulk Item Tag- Type Quantity Material Size Model / Design Manufacturers Negotiator Transportation Time Level Field Need Date

CODE Suffix US$ Strategy Level Level Weight Volume Date Date (weeks) Time (weeks) Considerations

E= Equipment Requirements

B10.0 HEATERS

Standardization -

3 B10.1 HEATER, RESISTANCE B CHROMALOX 1 0

Category B

B10.1 GAUMER PROCESS HEATERS

B10.1 THERMON ELECTRIC

B10.1 TYCO (RAYCHEM)

B10.1 WATLOW

B11.0 LIGHTING

Standardization -

B11.1 LIGHTING, EMERGENCY FIXTURES B CROUSE-HINDS 1 0

Category B

B11.1 THOMAS & BETTS

Standardization -

3 B11.2 LIGHTING, LAMPS B OSRAM SYLVANIA 1 0

Category C

B11.2 PHILIPS

Standardization -

B11.3 LIGHTING, PROCESS AREA FIXTURES B CROUSE-HINDS 1 0

Category B

EGS ELECTRICAL GROUP

B11.3

(APPLETON)

B11.3 THOMAS & BETTS (HAZLUX)

Standardization -

B11.4 LIGHTING, HIGH BAY / LOW BAY B CROUSE-HINDS 1 0

Category B

EGS ELECTRICAL GROUP

B11 4

B11.4

(APPLETON)

B11.4 HOLOPHANE

B11.4 THOMAS & BETTS (HAZLUX)

GENLYTE THOMAS (DAY- Standardization -