Documente Academic

Documente Profesional

Documente Cultură

Force Feed Lubricator Pump: Priming

Încărcat de

gustavofx21Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Force Feed Lubricator Pump: Priming

Încărcat de

gustavofx21Drepturi de autor:

Formate disponibile

The contents of this document are proprietary and confidential.

They are the

ENGINEERING REFERENCE property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

Force Feed Lubricator Pump

Ariel supplies force feed lubricator 1 6 7 8 1. Priming Button

pumps on all new compressors, 2. Flow Adjustment Boot

or for ordered replacement 2 3. Flow Adjustment

pumps in three sizes. The pumps 4. Flow Adjustment

are completely physically and Locknut

3 9

functionally interchangeable, size 5. Gasket

for size as a complete pump for 6. Pump Inlet (1/8 NPT)

any pump used on an Ariel force 4 7. Pump Outlet (1/8

NPT)

feed lubricator.

8. Discharge Check

NOTE: Pump component parts, Valve

including the gasket, may not 9. Pump Body

be interchangeable. 5

Priming

1. Install pump in lubricator res- FIGURE 1 Ariel Force

ervoir. Feed Lubricator Pump

2. Fill pump inlet with oil and

push the priming button

repeatedly until air-free oil flows from pump outlet.

NOTE: To expel air from pump may require a manual priming gun connected to the inlet - 150

psig maximum inlet pressure.

Flow Rate Adjustment

1. Check force feed lubricator data plate for correct lube rate.

2. Loosen flow adjustment locknut.

3. Turn flow adjustment counter-clockwise to increase flow, clockwise to decrease it.

NOTE: The pump is at full stroke when the bottom of the knurled portion of the knurled

nut on the flow adjustment is as high as the top of the pump body (as shown in figure). To

achieve minimum stroke from the full stroke position, turn flow adjustment eleven turns

clockwise. Additional turns shut off the pump.

4. Tighten flow adjustment locknut when desired flow is achieved.

REV DESCRIPTION REV EC DATE REV EC DATE

1 Replaced Procured Product Literature header with ER

header.

1 018457 9-20-12

0 017848 12-6-11

PAGE 1 OF 2 REV 1 ER-105.4

The contents of this document are proprietary and confidential. They are the

ENGINEERING REFERENCE property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

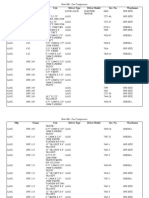

Specifications

Ariel Piston Max. Displacement per Max. Working

Diameter 7/16 (11.112 mm) Stroke Pressure Oil Viscosity

Part

SUS (cSt = mm2/s)

Number Inches (mm) Inches3 (cm3) PSI (bar)

A-9476 3/16 (4.762) 0.012 (0.197) 7,500 (517)

Max.: 8,000 SUS (1760 cSt)

A-9477 1/4 (6.350) 0.021 (0.344) 8,000 (552)

Min.: 90 SUS (17.8 cSt)

A-9478 3/8 (9.525) 0.048 (0.787) 4,000 (276)

Ariel Contact Information

Contact Telephone Fax E-Mail

Ariel Response Center 888-397-7766 740-397-1060 arc@arielcorp.com

Spare Parts (toll free USA & Canada) or 740-393-5054 spareparts@arielcorp.com

Order Entry 740-397-3602 (International) 740-397-3856 ---

Ariel World Headquarters info@arielcorp.com

740-397-0311 740-397-3856

Technical Services fieldservice@arielcorp.com

Web Site: www.arielcorp.com

Ariel Response Center Technicians or Switchboard Operators answer telephones during Ariel

business hours, Eastern Time - USA or after hours by voice mail. Contact an authorized distributor to

purchase Ariel parts. Always provide Ariel equipment serial number(s) to order spare parts.

The after-hours Telephone Emergency System works as follows:

1. Follow automated instructions to Technical Services Emergency Assistance or Spare Parts

Emergency Service. Calls are answered by voice mail.

2. Leave a message: caller name and telephone number, serial number of equipment in question

(frame, cylinder, unloader), and a brief description of the emergency.

3. Your voice mail routes to an on-call representative who responds as soon as possible.

PAGE 2 OF 2 REV 1 ER-105.4

S-ar putea să vă placă și

- Sewage Plant Operator: Passbooks Study GuideDe la EverandSewage Plant Operator: Passbooks Study GuideÎncă nu există evaluări

- Ancla Antitorque DTA XBDocument2 paginiAncla Antitorque DTA XBalfredozavÎncă nu există evaluări

- EHT Application NoteDocument3 paginiEHT Application NoteJuan SanchezÎncă nu există evaluări

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocument11 pagini1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 paginiPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahÎncă nu există evaluări

- QL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsDocument8 paginiQL Series: Vertical, Double-Suction Twin-Volute Turbine PumpstangouzeÎncă nu există evaluări

- Quick Reference - Hose & Couplings: Replace Hoses Immediately If They AreDocument1 paginăQuick Reference - Hose & Couplings: Replace Hoses Immediately If They AreFranquÎncă nu există evaluări

- Kunkletabla Seleccion PSVDocument12 paginiKunkletabla Seleccion PSVedwinmenaÎncă nu există evaluări

- Project: Title:: Equipment ListDocument3 paginiProject: Title:: Equipment ListMartin DanzeÎncă nu există evaluări

- IECEx CML 14.0047X 0 PDFDocument7 paginiIECEx CML 14.0047X 0 PDFINSTECH ServicesÎncă nu există evaluări

- Datasheet BombaDocument4 paginiDatasheet BombasaculÎncă nu există evaluări

- Walker1 PDFDocument2 paginiWalker1 PDFDian SikumbangÎncă nu există evaluări

- Post Job Report: Aminex Petroleum CompanyDocument12 paginiPost Job Report: Aminex Petroleum CompanyaliÎncă nu există evaluări

- QCI 10K ESP Packer Penetrator BrochureDocument1 paginăQCI 10K ESP Packer Penetrator BrochureJeff NehmeÎncă nu există evaluări

- Ajax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMDocument2 paginiAjax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMRafael ZuritaÎncă nu există evaluări

- Catalogo EagleBurgmann API 682 3ra Edición (58 E) PDFDocument30 paginiCatalogo EagleBurgmann API 682 3ra Edición (58 E) PDFRobert VillavicencioÎncă nu există evaluări

- 100T Pump Parts List PDFDocument30 pagini100T Pump Parts List PDFGabriel Andres ValenciaÎncă nu există evaluări

- Hoc3 CatalogoDocument12 paginiHoc3 CatalogoChristianReinoso0% (1)

- Ensival Moret GeneralDocument2 paginiEnsival Moret GeneralPatricia J ÁngelesÎncă nu există evaluări

- Introduction To Tubulars Page 06 of 10Document1 paginăIntroduction To Tubulars Page 06 of 10Shodji MabungaÎncă nu există evaluări

- Long Stroke Sucker Rod Units SSIL Vs Rotaflex WFTDocument20 paginiLong Stroke Sucker Rod Units SSIL Vs Rotaflex WFTMohamed GhareebÎncă nu există evaluări

- XMZ 210Document3 paginiXMZ 210Carlos GutierrezÎncă nu există evaluări

- TubingDocument12 paginiTubingJose Marval RodriguezÎncă nu există evaluări

- Ring Type Joint Gaskets Styles: R, RX, BXDocument2 paginiRing Type Joint Gaskets Styles: R, RX, BXiswantmachooÎncă nu există evaluări

- Grove g4n Gate Valve BrochureDocument24 paginiGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Kudu PCP SpecificationsDocument1 paginăKudu PCP SpecificationsBledarÎncă nu există evaluări

- (New) Ideal Prime Rig Fact SheetDocument1 pagină(New) Ideal Prime Rig Fact SheetterrorknightÎncă nu există evaluări

- Stray Current Corrosion in Submersible PumpsDocument5 paginiStray Current Corrosion in Submersible PumpsMachineryengÎncă nu există evaluări

- ChecklistDocument3 paginiChecklistAndy Noven KrisdiantoÎncă nu există evaluări

- MSS55 ManualDocument21 paginiMSS55 ManualJhon B Herrera100% (1)

- ESP CentriliftDocument102 paginiESP CentriliftJB BalcacerÎncă nu există evaluări

- Emc-Ssi Jan 2017Document44 paginiEmc-Ssi Jan 2017mghareebÎncă nu există evaluări

- 01 RR Griswold 811 General BrochureDocument20 pagini01 RR Griswold 811 General BrochureGiftObionochieÎncă nu există evaluări

- 3600 Reader SpreadsDocument12 pagini3600 Reader SpreadsfurqanÎncă nu există evaluări

- SUPERCHANGER Plate and FrameDocument28 paginiSUPERCHANGER Plate and Framejack-bcÎncă nu există evaluări

- Asi X Packer 105243965Document3 paginiAsi X Packer 105243965Esteban RochaÎncă nu există evaluări

- Plunger Lift BrochureDocument4 paginiPlunger Lift BrochureCluis KeÎncă nu există evaluări

- Affinity Laws: Centrifugal PumpsDocument2 paginiAffinity Laws: Centrifugal PumpsPrudhvi RajÎncă nu există evaluări

- 2020 Style 688 Split SealtekDocument8 pagini2020 Style 688 Split SealtekdiamsamÎncă nu există evaluări

- High Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Document24 paginiHigh Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Wong DaÎncă nu există evaluări

- DeepFlex BrochureDocument4 paginiDeepFlex Brochureribeiro30Încă nu există evaluări

- Business Opportunity - Thru Tubing ToolsDocument24 paginiBusiness Opportunity - Thru Tubing ToolsSohaib RashidÎncă nu există evaluări

- T Rex PumpDocument4 paginiT Rex PumpWong DaÎncă nu există evaluări

- Slurry High Pressure PumpDocument15 paginiSlurry High Pressure PumpOhmar Jamon LuzanoÎncă nu există evaluări

- Advances in Oil & Gas DrillingDocument35 paginiAdvances in Oil & Gas DrillingKhanzzÎncă nu există evaluări

- Lista de Referencias Sudamerica Bombas ABELDocument4 paginiLista de Referencias Sudamerica Bombas ABELGabrielÎncă nu există evaluări

- P25E Choke: 5 000 Psig / Max CV 36 / Max Bean Size 93Document4 paginiP25E Choke: 5 000 Psig / Max CV 36 / Max Bean Size 93Hùng DươngÎncă nu există evaluări

- Lufkin Automation PDFDocument4 paginiLufkin Automation PDFy149487Încă nu există evaluări

- RT Series Lobe Pump CatalogueDocument15 paginiRT Series Lobe Pump Cataloguevj4249Încă nu există evaluări

- ES Damen DOP 12-2016Document23 paginiES Damen DOP 12-2016shoaib lodhiÎncă nu există evaluări

- Stock Piston Rod CylindersDocument9 paginiStock Piston Rod CylindersALdinoÎncă nu există evaluări

- What Flange Does This Ring Gasket Fit - Ring Gasket Numbers, Flange SizesDocument4 paginiWhat Flange Does This Ring Gasket Fit - Ring Gasket Numbers, Flange SizesTg TarroÎncă nu există evaluări

- PX-260 Performance CurveDocument1 paginăPX-260 Performance CurveRoberto Leon MendezÎncă nu există evaluări

- TS6 4.5 TUBING 15.5ppfDocument1 paginăTS6 4.5 TUBING 15.5ppfKhairilsyam Abdul RashidÎncă nu există evaluări

- App10 Fundamentals of ConnectionsDocument23 paginiApp10 Fundamentals of ConnectionsjdmacbookÎncă nu există evaluări

- Warman Technical CatalogueDocument1 paginăWarman Technical CatalogueMamiherintsoa Issaia RanaivoarimananaÎncă nu există evaluări

- FPD 21 e PDFDocument8 paginiFPD 21 e PDFrasheedillikkal100% (1)

- High Pressure Drilling Hoses: Fleximak Industrial CatalogueDocument5 paginiHigh Pressure Drilling Hoses: Fleximak Industrial CatalogueitangÎncă nu există evaluări

- Hevvy Hns Brocuhre enDocument11 paginiHevvy Hns Brocuhre enJacobo MartínezÎncă nu există evaluări

- RP2 Manual2 - 1Document171 paginiRP2 Manual2 - 1Jonathan maximiliano0% (1)

- Woodward Mechanical TG Governor PDFDocument52 paginiWoodward Mechanical TG Governor PDFgustavofx21Încă nu există evaluări

- Proflo Jr. No-Flow SwitchDocument3 paginiProflo Jr. No-Flow Switchgustavofx21Încă nu există evaluări

- Rino KK - Gas CompressorsDocument20 paginiRino KK - Gas Compressorsgustavofx21Încă nu există evaluări

- Recommended Maintenance Intervals For Continuous Duty Reciprocating CompressorsDocument7 paginiRecommended Maintenance Intervals For Continuous Duty Reciprocating Compressorsgustavofx21Încă nu există evaluări

- Ariel-Er-105 1 1Document9 paginiAriel-Er-105 1 1gustavofx21Încă nu există evaluări

- Demo 24x3ringDocument20 paginiDemo 24x3ringgustavofx21Încă nu există evaluări

- CATERPILLAR 3516 TA Parts 1 PrelubricadoraDocument2 paginiCATERPILLAR 3516 TA Parts 1 Prelubricadoragustavofx21Încă nu există evaluări

- York Centrifugal M PamphletDocument8 paginiYork Centrifugal M Pamphletgustavofx21Încă nu există evaluări

- Psu 2 PDFDocument2 paginiPsu 2 PDFgustavofx21Încă nu există evaluări

- P 172Document2 paginiP 172gustavofx21Încă nu există evaluări

- U 134Document2 paginiU 134gustavofx21Încă nu există evaluări

- P 172Document2 paginiP 172gustavofx21Încă nu există evaluări

- H 276Document46 paginiH 276gustavofx21Încă nu există evaluări

- HG 12 SeriesDocument2 paginiHG 12 Seriesgustavofx21Încă nu există evaluări

- ITW Philadelphia Resins Material Safety Data Sheet: Chockfast Black HardenerDocument14 paginiITW Philadelphia Resins Material Safety Data Sheet: Chockfast Black Hardenergustavofx21Încă nu există evaluări

- 642G Chockfast InstallDocument6 pagini642G Chockfast Installgustavofx21Încă nu există evaluări

- 6320 Spare Parts ListDocument6 pagini6320 Spare Parts Listgustavofx21Încă nu există evaluări

- Model 6320/VA: Four Channel Vibration AnalyzerDocument2 paginiModel 6320/VA: Four Channel Vibration Analyzergustavofx21Încă nu există evaluări

- Enhanced Refrigerant ManagementDocument1 paginăEnhanced Refrigerant ManagementTrần Lê Quang NgọcÎncă nu există evaluări

- OM Power StationsDocument95 paginiOM Power StationsAditi SinghÎncă nu există evaluări

- Spe 172359 MSDocument12 paginiSpe 172359 MSamramazon88Încă nu există evaluări

- Mecorrel3 - Thermodynamics Ii PDFDocument3 paginiMecorrel3 - Thermodynamics Ii PDFJustinnÎncă nu există evaluări

- Hand PumpDocument4 paginiHand PumpMagdalena Belen Sepulveda LavanchyÎncă nu există evaluări

- Packoff and Slim Hole Gas Lift MandrelsDocument3 paginiPackoff and Slim Hole Gas Lift MandrelsashwaniÎncă nu există evaluări

- NINNELT-FASGNS Presentation Correct PreviewDocument13 paginiNINNELT-FASGNS Presentation Correct PreviewLpg Power SupplyÎncă nu există evaluări

- spr2 PDFDocument301 paginispr2 PDFPatrick Silva OliveiraÎncă nu există evaluări

- Thermal Analysis of Shell and Tube Heat Exchangers For Improving Heat Transfer Rate Using Nanofluid MixturesDocument11 paginiThermal Analysis of Shell and Tube Heat Exchangers For Improving Heat Transfer Rate Using Nanofluid MixturesFawaz Bukht MajmaderÎncă nu există evaluări

- Engine Notations & FlowsDocument6 paginiEngine Notations & FlowsInterogator5Încă nu există evaluări

- Increasing Profits Through Utility Reduction, Saving Our Clients MoneyDocument2 paginiIncreasing Profits Through Utility Reduction, Saving Our Clients MoneyramquimicaÎncă nu există evaluări

- Francis Turbine Test Rig: TheoryDocument4 paginiFrancis Turbine Test Rig: Theoryanil chejaraÎncă nu există evaluări

- Sab202 Manual OperationDocument39 paginiSab202 Manual Operationdaneshii100% (1)

- PVT PropertiesDocument20 paginiPVT PropertiesJoseph YepezÎncă nu există evaluări

- Engineering ToolboxDocument7 paginiEngineering ToolboxBahaa AlhaddadÎncă nu există evaluări

- Roto Inject Fluid NDURANCE: Atlas Copco LubricantsDocument2 paginiRoto Inject Fluid NDURANCE: Atlas Copco LubricantsJoao BotasÎncă nu există evaluări

- Final ReportDocument127 paginiFinal ReportRyan Edel DantisÎncă nu există evaluări

- DP Pump TechDocument48 paginiDP Pump TechDewesh SinghÎncă nu există evaluări

- CHE 311 HEAT TRANSFER TablesDocument24 paginiCHE 311 HEAT TRANSFER TablesJack O'MeraÎncă nu există evaluări

- Torrent G.I Job CardDocument5 paginiTorrent G.I Job Cardshanivi vrindavanÎncă nu există evaluări

- Welding ProcessDocument9 paginiWelding ProcessrajuÎncă nu există evaluări

- Air Driven Hydraulic PumpsDocument32 paginiAir Driven Hydraulic Pumpsdejanr111Încă nu există evaluări

- Refrigeration Practical 1Document6 paginiRefrigeration Practical 1SamÎncă nu există evaluări

- Assignment Cat 1Document2 paginiAssignment Cat 1ppraveenksrceÎncă nu există evaluări

- Final Round and ClincherDocument8 paginiFinal Round and Clincherponcatoera0% (2)

- Fiche Technique: Revision CodeDocument24 paginiFiche Technique: Revision CodeamirÎncă nu există evaluări

- Type MV Directional Spray Nozzles, Open Medium Velocity General DescriptionDocument14 paginiType MV Directional Spray Nozzles, Open Medium Velocity General Descriptionrusli bahtiarÎncă nu există evaluări

- Framo Operational ManualDocument20 paginiFramo Operational ManualViijaay Nehra100% (1)

- Ventury Scrubber Design MethodDocument3 paginiVentury Scrubber Design MethodPukhraj DagaÎncă nu există evaluări

- Valve Philosophy Valve Application GeneralDocument3 paginiValve Philosophy Valve Application GeneralWade ColemanÎncă nu există evaluări