Documente Academic

Documente Profesional

Documente Cultură

RVS 310 Grades

Încărcat de

Juan LeonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RVS 310 Grades

Încărcat de

Juan LeonDrepturi de autor:

Formate disponibile

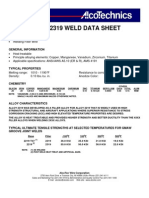

Austenitic stainless steel

grades

AISI 310

General Characteristics

AISI EU code EN 10088 ASTM A 167/240 Comply to max. temps of 1000C (309 types) in air

304H X6CrNi18-10 / 1.4948 UNS30409 Comply to max. temps of 1100C (310 types) in air

309(Si) X15CrNi20-12 / 1.4828 UNS30900 Good resistance to carburizing

309S X12CrNi23-13 / 1.4833 UNS30908 Very high resistance to corrosion and oxidation

309H X12CrNi23-13 UNS30909 Good weldability and formability

310(Si) X15CrNiSi25-20 / 1.4841 UNS31000 Best mechanical properties rg. creep deformation

310S X12Cr-Ni25-20 / 1.4842 UNS31008 AISI 310 grades comply to:

310H X12Cr-Ni25-20 UNS31009 European Directive 2000/53/EC end-of-life vehicles

321H X8CrNiTi18-10 / 1.4878 UNS32109 EU Material Safety Data Sheet n1/2001/58/EC

Chemical Mechanical

Elements % C N S Si Mn Cr Ni @ 100C Rm Re/Rp A%

309 1.4828 0.20 -- 0.030 0.75 2.00 24.00 15.00 1.4828 600 (MPa) 275 (MPa) 48

309S 1.4833 0.08 -- 0.030 0.75 2.00 24.00 15.00 1.4833 650 (MPa) 330 (MPa) 44

309Si 1.4828 0.20 0.11 0.015 2.50 2.00 21.00 13.00 1.4828 600 (MPa) 275 (MPa) 48

310 1.4841 0.25 -- 0.030 1.50 2.00 26.00 22.00 1.4841 615 (MPa) 290 (MPa) 45

310S 1.4842 0.08 -- 0.030 1.50 2.00 26.00 22.00 1.4842 615 (MPa) 300 (MPa) 42

310Si 1.4841 0.20 0.11 0.015 1.50 2.00 26.00 22.00 1.4841 615 (MPa) 290 (MPa) 45

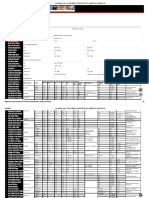

Mechanical values @ elevated C

Yield/Strength Ao%

650 130 309 yield

309 strength

550 110 309 elongation

450 90

309S yield

350 70 309S strength

309S elongation

250 50

150 30 310S yield

310S strength

10 310S elongation

0 250 500 750 1000

Dimensions Delivery range / forms of sheets, coils, blanks and strips

Cold rolled (CR finish 2B/2D) Hot rolled (HR finish 1D/2E)

Width (mm) Width (mm)

2000 2000

1500 1500

1250 1250

1000 1000

Thickness (mm) 0.75 1.0 2.5 5.0 7.5 Thickness (mm) 3.0 4.0 5.0 8.0 12.0

Applications Metal working

Industrial and chemical engineering structures Good bending up to 180; bending radii for t < 0.8

Road transport, f.e. tanks, bodies and trailers For t > 0.8 a bending radius of x t is recommended

Heating, boilers, tanks and piping systems, for: Acceptable Limiting Drawing Ratios grade 310-series

Naval industry and engineering For welding, no preheat, nor postheating required

Chemical and farmaceutical industry Annealing @ 1050C 25C restores microstructures

Water-, oil- and gas industry and engineering (recrystallisation) and eliminates internal stresses

Deze publicatie is zorgvuldig gecreerd op basis van actuele kennis en inzichten. MEKA steel BV is niet verantwoordelijk voor enige directe, indirecte of gevolgschade of fouten, die

worden veroorzaakt door het gebruik of de onbruik van de informatie of door onjuiste of onvolledige informatie. MEKA Steel BV behoudt zich het recht voor om wijzigingen aan te

brengen. Vraag de engineers van MEKA Steel BV om advies en verdere toelichting. Versie 2/5.2015

S-ar putea să vă placă și

- Midalloy ER309 PDFDocument1 paginăMidalloy ER309 PDFAnonymous hk1fhAkwyÎncă nu există evaluări

- Parts Book: BreakerDocument24 paginiParts Book: BreakerJose Luis Poma MÎncă nu există evaluări

- A 2319 TdsDocument2 paginiA 2319 TdsSyam NathÎncă nu există evaluări

- PC1250-7 Parts BookDocument971 paginiPC1250-7 Parts BookM Ramzi100% (1)

- Dual Phase Steels Voestalpine EN 12062019Document4 paginiDual Phase Steels Voestalpine EN 12062019pranayÎncă nu există evaluări

- SA/AS1548 - 7 - 460R: XlerplateDocument3 paginiSA/AS1548 - 7 - 460R: XlerplatenavÎncă nu există evaluări

- 0218 Ja enDocument1 pagină0218 Ja enHoque AnamulÎncă nu există evaluări

- Dual Phase Steels Voestalpine EN 28092018Document4 paginiDual Phase Steels Voestalpine EN 28092018Silverio AcuñaÎncă nu există evaluări

- Accutherm Riello Gi Emme 300 - 900 Series Package Dual Fuel Burner 130930105241Document8 paginiAccutherm Riello Gi Emme 300 - 900 Series Package Dual Fuel Burner 130930105241Ruben David Ibañez RetamalÎncă nu există evaluări

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningDocument4 paginiFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaÎncă nu există evaluări

- Brosur Breaker SOOSAN SB Series (New)Document8 paginiBrosur Breaker SOOSAN SB Series (New)HidayatÎncă nu există evaluări

- PC160LC-7 Part Book Motor Saa4d102e 2e S N 30204043 and U PDFDocument73 paginiPC160LC-7 Part Book Motor Saa4d102e 2e S N 30204043 and U PDFRicardoÎncă nu există evaluări

- Swing Bearing - KTR PDFDocument2 paginiSwing Bearing - KTR PDFflytorahul100% (1)

- Alloy C-4300MDocument1 paginăAlloy C-4300Malex diazÎncă nu există evaluări

- Data Sheet Aton Pump 3 CompressedDocument4 paginiData Sheet Aton Pump 3 Compressedfajar kusumaÎncă nu există evaluări

- Parts Book: Wheel LoaderDocument781 paginiParts Book: Wheel LoaderAang100% (4)

- Parts Book Pc228-3 KomatsuDocument582 paginiParts Book Pc228-3 Komatsuazry_alqadry91% (11)

- Sdg100as 3a6Document36 paginiSdg100as 3a6КонстантинÎncă nu există evaluări

- D61EX 15E0 EngineDocument61 paginiD61EX 15E0 EngineRaphael RodriguesÎncă nu există evaluări

- WA130Document9 paginiWA130antonÎncă nu există evaluări

- PC228 - Engine - SAA6D107E 1G W S N 26500006 UPDocument89 paginiPC228 - Engine - SAA6D107E 1G W S N 26500006 UPThiago Fredy100% (1)

- Properties of Stainless SteelsDocument22 paginiProperties of Stainless Steelsngoclinh87Încă nu există evaluări

- Hot-Rolled Steel FL AtsDocument3 paginiHot-Rolled Steel FL AtsĐình Khoa PhanÎncă nu există evaluări

- PC350LC 8 W2 S N 60001 UpDocument634 paginiPC350LC 8 W2 S N 60001 UpLuzioNetoÎncă nu există evaluări

- Grade Data Sheet: Grade 301 Is A High Work-Hardening RateDocument2 paginiGrade Data Sheet: Grade 301 Is A High Work-Hardening RateGovind RaoÎncă nu există evaluări

- Tabla de Referencias de Aceros Inoxidables (ASTM A213)Document1 paginăTabla de Referencias de Aceros Inoxidables (ASTM A213)Baltasar BuchiniÎncă nu există evaluări

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 paginiINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezÎncă nu există evaluări

- A0 EngineDocument125 paginiA0 Engineazry_alqadryÎncă nu există evaluări

- Consteel Catalogue BARS FlatDocument2 paginiConsteel Catalogue BARS FlatWei YaoÎncă nu există evaluări

- Consteel Catalogue PLATES ChequeredPlatesDocument3 paginiConsteel Catalogue PLATES ChequeredPlatesrichard richÎncă nu există evaluări

- Catalago Peças PC200F-8M0Document400 paginiCatalago Peças PC200F-8M0Anderson silvaÎncă nu există evaluări

- Insert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ADocument2 paginiInsert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ATaller PahrÎncă nu există evaluări

- PC200-8 SN 60001 Up - 1Document40 paginiPC200-8 SN 60001 Up - 1re GaÎncă nu există evaluări

- Select 90c d2Document1 paginăSelect 90c d2nateÎncă nu există evaluări

- SS 309 All PropertiesDocument1 paginăSS 309 All Propertiessharafudheen_sÎncă nu există evaluări

- EN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelDocument4 paginiEN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelNaiduÎncă nu există evaluări

- Parts Catalog Engine Generator SDG100S 6A6Document30 paginiParts Catalog Engine Generator SDG100S 6A6Teddy NsÎncă nu există evaluări

- IFS Stancor SEW50 DatasheetDocument2 paginiIFS Stancor SEW50 DatasheetMaruRojaÎncă nu există evaluări

- 014 ST ApplicableDocument3 pagini014 ST ApplicableGrover Miranda VallejosÎncă nu există evaluări

- Commercial Range Acm 250-315Document2 paginiCommercial Range Acm 250-315HannaanÎncă nu există evaluări

- 410 Welding Wire and RodDocument1 pagină410 Welding Wire and RodJenderalKancilÎncă nu există evaluări

- Sa4d102e 1ab S N 21240928 UpDocument120 paginiSa4d102e 1ab S N 21240928 UpRAMON TEIXIDORÎncă nu există evaluări

- General Auger Parts DiagramDocument34 paginiGeneral Auger Parts DiagramgomooneyÎncă nu există evaluări

- EN Spare Parts ManualDocument24 paginiEN Spare Parts ManualSerkanAl100% (1)

- 303 Spec SheetDocument2 pagini303 Spec SheetYankMulya MusaÎncă nu există evaluări

- Weg Fire Pump Motors PDFDocument8 paginiWeg Fire Pump Motors PDFViệt Đặng XuânÎncă nu există evaluări

- Expansion: JointDocument40 paginiExpansion: JointVignesh NadimuthuÎncă nu există evaluări

- Din En1563-2018Document2 paginiDin En1563-2018FAPEMA SGQÎncă nu există evaluări

- WWW Rfshydraulics Com Ferrule Fittings HTMLDocument10 paginiWWW Rfshydraulics Com Ferrule Fittings HTMLMuhammad HafizuddinÎncă nu există evaluări

- 1.4466 (310L Ug)Document4 pagini1.4466 (310L Ug)ramramjeyÎncă nu există evaluări

- SAA6D102E-2JJ-8 S/N 26274903-UP: EngineDocument2 paginiSAA6D102E-2JJ-8 S/N 26274903-UP: EngineBuku DigitalÎncă nu există evaluări

- PDS390S-4B1, Hal 15Document4 paginiPDS390S-4B1, Hal 15AkmalÎncă nu există evaluări

- 2 PDFDocument2 pagini2 PDFMbahdiro KolenxÎncă nu există evaluări

- 2 PDFDocument2 pagini2 PDFMbahdiro KolenxÎncă nu există evaluări

- MONTABERTDocument6 paginiMONTABERTMiguelÎncă nu există evaluări

- PressedDocument46 paginiPressedsameh aboulsoudÎncă nu există evaluări

- FuyDocument24 paginiFuyChakrouneÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Database Management Systems: Understanding and Applying Database TechnologyDe la EverandDatabase Management Systems: Understanding and Applying Database TechnologyEvaluare: 4 din 5 stele4/5 (8)

- Ascometal Grades en PDFDocument8 paginiAscometal Grades en PDFJuan LeonÎncă nu există evaluări

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 paginiWear Resistant Steel: Material Data Sheet, Edition April 2016Juan LeonÎncă nu există evaluări

- Astm A532 PDFDocument4 paginiAstm A532 PDFJuan Leon100% (1)

- Ensayos de Impacto E23Document28 paginiEnsayos de Impacto E23Juan LeonÎncă nu există evaluări

- Bronces y Latones ThyssenDocument96 paginiBronces y Latones ThyssenJuan LeonÎncă nu există evaluări

- Forging Design ConsiderationsDocument81 paginiForging Design ConsiderationssuneethaÎncă nu există evaluări

- PERFORMANCE TASK 2 ScienceDocument5 paginiPERFORMANCE TASK 2 ScienceCUIZON, GEORDETTE DIVINEÎncă nu există evaluări

- 26875303Document9 pagini26875303Haresh RaisinghaniÎncă nu există evaluări

- Our Know-How Your Higher Performance: Danieli Lynxs ShreddersDocument7 paginiOur Know-How Your Higher Performance: Danieli Lynxs ShreddersrezaÎncă nu există evaluări

- RT Standards NotesDocument4 paginiRT Standards NotesprabhuÎncă nu există evaluări

- Compare D2 and D3Document2 paginiCompare D2 and D3GANESHÎncă nu există evaluări

- GAS PROBLEM in Steel Sand CastingsDocument7 paginiGAS PROBLEM in Steel Sand CastingsVasu RajaÎncă nu există evaluări

- Din MaterialDocument110 paginiDin MaterialLaura Lisianu100% (1)

- TIME SCHEDULE UpdateDocument16 paginiTIME SCHEDULE UpdateCahyani Permata YpÎncă nu există evaluări

- Böhler Fox Skwam: Classifi CationsDocument1 paginăBöhler Fox Skwam: Classifi CationsBranko FerenčakÎncă nu există evaluări

- Mild Steel Product Guide 25Document25 paginiMild Steel Product Guide 25shani5573Încă nu există evaluări

- Metallography Heat Treatment: MW-343 For D.A.E Metallurgy and Welding Third YearDocument7 paginiMetallography Heat Treatment: MW-343 For D.A.E Metallurgy and Welding Third YearM.Khaliq u zaman 151100% (1)

- High Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlDocument4 paginiHigh Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlSyed Zakir Hussain ZaidiÎncă nu există evaluări

- IPS d-SIGN 98Document2 paginiIPS d-SIGN 98Toma IoanaÎncă nu există evaluări

- Material Comparison For Sa240 TP304Document3 paginiMaterial Comparison For Sa240 TP304QC Taner 453Încă nu există evaluări

- BoltsDocument14 paginiBoltsBelalNorÎncă nu există evaluări

- UNITED ALLOY 392 EditedDocument1 paginăUNITED ALLOY 392 EditedwhatintheboxÎncă nu există evaluări

- Merlo 75 FT Steel PoleDocument1 paginăMerlo 75 FT Steel Polearlene borborÎncă nu există evaluări

- Gonzalez 21399Document11 paginiGonzalez 21399Yogesh S Yogi SÎncă nu există evaluări

- CC5 FlyerDocument1 paginăCC5 FlyerGustavo Urueña OrozcoÎncă nu există evaluări

- Welding Electrodes SelectionDocument19 paginiWelding Electrodes SelectionjerickÎncă nu există evaluări

- Press ToolsDocument6 paginiPress ToolsSamir BoseÎncă nu există evaluări

- IsuzuDocument8 paginiIsuzuImam Zulkifli100% (1)

- Fittings For Grooved-End Pipe: FIG. 7060 FIG. 7076Document1 paginăFittings For Grooved-End Pipe: FIG. 7060 FIG. 7076ErickÎncă nu există evaluări

- Forming Interview Questions and Answers For Freshers - SanfoundryDocument4 paginiForming Interview Questions and Answers For Freshers - SanfoundryrahmaÎncă nu există evaluări

- Gsce ChemistryDocument2 paginiGsce ChemistryAaravÎncă nu există evaluări

- Plasma Flame Spray Book PDFDocument176 paginiPlasma Flame Spray Book PDFAlexis O'NeillÎncă nu există evaluări

- Chapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesDocument25 paginiChapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesAlissa Saphira PutriÎncă nu există evaluări

- B253 PDFDocument8 paginiB253 PDFSky LeeÎncă nu există evaluări

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 paginăB Boehler Aws E316l 17 Se en 5a Mds PDFInaamÎncă nu există evaluări