Documente Academic

Documente Profesional

Documente Cultură

Smith 1965

Încărcat de

Nassar Al-Essawi0 evaluări0% au considerat acest document util (0 voturi)

2 vizualizări2 paginiVacuum Deposited Thin Films Using a Ruby Laser

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentVacuum Deposited Thin Films Using a Ruby Laser

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

2 vizualizări2 paginiSmith 1965

Încărcat de

Nassar Al-EssawiVacuum Deposited Thin Films Using a Ruby Laser

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

For a powder source the material was ground fine with pestle

and mortar, placed loosely in a crucible and the surface smoothed.

Lateral motion of the lens allowed the focal spot to fall on the

powder surface where desired. The laser beam generally produced

a 1-mm to 2-mm diam crater at the impact point. After removal

from the bell jar little or no evidence of sintering or melting

around a crater could be observed under the microscope. All

traces of a crater disappeared on shaking the crucible slightly.

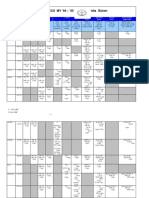

Table I lists those materials which in powder form gave opti-

cally satisfactory films as determined by simple inspection of their

interference colors or the quality of their specular reflectance.

The first column has the experimentally determined optical film

thickness, nd, in microns obtained per single laser pulse of

energy P 3 J, all film thicknesses being normalized to a throw

of 1 cm from sample to substrate under the assumption of the

Vacuum Deposited Thin Films inverse-square law. Experimental film thicknesses were esti-

Using a Ruby Laser mated visually on the basis of interference fringe counts. The

Howard M. Smith and A. F. Turner second column of Table I contains nominal refractive indices, n,

for thin films of the listed materials. Columns 4 and 5 give hand-

Howard M. Smith is at the Institute of Optics, University of book values of melting points and boiling points.

Rochester, Rochester, New York, and A. F . Turner is a t The materials in Table I are listed in order of increasing diffi-

Bausch & Lomb Inc., Rochester, New York. culty of producing evaporated films from them, as indicated by

Received 18 September 1964. the decreasing values of the entries in the first column. Their

Partially sponsored by the U.S. Army Research Office, Dur- sequence bears no obvious correlation with the melting points

ham, North Carolina. Paper TC18 presented at the Optical and boiling points. I t will be noted t h a t even with the most

Society of America meeting, Rochester, New York, October easily evaporated material, Sb2S3, for which nd/P = 0.35, eight

1962. pulses are required for a quarter-wave film in the visible using a

The vaporization of materials in air by a laser is a familiar throw of 4 cm.

phenomenon. I t suggests the use of a laser beam to evaporate The difference in the evaporation efficiency of the laser beam on

materials in vacuum for the deposition of optical thin films. P b C l 2 and MoO 3 powders is noteworthy. Each can be evaporated

The success of this technique cannot be predicted a priori since easily by conventional methods from resistance-heated boats.

the constituent character of the vapor product, often visible in Under the laser beam there was no difficulty in obtaining films of

air as a plume, is still problematical and its film-forming potential MoO 3 . However, no films could be produced from the PbCl 2

unknown. powder until it was artificially darkened by the admixture of

This work was undertaken to test empirically the technique by carbon dust, the latter alone producing no film. Initially the

applying it to a number of materials of interest in the vacuum PbCl 2 powder was very white, the MoO 3 powder slightly greyish-

coating field. I t is found that many materials can be vaporized green. Thus the transfer of energy from the laser beam to the

in vacuum by a directed laser beam and condensed on substrates powder samples appears rather critically dependent on small

as good optical films but t h a t others cannot, at least not under amounts of absorption.

the same conditions. Apparently each material will require Q-switching had the opposite effect on the evaporation effi-

individual study. The work reported here is of a preliminary ciency of Ge and MoO 3 powders, allowing films to be evaporated

survey nature only, but it shows the feasibility in many instances more easily from the former and less readily from the latter than

of thin-film vacuum coating utilizing a laser external to the shown in Table I. This could be related to a lower heat conduc-

vacuum chamber as the evaporation power source. tivity of the MoO3, since Q-switching may restrict the amount of

The evaporations were carried out in the 1 0 4 torr pressure material vaporized if the heat conductivity is insufficient for the

range using a vacuum coater with a 10-cm oil diffusion pump. flow of thermal energy to an appreciable depth during the time of

T h e laser equipment was the Trion LS-2 (Lear Siegler). A lens one pulse. The superheated top layers, by not vaporizing rapidly

focused the radiation from the T I R ruby rod through a window enough during the short Q pulse time, could shield the material

in the bell jar onto the surface of the sample to be evaporated. below from evaporating. 1

When cooled with liquid N 2 the rod furnished about 3 J per pulse. Films of the semiconductor compounds CdTe, PbTe, and ZnTe

I t was fired at a rate of 1 pulse/min. For an 0.5 beam divergence all can be evaporated by conventional methods. The laser

and a 50-mm focal length lens, the minimum spot diameter was beam, however, produced only rough and optically unsatisfactory

0.5 mm. Assuming a 1 msec pulse the power density a t focus films of CdTe, having the appearance of being splashed on, al-

was therefore 10G W/cm 2 . Q-switching by means of the Trion though good films of PbTe and ZnTe were obtained easily. X -

MH-1 rotating mirror was used occasionally, as noted below, with ray diffractometer lines of CdTe films were sharp, indicating

the rod uncooled. The estimated power density at focus was large crystallites, those of P b T e and ZnTe films were broad,

then 108 W/cm 2 . indicating fine crystallinity. Spectrophotometric transmittance

Most of films were evaporated from powdered materials con- measurements on the ZnTe films showed the absorption edge at

tained in small inclined crucibles in the bell jar. The powder 0.8 as expected. I n PbTe films, the edge appeared to be at

surfaces were at 45 to the horizontal laser beam. The electric about 1.5 instead of at the usual 3.5- position. For these very

vector was in the plane of incidence. Some stibnite (Sb 2 S 3 ) films thin films, this would not be in disagreement with published data 2

also were evaporated from single crystals. Unheated glass, mica, on the absorption coefficient which indicate a stepped curve, the

BaF 2 , or As2S3 substrate plates on which to deposit the films initial steep rise in absorption taking place at 3.5 , with a second

were positioned in the bell jar 20 mm to 50 mm above the cru- steep rise around 1.5 .

cibles. Because of this short throw the films were not of uniform The stoichiometry of the laser beam-produced films in compari

thickness and often showed lively interference colors. son with the parent material is of interest. Semiquantitative

January 1965 / Vol. 4, No. 1 / APPLIED OPTICS 147

analyses of films of PbTe (0.2 thick) and ZnTe (0.4 thick) experimental sequence from Table I. The actual observed

were made by x-ray fluorescence. As far as the experiments thicknesses were, however, only 1% to 5 % of the computed,

could be carried, it was found that stoichiometrically the latter which is perhaps not surprising in view of the many experimental

definitely corresponded to its parent, while the P b T e film was uncertainties tending to produce a discrepancy in this direc

very probably the same as its parent. The composition of films tion. Careful yield determinations in the future could help in

produced from InAs powder was examined by x-ray diffraction answering the question whether laser beam evaporation is simply

with the E M X electron microprobe of Applied Research Labora thermal, depending only on the beam energy and not on its special

tories, Inc. Since this samples an area of only about 1 2, optical attributes.

individual particles blown up from the InAs powder onto the sub Thin film evaporation by means of a laser beam can offer

strate during the evaporation, commonly called spit, could be several unique advantages as the technique is developed further.

analyzed. On the basis of the detector counting rates for these I t will allow film formation under ultraclean vacuum conditions,

spit particles, the ratio of In to As was 2.5 times t h a t in an original e.g., by directing the beam through the wall of a thoroughly baked-

crystal of InAs, while in the film (0.2 thick) this ratio was re out and sealed-off bulb which needs to contain only the evaporant

versed with thirty-five times as much As compared to In as in the and a substrate to receive the film. Freedom from film contami

original. I t must be concluded that As was evaporated preferen nation is assured further by the surface evaporation characteristic

tially, and that the film is In-doped arsenic. of the beam. Because of the small beam divergence, the laser

I t was hoped that the laser beam technique would evaporate and associated equipment could be located at a considerable

stoichiometric films of some of the semiconductor compounds distance, an attractive possibility in radioactive areas. Once the

which ordinarily cause difficulty by conventional methods due to question of stoichiometry is resolved, applications of the laser

decomposition. Justification for this hope was by analogy with beam evaporation technique to vapor source instrumentation for

the flash method of producing films of some alloys by repeatedly solids in mass spectrometers also are apparent.

evaporating very small quantities to completion and relying on

We wish to thank L. Hadley, Colorado State University, for

recombination on the substrate of any decomposition products.

electron diffraction examinations of some of the films, and R. Roy

With the materials tried to date the laser beam technique has not

and E. W. White, The Pennsylvania State University, for the x-ray

been successful. Cu2O decomposed to give a film of Cu and no

fluorescence and E M X electron microprobe studies.

films could be produced from ZnO or InSb. InAs, discussed

above, decomposes badly under vacuum in a resistance-heated T a

boat to produce a grey deposit. The fact, however, t h a t with the Table I. Powdered Materials Producing Optically

laser clear films are obtained from InAs with as much as 3 % Satisfactory Films

concentration of I n relative to the original crystal, leads one to

suspect that success in stoichiometric films may depend on con

trolled laser-power operating conditions as has been shown neces

sary for laser welding. 3

Films of stibnite Sb 2 S 3 were produced from large single crystals

as well as from powder sources. The films are formed so easily

t h a t the entrance window into the vacuum chamber rapidly be

comes coated. Each successive laser pulse re-evaporates an

aperture in this coating so that it offers little obstruction to the

beam. The action of the beam on the stibnite crystal ejects a

white plume several millimeters long in the vacuum, as also ob

served from many of the powder samples. High-speed streak

camera pictures of the stibnite plume by G. Milne (University of

Rochester) showed that the generation of the plume was inter

mittent and followed the spiking of the ruby laser. This would

agree with the thermal spiking predicted for metals by Ready. 1

If the vaporization phenomenon is purely thermal, the amount

References

of material evaporated per absorbed joule of laser radiation can be 1. J. F . Ready, J. Opt. Soc. Am. 53, 514 (1963).

calculated from known specific heats and changes in enthalpy, 2. M. E. Lasser and H. Levinstein, Phys. Rev. 96, 47 (1954).

and from this the film thickness predicted for any given distance 3. G. W. Dunlap and D. L. Williams, Proc. Natl. Electron.

from the evaporant to substrate. Using published thermo- Conf., 18, 601 (1962).

dynamical data 4 this was done for Se, Te, and Ge, with the result 4. D . E . Gray, ed., A.I.P. Handbook, 2nd ed. (McGraw-Hill,

that the sequence of relative film thicknesses agreed with the New York, 1963).

148 APPLIED OPTICS / Vol. 4, No. 1 / January 1965

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Archer C7 (EU&US) Datasheet 5.0Document7 paginiArcher C7 (EU&US) Datasheet 5.0Nassar Al-EssawiÎncă nu există evaluări

- Front Power Seat Control System For Camry2009Document4 paginiFront Power Seat Control System For Camry2009Nassar Al-EssawiÎncă nu există evaluări

- GENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFDocument43 paginiGENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFhasib_07Încă nu există evaluări

- Hall 00 SDocument34 paginiHall 00 SNassar Al-EssawiÎncă nu există evaluări

- Front Power Seat Control System For Camry2009Document4 paginiFront Power Seat Control System For Camry2009Nassar Al-EssawiÎncă nu există evaluări

- Power Mirror Control System: Parts LocationDocument24 paginiPower Mirror Control System: Parts LocationNassar Al-EssawiÎncă nu există evaluări

- New Headway Intermediate 4th Students Book PDFDocument8 paginiNew Headway Intermediate 4th Students Book PDFNassar Al-Essawi50% (2)

- Wiper and WasherDocument29 paginiWiper and WasherNassar Al-EssawiÎncă nu există evaluări

- 2GR-FE Ignition PDFDocument12 pagini2GR-FE Ignition PDFNassar Al-Essawi100% (1)

- طبعتFluid Specs PDFDocument10 paginiطبعتFluid Specs PDFNassar Al-EssawiÎncă nu există evaluări

- 2GR-FE Exhaust PDFDocument5 pagini2GR-FE Exhaust PDFNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- 2GR-FE Oil Filter Replacement GuideDocument20 pagini2GR-FE Oil Filter Replacement GuideNassar Al-EssawiÎncă nu există evaluări

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 paginiToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsÎncă nu există evaluări

- Axle System: Problem Symptoms TableDocument21 paginiAxle System: Problem Symptoms TableNassar Al-EssawiÎncă nu există evaluări

- Emission Control System: Parts LocationDocument23 paginiEmission Control System: Parts LocationNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- صادية عبيد بن الابرصDocument38 paginiصادية عبيد بن الابرصNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- P 09-11 PDFDocument3 paginiP 09-11 PDFNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System Communication SignalsDocument3 paginiElectronic Power Steering System Communication SignalsNassar Al-EssawiÎncă nu există evaluări

- Electronic Power Steering System: PrecautionDocument2 paginiElectronic Power Steering System: PrecautionNassar Al-EssawiÎncă nu există evaluări

- P 01-02Document77 paginiP 01-02Nassar Al-EssawiÎncă nu există evaluări

- On-Vehicle Inspection: Power Steering - Power Steering SystemDocument1 paginăOn-Vehicle Inspection: Power Steering - Power Steering SystemNassar Al-EssawiÎncă nu există evaluări

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 paginiToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Wassce / Waec Chemistry Syllabus: 1. Structure of The AtomDocument30 paginiWassce / Waec Chemistry Syllabus: 1. Structure of The AtomJesse Lartey100% (1)

- Water Labs FullDocument4 paginiWater Labs FulljohnosborneÎncă nu există evaluări

- Practice Periodical Structural Design ConstructionDocument4 paginiPractice Periodical Structural Design ConstructionSen HuÎncă nu există evaluări

- Physics 12 - Vector Kinematics Practice Test KeyDocument4 paginiPhysics 12 - Vector Kinematics Practice Test KeyAnna Marthea VeronichaÎncă nu există evaluări

- Aircooled Heat Exchanger Process Data SheetDocument2 paginiAircooled Heat Exchanger Process Data SheetamitkrayÎncă nu există evaluări

- VJC H2 Chem P2Document18 paginiVJC H2 Chem P2clarissa yeoÎncă nu există evaluări

- Chiller Carrier 30XA-400Document26 paginiChiller Carrier 30XA-400EdwinRamirezÎncă nu există evaluări

- Kea - Kar.nic - in Vikasana Timetable May2012Document5 paginiKea - Kar.nic - in Vikasana Timetable May2012saraÎncă nu există evaluări

- Machine Elements Tutorial on Screw Design and EfficiencyDocument2 paginiMachine Elements Tutorial on Screw Design and EfficiencydvarsastryÎncă nu există evaluări

- Chapter 9/19 (71 Marks) : MarkschemeDocument28 paginiChapter 9/19 (71 Marks) : MarkschemeSemwezi EnockÎncă nu există evaluări

- Measuring Devices (Sensors & Transducers)Document16 paginiMeasuring Devices (Sensors & Transducers)mani.mit2005Încă nu există evaluări

- Chevron GST 2300Document2 paginiChevron GST 2300Asuh Rifqi PrihandanaÎncă nu există evaluări

- Physics Final Exam I ReviewDocument58 paginiPhysics Final Exam I ReviewNicole WheelerÎncă nu există evaluări

- Reverse Bias: Understanding Avalanche BreakdownDocument12 paginiReverse Bias: Understanding Avalanche BreakdownMuhmmad hamza TahirÎncă nu există evaluări

- Ae 1299 R5Document16 paginiAe 1299 R5last730Încă nu există evaluări

- AISC ASD Base Plate Thickness V2016-2Document9 paginiAISC ASD Base Plate Thickness V2016-2yusuf_jtÎncă nu există evaluări

- Evaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesDocument14 paginiEvaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesGözde BayazitÎncă nu există evaluări

- Cartabond EZI Liquid FTDocument4 paginiCartabond EZI Liquid FTMiguel Perenguez100% (1)

- Mis Ce2201Document2 paginiMis Ce2201Ashan ShamikaÎncă nu există evaluări

- HewlettPackard OptoelectronicsApplicationsManualOCRDocument292 paginiHewlettPackard OptoelectronicsApplicationsManualOCRAbraham JyothimonÎncă nu există evaluări

- Electromagnetism ReferencesDocument7 paginiElectromagnetism ReferencesNivethithaa DhanrajÎncă nu există evaluări

- Fans and BlowersDocument51 paginiFans and BlowersJohn Kennedy FernandesÎncă nu există evaluări

- Fluid Flow OperationDocument2 paginiFluid Flow OperationShubham imtsÎncă nu există evaluări

- Automotive Air Conditioning SystemDocument46 paginiAutomotive Air Conditioning SystemHimanshu Katara80% (5)

- NVH Ford PDFDocument188 paginiNVH Ford PDFReshma Mohamed71% (7)

- Cryogenic Emissivity Properties of Ball Infrared Black: Articles You May Be Interested inDocument9 paginiCryogenic Emissivity Properties of Ball Infrared Black: Articles You May Be Interested inRev TamasÎncă nu există evaluări

- Di Bella Et Al 2004Document13 paginiDi Bella Et Al 2004Emilio Patané SpataroÎncă nu există evaluări

- Design and Analysis of Multistoried Commercial Building (g+4) Using Staad Pro & Manual DesigningDocument6 paginiDesign and Analysis of Multistoried Commercial Building (g+4) Using Staad Pro & Manual DesigningSarah FatimaÎncă nu există evaluări

- Psychrometric Chart SIDocument1 paginăPsychrometric Chart SItleeanneraÎncă nu există evaluări

- Light Interference Tutorial and AssignmentsDocument4 paginiLight Interference Tutorial and AssignmentsRitesh MeelÎncă nu există evaluări