Documente Academic

Documente Profesional

Documente Cultură

Zirconia Dental Implants - A Literature Review

Încărcat de

Ledir Luciana Henley de AndradeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Zirconia Dental Implants - A Literature Review

Încărcat de

Ledir Luciana Henley de AndradeDrepturi de autor:

Formate disponibile

LITERATURE REVIEW

Zirconia Dental Implants:

A Literature Review

Zeynep Ozkurt, DDS, PhD*

Ender Kazazoglu, DDS, PhD

Titanium and titanium alloys are widely used for fabrication of dental implants. Because of

potential immunologic and possible esthetic compromises with titanium implants, novel

implant technologies are being developed. However, these novel technologies must

maintain the characteristics that provide titanium implants with their high success rates.

Zirconia implants were introduced into dental implantology as an alternative to titanium

implants. Zirconia seems to be a suitable implant material because of its toothlike color,

mechanical properties, biocompatibility, and low plaque affinity. The aim of this study is to

review clinical and research articles conducted on zirconia dental implants, compare them

with titanium dental implants, and provide information on zirconia dental implant

osseointegration and mechanical strength. Zirconia dental implants have the potential to

become alternative dental implants to titanium dental implants, but they are not yet in

routine clinical use.

Key Words: zirconia, dental, implant

INTRODUCTION which forms the basis of its biocompatibility.

The properties of the oxide layer are of great

T

he rehabilitation of completely

importance for the biological outcome of the

and partially edentulous patients

osseointegration of titanium implants.4

with dental implants is a scientif-

The principal disadvantage of titanium is

ically accepted and well docu-

its dark grayish color, which often is visible

mented treatment modality.1

through the peri-implant mucosa, therefore

Currently, titanium and titanium alloys are

impairing esthetic outcomes in the presence

the materials most often used in implant

of a thin mucosal biotype. Unfavorable soft

manufacturing and have become a gold

tissue conditions or recision of the gingiva

standard for tooth replacement in dental

may lead to compromised esthetics. This is of

implantology. These materials have attained

great concern when the maxillary incisors are

mainstream use because of their excellent

involved.5 Furthermore, reports suggest that

biocompatibility, favorable mechanical prop-

metals are able to induce a nonspecific

erties, and well documented beneficial re-

immunomodulation and autoimmunity.6 Gal-

sults.2,3 When exposed to air, titanium

vanic side effects after contact with saliva and

immediately develops a stable oxide layer,

fluoride are also described.7 Although allergic

reactions to titanium are very rare, cellular

Department of Prosthodontics, Faculty of Dentistry,

Yeditepe University, Goztepe, Istanbul, Turkey. sensitization has been demonstrated.8,9

* Corresponding author, e-mail: zeynepozkurt@hotmail. Because of these disadvantages, novel

com

DOI: 10.1563/AAID-JOI-D-09-00079 implant technologies that produce ceramic

Journal of Oral Implantology 367

Zirconia Dental Implants: A Literature Review

implants are being developed.10 However, Japan), the Konus system (Konus Dental,

ceramics are known to be sensitive to shear Bingen, Germany), the Z-systems (Z-systems,

and tensile loading, and surface flaws may Konstanz, Germany), and the Ziterion system

lead to early failure. These realities imply a (Ziterion, Uffenheim, Germany).

high risk for fracture.11 In recent years, high- Material composition and surface topog-

strength zirconia ceramics have become raphy of a biomaterial play a fundamental

attractive as new materials for dental im- role in osseointegration. According to Al-

plants. They are considered to be inert in the brektsson et al, the quality of the implant

body and exhibit minimal ion release com- surface is one major factor that influences

pared with metallic implants. Yttrium-stabi- wound healing at the implantation site

lized tetragonal zirconia polycrystals appear and subsequently affects osseointegration.17

to offer advantages over aluminum oxide for Therefore, various chemical and physical

dental implants because of their higher surface modifications have been developed

fracture resilience and higher flexural to improve osseous healing.2 To improve

strength.12 They have also been used suc- surface properties, 2 main approaches may

cessfully in orthopedic surgery to manufac- be used, such as optimizing the micro-

ture ball heads for total hip replacements; roughness (sandblasting, acid-etching) or

this is still the current main application of applying bioactive coatings (calcium phos-

this biomaterial.13,14 Zirconia seems to be a phate, bisphosphonate, collagen).18 The clin-

suitable dental implant material because of ical use of zirconia dental implants is limited

its toothlike color, mechanical properties, because fabrication of surface modifications

and therefore biocompatibility.2 Apical bone is difficult, and smooth implant surfaces are

loss and gingival recession associated with not beneficial for osseointegration because

implants often uncover portions of the metal of poor interaction with tissues.19

implant, revealing a bluish discoloration of Although zirconia may be used as an

the overlying gingiva. The use of zirconia implant material by itself, zirconia particles

implants avoids this complication and ac- are also used as a coating material of titanium

cedes to the request of many patients for dental implants. A sandblasting process with

metal-free implants. The material also pro- round zirconia particles may be an alternative

vides high strength, fracture toughness, and surface treatment to enhance the osseointe-

biocompatibility.14 The inflammatory re- gration of titanium implants.

sponse and bone resorption induced by Many research articles have been written

ceramic particles are less than those induced about zirconia dental implants. Thus, the

by titanium particles, suggesting the bio- purpose of this review is to summarize

compatibility of ceramics.15,16 research articles conducted on zirconia

Currently, 9 zirconia dental implant sys- dental implants, compare them with titani-

tems are commercially available. The Sigma um dental implants, and provide information

implant (Sandhause, Incermed, Lausanne, on zirconia dental implant osseointegration.

Switzerland), which was developed in 1987,

was the first zirconia dental implant system.

MATERIALS AND METHODS

Additional zirconia implant systems are the

CeraRoot system (Oral Iceberg, Barcelona, This review started with a PubMed search

Spain), the ReImplant system (ReImplant, from 1975 to 2009. The search was conduct-

Hagen, Germany), the White Sky system ed using the following key words: zirconia or

(Bredent Medical, Senden, Germany), the zirconium dioxide, dental, and implant. The

Goei system (Goei Inc, Akitsu-Hiroshima, full text of articles was obtained where

368 Vol. XXXVII/No. Three/2011

Ozkurt and Kazazoglu

possible. If it was not possible to obtain a full zirconia could be considered a superior

text, the electronically available abstracts ceramic coating to alumina. Nordlund et al21

were collected. Thus, the inclusion criteria studied the tissue integration of 3 types of

for articles were as follows: (1) Articles were implant materials in monkeys: (1) alumina with

related to zirconia dental implants, and (2) 4% zirconia and 25% magnesia, (2) alumina

abstracts were obtained when the full texts with 25% silicon carbide, and (3) unalloyed

could not be obtained. Articles about titanium implants. No difference in tissue

zirconia implants for orthopedic usage were reaction around these 3 types of implant

excluded from the review. materials was observed after 68 months.

Franchi et al22 evaluated peri-implant

tissues of zirconia-coated titanium implants

RESULTS

and acid-etched titanium implants by light

The PubMed search resulted in 108 articles. microscopy. All implants showed new bone

The total number of papers that met the trabeculae, vascularized medullary spaces,

inclusion criteria for this review was 37. Of and close contact with preexisting bone at

these, 30 were laboratory studies, 3 were 2 weeks. Franchi et al23 also evaluated in an

clinical studies, 2 were case reports, and 2 animal study peri-implanted tissues for

were review articles. titanium implants with different surfaces

Most of the studies were conducted smooth, titanium plasma sprayed, and zirco-

in vitro.1,2,11,18,2045 Osseointegration and nia blasted. At 3 months, it was observed

bone-implant contact (BIC) were investigat- that implant surface morphology strongly

ed in 18 articles,2,18,2035 surface analyses in 4 influenced the rate and the modality of peri-

articles,1,3638 removal torque testing (RTQ) implant osteogenesis. Rough surfaces and in

in 4 studies,1,3941 mechanical strength in 4 particular zirconia-blasted implants seemed

articles,11,4244 and stress analyses in 1 arti- to favor bone deposition on the titanium

cle.45 Three clinical studies involved clinical surface. In another study, the same group24

survival rate.4648 Other published articles investigated peri-implant osteogenesis and

were case reports49,50 and reviews.51,52 biologic fixation for various zirconia sand-

blasted titanium implant surfaces and a

1. Osseointegration, histologic analyses, machined titanium surface. The highest

and BIC

values for BIC, bone ingrowth, and Vickers

Eighteen articles discussed osseous healing, hardness were measured in implants sand-

histologic analyses, and BIC of zirconia blasted with zirconia particles, which have

dental implants.2,18,2035 Seven of these higher surface roughness (arithmetical mean

articles evaluated zirconia as a coating roughness [Ra]: 1.52 mm, maximum peak [Rt]:

material,2026 and 11 evaluated zirconia 12.06 mm, and ten-point mean roughness

dental implants.2,18,2735 [Rz]: 11.54 mm), followed by zirconia sand-

blasted implants with lower surface rough-

Zirconia as a Coating Material

ness (Ra: 1.32 mm, Rt: 8.76 mm, and Rz:

Cranin et al20 investigated the osseointegra- 8.86 mm).

tion of vitallium implants with the addition Sollazo et al25 observed titanium implant

of ceramic coatings, such as alumina (n 5 9) surfaces coated with zirconia, which can

or zirconia (n 5 9). All alumina-coated potentially have specific biologic effects. The

vitallium implants and 5 of the zirconia- BIC percentage was 31.8 6 3.05% for

coated vitallium implants failed after uncoated titanium implants and 43.8 6

32 weeks. Investigators concluded that 2.05% for titanium implants coated with

Journal of Oral Implantology 369

Zirconia Dental Implants: A Literature Review

zirconia at 4 weeks. It was found that and zirconia (Sigma, Lausanne, Switzerland);

zirconia coating would enhance implant these were placed into the dog mandible. At

osseointegration. Bacchelli et al26 examined 10 months, BIC was found to be 68% for

peri-implant osseointegration and found the alumina, 64.6% for zirconia, and 54% for

following: Machined titanium implants had titanium. No statistically significant differ-

34.5% BIC, titanium plasma-sprayed titanium ence was noted between the 3 types of

implants had 44.7% BIC, alumina-blasted implants. Scarano et al30 demonstrated the

titanium implants had 53.4% BIC, and bone response to zirconia implants at

zirconia-blasted titanium implants had 4 weeks. A great quantity of newly formed

35.5% BIC at 2 weeks. This was the only bone was observed with zirconia surfaces,

study that found zirconia coating was not and the percentage of BIC was 68.4%. These

superior to the other groups; this finding studies concluded that zirconia implants are

may be attributed to short evaluation time highly biocompatible and osteoconductive.

(2 weeks). Mosgau et al31 evaluated the BIC of

zirconia endodontic endosseous cones in

Zirconia as an Implant

apicectomy. The ratio between the total

Akagawa et al27 examined the initial implant- cone/bone contact circumference (ram) and

bone interface with the 1-stage zirconia screw the total cone/fibrous tissue contact circum-

implant (Goei Industry, Akitsu-Hiroshima, ference (ram) was 0.95 on the titanium

Japan) with different occlusal loading condi- surface and 1.47 on the zirconia surface. This

tions after 3 months in beagle dogs. In the indicates that, proportionately speaking,

nonloaded group, no superstructure was significantly greater bony healing was seen

seen; the loaded group had metal superstruc- on the zirconia surface than on the titanium

tures. At 3 months, no significant difference surface.

was noted for BIC between the 2 groups. The Kohal et al32 evaluated the soft and hard

BIC was 81.9% for the nonloaded group and tissue conditions of sandblasted zirconia

69.8% for the loaded group. The same implants (ReImplant, Hagen, Germany) and

researchers28 observed the role of osseointe- compared them with sandblasted and acid-

gration around the 1-stage zirconia screw etched (SLA) titanium implants. The mean

implant (Goei) with various conditions for mineralized BIC achieved after 9 months of

loading support after 2 years of function in healing and 5 months of loading was 72.9%

monkeys. Three types of superstructure were for titanium implants and 67.4% for zirconia

provided in each animal to obtain different implants.

concepts of support: (1) single freestanding Hoffmann et al33 histologically assessed

implants, (2) connected freestanding im- the degree of early bone apposition around

plants, and (3) a combination of implant and zirconia dental implants (Z-system, Konstanz,

tooth. Clinically, all implants were immobile Germany) at 2 and 4 weeks following

for 24-month loading, and healthy peri- insertion. The zirconia implants demonstrat-

implant mucosa was achieved in the single ed a slightly higher degree of bone apposi-

freestanding, connected freestanding, and tion (54%55%) compared with the titanium

implant-tooth support groups, with favorable implants (42%52%) at the 2-week time

values for clinical parameters. Histologically, point, but bone apposition was higher in

the direct bone-implant interface was gener- titanium (68%91%) than in zirconia (62%

ally attained in all observed zirconia implants. 80%) at 4 weeks.

Dubruille et al29 compared the BIC on 3 Langhoff et al18 compared the BIC of

types of dental implants: titanium, alumina, chemically modified (plasma-anodized or

370 Vol. XXXVII/No. Three/2011

Ozkurt and Kazazoglu

coated with calcium phosphate) titanium BIC was slightly better on titanium than on

implants, pharmacologically coated (bis- zirconia surfaces. However, a statistically

phosphonate or collagen type I with chon- significant difference between the 2 groups

droitin sulphate) titanium implants, SLA was not observed. Results demonstrated

titanium implants, and SLA zirconia implants. that zirconia implants with modified surfaces

The zirconia implants presented 20% more resulted in an osseointegration that was

bone contact than the titanium implants at comparable with that of titanium implants.

2 weeks, improved toward 4 weeks, then

2. Surface analyses

were reduced at 8 weeks. Although statisti-

cally not significant, a clear tendency was Surface analyses were performed in 4

noted for the chemically and pharmacolog- studies.1,3638 In the first study, Yang et al36

ically modified implants to show better BIC investigated zirconia with 4% CeO2 and

values at 8 weeks compared with the anodic zirconia with 3% Y2O3 coatings, which were

plasma treated-surface of zirconia implants. deposited on titanium and CoCrMo implants

All titanium implants had similar BIC at using the plasma spraying technique. Adhe-

2 weeks (57%61%); only zirconia was found sive, morphologic, and structural properties

to be better (77%). of the plasma-sprayed coatings were evalu-

In a study conducted by Deprich et al,34 ated. The average surface roughness of

24 screw-type zirconia implants (Konus zirconia with 3% Y2O3 and of zirconia with

Dental, Bingen, Germany) with acid-etched 4% CeO2 was correlated with the starting

surfaces were compared with 24 implants of powder size and substrates. The size of

commercially pure titanium with acid-etched zirconia with 3% Y2O3 powders was 40

surfaces. At 12 weeks, ultrastructural evi- 100 mm, and the size of zirconia with 4%

dence of successful osseointegration of both CeO2 powders was 1020 nm. No significant

implant systems was found. No significant difference was observed between the hard-

differences in strength and stiffness of ness of all coatings and substrates. The

attachment between the 2 implant designs adhesive strength of zirconia with 4% CeO2

were detected at this time point. The same coating to titanium and CoCrMo substrates

researchers compared osteoblast behavior was higher than 68 MPa and significantly

on structured zirconia (Konus) and titanium greater than that of zirconia with 3% Y2O3

surfaces in another study.35 Attachment coatings (32.3 MPa for titanium and 24.7 MPa

kinetics, proliferation rate, and synthesis of for CoCrMo).

bone-associated proteins on both surfaces In the other study,37 machined zirconia,

were examined and compared. At day 1, cell sandblasted zirconia, and SLA zirconia sur-

proliferation of zirconia surfaces was similar faces were evaluated. The surface roughness

to that of titanium surfaces. At day 3, cell of zirconia was increased by airborne particle

growth was significantly higher on the abrasion and additionally by acid-etching.

zirconia surfaces than on the titanium Cell proliferation revealed statistically signif-

surfaces. At day 5, cell proliferation contin- icant greater values at 3 days for surface-

ued to be significantly higher on zirconia treated zirconia as compared with machined

surfaces than on titanium surfaces. In the last zirconia. However, no differences were ob-

study conducted by this group,2 the osseous served between the zirconia groups and SLA

healing of zirconia implants (Konus) was titanium at 6 and 12 days.

compared with that of acid-etched titanium In another study,1 Gahlert et al examined

implants with the same macroscopic design zirconia implants with a machined or a

in an animal experiment. At 1, 4, or 12 weeks, sandblasted surface and compared them

Journal of Oral Implantology 371

Zirconia Dental Implants: A Literature Review

with SLA titanium implants. Surface analyses and implant, as well as the cell compatibility

revealed that the highest surface roughness of screw-shaped titanium dental implants.

was measured for the SLA titanium implant, Biomechanical testing was carried out at 2, 6,

followed by the sandblasted zirconia implant and 18 weeks healing time points. An

and the machined zirconia implant. In the increase in RTQ values was noted in the

last study conducted by Stubinger et al,38 bone-implant interface with time, and the

the influence of erbium-doped yttrium highest increment in bond strength was

aluminium garnet (Er:YAG), carbon dioxide recorded for implants coated with 50%

(CO2), and diode laser irradiation on surface hydroxyapatite and 50% zirconia. The inter-

properties of polished zirconia implants was face reaction of bone toward coated im-

evaluated. SEM analyses demonstrated that plants was faster than toward uncoated

diode and Er:YAG lasers did not cause any ones.

visible surface alterations. However, the CO2 Ferguson et al41 compared the biome-

laser produced distinct surface alterations to chanical properties of 6 types of implant

zirconia. surfaces and found the RTQ values of SLA

titanium as 1884 N/mm, SLA and calcium

3. RTQ (removal torque testing)

phosphate (CaP)-coated titanium as 1683

Sennerby et al39 observed bone tissue N/mm, SLA and anodic plasma chemical

responses to machined and surface-modified surface-treated titanium as 919 N/mm, SLA

zirconia implants. To achieve a porous and bisphosphonate-coated titanium as

surface, the zirconia implants were coated 1835 N/mm, SLA and collagen-coated titani-

with 2 different slurries containing zirconia um as 1593 N/mm, and SLA zirconia as

powder and a pore-former, which gave 1005 N/mm. At 8 weeks, RTQ values of

different surface structures. Noncoated zir- zirconia were significantly lower.

conia implants were used as controls. In

4. Strength

addition, titanium implants were used. The

coated zirconia implants and the titanium Minamizato et al42 investigated the com-

implants showed higher RTQ than the pressive strength of the blade type of

machined zirconia implants. zirconia dental implants with tunnels drilled

Gahlert et al1 evaluated the RTQ values of by laser process, and found that specimens

machined zirconia implants, sandblasted with tunnels showed lower compressive

zirconia implants, and SLA titanium implants. strength (237 kg/mm2) than specimens

The machined zirconia implants showed without tunnels (371.5 kg/mm2). They con-

statistically significant lower RTQ values than cluded that zirconia blades had adequate

the other 2 implant types after 8 and strength in occlusion.

12 weeks, and the SLA titanium implant Kohal et al43 evaluated the fracture

showed significantly higher RTQ values than strength of titanium implants with metal-

the sandblasted zirconia surface at 8 weeks. ceramic crowns, zirconia implants with Em-

The mean RTQ for machined zirconia im- press I crowns, and zirconia implants with

plants was 25.9 N/cm, the mean RTQ for Procera (Al2O3 based) crowns before and

zirconia rough implants was 40.5 N/cm, and after exposure to the artificial mouth. In the

the mean RTQ for SLA titanium implants was nonloaded group, fracture strength was

105.2 N/cm. 531.4 N for titanium, 512.9 N for zirconia-

Alzubaydi et al40 evaluated the effects of Empress I, and 575.7 N for zirconia-Procera.

ceramic coatings (hydroxyapatite and zirco- After a chewing load of 1.2 million cycles,

nia) on the bond strength between bone fracture strength was 668.6 N for titanium,

372 Vol. XXXVII/No. Three/2011

Ozkurt and Kazazoglu

410.7 N for zirconia-Empress I, and 555.5 N osseointegration and soft tissue response

for zirconia-Procera. Fracture values for that is superior to that of titanium dental

metal-ceramic and Procera crowns after implants. Oliva et al47 reported the first

artificial loading were significantly higher clinical evaluation of 100 zirconia implants

than for the loaded Empress I crowns. (CeraRoot, Barcelona, Spain) with 2 different

Zirconia implants restored with the Procera surface roughnesses in humans after 1 year

crowns possibly fulfill the biomechanical of follow-up. Two implants failed after

requirements for anterior teeth. 15 days. These failed implants were placed

Silva et al44 examined the effects of full in situations where sinus elevation was

crown preparation on the reliability of the 1- required. The overall success rate was

piece zirconia implant. They found that the reported as 98%. Given the sinus elevation

fracture strength of zirconia implants without requirement, future investigators may ex-

preparation was 1023.3 N, and with full crown clude patients with less than 5 mm residual

preparation was 1111.7 N. However, in bone. Pirker et al48 placed a zirconia implant

another study, it was concluded that prepa- to the maxillary first premolar region imme-

ration of the implant heads had a significantly diately and evaluated the clinical outcome of

negative influence on implant fracture this implant. At 2-year follow-up, a stable

strength.11 Investigators evaluated the frac- implant and an unchanged peri-implant

ture strength of 1-piece zirconia implants marginal bone level were observed. No

(Sigma) after exposure to the artificial mouth, bleeding was detected on probing.

where a clinical service of 5 years was

7. Case reports

simulated. Zirconia implant fracture occurred

at 725 to 850 N when the implant heads were Kohal et al49 presented the first clinical case

not prepared, and at 539 to 607 N when report of a zirconia dental implant in the

prepared. They concluded that the mean literature. A custom-made 2-piece zirconia

fracture strength of zirconia implants ranged implant was used to replace a left upper

within the limits of clinical acceptance. central incisor with zirconia abutment and a

zirconia-based single crown. Furthermore,

5. Stress analysis

Oliva et al50 reported the first clinical case

One study evaluated stress analysis. Kohal et of an ovoid zirconia dental implant. An

al45 observed the stress distribution patterns anatomically oriented ovoid zirconia implant

of zirconia implants (ReImplant), which were (CeraRoot Type 14), which was specially

found to have low, well distributed, and designed to replace a missing premolar,

similar stress distribution compared with was discussed.

titanium implants. These patterns could be

characterized as favorable or nondestructive.

CONCLUSION

Stress values were found to be similar for

both models for all regions. On the basis of available peer-reviewed data,

osseointegration of zirconia dental implants

6. Clinical studies

may be comparable with that of titanium

Three clinical studies investigated zirconia implants. They were also found to have low,

implants. Blaschke et al46 reported that well distributed, and similar stress distribu-

dental implants made from zirconia are a tion when compared with titanium implants.

feasible alternative to titanium dental im- Furthermore, zirconia particles used for

plants. In addition to excellent cosmetic surface modifications of titanium implants

results, zirconia implants allow a degree of may have the potential to improve initial

Journal of Oral Implantology 373

Zirconia Dental Implants: A Literature Review

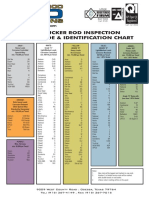

TABLE 1

In vitro studies examining bone-implant contact of different implants

Investigator Type of Implant Follow-up Period Bone-Implant Contact, %

Akagawa, 1993 Nonloaded zirconia 3 mo 81.9

Loaded zirconia 3 mo 69.8

Dubruille, 1999 Titanium 10 mo 54

Alumina 10 mo 68

Zirconia 10 mo 64.6

Scarano, 2003 Zirconia 4 wk 68.4

Kohal, 2004 Sandblasted zirconia 14 mo 67.4

Sandblasted titanium 14 mo 72.9

Hoffmann, 2008 Titanium 2 wk 4252

Zirconia 2 wk 5455

Titanium 4 wk 6891

Zirconia 4 wk 6280

Sollazzo, 2008 Titanium 4 wk 31.8

Zirconia-coated titanium 4 wk 43.8

Bacchelli, 2009 Machined titanium 2 wk 34.5

Titanium plasma-sprayed titanium 2 wk 44.7

Aluminum-blasted titanium 2 wk 53.4

Zirconia-blasted titanium 2 wk 35.5

bone healing and resistance to removal of be beneficial. Although a few short-term

torque. The surface roughness of zirconia clinical reports are available and provide

was found to be comparable with that of satisfactory results, controlled clinical trials

titanium implants. Although fabrication of with a follow-up of 5 years or longer should

surface modifications for zirconia is difficult, be performed to properly evaluate the

CO2 lasers revealed distinct surface alter- clinical performance of zirconia implants

ations to zirconia, and additional studies and to recommend them for routine clinical

about this technique may help to improve use.

surface roughness. Coated or surface-modi-

fied zirconia implants showed higher remov-

ABBREVIATIONS

al torque values than machined zirconia

implants. To fulfill biomechanical require- BIC: bone-implant contact

ments, restoring zirconia implants with high- CaP: calcium phosphate

strength ceramics or metal ceramics would CO2: carbon dioxide

TABLE 2

Removal torque testing (RTQ) evaluation according to surface characteristic of implants

Investigator Surface Characteristics of Implants* Results of RTQ

Gahlert, 2007 Machined zirconia 25.9 N/cm

Sandblasted zirconia 40.5 N/cm

SLA titanium 105.2 N/cm

Sennerby, 2005 Machined zirconia Significantly lower RTQ values

Surface-coated zirconia

Titanium

Ferguson, 2008 SLA titanium 1884 N/mm

SLA + CaP-coated titanium 1683 N/mm

SLA + anosdic plasma-treated titanium 919 N/mm

SLA + bisphosphonate-coated titanium 1835 N/mm

SLA + collagen-coated titanium 1593 N/mm

SLA zirconia 1005 N/mm

*CaP indicates calcium phosphate; SLA, sandblasted and acid-etched.

374 Vol. XXXVII/No. Three/2011

Ozkurt and Kazazoglu

Er:YAG: erbium-doped yttrium aluminium quirements for ensuring a longlasting, direct bone-to-

implant anchorage in man. Acta Orthop Scand. 1981;52:

garnet 155170.

RTQ: removal torque testing 18. Langhoff JD, Voelter K, Scharnweber D, et al.

Comparison of chemically and pharmaceutically mod-

SLA: sandblasted and acid-etched ified titanium and zirconia implant surfaces in dentistry:

a study in sheep. Int J Oral Maxillofac Surg. 2008;37:

11251132.

19. Puleo DA, Thomas MV. Implant surfaces. Dent

REFERENCES Clin North Am. 2006;50:323338.

1. Gahlert M, Gudehus T, Eichhorn S, Steinhauser E, 20. Cranin AN, Schnitman PA, Rabkin SM, Onesto

Kniha H, Erhardt W. Biomechanical and histomorpho- EJ. Alumina and zirconia coated vitallium oral endosteal

metric comparison between zirconia implants with implants in beagles. J Biomed Mater Res. 1975;9:257

varying surface textures and a titanium implant in the 262.

maxilla of miniature pigs. Clin Oral Implants Res. 21. Nordlund A, Zetterqvist L, Oden A. A compar-

2007;18:662668. ative experimental investigation in monkeys between

three different implant materials. Int J Oral Maxillofac

2. Depprich R, Zipprich H, Ommerborn M, et al.

Surg. 1989;18:373377.

Osseointegration of zirconia implants compared with

22. Franchi M, Bacchelli B, Martini D, et al. Early

titanium: an in vivo study. Head Face Med. 2008;4:30.

detachment of titanium particles from various different

3. Steinemann SG. Titaniumthe material of

surfaces of endosseous dental implants. Biomaterials.

choice? Periodontol 2000. 1998;17:721.

2004;25:22392246.

4. Sykaras N, Iacopino AM, Marker VA, Triplett RG,

23. Franchi M, Orsini E, Trire A, et al. Osteogenesis

Woody RD. Implant materials, designs, and surface

and morphology of the peri-implant bone facing dental

topographies: their effect on osseointegration. A

implants. Scientific World Journal. 2004;4:10831095.

literature review. Int J Oral Maxillofac Implants.

24. Franchi M, Bacchelli B, Giavaresi G, et al.

2000;15:675690.

Influence of different implant surfaces on peri-implant

5. Heydecke G, Kohal R, Glaser R. Optimal esthetics

osteogenesis: histomorphometric analysis in sheep. J

in singletooth replacement with the re-implant system:

Periodontol. 2007;78:879888.

a case report. Int J Prosthodont. 1999;12:184189.

25. Sollazzo V, Pezzetti F, Scarano A, et al.

6. Stejskal J, Stejskal VD. The role of metals in Zirconium oxide coating improves implant osseointe-

autoimmunity and the link to neuroendocrinology. gration in vivo. Dent Mater. 2008;24:357361.

Neuroendocrinol Lett. 1999;20:351364. 26. Bacchelli B, Giavaresi G, Franchi M, et al.

7. Tschernitschek H, Borchers L, Geurtsen W. Influence of a zirconia sandblasting treated surface on

Nonalloyed titanium as a bioinert metala review. peri-implant bone healing: an experimental study in

Quintessence Int. 2005;36:523530. sheep. Acta Biomater. 2009;5:22462257.

8. Valentine-Thon E, Schiwara HW. Validity of 27. Akagawa Y, Ichikawa Y, Nikai H, Tsuru H.

MELISA for metal sensitivity testing. Neuroendocrinol Interface histology of unloaded and early loaded

Lett. 2003;24:5764. partially stabilized zirconia endosseous implant in initial

9. Yamauchi R, Morita A, Tsuji T. Pacemaker bone healing. J Prosthet Dent. 1993;69:599604.

dermatitis from titanium. Contact Dermatitis. 2000;42: 28. Akagawa Y, Hosokawa R, Sato Y, Kamayama K.

5253. Comparison between freestanding and tooth-connect-

10. Kohal RJ, Klaus G. A zirconia implant-crown ed partially stabilized zirconia implants after two years

system: a case report. Int J Periodontics Restorative Dent. function in monkeys: a clinical and histologic study. J

2004;24:147153. Prosthet Dent. 1998;80:551558.

11. Andreiotelli M, Kohal RJ. Fracture strength of 29. Dubruille JH, Viguier E, Le Naour G, Dubruille

zirconia implants after artificial aging. Clin Implant Dent MT, Auriol M, Le Charpentier Y. Evaluation of combi-

Relat Res. 2009;11:158166. nations of titanium, zirconia, and alumina implants with

12. Sennerby L, Dasmah A, Larsson B, Iverhed M. 2 bone fillers in the dog. Int J Oral Maxillofac Implants.

Bone tissue responses to surface-modified zirconia 1999;14:271277.

implants: a histomorphometric and removal torque 30. Scarano A, Di Carlo F, Quaranta M, Piattelli A.

study in the rabbit. Clin Implant Dent Relat Res. Bone response to zirconia ceramic implants: an

2005;7(suppl 1):S13S20. experimental study in rabbits. J Oral Implantol.

13. Piconi C, Maccauro G, Muratori F, Brach del 2003;29:812.

Prever E. Alumina and zirconia ceramics in joint 31. Schultze-Mosgau S, Schliephake H, Radespiel-

replacements. J Appl Biomater Biomech. 2003;1:1932. Troger M, Neukam FW. Osseointegration of endodontic

14. Piconi C, Maccauro G. Zirconia as a ceramic endosseous cones: zirconium oxide vs titanium. Oral

biomaterial. Biomaterials. 1999;20:125. Surg Oral Med Oral Pathol Oral Radiol Endod. 2000;89:

15. Ichikawa Y, Akagawa Y, Nikai H, Tsuru H. Tissue 9198.

compatibility and stability of a new zirconia ceramic in 32. Kohal RJ, Weng D, Bachle M, Strub JR. Loaded

vivo. J Prosthet Dent. 1992;68:322326. custom-made zirconia and titanium implants show

16. Warashina H, Sakano S, Kitamura S, et al. similar osseointegration: an animal experiment. J

Biological reaction to alumina, zirconia, titanium and Periodontol. 2004;75:12621268.

polyethylene particles implanted onto murine calvaria. 33. Hoffmann O, Angelov N, Gallez F, Jung RE,

Biomaterials. 2003;24:36553661. Weber FE. The zirconia implant-bone interface: a

17. Albrektsson T, Branemark PI, Hansson HA, preliminary histologic evaluation in rabbits. Int J Oral

Lindstrom J. Osseointegrated titanium implants: re- Maxillofac Implants. 2008;23:691695.

Journal of Oral Implantology 375

Zirconia Dental Implants: A Literature Review

34. Depprich R, Zipprich H, Ommerborn M, et al. load: a pilot investigation. Clin Oral Implants Res.

Osseointegration of zirconia implants: an SEM obser- 2006;17:565571.

vation of the bone-implant interface. Head Face Med. 44. Silva NR, Coelho PG, Fernandes CA, Navarro JM,

2008;4:25. Dias RA, Thompson VP. Reliability of one-piece ceramic

35. Depprich R, Ommerborn M, Zipprich H, et al. implant. J Biomed Mater Res B Appl Biomater. 2009;88:

Behavior of osteoblastic cells cultured on titanium and 419426.

structured zirconia surfaces. Head Face Med. 2008;4:29. 45. Kohal RJ, Papavasiliou G, Kamposiora P, Tripo-

36. Yang Y, Ong JL, Tian J. Deposition of highly adhe- dakis A, Strub JR. Three-dimensional computerized

sive ZrO(2) coating on Ti and CoCrMo implant materials stress analysis of commercially pure titanium and

using plasma spraying. Biomaterials. 2003;24:619627. yttrium-partially stabilized zirconia implants. Int J

37. Bachle M, Butz F, Hubner U, Bakalinis E, Kohal Prosthodont. 2002;15:189194.

RJ. Behavior of CAL72 osteoblast-like cells cultured on 46. Blaschke C, Volz U. Soft and hard tissue

zirconia ceramics with different surface topographies. response to zirconium dioxide dental implantsa

Clin Oral Implants Res. 2007;18:5359. clinical study in man. Neuroendocrinol Lett. 2006;27

38. Stubinger S, Homann F, Etter C, Miskiewicz M, (suppl 1):6972.

Wieland M, Sader R. Effect of Er:YAG, CO(2) and diode 47. Oliva J, Oliva X, Oliva JD. One-year follow-up of

laser irradiation on surface properties of zirconia endoss- first consecutive 100 zirconia dental implants in

eous dental implants. Lasers Surg Med. 2008;40:223228. humans: a comparison of 2 different rough surfaces.

39. Sennerby L, Dasmah A, Larsson B, Iverhed M. Int J Oral Maxillofac Implants. 2007;22:430435.

Bone tissue responses to surface-modified zirconia 48. Pirker W, Kocher A. Immediate, non-sub-

implants: a histomorphometric and removal torque merged, root-analogue zirconia implant in single tooth

study in the rabbit. Clin Implant Dent Relat Res. replacement. Int J Oral Maxillofac Surg. 2008;37:293

2005;7(suppl 1):S13S20. 295.

40. Alzubaydi TL, Alameer SS, Ismaeel T, Alhijazi AY, 49. Kohal RJ, Klaus G. A zirconia implant-crown

Geetha M. In vivo studies of the ceramic coated titanium system: a case report. Int J Periodontics Restorative Dent.

alloy for enhanced osseointegration in dental applica- 2004;24:147153.

tions. J Mater Sci Mater Med. 2009;20(suppl 1):S35S42. 50. Oliva J, Oliva X, Oliva JD. Ovoid zirconia

41. Ferguson SJ, Langhoff JD, Voelter K, et al. implants: anatomic design for premolar replacement.

Biomechanical comparison of different surface modifi- Int J Periodontics Restorative Dent. 2008;28:609615.

cations for dental implants. Int J Oral Maxillofac 51. Lacefield WR. Materials characteristics of un-

Implants. 2008;23:10371046. coated/ceramic-coated implant materials. Adv Dent Res.

42. Minamizato T. Slip-cast zirconia dental roots 1999;13:2126.

with tunnels drilled by laser process. J Prosthet Dent. 52. Wenz HJ, Bartsch J, Wolfart S, Kern M.

1990;63:677684. Osseointegration and clinical success of zirconia dental

43. Kohal RJ, Klaus G, Strub JR. Zirconia-implant- implants: a systematic review. Int J Prosthodont.

supported all-ceramic crowns withstand long-term 2008;21:2736.

376 Vol. XXXVII/No. Three/2011

S-ar putea să vă placă și

- Orthodontically Driven Corticotomy: Tissue Engineering to Enhance Orthodontic and Multidisciplinary TreatmentDe la EverandOrthodontically Driven Corticotomy: Tissue Engineering to Enhance Orthodontic and Multidisciplinary TreatmentFederico BrugnamiÎncă nu există evaluări

- Implant and Periodontal ConsiderationsDocument53 paginiImplant and Periodontal ConsiderationsAlphonse ThangapradeepÎncă nu există evaluări

- Emerging Nanotechnologies in DentistryDe la EverandEmerging Nanotechnologies in DentistryKarthikeyan SubramaniÎncă nu există evaluări

- A New Classification Scheme For Periodontal and Peri-Implant Diseases and Conditions - Introduction and Key Changes From The 1999 ClassificationDocument8 paginiA New Classification Scheme For Periodontal and Peri-Implant Diseases and Conditions - Introduction and Key Changes From The 1999 Classificationvaleria Gonzalez BalloteÎncă nu există evaluări

- Berglundh Et Al (2018) - Peri Implant Diseases and Conditions - Consensus Report of Workgroup 4 - 1Document9 paginiBerglundh Et Al (2018) - Peri Implant Diseases and Conditions - Consensus Report of Workgroup 4 - 1FelipeOyarceSalazarÎncă nu există evaluări

- Peri Implant Disease PDFDocument32 paginiPeri Implant Disease PDFHajra FarooqÎncă nu există evaluări

- Endodontics or Implants. A Review of Decisive Criteria and GuidelinesDocument19 paginiEndodontics or Implants. A Review of Decisive Criteria and GuidelinesJuan David Torres CanoÎncă nu există evaluări

- Peri Implantitisetiologydiagnosisandmanagement PDFDocument49 paginiPeri Implantitisetiologydiagnosisandmanagement PDFRobins DhakalÎncă nu există evaluări

- 5 PDFDocument8 pagini5 PDFoskar ORTIZÎncă nu există evaluări

- Gingival Retraction Techniques: A Review: Dental Update April 2018Document10 paginiGingival Retraction Techniques: A Review: Dental Update April 2018Varun bharathiÎncă nu există evaluări

- Medical Engineering & PhysicsDocument6 paginiMedical Engineering & PhysicsLuis Fernando Guayllas PomaÎncă nu există evaluări

- #1 Rationale ImplantDocument5 pagini#1 Rationale Implantsohaib197Încă nu există evaluări

- Journal ClubDocument15 paginiJournal Clubperiodontics07Încă nu există evaluări

- Laser in PerioDocument24 paginiLaser in Periodhwanit31Încă nu există evaluări

- Transitioning Patients From Teeth To ImplantsDocument11 paginiTransitioning Patients From Teeth To ImplantsAlexandra DumitracheÎncă nu există evaluări

- 2006 Implant SurfacesDocument16 pagini2006 Implant SurfacesLukas Lopez RamirezÎncă nu există evaluări

- Berglundh Et Al-2018-Journal of Clinical PeriodontologyDocument6 paginiBerglundh Et Al-2018-Journal of Clinical PeriodontologyCristian CulcitchiÎncă nu există evaluări

- Perio 2000 VOL-76 Treatment of Pathologic Peri-Implant Pocket PDFDocument11 paginiPerio 2000 VOL-76 Treatment of Pathologic Peri-Implant Pocket PDFchandanaÎncă nu există evaluări

- Implant Loading Protocols For The Partially Edentulous Esthetic ZoneDocument11 paginiImplant Loading Protocols For The Partially Edentulous Esthetic ZoneKarla AlanisÎncă nu există evaluări

- Peri-Implantitis: Presented By: Kriti Dalmia. Moderated By: Dr. Shobha RDocument29 paginiPeri-Implantitis: Presented By: Kriti Dalmia. Moderated By: Dr. Shobha RDr Farhat100% (1)

- UntitledDocument70 paginiUntitledPerebyinis PavloÎncă nu există evaluări

- Prevention of Peri Implantitis A Narrative Review1Document7 paginiPrevention of Peri Implantitis A Narrative Review1asdÎncă nu există evaluări

- Dental Implants: Dr. D.M. Ajayi. August, 2017Document129 paginiDental Implants: Dr. D.M. Ajayi. August, 2017Kassim OboghenaÎncă nu există evaluări

- Oral Diagnosis and Treatment Planning: Part 7. Treatment Planning For Missing TeethDocument11 paginiOral Diagnosis and Treatment Planning: Part 7. Treatment Planning For Missing TeethalfredoibcÎncă nu există evaluări

- Implant Maintenance - A Clinical UpdateDocument9 paginiImplant Maintenance - A Clinical UpdateDr. Minkle GulatiÎncă nu există evaluări

- The Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisDocument17 paginiThe Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisBagis Emre GulÎncă nu există evaluări

- Immediate Loading Principles - Requirements - and Soft-Tissue Management PDFDocument11 paginiImmediate Loading Principles - Requirements - and Soft-Tissue Management PDFMahmoud Ahmad100% (1)

- Classification of Facial Peri-Implant Soft Tissue Zucchelli 2019 ColDocument9 paginiClassification of Facial Peri-Implant Soft Tissue Zucchelli 2019 ColSebastián BernalÎncă nu există evaluări

- Preprosthetic and Reconstructive SurgeryDocument32 paginiPreprosthetic and Reconstructive Surgeryruoiconmapu100% (1)

- Generic Root Form Component Terminology: Carl E. MischDocument11 paginiGeneric Root Form Component Terminology: Carl E. MischbubuvulpeaÎncă nu există evaluări

- Rethinking FerruleDocument10 paginiRethinking FerruleteodudeÎncă nu există evaluări

- 0 - A Clinical Guide To OcclusionDocument1 pagină0 - A Clinical Guide To Occlusionyhajo100% (1)

- The Role and Various Uses of Laser in Oral and Maxillofacial SurgeryDocument54 paginiThe Role and Various Uses of Laser in Oral and Maxillofacial SurgeryObinna IgwiloÎncă nu există evaluări

- Implant Occlusion Articles AbstractDocument4 paginiImplant Occlusion Articles AbstractMrunal DoiphodeÎncă nu există evaluări

- Relationship Between Bruxism and Temporomandibular Disorders: A Systematic Review of Literature From 1998 To 2008Document25 paginiRelationship Between Bruxism and Temporomandibular Disorders: A Systematic Review of Literature From 1998 To 2008AARON DIAZ RONQUILLOÎncă nu există evaluări

- The Biophysics of Mandibular Fractures - An Evolution Toward UnderstandingDocument13 paginiThe Biophysics of Mandibular Fractures - An Evolution Toward UnderstandingMikeunoeÎncă nu există evaluări

- JC 11 A Systematic Review of The Survival and ComplicationDocument41 paginiJC 11 A Systematic Review of The Survival and ComplicationMrinmayee ThakurÎncă nu există evaluări

- Os SEO IntegrationDocument45 paginiOs SEO IntegrationDrKrishna DasÎncă nu există evaluări

- Implant Course.Document76 paginiImplant Course.mustafaÎncă nu există evaluări

- Oral ImplantologyDocument26 paginiOral ImplantologyPrathik RaiÎncă nu există evaluări

- Peri-Implantitis: A Curse To ImplantsDocument11 paginiPeri-Implantitis: A Curse To ImplantsIJRASETPublicationsÎncă nu există evaluări

- Crestal Bone Changes On Platform - Switched Implants and Adjacent Teeth When The Tooth-Implant Distance Is Less Than 1.5 MMDocument10 paginiCrestal Bone Changes On Platform - Switched Implants and Adjacent Teeth When The Tooth-Implant Distance Is Less Than 1.5 MMJuanOso Gutierrez ArayaÎncă nu există evaluări

- Renvert Et Al (2018) - Peri Implant Health, Peri Implant Mucositis, and Peri Implantitis - Case Definitions and Diagnostic Considerations - 1Document9 paginiRenvert Et Al (2018) - Peri Implant Health, Peri Implant Mucositis, and Peri Implantitis - Case Definitions and Diagnostic Considerations - 1FelipeOyarceSalazarÎncă nu există evaluări

- Schwarz Et Al (2018) - Peri Implantitis - 1Document23 paginiSchwarz Et Al (2018) - Peri Implantitis - 1FelipeOyarceSalazarÎncă nu există evaluări

- 2010 - Rossouw, PE - A Historical Overview of The Development of The Acid Etch Bonding System in OrthodonticsDocument22 pagini2010 - Rossouw, PE - A Historical Overview of The Development of The Acid Etch Bonding System in Orthodonticsbajobajic100% (1)

- Implant Failure and Their ManagementDocument61 paginiImplant Failure and Their ManagementDharshiniÎncă nu există evaluări

- Peri-Implantitis: Srijana Heka Bds Iv Year Roll No: 17Document60 paginiPeri-Implantitis: Srijana Heka Bds Iv Year Roll No: 17cz22naÎncă nu există evaluări

- 3.factors and Techniques Influencing Peri-Implant Papillae - PDFDocument12 pagini3.factors and Techniques Influencing Peri-Implant Papillae - PDFMargarita María Blanco LópezÎncă nu există evaluări

- Digital Impression 2022Document23 paginiDigital Impression 2022AseelÎncă nu există evaluări

- Ke Principles of Implant Dentistr in The Esthetic Zone: Michael Sonick, DMD Debb Hwang, DMDDocument6 paginiKe Principles of Implant Dentistr in The Esthetic Zone: Michael Sonick, DMD Debb Hwang, DMDVikas Aggarwal100% (1)

- Post-Surgical Complications and Management in Dental ImplantsDocument41 paginiPost-Surgical Complications and Management in Dental ImplantspipyirÎncă nu există evaluări

- Osseointegration of Bone ImplantsDocument15 paginiOsseointegration of Bone ImplantsBaris BogazkesenliÎncă nu există evaluări

- Peri-Implant Health, Peri-Implant Mucositis, and Peri-Implantitis: Case Definitions and Diagnostic ConsiderationsDocument9 paginiPeri-Implant Health, Peri-Implant Mucositis, and Peri-Implantitis: Case Definitions and Diagnostic ConsiderationsFrancisca Cardenas OñateÎncă nu există evaluări

- Whale's Tail TechniqueDocument32 paginiWhale's Tail Techniquevijeta vyasÎncă nu există evaluări

- Biological Properties of Dental Materials 1-General Dentistry / Orthodontic Courses by Indian Dental AcademyDocument76 paginiBiological Properties of Dental Materials 1-General Dentistry / Orthodontic Courses by Indian Dental Academyindian dental academyÎncă nu există evaluări

- Chapter 6 Midi Implant ProcedureDocument9 paginiChapter 6 Midi Implant Procedurezeus_1949Încă nu există evaluări

- Management of Peri-Implant Mucositis and Peri-Implantitis PDFDocument19 paginiManagement of Peri-Implant Mucositis and Peri-Implantitis PDFgirl33Încă nu există evaluări

- Nanohybrid Versus Nano LL Composite in Class I CavitiesDocument5 paginiNanohybrid Versus Nano LL Composite in Class I CavitiessonygabrielÎncă nu există evaluări

- Published Immediate ImplantDocument6 paginiPublished Immediate Implantshayma rafatÎncă nu există evaluări

- Complete Denture TechniquesDocument6 paginiComplete Denture TechniquesJohn Hyunuk ChoÎncă nu există evaluări

- Oral Maxillofac Surg Clin North Am v.b20, n.b02, May 2008Document164 paginiOral Maxillofac Surg Clin North Am v.b20, n.b02, May 2008Ledir Luciana Henley de AndradeÎncă nu există evaluări

- Severe Anterior Open Bite With Mandibular Retrusion Treated With Multiloop Edgewise Archwires and Microimplant Anchorage ComplementedDocument10 paginiSevere Anterior Open Bite With Mandibular Retrusion Treated With Multiloop Edgewise Archwires and Microimplant Anchorage ComplementedLedir Luciana Henley de AndradeÎncă nu există evaluări

- The Positioning and Magnification of Faces and Skulls For Photographic SuperimpositionDocument11 paginiThe Positioning and Magnification of Faces and Skulls For Photographic SuperimpositionLedir Luciana Henley de AndradeÎncă nu există evaluări

- Horizontal and Vertical Ridge Augmentation in Localized Alveolar Deficient Sites - A Retrospective Case Series PDFDocument11 paginiHorizontal and Vertical Ridge Augmentation in Localized Alveolar Deficient Sites - A Retrospective Case Series PDFLedir Luciana Henley de AndradeÎncă nu există evaluări

- A Longitudinal Study of Combined Periodontal and Prosthetic Treatment of Patients With Advanced Periodontal DiseaseDocument7 paginiA Longitudinal Study of Combined Periodontal and Prosthetic Treatment of Patients With Advanced Periodontal DiseaseLedir Luciana Henley de AndradeÎncă nu există evaluări

- Association of Lip Pigmentation With Smoking and Gingival Melanin PigmentationDocument6 paginiAssociation of Lip Pigmentation With Smoking and Gingival Melanin PigmentationLedir Luciana Henley de AndradeÎncă nu există evaluări

- A Cephalometric Evaluation of The Dental and Facial-Skeletal Effects Using The Bionator With Stepwise Protrusive ActivationsDocument8 paginiA Cephalometric Evaluation of The Dental and Facial-Skeletal Effects Using The Bionator With Stepwise Protrusive ActivationsLedir Luciana Henley de AndradeÎncă nu există evaluări

- Using Orthodontic Intrusion of Abraded Incisors To Facilitate Restoration The Technique's Effects On Alveolar Bone Level and Root LengthDocument10 paginiUsing Orthodontic Intrusion of Abraded Incisors To Facilitate Restoration The Technique's Effects On Alveolar Bone Level and Root LengthLedir Luciana Henley de AndradeÎncă nu există evaluări

- A Case Series On Crestal Sinus Elevation With Rotary InstrumentsDocument8 paginiA Case Series On Crestal Sinus Elevation With Rotary InstrumentsLedir Luciana Henley de AndradeÎncă nu există evaluări

- Logy A Clinical Textbook 2009Document502 paginiLogy A Clinical Textbook 2009Ledir Luciana Henley de AndradeÎncă nu există evaluări

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 paginiCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiÎncă nu există evaluări

- Cbse Class 9 Science Solved Practice Paper Set IDocument19 paginiCbse Class 9 Science Solved Practice Paper Set IDhiraj PadamwarÎncă nu există evaluări

- Studi Kasus Kandungan Formalin Pada Ikan Teri Nasi (Stolephorus Commersoni Lac.) Asin Kering Di Pasar Rau Serang Banten - DocDocument4 paginiStudi Kasus Kandungan Formalin Pada Ikan Teri Nasi (Stolephorus Commersoni Lac.) Asin Kering Di Pasar Rau Serang Banten - DocRini YanuartiÎncă nu există evaluări

- EOCQ Ans 6Document2 paginiEOCQ Ans 6harshanauoc100% (2)

- NF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralDocument2 paginiNF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: Generalwilmer cantilloÎncă nu există evaluări

- TmaDocument5 paginiTmaShan Dela VegaÎncă nu există evaluări

- Sika Viscocrete: TechnologyDocument13 paginiSika Viscocrete: TechnologyacarthurÎncă nu există evaluări

- NEET/JEE: 2020-21: Periodic PropertiesDocument3 paginiNEET/JEE: 2020-21: Periodic Propertiesshantinath123gmailcoÎncă nu există evaluări

- Hempel Protective Infrastructure Corrosion Protection For Cargo Handling Equipment Low ResDocument12 paginiHempel Protective Infrastructure Corrosion Protection For Cargo Handling Equipment Low Reskamardheen majithÎncă nu există evaluări

- PhysicsDocument396 paginiPhysicsGreeny34Încă nu există evaluări

- 87 Kerabondplus GB in PDFDocument4 pagini87 Kerabondplus GB in PDFpankajÎncă nu există evaluări

- Permian Rod Operations - Sucker Rod Identification Chart PDFDocument1 paginăPermian Rod Operations - Sucker Rod Identification Chart PDFMinimaxou78Încă nu există evaluări

- Alchemy at The Crowning of NatureDocument30 paginiAlchemy at The Crowning of NatureMano DasruthiÎncă nu există evaluări

- Requisitions IndexDocument13 paginiRequisitions IndexKarnan ThirugnanamÎncă nu există evaluări

- Spider SilkDocument5 paginiSpider SilkimranÎncă nu există evaluări

- CH 06Document18 paginiCH 06Abdul Shokor Abd TalibÎncă nu există evaluări

- Unidad 6 Orificios. Vertederos Y Resalto HidráulicoDocument5 paginiUnidad 6 Orificios. Vertederos Y Resalto HidráulicoPascual JhonnÎncă nu există evaluări

- Rydlyme: The Solution To Your Water Scale ProblemsDocument4 paginiRydlyme: The Solution To Your Water Scale Problemswq3erwqerwerÎncă nu există evaluări

- Design of Cold Storage Structure For Thousand PDFDocument8 paginiDesign of Cold Storage Structure For Thousand PDFzhyhhÎncă nu există evaluări

- Free Particle PropagatorDocument2 paginiFree Particle PropagatorstephenbankesÎncă nu există evaluări

- Resitivity LogDocument30 paginiResitivity LogMuhammad AneesÎncă nu există evaluări

- ABB Raw Mix Preparation PDFDocument8 paginiABB Raw Mix Preparation PDFrudye kardun100% (1)

- STAT152 Test Prep 1Document6 paginiSTAT152 Test Prep 1Hilmi HusinÎncă nu există evaluări

- mp1 2 PDFDocument1 paginămp1 2 PDFAmer MehmoodÎncă nu există evaluări

- Titration of Sodium Hydroxide With Hydrochloric AcidDocument3 paginiTitration of Sodium Hydroxide With Hydrochloric AcidMir HashemiÎncă nu există evaluări

- Phystcs B (Advancing Physics) U Nderstanding Processes: Friday AfternoonDocument21 paginiPhystcs B (Advancing Physics) U Nderstanding Processes: Friday AfternoonKelen KawasakiÎncă nu există evaluări

- Bulletin RHIDocument76 paginiBulletin RHIwaqasaziz786Încă nu există evaluări

- Is 13871 1993 Powder Coating SpecificationDocument14 paginiIs 13871 1993 Powder Coating SpecificationArunashish Mazumdar50% (2)

- Hysteretic Relative Permeability EffectsDocument8 paginiHysteretic Relative Permeability Effectshfdshy12Încă nu există evaluări

- ME Vol 2 FMDocument364 paginiME Vol 2 FMDeepak Gupta100% (4)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDe la EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyEvaluare: 4.5 din 5 stele4.5/5 (5)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansEvaluare: 4.5 din 5 stele4.5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)De la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Încă nu există evaluări

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDe la EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeEvaluare: 4.5 din 5 stele4.5/5 (59)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownDe la EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownÎncă nu există evaluări

- Troubleshooting and Repair of Diesel EnginesDe la EverandTroubleshooting and Repair of Diesel EnginesEvaluare: 1.5 din 5 stele1.5/5 (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Geotechnical Engineering Calculations and Rules of ThumbDe la EverandGeotechnical Engineering Calculations and Rules of ThumbEvaluare: 4 din 5 stele4/5 (17)

- Summary of Mark Owens & Delia Owens's Cry Of The KalahariDe la EverandSummary of Mark Owens & Delia Owens's Cry Of The KalahariÎncă nu există evaluări

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDe la EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesÎncă nu există evaluări

- Structural Analysis 1: Statically Determinate StructuresDe la EverandStructural Analysis 1: Statically Determinate StructuresÎncă nu există evaluări

- Summary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementDe la EverandSummary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementÎncă nu există evaluări

- Rock Fracture and Blasting: Theory and ApplicationsDe la EverandRock Fracture and Blasting: Theory and ApplicationsEvaluare: 5 din 5 stele5/5 (2)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementDe la EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementÎncă nu există evaluări