Documente Academic

Documente Profesional

Documente Cultură

SC Nissan Sentra B16

Încărcat de

Alex HernandezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SC Nissan Sentra B16

Încărcat de

Alex HernandezDrepturi de autor:

Formate disponibile

ELECTRICAL

SC

A

B

SECTION

STARTING & CHARGING SYSTEM C

E

CONTENTS

SERVICE INFORMATION ............................ 2 STARTING SYSTEM ......................................... 11 F

System Description ..................................................11

PRECAUTIONS ................................................... 2 Wiring Diagram - START - .......................................13

Precaution for Supplemental Restraint System Trouble Diagnosis with Multitasking Battery Diag- G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- nostic Station (Starting) ...........................................20

SIONER" ................................................................... 2 Removal and Installation MR20DE ..........................24

Precaution Necessary for Steering Wheel Rota- Removal and Installation QR25DE ..........................24 H

tion After Battery Disconnect ..................................... 2

CHARGING SYSTEM ....................................... 26

PREPARATION ................................................... 4 System Description ..................................................26

Special Service Tool ................................................. 4 Wiring Diagram - CHARGE - ...................................27 I

Commercial Service Tool .......................................... 4 Trouble Diagnosis with Multitasking Battery Diag-

nostic Station (Charging) .........................................29

BATTERY ............................................................ 5 Removal and Installation MR20DE ..........................32

How to Handle Battery .............................................. 5 J

Removal and Installation QR25DE ..........................33

Trouble Diagnosis with Multitasking Battery Diag- Generator Pulley Inspection ....................................33

nostic Station ............................................................. 7

Removal and Installation (MR20DE Battery) ............ 7 SERVICE DATA AND SPECIFICATIONS SC

Removal and Installation (QR25DE Battery) ............. 8 (SDS) ................................................................. 35

Exploded View (QR25DE Battery Tray) .................... 9 Battery .....................................................................35

Removal and Installation (QR25DE Battery Tray)...... 9 Starter ......................................................................35 L

Required Procedures After Battery Disconnection.... 10 Generator ................................................................35

Revision: July 2010 SC-1 2011 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000006152125

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000006152126

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: July 2010 SC-2 2011 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

5. When the repair work is completed, return the ignition switch to the LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.) A

6. Perform a self-diagnosis check of all control units using CONSULT-III.

SC

Revision: July 2010 SC-3 2011 Sentra

PREPARATION

< SERVICE INFORMATION >

PREPARATION

Special Service Tool INFOID:0000000006152127

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

Tests batteries, starting and charging sys-

( ) Model GR-8 tems.

Multitasking Battery Diagnostic Sta- For operating instructions, refer to diagnostic

tion station instruction manual.

AWIIA1239ZZ

Commercial Service Tool INFOID:0000000006152128

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: July 2010 SC-4 2011 Sentra

BATTERY

< SERVICE INFORMATION >

BATTERY

A

How to Handle Battery INFOID:0000000006152129

CAUTION: B

If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact. C

Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

D

The following precautions must be taken to prevent over-discharging

a battery.

The battery surface (particularly its top) should always be kept

clean and dry. E

The terminal connections should be clean and tight.

At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as low maintenance and

F

maintenance-free.

G

MEL040F

When the vehicle is not going to be used over a long period of

H

time, disconnect the negative battery terminal.

MEL041F

SC

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

L

close check on charge condition to prevent over-discharge.

MEL042F

CHECKING ELECTROLYTE LEVEL O

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con- P

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Revision: July 2010 SC-5 2011 Sentra

BATTERY

< SERVICE INFORMATION >

Remove the cell plug using a suitable tool.

Add distilled water up to the MAX level.

MEL043F

Sulfation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulfation on the cell plates.

To determine if a battery has been sulfated, note its voltage and

current when charging it. Less current and higher voltage are

observed in the initial stage of charging sulfated batteries, as

shown.

A sulfated battery may sometimes be brought back into service

by means of a long, slow charge, 12 hours or more, followed by

a battery capacity test.

WKIA4166E

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Use the following chart to correct your hydrometer reading

according to electrolyte temperature.

MEL042FA

Hydrometer Temperature Correction

Battery electrolyte temperature C (F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) 0.004

16 (60) 0.008

10 (50) 0.012

4 (40) 0.016

1 (30) 0.020

Revision: July 2010 SC-6 2011 Sentra

BATTERY

< SERVICE INFORMATION >

Battery electrolyte temperature C (F) Add to specific gravity reading

A

7 (20) 0.024

12 (10) 0.028

18 (0) 0.032 B

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged C

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

D

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged E

CHARGING THE BATTERY

CAUTION: F

Do not quick charge a fully discharged battery.

Keep the battery away from open flame while it is being charged.

When connecting the charger, connect the leads first, then turn on the charger. Do not turn on the

charger first, as this may cause a spark. G

If battery electrolyte temperature rises above 55C (131F), stop charging. Always charge battery at a

temperature below 55C (131F).

Charging Rates H

Amps Time

I

50 1 hour

25 2 hours

10 5 hours J

5 10 hours

Do not charge at more than 50 ampere rate.

NOTE: SC

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate. L

If, after charging, the specific gravity of any two cells varies more than 0.050, the battery should be replaced.

Trouble Diagnosis with Multitasking Battery Diagnostic Station INFOID:0000000006152130

M

Refer to diagnostic station instruction manual.

Removal and Installation (MR20DE Battery) INFOID:0000000006152131

N

REMOVAL MR20DE

1. Loosen battery terminal nuts (A), and disconnect both negative

O

and positive battery terminals.

CAUTION:

When disconnecting, disconnect the battery negative termi-

nal first. P

2. Remove battery frame nuts (B) and battery frame.

3. Remove battery.

PKIC0535E

Revision: July 2010 SC-7 2011 Sentra

BATTERY

< SERVICE INFORMATION >

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Battery frame nuts : 5.4 Nm (0.55 kg-m, 48 in-lb)

Battery terminal nuts : 5.4 Nm (0.55 kg-m, 48 in-lb)

Reset electronic systems as necessary. Refer to SC-10, "Required Procedures After Battery Disconnection".

Removal and Installation (QR25DE Battery) INFOID:0000000006152132

REMOVAL

1. Loosen battery terminal nuts (A), and disconnect both negative

and positive battery terminals.

CAUTION:

When disconnecting, disconnect the battery negative termi-

nal first.

2. Remove battery hold-down wedge bolt (B) and battery wedge

bracket.

3. Remove battery.

4. Remove battery tray liner, if necessary.

LKIA0928E

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Battery wedge bracket bolt : 30 Nm (3.1 kg-m, 22 ft-lb)

Battery terminal nuts : 5.4 Nm (0.55 kg-m, 48 in-lb)

Reset electronic systems as necessary. Refer to SC-10, "Required Procedures After Battery Disconnection".

Revision: July 2010 SC-8 2011 Sentra

BATTERY

< SERVICE INFORMATION >

Exploded View (QR25DE Battery Tray) INFOID:0000000006152133

AWMIA1186GB J

1. Battery 2. Battery wedge bracket 3. Battery tray liner

4. Battery tray 5. ECM 6. ECM harness bracket

SC

7. Transmission control module Vehicle front

(TCM) (CVT models)

Removal and Installation (QR25DE Battery Tray) INFOID:0000000006152134 L

REMOVAL

1. Remove battery and battery tray liner. Refer to SC-8, "Removal and Installation (QR25DE Battery)". M

2. Disconnect ECM.

3. Disconnect TCM (CVT models).

N

4. Remove the battery tray bolts and battery tray.

5. Remove the ECM harness bracket, if necessary.

6. Remove the ECM, if necessary. O

7. Remove the TCM (CVT models), if necessary.

INSTALLATION

Installation is in the reverse order of removal. P

Reset electronic systems as necessary. Refer to SC-10, "Required Procedures After Battery Disconnection".

Revision: July 2010 SC-9 2011 Sentra

BATTERY

< SERVICE INFORMATION >

Required Procedures After Battery Disconnection INFOID:0000000006152135

System Item Reference

EC-99 (MR20DE for California)

Engine Control System Idle Air Volume Learning EC-649 (MR20DE except for California)

EC-1183 (QR25DE)

Glasses, Window System & Mirrors Power Window System Initialization GW-51

Roof Sunroof Memory Reset/Initialization RF-11

Audio (Radio Preset) Refer to Owners Manual.

Audio, Visual, Navigation & Telephone System

Navigation System Refer to Owners Manual.

Revision: July 2010 SC-10 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

STARTING SYSTEM

A

System Description INFOID:0000000006152136

M/T Models with MR20DE B

Power is supplied at all times

through 225A fusible link [letter a, located in the fusible link box (battery) or

to starter motor terminal B and C

through 40A fusible link (letter m, located in the fuse and fusible link box)

to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

from ignition switch terminal ST D

to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)] E

to the clutch interlock switch terminal 2.

With the clutch pedal depressed, power is supplied

through the clutch interlock switch terminal 1

to IPDM E/R terminal 35. F

Ground is supplied at all times

to IPDM E/R terminals 39 and 59

through body grounds E9, E15 and E24. G

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

through terminal 19 of the IPDM E/R

H

to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates. I

M/T Models with QR25DE

Power is supplied at all times

through fusible link box (battery) J

to starter motor terminal B and

through 40A fusible link (letter m, located in the fuse and fusible link box)

to ignition switch terminal B. SC

With the ignition switch in the START position, power is supplied

from ignition switch terminal ST

to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied L

through 10A fuse [No. 12, located in the fuse block (J/B)]

to clutch interlock switch terminal 2.

With the clutch pedal depressed, power is supplied M

through clutch interlock switch terminal 1

to IPDM E/R terminal 35.

Ground is supplied at all times

to IPDM E/R terminals 39 and 59 N

through body grounds E9 and E15.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied O

through terminal 19 of the IPDM E/R

to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor P

operates.

CVT Models with MR20DE

Power is supplied at all times

through 225A fusible link [letter a, located in the fusible link box (battery)]

to starter motor terminal B, and

through 40A fusible link (letter m, located in the fuse and fusible link box)

Revision: July 2010 SC-11 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

from ignition switch terminal ST

to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)]

to transmission range switch terminal 7.

With the shift selector in the P or N position, power is supplied

through transmission range switch terminal 6

to IPDM E/R terminal 35.

Ground is supplied at all times

to IPDM E/R terminals 39 and 59

through body grounds E9, E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

through terminal 19 of the IPDM E/R

to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

CVT Models with QR25DE

Power is supplied at all times

through fusible link box (battery)

to starter motor terminal B, and

through 40A fusible link (letter m, located in the fuse and fusible link box)

to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

from ignition switch terminal ST

to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)]

to transmission range switch terminal 7.

With the shift selector in the P or N position, power is supplied

through transmission range switch terminal 6

to IPDM E/R terminal 35.

Ground is supplied at all times

to IPDM E/R terminals 39 and 59

through body grounds E9 and E15.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

through terminal 19 of the IPDM E/R

to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

Revision: July 2010 SC-12 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

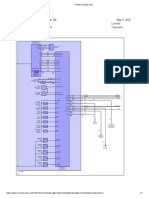

Wiring Diagram - START - INFOID:0000000006152137

A

M/T Models - MR20DE

SC

P

WKWA5772E

Revision: July 2010 SC-13 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

BKWA0739E

Revision: July 2010 SC-14 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

M/T Models - QR25DE

A

SC

WKWA5773E

P

Revision: July 2010 SC-15 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

WKWA5774E

Revision: July 2010 SC-16 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

CVT Models - MR20DE

A

SC

WKWA5775E

P

Revision: July 2010 SC-17 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

ABBWA0641GB

Revision: July 2010 SC-18 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

CVT Models - QR25DE

A

SC

WKWA5777E

P

Revision: July 2010 SC-19 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

ABBWA0642GB

Trouble Diagnosis with Multitasking Battery Diagnostic Station (Starting) INFOID:0000000006152138

Perform the starting system test with multitasking battery diagnostic station. For details and operating instruc-

tions, refer to diagnostic station instruction manual.

Revision: July 2010 SC-20 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

SC

AWBIA0768GB

P

DIAGNOSTIC PROCEDURE 1

Check Starter Motor Circuit

1.CHECK POWER SUPPLY TO STARTER MOTOR

1. Remove the fuel pump fuse.

Revision: July 2010 SC-21 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Check that the starter motor connector F27 connection is clean and tight.

5. Check voltage between starter motor connector F27 terminal B

and ground using a digital circuit tester.

Battery voltage should exist

OK or NG

OK >> GO TO 2.

NG >> Check harness between the battery and the starter

motor for open circuit.

WKIA0137E

2.CHECK VOLTAGE DROP ON STARTER MOTOR CIRCUIT

Check voltage between starter motor connector F27 terminal B and

battery positive terminal using a digital circuit tester.

Ignition switch in : Less than 0.2V

START

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter

motor for poor continuity.

WKIA0138E

3.CHECK VOLTAGE DROP ON STARTER MOTOR GROUND CIRCUIT

Check voltage between starter motor case and battery negative ter-

minal using a digital circuit tester.

Ignition switch in : Less than 0.2V

START

OK or NG

OK >> Starter motor ground circuit is OK. Further inspection is

necessary. Refer to "Trouble Diagnoses with Multitask-

ing Battery Diagnostic Station (Starting)".

NG >> Check harness between the starter motor case and

WKIA0139E

ground for poor continuity.

DIAGNOSTIC PROCEDURE 2

Check Magnetic Switch Circuit

1.CHECK POWER SUPPLY TO MAGNETIC SWITCH

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F28.

Revision: July 2010 SC-22 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

5. Check voltage between starter motor connector F28 terminal S

and ground using a digital circuit tester. A

Ignition switch in : Battery voltage

START B

OK or NG

OK >> GO TO 2.

NG >> Check the following: C

40A fusible link (letter m, located in the fuse and fus-

ible link box)

WKIA5736E

10A fuse [No. 12, located in the fuse block (J/B)] D

15A fuse (No. 52, located in the IPDM E/R)

20A fuse (No. 53, located in the IPDM E/R)

Transmission range switch (CVT models) or clutch interlock switch (M/T models)

Ignition switch E

Ignition relay (IPDM E/R)

Starter relay (IPDM E/R)

Starter relay request ON signal from BCM F

Harness for open or short circuit

2.CHECK VOLTAGE DROP ON MAGNETIC SWITCH CIRCUIT

1. Connect starter motor connector F28. G

2. Check voltage between starter motor connector F28 terminal S

and battery positive terminal using a digital circuit tester.

H

Ignition switch in : Less than 1V

START

OK or NG I

OK >> Magnetic switch circuit is OK. Further inspection is nec-

essary. Refer to "Trouble Diagnoses with Multitasking

Battery Diagnostic Station (Starting)". J

NG >> Check harness, components and connections between

WKIA5737E

the battery and the magnetic switch for poor continuity.

SC

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

L

Engine coolant temperature Voltage V

30C to 20C (22F to 4F) 8.4

19C to 10C (2F to 14F) 8.9 M

9C to 0C (16F to 32F) 9.3

More than 1C (More than 34F) 9.7

N

Revision: July 2010 SC-23 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

Removal and Installation MR20DE INFOID:0000000006152139

ALBIA0633ZZ

1. "S" terminal harness 2. "B" terminal harness 3. Starter motor

4. Cylinder block Vehicle front

REMOVAL

1. Disconnect the battery negative terminal. Refer to SC-7, "Removal and Installation (MR20DE Battery)".

2. Remove "S" terminal nut.

3. Remove B terminal nut.

4. Remove starter motor bolts.

5. Remove starter motor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten B terminal nut carefully.

Removal and Installation QR25DE INFOID:0000000006152140

CVT Models

AWBIA0871GB

Revision: July 2010 SC-24 2011 Sentra

STARTING SYSTEM

< SERVICE INFORMATION >

1. "S" terminal harness 2. Starter motor 3. "B" terminal A

M/T Models

AWBIA0872GB

I

1. Starter motor 2. "B" terminal 3. "S" terminal

4. Transaxle assembly Engine front

J

REMOVAL

1. Disconnect the battery negative terminal. Refer to SC-8, "Removal and Installation (QR25DE Battery)".

SC

2. Raise vehicle.

3. Disconnect S terminal connector.

4. Remove B terminal nut.

L

5. Remove starter motor bolts.

6. Remove starter motor.

M

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: N

Be sure to tighten B terminal nut carefully.

Revision: July 2010 SC-25 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

CHARGING SYSTEM

System Description INFOID:0000000006152141

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

10A fuse [No. 26, located in the fuse block (J/B)].

Power is supplied through terminal 1 to charge the battery and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 225A fusible link

[letter a, located in the fusible link box (battery)].

Ground is supplied

to generator terminal 5

through body ground F5 (MR20DE)

through body ground E62 (QR25DE) and

through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 14, located in the fuse block (J/B)]

to combination meter terminal 2 for the charge warning lamp.

The IC regulator controls ground to terminal 32 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes available at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will illuminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Revision: July 2010 SC-26 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

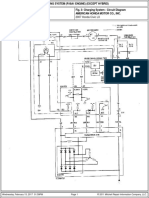

Wiring Diagram - CHARGE - INFOID:0000000006152142

A

MR20DE

SC

P

AAMWA0189GB

Revision: July 2010 SC-27 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

QR25DE

AAMWA0190GB

Revision: July 2010 SC-28 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

Trouble Diagnosis with Multitasking Battery Diagnostic Station (Charging) INFOID:0000000006152143

A

Perform the charging system test with multitasking battery diagnostic station. For details and operating instruc-

tions, refer to diagnostic station instruction manual.

B

SC

O

AWMIA1142GB

DIAGNOSTIC PROCEDURE 1

P

Check Charge Warning Lamp Circuit

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Check to see if terminal 2 is clean and tight.

OK or NG

Revision: July 2010 SC-29 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

OK >> GO TO 2.

NG >> Repair terminal 2 connection. Confirm repair by performing complete Starting/Charging system

test. Refer to diagnostic station instruction manual.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F14.

2. Apply ground to generator connector F14 terminal 2 with the

ignition switch in the ON position.

CHARGE lamp should light up.

OK or NG

OK >> GO TO "Trouble Diagnoses with Multitasking Battery

Diagnostic Station (Charging)".

NG >> Check the following.

10A fuse [No. 14, located in fuse block (J/B)]

CHARGE lamp

WKIA5577E

Harness for open or short between combination meter

and fuse

Harness for open or short between combination meter and generator

DIAGNOSTIC PROCEDURE 2

Check Battery Circuit

1.CHECK BATTERY CIRCUIT CONNECTION

Check to see if connector F15 terminal 1 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair connector F15 terminal 1 connection. Confirm repair by performing complete Starting/

Charging system test. Refer to diagnostic station instruction manual.

2.CHECK BATTERY CIRCUIT

Check voltage between generator connector F15 terminal 1 and

ground using a digital circuit tester.

Battery voltage should exist.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

225A fusible link [letter a, located in fusible link box

(battery)]

Harness for open or short between generator and fus-

WKIA5547E

ible link

3.CHECK VOLTAGE DROP ON BATTERY CIRCUIT

Check voltage between generator connector F15 terminal 1 and bat-

tery positive terminal using a digital circuit tester.

With engine running : Less than 0.2V

at idle and warm

OK or NG

OK >> Replace the generator. Refer to SC-32, "Removal and

Installation MR20DE". Confirm repair by performing

complete Starting/Charging system test. Refer to diag-

nostic station instruction manual.

WKIA5578E

NG >> Check harness between the battery and the generator

for poor continuity.

Revision: July 2010 SC-30 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

DIAGNOSTIC PROCEDURE 3

A

Check Voltage Regulator Circuit

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION B

Check to see if connector F14 terminal 3 is clean and tight.

OK or NG C

OK >> GO TO 2.

NG >> Repair connector F14 terminal 3 connection. Confirm repair by performing complete Starting/

Charging system test. Refer to diagnostic station instruction manual.

D

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator connector F14 terminal 3 and

ground using a digital circuit tester. E

Battery voltage should exist.

OK or NG F

OK >> GO TO 3.

NG >> Check the following.

10A fuse [No. 26, located in fuse block (J/B)] G

Harness for open or short between generator and fuse

WKIA5579E

3.CHECK VOLTAGE DROP ON VOLTAGE REGULATOR CIRCUIT H

Check voltage between generator connector F14 terminal 3 and bat-

tery positive terminal using a digital circuit tester. I

With engine running : Less than 0.2V

at idle and warm

J

OK or NG

OK >> Replace the generator. Refer to SC-32, "Removal and

Installation MR20DE". Confirm repair by performing SC

complete Starting/Charging system test. Refer to diag-

nostic station instruction manual.

WKIA5580E

NG >> Check harness between the battery and the generator

for poor continuity. L

Revision: July 2010 SC-31 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

Removal and Installation MR20DE INFOID:0000000006152144

SKIB1945J

1. Generator bracket bolt 2. Generator bracket 3. Generator bolt

4. Generator 5. Generator "B" terminal harness 6. "B" terminal nut

7. Generator connector

REMOVAL

1. Disconnect the battery negative terminal. Refer to SC-7, "Removal and Installation (MR20DE Battery)".

2. Remove RH front wheel and tire. Refer to WT-7, "Adjustment".

3. Remove splash shield RH. Refer to EI-23, "Component".

4. Remove drive belt. Refer to EM-13, "Removal and Installation".

5. Disconnect generator connector.

6. Remove B terminal nut.

7. Remove generator bolts.

8. Remove generator assembly from the vehicle.

INSTALLATION

CAUTION:

Generator bolts must be tightened in sequence.

1. Install and temporarily tighten the lower generator bolt.

2. Install and temporarily tighten the upper generator bolt.

3. Tighten the upper generator bolt to specification.

4. Tighten the lower generator bolt to specification.

NOTE:

Slide bushing must contact engine bracket after generator is installed.

Installation of the remaining components is in the reverse order of removal.

CAUTION:

Be sure to tighten B terminal nut carefully.

Revision: July 2010 SC-32 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

Removal and Installation QR25DE INFOID:0000000006152145

AWBIA0873GB

I

1. Generator bracket 2. Water pump 3. Generator

4. Generator "B" terminal harness 5. Generator connector

J

REMOVAL

1. Disconnect the battery negative terminal. Refer to SC-8, "Removal and Installation (QR25DE Battery)".

2. Remove splash shield RH. Refer to EI-23, "Component". SC

3. Remove drive belt. Refer to EM-13, "Removal and Installation".

4. Disconnect generator connector.

5. Remove B terminal nut. L

6. Remove harness bracket and position aside.

7. Remove generator bolts.

M

8. Remove generator assembly from the vehicle.

INSTALLATION

CAUTION: N

Generator bolts must be tightened in sequence.

1. Install and temporarily tighten the lower generator bolt.

2. Install and temporarily tighten the upper generator bolt.

3. Tighten the upper generator bolt to specification. O

4. Tighten the lower generator bolt to specification.

NOTE:

Slide bushing must contact engine bracket after generator is installed. P

Installation of the remaining components is in the reverse order of removal.

CAUTION:

Be sure to tighten B terminal nut carefully.

Generator Pulley Inspection INFOID:0000000006152146

GENERATOR PULLEY INSPECTION

Revision: July 2010 SC-33 2011 Sentra

CHARGING SYSTEM

< SERVICE INFORMATION >

One-Way Clutch Pulley Check

CAUTION:

Be careful not to damage rotor

NOTE:

Secure rotor using suitable tool and a rolled shop towel.

1. Check for locking; (Outer ring is turned clockwise when viewed

from front.)

If it rotates in both directions, replace generator.

2. Check for dragging. (Outer ring is turned counterclockwise when

viewed from front.)

If it locks or unusual resistance is felt, replace generator.

SKIB0529E

Revision: July 2010 SC-34 2011 Sentra

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

A

Battery INFOID:0000000006152147

B

Engine MR20DE QR25DE

Type* 21 R 40R

Capacity (20 HR) minimum V-AH 12 V - 49 AH minimum 12V - 60 AH minimum C

Cold Cranking Amps 470 @ -18C (0F) 550 @ -18C (0F)

*: Always check with the Parts Department for the latest parts information

D

Starter INFOID:0000000006152148

E

Engine MR20DE QR25DE

Application California Except California CVT M/T

S114-944A S114-955 M000TA0271ZC M000T22272ZC F

Type* HITACHI MITSUBISHI

Reduction gear type

G

System voltage 12 V

Terminal voltage 11 V

No-load Current Less than 110 A Less than 90A H

Revolution More than 3,750 rpm More than 3,000 rpm More than 2,400 rpm More than 2,000 rpm

*: Always check with the Parts Department for the latest parts information

I

Generator INFOID:0000000006152149

Engine MR20DE QR25DE

J

A002TG1581AC TG11S102

Type*

MITSUBISHI VALEO SC

Nominal rating 12 V - 100 A 12 V - 110 A

Ground polarity Negative

Minimum revolution under no-load Less than 1,000 rpm Less than 1,200 rpm L

More than 46 A/1,500 rpm

More than 16 A/1,300 rpm

More than 68 A/1,800 rpm

Hot output current (when 13.5 V is applied) More than 82 A/2,500 rpm

More than 97 A/5,000 rpm

More than 91 A/2,500 rpm M

More than 105 A/5,000 rpm

Regulated output voltage 14.1 - 14.7 V 11.4 - 15.6 V

*: Always check with the Parts Department for the latest parts information N

Revision: July 2010 SC-35 2011 Sentra

S-ar putea să vă placă și

- 4HK1 & 6HK1 ManualDocument352 pagini4HK1 & 6HK1 Manuallionkinghd94% (104)

- ZD30 CRD 2008 1Document74 paginiZD30 CRD 2008 1powermanager96% (28)

- FORD Falcon XA Repair ManualDocument770 paginiFORD Falcon XA Repair ManualMark Kenzie100% (10)

- NPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFDocument121 paginiNPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFRoyert Salas96% (81)

- ISUZU Truck Service Manual PDFDocument439 paginiISUZU Truck Service Manual PDFkaled ben abdallah67% (3)

- Service Manual Common Rail System Isuzu 4HK1 6HK1Document48 paginiService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- Transfer Case Electrical RMDocument51 paginiTransfer Case Electrical RMDaniel Canales75% (4)

- ISUZU 4HK1 6HK1 Type Engine PDFDocument48 paginiISUZU 4HK1 6HK1 Type Engine PDFЙОРДАН ГЕОРГИЕВ90% (21)

- Hydra 2.5 ManualDocument59 paginiHydra 2.5 Manualdavescott670150% (2)

- YD25 CR Fault Diagnosis PDFDocument101 paginiYD25 CR Fault Diagnosis PDFMaurihuaanaa Navarro Santana100% (6)

- 2014 Nissan Versa 39409Document39 pagini2014 Nissan Versa 39409Evgeniy TruniakovÎncă nu există evaluări

- MUGEN K20 CN WTCC FIA Parts 2013 3 PDFDocument1 paginăMUGEN K20 CN WTCC FIA Parts 2013 3 PDFJdkdkd KddkfkÎncă nu există evaluări

- Sat Filter Left 110HzDocument2 paginiSat Filter Left 110HzxxÎncă nu există evaluări

- 09 at 016Document4 pagini09 at 016David ParariÎncă nu există evaluări

- YD25 Engine MechDocument35 paginiYD25 Engine MechAlex Hernandez100% (2)

- Nissan Rogue 2014 Service Repair ManualDocument4.971 paginiNissan Rogue 2014 Service Repair ManualAlex Hernandez100% (1)

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFDocument199 pagini4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFโจ้ สแปร์แร็ค92% (74)

- 54 - Fuller FSO 6109A Transmission Service Manual PDFDocument134 pagini54 - Fuller FSO 6109A Transmission Service Manual PDFJulio OrtegaÎncă nu există evaluări

- Nissan Patrol ZD30 Y61 Reference Document - ColourDocument129 paginiNissan Patrol ZD30 Y61 Reference Document - ColourIurie Maxim92% (12)

- Leaflet CycleManager Ep CycleManager ErDocument7 paginiLeaflet CycleManager Ep CycleManager ErValeska ArdilesÎncă nu există evaluări

- STC NISSAN SENTRA B16Document22 paginiSTC NISSAN SENTRA B16Alex HernandezÎncă nu există evaluări

- Bateria MotorDeArranque Alternador Nissan VersaDocument34 paginiBateria MotorDeArranque Alternador Nissan VersaHumberto Vega SanchezÎncă nu există evaluări

- Nissan Tiida 2006 Manual ServicioDocument60 paginiNissan Tiida 2006 Manual ServicioRicardo RaulÎncă nu există evaluări

- Codigos Toyota y ObdDocument1 paginăCodigos Toyota y ObdCarlos Alberto Vega AlfaroÎncă nu există evaluări

- Nissan B16Document1.060 paginiNissan B16Ahamed Delmon Ramos Vanegas100% (1)

- 2006 Nissan XTrail New PDFDocument281 pagini2006 Nissan XTrail New PDFCarlos DumonÎncă nu există evaluări

- Artorimp 3Document586 paginiArtorimp 3repuestosr4100% (1)

- Atos Fuel SDocument133 paginiAtos Fuel Singenieriaelectronic100% (1)

- SsangYong Actyon 2008 Service Repair Manual PDFDocument2.425 paginiSsangYong Actyon 2008 Service Repair Manual PDFDavid CalugaruÎncă nu există evaluări

- Mazda Bulletin No 01-037-08Document5 paginiMazda Bulletin No 01-037-08prvi72Încă nu există evaluări

- Transmision Fluid Presure Nissan Sentra 2008Document2 paginiTransmision Fluid Presure Nissan Sentra 2008Brian Moreno100% (1)

- Can Bus de Chery Orinoco M11Document2 paginiCan Bus de Chery Orinoco M11Jimmy Quise LlamoccaÎncă nu există evaluări

- Rexton W 201206Document1.138 paginiRexton W 201206SebastianoÎncă nu există evaluări

- S15 SR20DET: Pin # Color Pin # Color Description DescriptionDocument2 paginiS15 SR20DET: Pin # Color Pin # Color Description DescriptionazisÎncă nu există evaluări

- G Electrical Wiring Routing: Position of Parts in Engine CompartmentDocument8 paginiG Electrical Wiring Routing: Position of Parts in Engine CompartmentTec RomeroÎncă nu există evaluări

- Automatic Transaxle Diag Trouble CodesDocument3 paginiAutomatic Transaxle Diag Trouble CodesSteven Casey JonesÎncă nu există evaluări

- EC Frontier QR25 NP300Document1.411 paginiEC Frontier QR25 NP300nestorÎncă nu există evaluări

- S14 Kouki SR20 PinoutDocument2 paginiS14 Kouki SR20 PinoutCelso BrantesÎncă nu există evaluări

- Engine+immobilizer A19Document8 paginiEngine+immobilizer A19Jorge NegrettiÎncă nu există evaluări

- Renault Fluence 2Document2 paginiRenault Fluence 2Oliver lealÎncă nu există evaluări

- ActyonB0802016 PDFDocument7 paginiActyonB0802016 PDFRms AutomotrizÎncă nu există evaluări

- Versa 2010 FWDDocument11 paginiVersa 2010 FWDАртем Лысечко0% (1)

- Noblex 21TC667U STR-W6754 LA76933 LA78141-E R2S15908SPP LA72703 LA42205-E Chassis LA8-ADocument29 paginiNoblex 21TC667U STR-W6754 LA76933 LA78141-E R2S15908SPP LA72703 LA42205-E Chassis LA8-Amarquitos550b100% (1)

- Caja de Realy OptraDocument5 paginiCaja de Realy OptraVicent JesusÎncă nu există evaluări

- Motor & - Controller Products Table 2020Document14 paginiMotor & - Controller Products Table 2020María De Los Ángeles CastilloÎncă nu există evaluări

- Wireless Control Module (WCM) : Group 42CDocument102 paginiWireless Control Module (WCM) : Group 42CToponari MedveÎncă nu există evaluări

- Renault Matic D 2Document1 paginăRenault Matic D 2Pablo PedaltaÎncă nu există evaluări

- IAW 5SF Palio PDFDocument2 paginiIAW 5SF Palio PDFElvis Eliud HernándezÎncă nu există evaluări

- Generic Nissan ECU Sensor or Data Register Table Ver 2Document7 paginiGeneric Nissan ECU Sensor or Data Register Table Ver 2sinasayedanaÎncă nu există evaluări

- 1996 Dodge Grand Caravan Localizacion de ComponentesDocument28 pagini1996 Dodge Grand Caravan Localizacion de ComponentesLuis Angel BarajasÎncă nu există evaluări

- Grand Am Continental Tire Sports Integrating ECU PDFDocument31 paginiGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlÎncă nu există evaluări

- Maintenance Manual of Chery Karry - Circuit Diagramas PDFDocument16 paginiMaintenance Manual of Chery Karry - Circuit Diagramas PDFIsaac Galvez EscuderoÎncă nu există evaluări

- Fusilera Toyota Hilux 2011-13Document4 paginiFusilera Toyota Hilux 2011-13skppp100% (1)

- Transmision Diagrama Electrico PathfinderDocument1 paginăTransmision Diagrama Electrico PathfinderJORGE RUZ100% (1)

- Catalogo Filtros Highfil PDFDocument190 paginiCatalogo Filtros Highfil PDFAriel Taboada ZapataÎncă nu există evaluări

- Diagrama Electronico Toyota RunerDocument10 paginiDiagrama Electronico Toyota RunerOmar Jara FelixÎncă nu există evaluări

- Aw6040 GM Transmission 4Document1 paginăAw6040 GM Transmission 4Vicente Emilio MartinezÎncă nu există evaluări

- Chevrolet Luv Dmax CNG Wiring Harness: O SensorDocument1 paginăChevrolet Luv Dmax CNG Wiring Harness: O SensorFranklin Velandria100% (1)

- ECM PINOUT Chevrolet-Sail-1 PDFDocument2 paginiECM PINOUT Chevrolet-Sail-1 PDFjoseÎncă nu există evaluări

- Seat Ibiza - Konnektor Timoni 1Document17 paginiSeat Ibiza - Konnektor Timoni 1xacfsdfÎncă nu există evaluări

- Engine Control SystemACCENTpdfDocument1 paginăEngine Control SystemACCENTpdfDelsy SimbronÎncă nu există evaluări

- Nissan Murano Engine Air Intake DuctDocument8 paginiNissan Murano Engine Air Intake DuctenkcyongÎncă nu există evaluări

- Sistema de Arranque y CargaDocument27 paginiSistema de Arranque y Cargaastroboy2666Încă nu există evaluări

- Starting & Charging System: SectionDocument27 paginiStarting & Charging System: SectionemenelikÎncă nu există evaluări

- Starting & Charging System: SectionDocument25 paginiStarting & Charging System: SectionEduardo ColinÎncă nu există evaluări

- 2008 Nissan Versa 23Document18 pagini2008 Nissan Versa 23Daryl TimothyÎncă nu există evaluări

- STC Steering Control SystemDocument22 paginiSTC Steering Control Systemjorge rioboÎncă nu există evaluări

- Starting & Charging System: SectionDocument27 paginiStarting & Charging System: SectionSteven AmadorÎncă nu există evaluări

- Starting & Charging System: SectionDocument36 paginiStarting & Charging System: Sectionmuki461100% (1)

- Starting & Charging System: SectionDocument26 paginiStarting & Charging System: SectionascguateÎncă nu există evaluări

- Starting System: SectionDocument21 paginiStarting System: SectionjasleenÎncă nu există evaluări

- Starting and Charging SystemDocument26 paginiStarting and Charging SystemJagdeep Sekhon100% (2)

- SC PDFDocument36 paginiSC PDFRony CentenoÎncă nu există evaluări

- Engine Cooling System: SectionDocument29 paginiEngine Cooling System: SectionskpppÎncă nu există evaluări

- ISUZU N-Series 4HK1-manual-de-confianza-2Document34 paginiISUZU N-Series 4HK1-manual-de-confianza-2Alex Hernandez100% (6)

- Fusileras Fuso 2012Document4 paginiFusileras Fuso 2012Alex HernandezÎncă nu există evaluări

- DIAGNOSIS YD25ddtiDocument14 paginiDIAGNOSIS YD25ddtiAlex Hernandez100% (1)

- Nissan 2.4Document204 paginiNissan 2.4hectorgonzalezm100% (6)

- Isuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFDocument50 paginiIsuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFVirgo100% (5)

- Service Manual: Group 14A CoolingDocument27 paginiService Manual: Group 14A CoolingAlex HernandezÎncă nu există evaluări

- Transfer Control UnitDocument6 paginiTransfer Control UnitAlex HernandezÎncă nu există evaluări

- Denso CR - HP3 NissanDocument14 paginiDenso CR - HP3 NissanHerbert Sanchez75% (4)

- 6M60 High Idle Test - EPA '07Document2 pagini6M60 High Idle Test - EPA '07Alex HernandezÎncă nu există evaluări

- Honda Civic LX 2007Document1 paginăHonda Civic LX 2007Alex HernandezÎncă nu există evaluări

- Especificaciones Nissan ZD30 TD TERRANO II PDFDocument2 paginiEspecificaciones Nissan ZD30 TD TERRANO II PDFJefferson Humberto HerreraÎncă nu există evaluări

- Srs NISSAN SENTRA B16Document52 paginiSrs NISSAN SENTRA B16Alex HernandezÎncă nu există evaluări

- Steering Control SystemDocument22 paginiSteering Control SystemAlex Hernandez100% (1)

- Wiper and Washer Nissan b16Document29 paginiWiper and Washer Nissan b16Alex HernandezÎncă nu există evaluări

- Clutch NISSAN B16Document17 paginiClutch NISSAN B16Alex HernandezÎncă nu există evaluări

- Body LOCK SECURITY SYSTEMDocument231 paginiBody LOCK SECURITY SYSTEMAlex HernandezÎncă nu există evaluări

- Cooling System NISSAN B16Document56 paginiCooling System NISSAN B16Alex HernandezÎncă nu există evaluări

- Brake System NISSAN B16Document51 paginiBrake System NISSAN B16Alex HernandezÎncă nu există evaluări

- Streamline SWR (S) - Rev - 00-04-2019 PDFDocument2 paginiStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11Încă nu există evaluări

- TC AdvisoryDocument1 paginăTC AdvisoryJerome DelfinoÎncă nu există evaluări

- Disa Match: A Match You Can Count OnDocument8 paginiDisa Match: A Match You Can Count OngÎncă nu există evaluări

- Basic Principles of Remote SensingDocument24 paginiBasic Principles of Remote Sensingfelipe4alfaro4salas100% (1)

- EQ Cheat SheetDocument7 paginiEQ Cheat SheetGabrielÎncă nu există evaluări

- Scientific Exploration and Expeditions PDFDocument406 paginiScientific Exploration and Expeditions PDFana_petrescu100% (2)

- The Association Between Eating Disorders and Stress Among Medical Student: A Cross-Sectional StudyDocument11 paginiThe Association Between Eating Disorders and Stress Among Medical Student: A Cross-Sectional StudyIJAR JOURNALÎncă nu există evaluări

- Med Chem Exam 2Document24 paginiMed Chem Exam 2cÎncă nu există evaluări

- The Explanation of The Fundamentals of Islamic BeliefDocument95 paginiThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafÎncă nu există evaluări

- Paper 2 With Solution MathematicsDocument17 paginiPaper 2 With Solution MathematicsFaiz AhmadÎncă nu există evaluări

- Schneider Modicon M580 CatalogueDocument268 paginiSchneider Modicon M580 CatalogueKhaerul Imam HermanÎncă nu există evaluări

- Menstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalDocument4 paginiMenstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalMy Home KaviÎncă nu există evaluări

- Resource Access ControlDocument19 paginiResource Access Controlusamadar707Încă nu există evaluări

- Toptica AP 1012 Laser Locking 2009 05Document8 paginiToptica AP 1012 Laser Locking 2009 05Tushar GuptaÎncă nu există evaluări

- Suneet Narayan Singh (Updated CV), NDocument4 paginiSuneet Narayan Singh (Updated CV), Nnishant gajeraÎncă nu există evaluări

- Amies A 114 - 3Document17 paginiAmies A 114 - 3Syed Umar Farooq100% (1)

- Taper Lock BushesDocument4 paginiTaper Lock BushesGopi NathÎncă nu există evaluări

- ELC609F12 Lec0 IntroductionDocument16 paginiELC609F12 Lec0 IntroductionMohammed El-AdawyÎncă nu există evaluări

- FREEWAT Vol0 v.1.1.2Document159 paginiFREEWAT Vol0 v.1.1.2Jonathan QuirozÎncă nu există evaluări

- EY Enhanced Oil RecoveryDocument24 paginiEY Enhanced Oil RecoveryDario Pederiva100% (1)

- Modular Air Handling Unit (FMA)Document3 paginiModular Air Handling Unit (FMA)Salamet TeguhÎncă nu există evaluări

- CADS Revit Scia Engineer Link Best PracticesDocument32 paginiCADS Revit Scia Engineer Link Best PracticestrevorÎncă nu există evaluări

- z482 E3b en (3a2)Document2 paginiz482 E3b en (3a2)Gerencia General ServicesÎncă nu există evaluări

- CopernikDocument2 paginiCopernikSinister JinÎncă nu există evaluări

- An Appraisal of The Literature On Centric Relation. Part II: ReviewDocument11 paginiAn Appraisal of The Literature On Centric Relation. Part II: ReviewManjulika TysgiÎncă nu există evaluări

- Food Poisoning: VocabularyDocument9 paginiFood Poisoning: VocabularyHANG WEI MENG MoeÎncă nu există evaluări

- Mathematics For Engineers and Scientists 3 PDFDocument89 paginiMathematics For Engineers and Scientists 3 PDFShailin SequeiraÎncă nu există evaluări