Documente Academic

Documente Profesional

Documente Cultură

Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesM

Încărcat de

nsadnanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesM

Încărcat de

nsadnanDrepturi de autor:

Formate disponibile

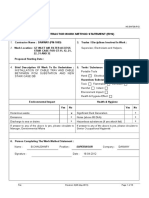

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY (4600003190) 3. Trades / Disciplines Involved In Work :

2. Work Location : POT LINE 1 A, ELECTRICAL Engineer, Supervisor, Electricians and Helpers.

ROOM - Bldg: 5115-01,

CONTROL ROOM-5910-01

Proposed Starting Date :

4. Brief Description of Work to Be Undertaken: 5. Tools / Substance

CABLE PULLING / LAYING (Power Cables, Control Portable Tools

Cables & FO Cables). Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste x Significant Dust Generation x

Emissions x Noise (above 85 DbA) x

Discharge to sea or drains x Hazardous substances (if yes attach list) x

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Position : Company :

Signature : Date :

File: Revision: 0(26-May-2011) Page 1 of 16

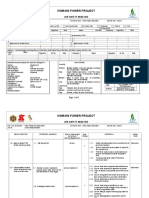

HS.SAF.09.F12

7. Approvals

Contractors Site Rep. Name Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 16

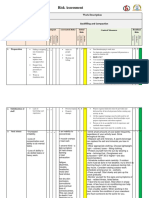

HS.SAF.09.F12

8. Safety Analysis

Severity x Probability

Identified Hazard(s) = Risk

Individual Activities To Complete Work. Persons Exposed To Precautions and Plan of actions To Be Taken

Associated With Residual Risk

List In Sequence of Activity Hazard To Remove / Control Hazards

Activity (Use Risk Estimator

Chart)

PREPARATION. Slips, trips and fall at Emal rep., Engr., After getting valid permit from EMAL only

Supv. Elec, and 2x2=4

the same level. starts work.

Hot environment helpers Engineer / supervisor ensure that the work

Manual handling permit is valid for the date and time

hazards. Electrical room is under Electrical

maintenance team and they should be

informed while doing the cable pulling job.

Electrical room having LV Live panels, care

should be taken not to touch or disturb the

live panel.

Control room occupies lot of critical servers

and panels and critical cables running

below the rasied floor. Extra care should be

taken not to damage/disturb those panels

and cables.

Minimum numbers of people are allowed to

work inside control room.

Ensure the operatives must be go through

EMAL POTLINE Electrical Hazard Training

and Big Five Training.

All personnel involve in the activities must

wear the required PPEs at all

times(eg.hard hat, appropriate safety glass,

File: Revision: 0(26-May-2011) Page 3 of 16

HS.SAF.09.F12

electrical insulated safety shoe, hand

gloves, dust mask, fire retardant long

sleeve shirt / pants)

All personnel involve in the activity must be

aware of heat stress, supervisor to ensure

cold drinking water and electrolyte are

available at site all time. Use heat

radiation shield.Ensure that Storage of

drinking water while working in Live Potline

and basement must be well outside the

Potline battery limit. (After the Yellow

barricade).

Power cables are running below false floor

care should be taken to not to damage

those cable while fixing the panel,

supervisor to ensure.

Ensure that Material handling through

ramp shall be manual handling only and

pick up and any other vehicles are not

allowed on that area.

Ensure that access ladder will be use only

for access, donot as a working platform

Ensure that people working in duct side

should be rotated every 1 hour.

Advance planning by contractor

considering the time consumption to

receive the permit from EMAL

Emergency procedure must be displayed

at prominent location and cascade to

operatives on regular interval and

recorded.

File: Revision: 0(26-May-2011) Page 4 of 16

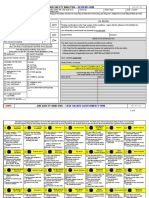

HS.SAF.09.F12

The operatives must be go through

DANWAY safety induction.

Extra care should be taken while working

in Live Potline and Basement.

Danway supervisor to ensure that danway

employees should not go near the live

pot / busbars and not touching the

superstructure.

Use only specific Entry and exit route to

potline.Co-ordinate with shift supervisor for

the specific Entry and exit route.

Only day shift are allowed to work in

potline and danway supervisor to ensure

that yellow lines should not crossed by the

any danway employees.

Hardhat, coverall and safety shoes, Visual

Trip, fall and

MATERIAL HANDLING Supv. Elec & helpers inspection. 3x1=3

stumble.

Ensure proper house keeping at all time.

Safety gloves. Visual and physical

Containers, nails

Elect & helpers inspection. 2x1=2

and brick edges.

Level area and all load-bearing equipment

Emal, Engr., Supv. in satisfactory condition. Physically check

Collapses. 3 x 1 =3

Elec, and helpers stability or condition of load bearing area or

equipment.

Physically check load is secure, ropes,

straps or tie downs, ensure load is

Emal, Engr., Supv.

Struck by unstable securely bound for strapped down. 3 x 1 =3

Elec, and helpers

load Use cable trolley to transport cable

drums.

File: Revision: 0(26-May-2011) Page 5 of 16

HS.SAF.09.F12

Operator must pass third party

competency test for crane operation and

secure competency certificate.

Operator should attend induction course

for carne operation.

Crane must have:

Valid registration from RTA to

Travel

Valid certificate of conformity or

through crane inspection from

OPENING THE CABLE CAMBER Unauthorized All workers invlove approved certification agencies. 2 x2=4

BY USING CRANE operation of crane in the activity Statement of insurance policy

Supervisor / Foreman to conduct daily

crew talks prior to start the activity

Implement close supervision during the

activity.

Ensure Crane is in good condition with

valid load test certificate and with EMAL

inspection sticker on it.

Assign a certified rigger.

Barricade the working area by using

safety cones warning tape / signboard.

Mechanical Failure All workers invlove Crane must be certified by approved

in the activity 2 x2=4

third party certification agencies.

Ensure that lifting gears, chains, and

slings should be inspected, certified and

valid colour coded on it.

Avoid overloading of transport

equipment.

Lift load for its specific load limit or safe

File: Revision: 0(26-May-2011) Page 6 of 16

HS.SAF.09.F12

working load.

Use tag lines or tag ropes to guide the

load towards its destination.

Having no control of All workers invlove

Assign a certified rigger/banksman. 3x1=3

the load in the activity

Barricade the working area by using safety

cones warning tape / signboard.

Supervisor to conduct tool box meeting

Manual handling

Electricians & about proper manual handling before prior

Injury to workers Helpers to start work

2 x 1 =2

(back,hands,foot)

Use proper PPEs.

No available Permit to work to obtained prior to start the

All workers invlove 2 x2=4

WORKING INSIDE CONFINED confined space in the activity job and daily toolbox talk to be given prior

permit to start the job, supervisor to monitor

Entry to the confined space through log

register only.

Stand by person to be deputed in the

entrance of confined space.

Lifeline to be attached with the employees 2 x2=4

All workers invlove

Access/Egress as required.

in the activity

Provide access ladder.Make sure that it

touchs the ground properly and should

have a meter excess outside the confined

space.ensure that the ladder to be used is

in good condition.

Unaware emergency All workers invlove Emergency procedure must be displayed

in the activity 2 x2=4

procedure of EMAL at prominent location and cascade to

operatives on regular interval and

recorded.

File: Revision: 0(26-May-2011) Page 7 of 16

HS.SAF.09.F12

Erect heavy duty scaffold and provide

safety barriers/barricades and safety

warning signals/sign boards.

Raise a beam in one guard rail for

connecting one pulley and life line.

A competent person will be positioned

outside the confined space is such a

manner that he will be able to monitor the

activity and status of the personnel

working inside.he will be the immediate

source of contact of those personnel in

confined space.

All personnel involve in activities must

wear P.P.E.'s at all times (hard hat, safety

glass, safety shoes, hand gloves, dust

mask 3M-8210, cover all. Clear safety

glasses inside confined space)

And any other P.P.E. should it be required

for the task

In case of emergency, immediately contact

EMAL/SLII Emergency Response Team,

EMERGENCY NO:02-509 2111

The number of persons in the confined

space should always be known and signed

onto the confined space permit before

Unknown quantity of

All workers invlove entry

workers inside the 3 x 1 =3

in the activity Confined space watchman to be posted at

confined space

entrance of confined space at all times and

to sign workers into and out of confined

space

File: Revision: 0(26-May-2011) Page 8 of 16

HS.SAF.09.F12

All workers invlove Workers must attend the Emal confined

Untrained workers 2 x 1 =2

in the activity space training.

Gas/oxygen test to be completed in daily

basis, Supervisor to monitor / As required.

Changing

All workers invlove Each shift provide safe access to work

environment in the activity

3 x 1 =3

location

conditions

Provide proper lights as per confined

space requirement

Gas /oxygen test to be conducted in hourly

Presents of toxic basis and keep record along with confined

All workers invlove space permit. 2 x2=4

gases and lack of in the activity

oxygen Positive ventilation to be provided into the

confined space If required

Slips, trips and fall at Maintain housekeeping around in the

the same level. All workers invlove working area.

3 x 1 =3

Slips, trips and fall in the activity Proper barrication around the manhole to

into manholes be provided.

Toolbox talks to be held at site, this shall

Unauthorized cover the method statement and Risk

workers at the area assessment.

TRANSPORTATION/UNLOADING

may injure due to Supv. Elect & Only competent and authorized personnel

/ SET UP OF CABLE DRUM FOR helpers

2x1=2

moving of to be deployed, supervisor to ensure all

PULLING (using boom truck). construction workers involve in the activity received the

equipments. EHS induction of EMAL and DANWAY.

Pre-work checklist has to be completed.

Inadequate access to Transport vehicles must be parked in

Supv. Elec, and 3 x 1 =3

off load materials helpers dedicated loading or unloading space or

Accidentally drop of as closer as is safely possible to the site.

load. Provide safety sign boards and barricade

File: Revision: 0(26-May-2011) Page 9 of 16

HS.SAF.09.F12

the area where loading and unloading

works will be initiated.

Make sure that the boomtruk surface,

where the cable will be placed, is clear

from any unnecessary materials.

Personnel should stand well clear of

equipment being loading or unloading.

Too close to existing

Personnel should not climb onto or work

Emal facilities

from the back of cable drum unless there

is absolutely no other way of loading or

unloading.

Secure the cable drum, as needed, on the

boomtruck to avoid any

unnecessary/unwanted movements

during transport

Bad housekeeping - Maintain house keeping around the area

Emal, Engr., Supv.

workers may slip, trip Elec, and helpers Walkway and gangway to be kept free of 3 x 1 =3

& fall at same ground. obstruction

Supervisor to give toolbox talk regarding

standard safe lifting operation prior to start

Bad condition

the lifting activity and documented.

of boom truck.

Ensure boom truck is in good condition

Incompetent of

with valid load test certificate and with SLI

boom truck operator Elec & helpers sticker on it. 2 x 2 =4

and banks man.

Competent boom truck operator & banks

Movement of

man with valid certificates to be deployed

cable drum while for lifting operation.

unloading.

Tag line to be attached to the load to guide

and control the movement of cable drum.

CABLE PULLING / LAYING ON Blocked access/exit Emal, Engr., Supv. Personnel shall ensure that correct 2x1=2

CABLE TRAYS, LADDERS & routes Elec, and helpers handling practices are used at all times,

File: Revision: 0(26-May-2011) Page 10 of 16

HS.SAF.09.F12

Fall of materials i.e. bending the knees and keeping the

and/or tools back straight.

Fall of personnel Personnel shall ensure that access routes

RACEWAYS Back injuries/strains are kept clear at all times and/or

alternative walkways are provided.

Personnel shall ensure that all tools and

equipment are kept secured at all times.

Sharp edges from Supv. Elec, and Extra care while or pulling or laying the

cable ladder /tray, helpers cable on cable ladder /tray, raceways ,Use

raceways. hand gloves

Touch up paint shall be applied to the cut 2x1=2

edges / scratches / damaged surface of

cable ladder /tray, raceways.

Use appropriate PPEs all the time.

Fall from height Elec, and helpers Provide proper access to work

overhead.ie(scaffolds or ladder)

Full body harness with double lanyards

shall be use when working at height 1.8m

and above. Ensure 100% tie off. 3 x 1 =3

Daily toolbox meetings to be conducted on

days activity, which will include TRA for

the activity

Implement close supervison

Unwanted fall of Emal, Engr., Supv. Cordon the work area to avoid 3 x 1 =3

objects, tools, and Elec, and helpers unauthorized entry.

materials may Provide applicable safety warning

cause head injury to signboards.

workers underneath No materials or hand tools to be stocked

on the top of scaffold/ladder.

Electrical tools, materials to be

File: Revision: 0(26-May-2011) Page 11 of 16

HS.SAF.09.F12

removed should be in safe manner one

by one--, ensure no materials to be

dropped.

Use appropriate PPEs

Use of A type Supv. Elec, and Use three point contacts while climbing up

ladder helpers and down ladder.

Always climb up and down facing the

ladder

Dont carry tools or materials in your hand

2x1=2

while climbing up and down ladder.

Wooden/fiber ladder to be used.

Ladder to have valid inspection tag.

Manually guiding of Elec, and helpers Extra care to be taken while manually

cable unto cable guiding of cable to the cable rollers, use

rollers. hand gloves. 2x1=2

Check each roller if it is rolling smoothly,

apply WD40 or grease as required.

Workers may get Elec, and helpers Supervisor to ensure all workers

injure due to poor understand the objective of the activity,

communication crew meeting to be held.

2x1=2

among workers Two way radio (walkie talkie) will be

during the cable used for communication.

pulling.

Workers may slip, Emal, Engr., Supv. Maintain housekeeping around the area.

trip & fall at same Elec, and helpers Walkway and gangway to be kept free of 2x1=2

ground or from obstruction.

height.

CABLE PULLING / LAYING ON Bad house keeping Emal, Engr., Supv. Maintain housekeeping around the area. 2x1=2

CABLE DUCTS - workers may slip, Elec, and helpers Walkway and gangway to be kept free of

trip & fall at same obstruction.

ground.

File: Revision: 0(26-May-2011) Page 12 of 16

HS.SAF.09.F12

Manual handling Toolbox talks to be held at site, this shall

hazards. cover the method statement and job safety

analysis.

Unauthorized Supv. Elec, and Only competent and authorized

or incompetent helpers

personnel to be deployed.

workers at working 3 x 1 =3

area may damage

Excavation check list has to be

property. completed.

Workers may get Elec, and helpers

Supervisor to ensure all workers

injure due to poor understand the objective of the activity,

communication crew meeting to be held. 2x1=2

among workers

Two way radio (walkie talkie) will be

during the cable

used for communication.

pulling.

Elec, and helpers Extra care to be taken while manually

Manually guiding of guiding of cable to the cable rollers/bell

cable unto cable mouth, use hand gloves. 2x1=2

rollers/bell mouth. Check each roller if it is rolling smoothly,

apply WD40 or grease as required.

Workers may Emal, Engr., Supv. Maintain housekeeping around the area.

slip, trip & fall at Elec, and helpers Walkway and gangway to be kept free of

3 x 1 =3

same ground or to obstruction, barricade the edge of the

the manholes. maneholes.

Detaching of pulling Cable pulling group

eye from the cable Connect pulling eye with cable properly.

while pulling: Check cable clamp with torque bar for

Improper connection correct torque. 2 x 2 =4

between pulling eye Ensure close Supervision through out the

and cable activity

Lack of supervision

File: Revision: 0(26-May-2011) Page 13 of 16

HS.SAF.09.F12

Cable rollers: Cable pulling group

Connecting swivels should be in good

Nip points created condition and rotate freely

by cable & Training on correct manual handling

rollers/ducts 3x1=3

Issue PPE

Improper handling

Ensure close Supervision through out the

of cable

activity

Lack of supervision

Blocked access/exit Emal, Engr., Supv. Personnel shall ensure that correct

routes Elec, and helpers handling practices are used at all times,

Fall of materials i.e. bending the knees and keeping the

and/or tools back straight.

Fall of personnel Personnel shall ensure that access routes 2x1=2

Back injuries/strains are kept clear at all times and/or

alternative walkways are provided.

Personnel shall ensure that all tools and

equipment are kept secured at all times.

High Ambient Emal, Engr., Supv. Wear recommended PPE; safety boots

Temperatures: Elec, and helpers overall, hardhat, gloves and safety

Heat Stress glasses.

Illness/Fatalities Give tool box talk regarding heat stress.

Cold drinking water and electrolyte to be 2 x 2 =4

available on site for employees.

Ensure area is clear.

Supervisor to ensure good housekeeping.

Regular inspections of area

Dust and ., Supv. Elec, and Supervisor to assess severity of storm.

sandstorm: helpers Low - provide personal protective

Low

3x1=3

equipment.

visibility/Nuisance High - stop work & take shelter.

File: Revision: 0(26-May-2011) Page 14 of 16

HS.SAF.09.F12

Unauthorized Other workers Only competent and authorized person to

do the inspection, ensure notified the 3x1=3

INSPECTION workers nearby

DUBAL with all necessary documents.

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

File: Revision: 0(26-May-2011) Page 15 of 16

HS.SAF.09.F12

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 16 of 16

S-ar putea să vă placă și

- Risk Assessment For GIS Preparation For HV Cable TestDocument11 paginiRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- RISK ASESSMENT For SKYLIGHTDocument23 paginiRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Jsa-004 Pressure WasherDocument4 paginiJsa-004 Pressure WasherDamien MonizeÎncă nu există evaluări

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 paginiRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanÎncă nu există evaluări

- Vacuum Test Risk AssessmentDocument6 paginiVacuum Test Risk AssessmentJohn Mark MacoyÎncă nu există evaluări

- DDC Systems2Document28 paginiDDC Systems2nsadnan100% (1)

- N16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSDocument5 paginiN16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSAntaryami Singh GoondiÎncă nu există evaluări

- Electrical Isolation Procedure for South Pars Gas FieldDocument12 paginiElectrical Isolation Procedure for South Pars Gas FieldJahel Looti100% (1)

- Risk Assessment - Installation of Ventilation FanDocument6 paginiRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment For Trial Pit Excavation-RevDocument15 paginiRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandÎncă nu există evaluări

- Duqm Refinery Fence Removal JSADocument15 paginiDuqm Refinery Fence Removal JSAAsad RazaÎncă nu există evaluări

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 paginăCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Ass. - AD 417 - Installation of SocketDocument6 paginiRisk Ass. - AD 417 - Installation of SocketnsadnanÎncă nu există evaluări

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 paginiRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanÎncă nu există evaluări

- Machinery and Equipment Safety - An Introduction: 1st EditionDocument22 paginiMachinery and Equipment Safety - An Introduction: 1st EditionAdel SukerÎncă nu există evaluări

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 paginiRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 paginiRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 paginiRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- 4wce 600700Document53 pagini4wce 600700Ahmed Elhoseeny100% (1)

- FO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineDocument4 paginiFO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineRidha Bennasr100% (1)

- LOTO ProcedureDocument2 paginiLOTO ProcedureRitesh Dev MaityÎncă nu există evaluări

- Permit To Work FormDocument2 paginiPermit To Work FormNate JamesÎncă nu există evaluări

- Metering Skid ErectionDocument4 paginiMetering Skid ErectionNature BeautiesÎncă nu există evaluări

- Busways Installation Risk AssessmentDocument38 paginiBusways Installation Risk AssessmentAjith Deva PrashanthÎncă nu există evaluări

- JSA For 33KV GIS and Panel TestingDocument13 paginiJSA For 33KV GIS and Panel TestingKhan WasimÎncă nu există evaluări

- 2 - REV. 2 Cable Pulling JHA Rev. 2Document23 pagini2 - REV. 2 Cable Pulling JHA Rev. 2naiyarÎncă nu există evaluări

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 paginiRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- AzSPU SSOW Procedure For ExcavationDocument29 paginiAzSPU SSOW Procedure For ExcavationAmir M. ShaikhÎncă nu există evaluări

- Work at Height ProcedureDocument36 paginiWork at Height ProcedureShams JogÎncă nu există evaluări

- ADDC Electricity Wiring Regulations - Mar.2014Document276 paginiADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- RA Cable PullingDocument3 paginiRA Cable PullingRandy Adisyah0% (1)

- Bus Duct Unloading, Shifting, Installing MS 01Document25 paginiBus Duct Unloading, Shifting, Installing MS 01Sufiyan KhedekarÎncă nu există evaluări

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 paginiRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanÎncă nu există evaluări

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 paginiRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanÎncă nu există evaluări

- 000 Za e m09401 - B Cable Pulling Ms 10 6Document18 pagini000 Za e m09401 - B Cable Pulling Ms 10 6syam prasadÎncă nu există evaluări

- 109 Installation CCTV Systems PDFDocument60 pagini109 Installation CCTV Systems PDFRodelDavidÎncă nu există evaluări

- Jsa For TIE INS in Accommodation BlockDocument4 paginiJsa For TIE INS in Accommodation BlockAliÎncă nu există evaluări

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 paginiPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanÎncă nu există evaluări

- Checklist For Commissioning of CCTV SystemDocument2 paginiChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Jsa FormDocument3 paginiJsa Formmiaicarba100% (1)

- Checklist For Access Control System InstallationDocument6 paginiChecklist For Access Control System Installationnsadnan71% (7)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 paginăTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- ITP For MV Power Cables & Accessories InstallationDocument1 paginăITP For MV Power Cables & Accessories InstallationAdil HasanovÎncă nu există evaluări

- Confined Space Work Guidelines: Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 paginiConfined Space Work Guidelines: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar Singh100% (1)

- HSW2 Workplace Risk AssessmentDocument3 paginiHSW2 Workplace Risk AssessmentNoel Nico Fernando100% (1)

- JSA Cable Pulling and Laying Works AutosavedDocument6 paginiJSA Cable Pulling and Laying Works AutosavedWisnu Wijaya100% (1)

- R A Working at Height ... ADDCDocument5 paginiR A Working at Height ... ADDCAjas AjuÎncă nu există evaluări

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDocument21 paginiKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçÎncă nu există evaluări

- Risk Assessment - Hot Water BoilersDocument4 paginiRisk Assessment - Hot Water BoilersUgonnaÎncă nu există evaluări

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 paginiHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocument6 paginiRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Checklist For Pre Commissioning of CCTV SystemDocument1 paginăChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- API Safety and Fire Protection PublicationDocument6 paginiAPI Safety and Fire Protection PublicationDan PascoÎncă nu există evaluări

- Method Statement For Cable Laying, Glanding and TerminationDocument12 paginiMethod Statement For Cable Laying, Glanding and TerminationSajid Raza100% (1)

- Work Permit Hand OutsDocument13 paginiWork Permit Hand OutsSuraj Bera100% (2)

- Construction Safety ManagementDocument19 paginiConstruction Safety ManagementASGaneshachar100% (2)

- Permit To Work Procedure RequirementsDocument27 paginiPermit To Work Procedure RequirementsVenkat Sujith50% (2)

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Document6 paginiMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectÎncă nu există evaluări

- Cable Pulling, Glanding and TerminationsDocument6 paginiCable Pulling, Glanding and TerminationsnsadnanÎncă nu există evaluări

- Rectification of Defective High Mast Lighting in Cast House Yard LightingDocument6 paginiRectification of Defective High Mast Lighting in Cast House Yard LightingnsadnanÎncă nu există evaluări

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocument8 paginiRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- D02 MS Ra Pov PDFDocument35 paginiD02 MS Ra Pov PDFnsadnanÎncă nu există evaluări

- Contractor Work Method Statement-GIS Parts, Equipmentand ToolsDocument10 paginiContractor Work Method Statement-GIS Parts, Equipmentand ToolsnsadnanÎncă nu există evaluări

- Electrical Maintenance & Testing Hazard IdentificationDocument10 paginiElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaÎncă nu există evaluări

- HSE Plan - HB2NP Habeeb (New)Document81 paginiHSE Plan - HB2NP Habeeb (New)nsadnanÎncă nu există evaluări

- Installation of AMI/AMR CablesDocument9 paginiInstallation of AMI/AMR Cablessalman100% (1)

- Electrical Safety Laws 2019Document4 paginiElectrical Safety Laws 2019mamillapalli sri harshaÎncă nu există evaluări

- HIRA Electrical Works HRC 002Document7 paginiHIRA Electrical Works HRC 002syed khaja misbhuddinÎncă nu există evaluări

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Document3 paginiPower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMAÎncă nu există evaluări

- HIRADC Assessment-INSTALLATION OF BUSDUCTDocument6 paginiHIRADC Assessment-INSTALLATION OF BUSDUCTTengkudin LatifÎncă nu există evaluări

- Ehs 019 Houston Contactor Safety ProcedureDocument17 paginiEhs 019 Houston Contactor Safety ProcedureSayed AbbasÎncă nu există evaluări

- TOA Public Address System CatalogDocument16 paginiTOA Public Address System CatalogHanif WiewekaÎncă nu există evaluări

- Backfilling and CompactionDocument6 paginiBackfilling and CompactionAbbas iraqiÎncă nu există evaluări

- JSA PRE-TEST UploadDocument2 paginiJSA PRE-TEST UploadDenny Kurniawan PrawiraÎncă nu există evaluări

- F-QAQC-17, Rev.B - FAT LV Panel PDFDocument3 paginiF-QAQC-17, Rev.B - FAT LV Panel PDFpw ptusa100% (1)

- Installation and Removal of High MastDocument3 paginiInstallation and Removal of High MastMohd Hafiz Muhamed100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 paginăJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseÎncă nu există evaluări

- Risk assessment for sewerage installation projectDocument2 paginiRisk assessment for sewerage installation projectmd_rehan_20% (1)

- Electricity Transmission Department Incident NotificationDocument17 paginiElectricity Transmission Department Incident NotificationBalakrishnan Krishnan0% (1)

- Stringing 30kV LineDocument7 paginiStringing 30kV LineSamuelTrinandoÎncă nu există evaluări

- CEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTDocument6 paginiCEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTtanaÎncă nu există evaluări

- Critical Task Inventory (CTI)Document1 paginăCritical Task Inventory (CTI)Salman FareesÎncă nu există evaluări

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocument8 paginiContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanÎncă nu există evaluări

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocument9 paginiRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanÎncă nu există evaluări

- Contractor Work Method Statement (Ehs)Document11 paginiContractor Work Method Statement (Ehs)nsadnanÎncă nu există evaluări

- Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003ADocument6 paginiRisk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003AnsadnanÎncă nu există evaluări

- Modification of Cable Ladder in Bath Processing PlantDocument14 paginiModification of Cable Ladder in Bath Processing PlantnsadnanÎncă nu există evaluări

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Document8 paginiFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanÎncă nu există evaluări

- ONVIF Profile Feature Overview v2-2Document6 paginiONVIF Profile Feature Overview v2-2nsadnanÎncă nu există evaluări

- ONVIF Profile - S Specification v1-2Document42 paginiONVIF Profile - S Specification v1-2nsadnan0% (1)

- BSIA Cyber Secure It January 2019Document16 paginiBSIA Cyber Secure It January 2019nsadnanÎncă nu există evaluări

- ONVIF Profile T Specification v1-0Document77 paginiONVIF Profile T Specification v1-0nsadnanÎncă nu există evaluări

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 paginiPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanÎncă nu există evaluări

- 1 45Document3 pagini1 45nsadnan0% (1)

- Exc Fibre Installation GuideDocument38 paginiExc Fibre Installation GuidensadnanÎncă nu există evaluări

- HVAC ManualDocument107 paginiHVAC ManualWissam JarmakÎncă nu există evaluări

- Excel Intelligent PduDocument21 paginiExcel Intelligent PdunsadnanÎncă nu există evaluări

- Excel Intelligent Pdu User InstructionsDocument2 paginiExcel Intelligent Pdu User InstructionsnsadnanÎncă nu există evaluări

- Exc Installation GuideDocument1 paginăExc Installation GuidensadnanÎncă nu există evaluări

- Sensor Line Cable InstallationDocument6 paginiSensor Line Cable InstallationnsadnanÎncă nu există evaluări

- Exc Fibre Installation GuideDocument16 paginiExc Fibre Installation GuideMohamad FaifÎncă nu există evaluări

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocument14 paginiRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanÎncă nu există evaluări

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocument5 paginiRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanÎncă nu există evaluări

- Cfp-Hse-Tbm Topic No. 004 Msds 02 Oct 2018Document1 paginăCfp-Hse-Tbm Topic No. 004 Msds 02 Oct 2018Shitoba YimchungruÎncă nu există evaluări

- 7524 Sigmadur 520Document4 pagini7524 Sigmadur 520ShaikhRizwanÎncă nu există evaluări

- Sigmazinc™ 68 SP: Product Data SheetDocument5 paginiSigmazinc™ 68 SP: Product Data SheetStuart LemonÎncă nu există evaluări

- Sigmafast 155YDocument5 paginiSigmafast 155YStephen Francis BothelloÎncă nu există evaluări

- OTIS Field Operations CR Training FINALDocument91 paginiOTIS Field Operations CR Training FINALSANAL KUMAR SÎncă nu există evaluări

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pagini3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- Health and Safety in WeldingDocument46 paginiHealth and Safety in Weldingegn2007Încă nu există evaluări

- MOS - Confined SpaceDocument5 paginiMOS - Confined Spacemuiqbal.workÎncă nu există evaluări

- OHS CodeDocument468 paginiOHS CodeHaider ElÎncă nu există evaluări

- SWC RoleCardsTemplatesDocument3 paginiSWC RoleCardsTemplatesAbdus SamadÎncă nu există evaluări

- OHS Worker Fatalities ReportDocument43 paginiOHS Worker Fatalities ReportSlav KornikÎncă nu există evaluări

- EM Safety Poster v02Document12 paginiEM Safety Poster v02Electrical EngineerÎncă nu există evaluări

- PlantDocument12 paginiPlantritika5656Încă nu există evaluări

- OHS Public Consultation 2014 Parts MiscellaneousDocument68 paginiOHS Public Consultation 2014 Parts MiscellaneousDeanLefebvreÎncă nu există evaluări

- JSA Review for Installing Electrical PanelDocument6 paginiJSA Review for Installing Electrical PanelMohammed HamzaÎncă nu există evaluări

- Work Permit SystemDocument50 paginiWork Permit SystemBin khammash and sons Co.Încă nu există evaluări

- Permit To WorkDocument3 paginiPermit To WorkMuStafaAbbasÎncă nu există evaluări