Documente Academic

Documente Profesional

Documente Cultură

Design of E - Glass Fibre Rainforced Plastic Pressure Vessel Design As Per ASME Sec X

Încărcat de

IJIRSTTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of E - Glass Fibre Rainforced Plastic Pressure Vessel Design As Per ASME Sec X

Încărcat de

IJIRSTDrepturi de autor:

Formate disponibile

IJIRST International Journal for Innovative Research in Science & Technology| Volume 3 | Issue 05 | October 2016

ISSN (online): 2349-6010

Design of E-Glass Fibre Rain forced Plastic

Pressure Vessel Design as per ASME Sec X

Shyam Lohar Lavish Patel

Student Student

Department of Mechanical Engineering Department of Mechanical Engineering

GIDC Degree Engineering College, Navsari, Gujarat, India GIDC Degree Engineering College, Navsari, Gujarat, India

Mohmadaszad Patel Vijul Desai

Student Student

Department of Mechanical Engineering Department of Mechanical Engineering

GIDC Degree Engineering College, Navsari, Gujarat, India GIDC Degree Engineering College, Navsari, Gujarat, India

Dr. Dilip Patel

Associate Professor

Department of Mechanical Engineering

GIDC Degree Engineering College, Navsari, Gujarat, India

Abstract

One Glass Fiber Reinforced Plastic pressure vessel, subjected to internal design pressure of 90 psi was designed in accordance

with the procedures set out in ASME Section X, mandatory design rules for class II vessels with Method A Design Rules.

Destructive testing was done to find out the modulus of elasticity and flexural modulus as per ASTM D 3039. All the design factors

were considered and designed the safe pressure vessel.

Keywords: Design of Composite Pressure Vessel, ASME Sec X, Material Testing, Reinforcement Pad Dimensions

_______________________________________________________________________________________________________

I. INTRODUCTION

Glass fibers are primarily composed of silicon dioxide with some modifying agents [2]. E-glass (electrical glass) accounts for the

largest production of glass fibers in industry due to its low cost despite its mechanical properties that are lower than other grades

of glass fibers. It is specially used in making chemical processing tanks and pressure vessels. These tanks and vessels are usually

large in size. Pipe branch connections, manholes etc. in the vessels are very common and are potential weak points. These opening

contain discontinuities in the structure. The large size combining with the discontinuities limit the operating pressure of these

vessels. Each tank and vessel is custom made and they are different. Economic consideration does not allow manufacturers to

destructively test one vessel to prove that another identical one meets the design requirements. These vessels therefore fall under

the standard code for design and fabrication of FRP pressure vessels, ASME has published Boiler and Pressure Vessel Code Section

X: Fiber-Reinforced Plastic pressure vessels Work has been reported for investigation of design of FRP vessels based on

philosophy of ASME Boiler and Pressure Vessel Code. Hisao Fukunaga et al. [3] discussed the optimum design of helically wound

composite pressure vessels. J. Blachut [4] analysed filament wound torispheres under external pressure. Paul et al. [5] discussed

damage criterion approach to design fiber reinforced vessel. Baoping Cai et al. [6] presented reliability-based load and resistance

factor design of composite pressure vessel under external hydrostatic pressure.

Work related to investigation of design of FRP pressure vessels based on philosophy of ASME Boiler and Pressure Vessel Code

has been reported but very little work has been reported about the step by step procedure for the design of various components of

FRP pressure vessel and selection of dimensions of certain components as per the standards given in ASME section X. The present

work deals with the design of small FRP pressure vessel subjected to internal design pressure of 90 psig with methodology given

in ASME Section X including material testing. After design, this vessel will be fabricated and burst test will be carried out by

applying hydrostatic pressure for research work.

II. PROBLEM DEFINITION

The vessel is designed with the methodology of ASME Section X, Class II vessel. In this approach also Method A was used to

design the vessel. It will be constructed of mat laminate with contact molding method. Section X requires the use of lamina

properties coupled with lamination analysis to determine the laminate properties for use in method A design. These properties were

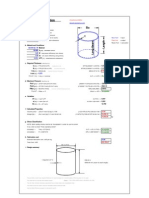

used together with the lamination theory equations in Section X. Fig.1 shows the overall dimensions of shell and nozzle with nozzle

location. The specification of nozzle has been given in Table I.

All rights reserved by www.ijirst.org 52

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

Fig. 1: Overall dimensions of shell and nozzle with nozzle location.

Table - 1

Specification of Nozzle

Mark Nominal Size (in) Elevation (in) Orientation (Deg) Location

A 3 30 90 Shell

III. MATERIAL TESTING

As per the methodology of ASME, section X, to design FRP pressure vessel, mechanical properties of FRP material like Modulus

of Elasticity, Flexural Modulus and Poissons Ratio are required. To find out these properties Article RD-12 is used for mat

laminate The thickness was taken as per ASTM D 3039: Standard Test Method for Tensile properties of Polymer Matrix

Composites Materials. And these obtained values by Rangoli FRP, Vapi are used by us. The selection of resin and fiber for this

panel was done as per ASME Section X. It was manufactured from Isophthalic Polyester resin and Eglass fiber, Chopped Strand

Mat (CSM) by a commercial fabricator using a hand lay-up technique.

Table 2

Mechanical Properties of Test Specimen (Lamina Properties)

Mean value of Modulus of Elasticity for specimens. 6.5*106 psi

Mean Value of Flexural Modulus 3.2*106 psi

Poissons Ratio 0.28

Table 3

Material Properties

Tensile modulus in axial direction(E1) 6.5*106 psi

Tensile modulus in hoop direction(E2) 1.8*106 psi

Flexural modulus in axial direction(E1f) 3.2*106 psi

Flexural Direction in hoop direction(E2f) 3.2*106 psi

Poissons ratio for stress in axial direction and contraction in hoop direction(1) 0.28

Poissons ratio for stress in hoop direction and contraction in axial direction(2) 0.28

IV. DESIGN OF FRP PRESSURE VESSEL

ASME Section X has two classes of vessels: I and II, both of which differ in scope. The classes are distinguished as follows:

Class I vessel design is qualified through possibly destructive fatigue and pressure testing of a prototype.

Class II vessel design is qualified through mandatory design rules and non-destructive acceptance testing, which includes an

Acoustic Emission examination

In present work, class II vessel design approach is used. The pressure scope for Class II vessels is more complicated, depending

on the size of the vessel. There are two methods for design calculations of Class II Vessels: Method A that uses design rules, and

Method B that provides for design by stress analysis. Irrespective to class or methods, Section X vessels must be between 6 in. and

192 in. in internal diameter. Vessels designed by Method A are limited to 100 psi internal design pressure and 144 in. internal

diameter. Vessels designed by Method B rules shall have pressure and diameter restrictions as follows:

Vessels may be designed using a combination of Methods A and B. For such vessels the maximum design pressure is limited to

100 psig with a maximum inside diameter of 144 in. Vessels designed by either Methods A or B are limited to a maximum external

pressure of 15 psig.

In present work, Method A was used and the internal diameter of vessel was considered as 15 in. (381 mm) and internal design

pressure of vessel was considered as 90 psi.

All rights reserved by www.ijirst.org 53

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

V. DESIGN CALCULATION

Do = outside diameter

E1 = 6.5*106 psi

= tensile modulus in the longitudinal (axial) direction, psi

E2 = 1.8*106 psi

= tensile modulus in the circumferential (hoop) direction, psi

F = design factor: 5 for external pressure on cylinders,10 for external pressure on spheres and heads, and internal pressure on

reinforcements

L = 42 in.

= length of cylinder

P = 90 psi

= internal pressure

Pa = allowable external pressure

R = 7.5 in.

= inside radius, shell or head

r = 1.5 in.

= inside radius, nozzle (in.)

SS = 1,000 psi

= secondary bond shear strength

t = thickness, in.

v1 = 0.28

= Poissons ratio, longitudinal (axial) direction

v2 = 0.28

= Poissons ratio, circumferential (hoop) direction

Cylindrical Shells under Uniform Internal Pressure

Design of Shell: Article RD-1171.1 of ASME section X gives the following rule for the minimum thickness of a cylindrical shell

subjected to internal pressure. The minimum thickness of cylindrical shells under internal pressure shall be greater of (a) and (b)

below, but not less than in. (6 mm).

Table 4

Nozzle and Nozzle Flange Dimensions [1]

Nominal Flange Bolt Bolt Hole Bolt Size(in.) and

Mark Flange Thickness (in.) Nozzle Thickness (in.)

Size(in.) OD(in.) Circle (in.) Dia. (in.) Number

A 3 7 1/2 6 3/4 5/8 and 4 1/2 1/4

Table 5

Shell Flange Dimensions [1]

Nominal Flange Bolt Circle Bolt Hole Dia. Bolt Size(in.) and Flange

Shell Thickness (in.)

Size(in.) OD(in.) (in.) (in.) Number Thickness(in.)

1 1 1 0.38 (As per design

15 23 21 1 1 and 16 1

2 4 8 calculations)

Longitudinal Stress

PR

t1 = (1)

2(0.0011 0.6)

90 7.5

=

2(6500 0.6 90)

= 0.052 inch

Circumferential Stress

PR

t2 = (0.001 (2)

2 0.6)

907.5

= (18000.690)

= 0.38 inch

Where 1 = structural wall thickness for longitudinal stress, 2 = structural wall thickness for circumferential stress, P = internal

pressure = 90 psi, R= inside radius of shell = 7.5 in. Therefore, let t = 2 =0.38 in.

Spherical Shells under Internal Pressure

Assume hand lay-up sphere with E1 = E2 = 1.8*106 psi:

PR

t = (3)

2(0.0010.6)

907.5

=

2(1800 0.690)

All rights reserved by www.ijirst.org 54

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

= 0.18 in.

Cylindrical Shells under External Pressure

Critical Length: Assume t = 0.38in. Therefore Do =2(R + t) = 15.76 in.

Do = 2(R + t) = 2 (7.5 + 0.38) = 15.76 in.

= 1.14 4(1 1 2 ). . (4)

15.76

= 1.14 41 (0.28 0.28) 15.76

0.38

= 143.19 in. > L

= 1 2

= 1.8 6.5 106

= 3.42*106 psi

2

K = 3.6 -

1 +2

= 2.77

For external pressure, let F = 5:

52

( )

=

1 0.45

3.42 106 15.76 0.38 52

2.77 ( )

= 5 42 15.76

0.38

1 0.45

15.76

= 69.015 psi

Spherical Shells under Uniform External Pressure

Assume hand lay-up sphere with E1= E2 = 1.8*106 psi. Therefore, let E = 1.8*106 psi and F = 10. Also,

Assume: t = 0.38 in. Therefore, Ro = R + t = 7.88 in.

Allowable pressure:

0.41 2

PA = (5)

2 3(11 2 )

6

1.8 10

0.41 0.382

= 10

7.882 3(1 0.28 0.28)

= 62.073 psi

Thickness of Heads under Internal Pressure

Assume hand lay-up head with E1 = E2 = 1.8*106 psi. Therefore, let E = 1.8 * 106 and let

D = 2R = inside diameter = 15 in.

Ellipsoidal Head

PD

t= (6)

2(0.0010.6)

15 90

=

2((0001 1.8 106 ) (0.6 90))

= 0.38 in.

Hemispherical Head

PR

t= (7)

2(0.0010.6)

1590

=

2((0.0011.8106 ) (0.690))

= 0.19 in.

Thickness of Heads under External Pressure

Assume hand lay-up head with E1 = E2 = 1.8 * 106 psi. Therefore, let E = 1.8 * 106 psi, and

F = 10. Also,

Assume: t = 0.38 in. so: Do = 2R + t = 15.76 in. and

Ko = 0.9 for 2:1 ellipsoidal heads

All rights reserved by www.ijirst.org 55

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

E

0.41t2

F

PA = 2

(8)

(Ko Do ) 3(1v1 v2 )

1.8106

0.41 0.382

10

= = 31.85 psi

(0.9 15.76)2 3(10.28 0.28)

Reinforcement of Openings and Nozzle Attachments

Nozzle attachments and reinforcing pad design: Table RD-620.1 of ASME Section X gives the dimensions of nozzles and their

flanges constructed of hand layup and pressure-moulded FRP. Nozzles and flanges of these dimensions satisfy the design

requirements of Section X. Flanges or nozzle designs not listed in this table can be designed by using Article RD-1176. Table V

lists the nozzle and nozzle flange dimensions and Table VI lists the shell flange dimensions for the test vessel, which were taken

from Table RD-620.1 of ASME section X and are for 90 psig internal pressure. Article RD-1174 of ASME section X gives the

methodology to design the reinforcement for openings in shell and head. Typical dimensions of reinforcement pad and nozzle

overlay are given in Fig. 4. For the reinforcing pad and the nozzle overlay to be fully defined, criteria (I) through (IV) below must

be met.

Length of Secondary Overlay on Nozzle

The secondary bond length, Lb on the nozzle shall be sufficient to withstand the internal pressure acting against the cross-sectional

area of the nozzle.

For internal pressure, let F = 10; also, let r = 3 in. = inside radius of nozzle.

Fig. 2: Dimensions of reinforcing pad and nozzle overlay [1]

= (9)

2

901.5

= 1000

2

10

= 0.675 in. < 3 in.

= 3 in.

Where P = Internal pressure which is 90 psi (Table x), r = Internal radius of nozzle which is 3 in,Ss = secondary bond strength

in shear which is 1000 psi maximum as per ASME section X and F= Design Factor which is 5 for external pressure on cylinders

and 10 for external pressure on spheres and heads and internal pressure on reinforcements as per ASME section X. So for test

vessel F= 10.

By putting above values one gets = 0.675 in. which is less than 3 in. So = 3 in.(76.2 mm).

or 3 in, whichever is greater.

So = 3 in.

Table 6

Component wise pressure

Component H (in.) P (psig)

Shell 42 90

Nozzle 30 89

Thickness of Secondary Overlay on Nozzle

The secondary overlay thickness tb on the nozzle shall be sufficient to withstand the nozzle internal pressure.

= ; Sut = 0.001*E = 1.8 * 103 (10)

0.6

90 1.5

= (1.8

103 )(0.6 90)

= 0.077 in.

Or 0.25 in., whichever is greater

So = 0.25 in.

Thickness of Reinforcement Pad on Shell or Head

The thickness tp of the reinforcing pad shall be the greater of (1) and (2) below:

All rights reserved by www.ijirst.org 56

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

A thickness of secondary overlay with strength equivalent to the tensile strength in the circumferential direction of the shell

thickness removed:

PR

tp1 = (11)

0.001E2

907.5

=

0.0011.8106

= 0.375 in.

A thickness of secondary overlay, which when added to the shell thickness, will reduce the bending stress at the opening to

an allowable level. The allowable bending stress shall be defined as 0.1% of the flexural modulus of the reinforcing laminate

in its circumferential direction. It will be calculated as follows.

a) Step 1: Compute Beta factor

4

3(11 2 )

= (12)

2

4

3(10.280.28) 1.5

=

2 7.50.38

= 0.57

Putting R = 6 in., r = 1.5 in., t = thickness of shell =0.5614 in and 1, 2 equal to 0.32 and 0.32 respectively one gets = 0.5234

b) Step 2

Figure RD-1174.3 of ASME section X, gives the value of stress concentration factors (Kt) for a circular hole in a pressurized

cylindrical shell. For test vessel the value of Kt for membrane plus bending from this graph is Kt = 5.2

= S2*Kt = 1.8 *103 *5.2 = 9360 psi

Where S2 = allowable stress for the shell laminate in the circumferential direction, defined as 0.001 E 2 = 0.001 x 1.8*106 psi =

1.8 *103 psi

So = 9360 psi

c) Step 4

Determine the moment M associated with the stress being applied at the edge of the opening. Assume a moment beam 1 in.

wide and having a thickness equal to the shell thickness, with the stress decreasing away from the edge of the opening.

2

= (13)

6

9360 0.382

=

6

= 592.8 in-lb

Where t = vessel shell thickness = 0.38 in

So M = 592.8 in. lb

Step 5: Determine the thickness of reinforcement that will reduce the stress imposed by the moment M to the allowable Sf,

defined as 0.001Ef, Assume an effective equivalent moment to be M/2.

M

62

t p2 = t (14)

Sf

592.8

6 2

= 0.38

20 103

= - 0.081 in.

Where = allowable stress, defined as 0.001 = 20 103 . Here is nothing but the flexural modulus of reinforcing laminate

in the circumferential direction which is equal to 20 106 psi (Table III). t = thickness of vessel shell = 0.38 in.

By putting above values, one can find out thickness of reinforcing pad ( ) as = - 0.081 in.

The thickness of the reinforcing pad shall be the greater of the thickness computed for (1) and (2) above. So = 0.375 in.(9.5

mm)

Length of Reinforcing Pad on shell ( ): The reinforcing pad shall project a distance from the edge of the opening. The

distance shall be at least as great as the greater of (1) and (2) below. The pad shall terminate in a taper over an additional distance

six times the thickness of the pad.

A secondary bond area on the shell shall provide sufficient shear area to resist the internal pressure force on the nozzle. By

convention this area will be expressed in terms of a distance that the reinforcing pad will extend out from the nozzle and

will be computed as follows:

L P

Lp = 4Scs (15)

F

390

= 41000

10

= 2.12 in. < 3 in

Lp = 3 in.

= 2r = 2*1.5

All rights reserved by www.ijirst.org 57

Design of E-Glass Fibre Rain forced Plastic Pressure Vessel Design as per ASME Sec X

(IJIRST/ Volume 3 / Issue 05/ 010)

= 3in.

Where F= design factor = 10, = Longest chord length of opening = 3 in., P = internal pressure = 90 psi, = Secondary bond

shear strength= 1000 psi

Minimum Reinforcing Pad Requirements

1) For nozzles 6 in. diameter and less, shall be at least as great as .

2) For nozzles greater than 6 in. (152 mm) diameter, but less than or equal to 12 in. (305 mm) diameter, = 6 in. or ,

whichever is greater.

3) For nozzles greater than 12 in. diameter, shall be at least as great as . See Fig. 4

So for test vessel, the diameter of nozzle is 3 in. which is less than 6 in. so shall be at least as great as . that is 3 in.

So finally = 3 in.(76.2mm)

P(R+t)

to = (16)

0.001E2

= 0.394 in.

PR

Lo =

2SS

( )

F

VI. CONCLUSIONS

In the present work, an attempt has been made to design glass-fiber reinforced plastic pressure vessel subjected to internal pressure

of 90 psig. Design is based on general accordance with the procedures set out in ASME Section X, mandatory design rules for

class II vessels with Method A - Design Rules. All the design factors were considered and designed the safe pressure vessel.

Following dimensions of FRP pressure vessel and reinforcement pad are drawn from present design

1) Shell Thickness (t) = 0.38 in.

2) Length of secondary overlay on nozzle ( ) = 3 in.

3) Thickness of secondary overlay on nozzle ( ) = 0.25 in.

4) Thickness of reinforcement pad on shell ( ) = .375 in.

5) Length of Reinforcing Pad on shell ( ) = 3 in.

REFERENCES

[1] ASME Section X: Fiber-Reinforced Plastic pressure vessels, ASME Boiler and Pressure Vessel Code, (2007)

[2] Gibson, R. F. 1994. Principles of composite material mechanics. New York: McGraw Hill.

[3] Hisao Fukunaga & Masuji Uemura, Optimum Design of Helically Wound Composite Pressure Vessels, Composite Structures, 1 (1983) 31-49

[4] J. Blachut, Filament wound torisphere under external pressure, Composite Structures 26 (1993) 47-54

[5] Paul H. Ziehl & Timothy J. Fowler, Fiber reinforced vessel design with a damage criterion, Composite Structures 61 (2003) 395- 411

[6] Baoping Cai, Yonghong LiuZengkai Liu, Xiaojie Tian, Renjie Ji, Hang Li, Reliability-based load and resistance factor design of composite pressure vessel

under external hydrostatic pressure , Composite Structures 93 (2011) 28442852

[7] ASTM D 3039: Standard Test Method for Tensile properties of Polymer Matrix Composites Materials. (2008)

[8] ASTM D 790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. (2002)

[9] K.R.Rao, Companion Guide to the ASME Boiler and Pressure Vessel Code, Volume 2, Third Edition, Chapter 25(2009)

All rights reserved by www.ijirst.org 58

S-ar putea să vă placă și

- FRP Vessel Design As Per ASME Sec XDocument6 paginiFRP Vessel Design As Per ASME Sec Xlalitlbw9150% (2)

- Design Fiber Glass Reinforcement Vesselt For AgitatorDocument11 paginiDesign Fiber Glass Reinforcement Vesselt For AgitatorAnonymous T8aah3JfÎncă nu există evaluări

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 paginiMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Pressure Vessel Design CalculationsDocument127 paginiPressure Vessel Design Calculationsajayghosh314086% (22)

- Design and Stress Analysis of FRP Composite Pressure VesselDocument8 paginiDesign and Stress Analysis of FRP Composite Pressure VesselIJMTST-Online JournalÎncă nu există evaluări

- Finglowv2Document16 paginiFinglowv2RobinReyndersÎncă nu există evaluări

- bs4994 Case Study PDFDocument4 paginibs4994 Case Study PDFA.Subin DasÎncă nu există evaluări

- Flange DesignDocument6 paginiFlange DesignDinesh VaghelaÎncă nu există evaluări

- FRP DesignDocument17 paginiFRP DesignRUSTSHIELD IndonesiaÎncă nu există evaluări

- Design of Pressure Vessel by Group 4Document46 paginiDesign of Pressure Vessel by Group 4anteneh tesfayeÎncă nu există evaluări

- FRPDocument165 paginiFRPAditya VardhanÎncă nu există evaluări

- Pressure Vessel Design ASME Sec. VIIIDocument37 paginiPressure Vessel Design ASME Sec. VIIIprayogo1010Încă nu există evaluări

- Ameron CatalogDocument719 paginiAmeron CatalogLeianne050610100% (5)

- Tutorial PV Elite 2005Document23 paginiTutorial PV Elite 2005Fredy David Hutahaean100% (2)

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Document7 paginiDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- Design of Pressure Vessel by Group 4Document46 paginiDesign of Pressure Vessel by Group 4anteneh tesfayeÎncă nu există evaluări

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 paginăHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanÎncă nu există evaluări

- Asme Sec XDocument1 paginăAsme Sec XSARSAN NDTÎncă nu există evaluări

- GRP Chemical Storage TanksDocument5 paginiGRP Chemical Storage TanksKarim El ShamashergyÎncă nu există evaluări

- Fatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceDocument7 paginiFatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceFisul RahumanÎncă nu există evaluări

- 일본 압력용기 및 배관 기준의 최신동향 PDFDocument36 pagini일본 압력용기 및 배관 기준의 최신동향 PDFhbsheenÎncă nu există evaluări

- Design of Saddle Support For Horizontal Pressure Vessel PDFDocument5 paginiDesign of Saddle Support For Horizontal Pressure Vessel PDFnizam1372100% (3)

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocument5 paginiAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringÎncă nu există evaluări

- Pvp2014-28980 Analysis and Testing of A Ring-Joint FlangeDocument15 paginiPvp2014-28980 Analysis and Testing of A Ring-Joint Flangematteo_1234Încă nu există evaluări

- Case Study of Vessel As Per BS 4994Document4 paginiCase Study of Vessel As Per BS 4994nagarathinam82100% (1)

- Design CalcDocument308 paginiDesign CalcPeja Jusoh100% (1)

- Cd4Mcu: For Corrosive & Abrasive ApplicationsDocument4 paginiCd4Mcu: For Corrosive & Abrasive ApplicationsAulia RahmanÎncă nu există evaluări

- Saddle LoadsDocument11 paginiSaddle LoadsAnthony Dudley0% (1)

- PVElite Course by Mr. AsgarzadeganDocument79 paginiPVElite Course by Mr. AsgarzadeganSaam Sasanian33% (3)

- Bolt Torque Calculations 1 PDFDocument1 paginăBolt Torque Calculations 1 PDFshazanÎncă nu există evaluări

- NozzlePRO PDFDocument185 paginiNozzlePRO PDFIan CarrÎncă nu există evaluări

- 58-0100 FRP - Process - Vessels PDFDocument20 pagini58-0100 FRP - Process - Vessels PDFmayukhguha1988Încă nu există evaluări

- Tank Design: EN 1993 4 2 Eurocode 3Document31 paginiTank Design: EN 1993 4 2 Eurocode 3אחמד סלאח כאמלÎncă nu există evaluări

- Welded Pressure Vessel CalculationDocument7 paginiWelded Pressure Vessel CalculationClark Ivan TorresÎncă nu există evaluări

- Sight Glass Selection Guide PDFDocument7 paginiSight Glass Selection Guide PDFani_datÎncă nu există evaluări

- The Definitive O Ring Design GuideDocument31 paginiThe Definitive O Ring Design GuideChezÎncă nu există evaluări

- Davit Cal 2251B (Davit Arm Calculation)Document4 paginiDavit Cal 2251B (Davit Arm Calculation)Prajwal Shetty100% (4)

- Flange DesignDocument23 paginiFlange DesignNirmalkumarÎncă nu există evaluări

- Skirt Design - For Small VesselsDocument7 paginiSkirt Design - For Small VesselsSakthi VelÎncă nu există evaluări

- Design, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselDocument7 paginiDesign, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselGRD JournalsÎncă nu există evaluări

- Shell Thickness CalcDocument1 paginăShell Thickness CalcDidi KurniadiÎncă nu există evaluări

- ASME DIV 2 Class 1 Vs Class 2Document3 paginiASME DIV 2 Class 1 Vs Class 2Idris SiddiquiÎncă nu există evaluări

- Velan Triple Offset Butterfly L - BF - 2006aDocument24 paginiVelan Triple Offset Butterfly L - BF - 2006amfcramerÎncă nu există evaluări

- EIGA Publication 24 08 EDocument19 paginiEIGA Publication 24 08 EManton ArksÎncă nu există evaluări

- ASME Code and Rupture Discs Requirements-FikeDocument4 paginiASME Code and Rupture Discs Requirements-FikeMaha Wasif Khan100% (1)

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pagini3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaÎncă nu există evaluări

- Design and Experimental Validation of Composite Pressure Vessel-Siddani2018Document5 paginiDesign and Experimental Validation of Composite Pressure Vessel-Siddani2018Hiến Đinh VănÎncă nu există evaluări

- Final Published Paper IJRMEJune 2016Document11 paginiFinal Published Paper IJRMEJune 2016akiramartianÎncă nu există evaluări

- Pressure Vessel Design As Per ASME Section VIII Division 2 and Its OptimizationDocument8 paginiPressure Vessel Design As Per ASME Section VIII Division 2 and Its OptimizationSunil MishraÎncă nu există evaluări

- Fiber Reinforced Plastics VesselsDocument5 paginiFiber Reinforced Plastics VesselsandreshuelvaÎncă nu există evaluări

- Design and Analysis of Composite High Pressure Vessel With Different Layers Using Fea IJERTV3IS111412 PDFDocument5 paginiDesign and Analysis of Composite High Pressure Vessel With Different Layers Using Fea IJERTV3IS111412 PDFEl Youbi MohammedÎncă nu există evaluări

- Design & Structural Analysis of Poppet Valves For TVS Luna BikeDocument8 paginiDesign & Structural Analysis of Poppet Valves For TVS Luna BikeAnonymous kw8Yrp0R5rÎncă nu există evaluări

- An Optimum Design of Pressure Vessel UsiDocument15 paginiAn Optimum Design of Pressure Vessel Usicyril nbhhÎncă nu există evaluări

- 4142 13402 3 PBDocument5 pagini4142 13402 3 PBalbasirzahranÎncă nu există evaluări

- HYBRIDJOINTSDocument12 paginiHYBRIDJOINTSJohn Robert Dizon GabrielÎncă nu există evaluări

- Finite Element Modelling and Analysis of Pressure VesselDocument7 paginiFinite Element Modelling and Analysis of Pressure VesselIJRASETPublicationsÎncă nu există evaluări

- Assessment of Corrosion Damage Acceptance Criteria in API579-ASME/1 CodeDocument12 paginiAssessment of Corrosion Damage Acceptance Criteria in API579-ASME/1 CodeIntegridad de Equipos y Gestión de Activos NelcamÎncă nu există evaluări

- Influence of Residual Stresses On Failure PressureDocument7 paginiInfluence of Residual Stresses On Failure PressureAnonymous P8Bt46mk5IÎncă nu există evaluări

- Analysis of Pressure Vessel: A ReviewDocument5 paginiAnalysis of Pressure Vessel: A ReviewIJIRSTÎncă nu există evaluări

- Satellite Dish Positioning SystemDocument5 paginiSatellite Dish Positioning SystemIJIRST100% (1)

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocument10 paginiPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTÎncă nu există evaluări

- Arduino-UNO Based Magnetic Field Strength MeasurementDocument4 paginiArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTÎncă nu există evaluări

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocument4 paginiDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTÎncă nu există evaluări

- Literature Review For Designing of Portable CNC MachineDocument3 paginiLiterature Review For Designing of Portable CNC MachineIJIRSTÎncă nu există evaluări

- Currency Recognition Blind Walking StickDocument3 paginiCurrency Recognition Blind Walking StickIJIRSTÎncă nu există evaluări

- Social Impact of Chukha Hydro Power On Its Local Population in BhutanDocument2 paginiSocial Impact of Chukha Hydro Power On Its Local Population in BhutanIJIRSTÎncă nu există evaluări

- Automated Online Voting System (AOVS)Document4 paginiAutomated Online Voting System (AOVS)IJIRSTÎncă nu există evaluări

- Transmission of SAE BajaDocument5 paginiTransmission of SAE BajaIJIRST100% (1)

- Analysis and Design of Shear Wall For An Earthquake Resistant Building Using ETABSDocument7 paginiAnalysis and Design of Shear Wall For An Earthquake Resistant Building Using ETABSIJIRSTÎncă nu există evaluări

- Analysis of Fraudulent in Graph Database For Identification and PreventionDocument8 paginiAnalysis of Fraudulent in Graph Database For Identification and PreventionIJIRSTÎncă nu există evaluări

- Modeled Sensor Database For Internet of ThingsDocument4 paginiModeled Sensor Database For Internet of ThingsIJIRSTÎncă nu există evaluări

- Broken BondsDocument20 paginiBroken Bondsapi-316744816Încă nu există evaluări

- AnticyclonesDocument5 paginiAnticyclonescicileanaÎncă nu există evaluări

- Tetralogy of FallotDocument8 paginiTetralogy of FallotHillary Faye FernandezÎncă nu există evaluări

- Theories of International InvestmentDocument2 paginiTheories of International InvestmentSamish DhakalÎncă nu există evaluări

- Rockaway Times 11818Document40 paginiRockaway Times 11818Peter J. MahonÎncă nu există evaluări

- Damodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaDocument25 paginiDamodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaSumanth RoxtaÎncă nu există evaluări

- Syllabus DresserDocument2 paginiSyllabus DresserVikash Aggarwal50% (2)

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocument253 paginiEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamÎncă nu există evaluări

- Ozone Therapy - A Clinical Review A. M. Elvis and J. S. EktaDocument5 paginiOzone Therapy - A Clinical Review A. M. Elvis and J. S. Ektatahuti696Încă nu există evaluări

- Technical Bulletin LXL: No. Subject Release DateDocument8 paginiTechnical Bulletin LXL: No. Subject Release DateTrunggana AbdulÎncă nu există evaluări

- Lesson 6 ComprogDocument25 paginiLesson 6 ComprogmarkvillaplazaÎncă nu există evaluări

- Nutrition and CKDDocument20 paginiNutrition and CKDElisa SalakayÎncă nu există evaluări

- Tribal Banditry in Ottoman Ayntab (1690-1730)Document191 paginiTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirÎncă nu există evaluări

- Kahneman & Tversky Origin of Behavioural EconomicsDocument25 paginiKahneman & Tversky Origin of Behavioural EconomicsIan Hughes100% (1)

- Shostack ModSec08 Experiences Threat Modeling at MicrosoftDocument11 paginiShostack ModSec08 Experiences Threat Modeling at MicrosoftwolfenicÎncă nu există evaluări

- LM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Document2 paginiLM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Nishant JhaÎncă nu există evaluări

- Talking Art As The Spirit Moves UsDocument7 paginiTalking Art As The Spirit Moves UsUCLA_SPARCÎncă nu există evaluări

- Proceeding of Rasce 2015Document245 paginiProceeding of Rasce 2015Alex ChristopherÎncă nu există evaluări

- Spesifikasi PM710Document73 paginiSpesifikasi PM710Phan'iphan'Încă nu există evaluări

- SMC 2D CADLibrary English 1Document590 paginiSMC 2D CADLibrary English 1Design IPGEÎncă nu există evaluări

- Assignment#10 Global Strategy and The Multinational CorporationDocument1 paginăAssignment#10 Global Strategy and The Multinational CorporationAnjaneth A. VillegasÎncă nu există evaluări

- of Thesis ProjectDocument2 paginiof Thesis ProjectmoonÎncă nu există evaluări

- Online Extra: "Economists Suffer From Physics Envy"Document2 paginiOnline Extra: "Economists Suffer From Physics Envy"Bisto MasiloÎncă nu există evaluări

- Chapter 1 To 5 For Printing.2Document86 paginiChapter 1 To 5 For Printing.2Senku ishigamiÎncă nu există evaluări

- Science7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Document25 paginiScience7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Bella BalendresÎncă nu există evaluări

- Powerpoint Speaker NotesDocument4 paginiPowerpoint Speaker Notesapi-273554555Încă nu există evaluări

- Classifications of AssessmentsDocument11 paginiClassifications of AssessmentsClaire CatapangÎncă nu există evaluări

- Huawei R4815N1 DatasheetDocument2 paginiHuawei R4815N1 DatasheetBysÎncă nu există evaluări

- Time-Sensitive Networking - An IntroductionDocument5 paginiTime-Sensitive Networking - An Introductionsmyethdrath24Încă nu există evaluări

- User S Manual AURORA 1.2K - 2.2KDocument288 paginiUser S Manual AURORA 1.2K - 2.2KEprom ServisÎncă nu există evaluări