Documente Academic

Documente Profesional

Documente Cultură

Traditional Workbench

Încărcat de

aguinaldo6690Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Traditional Workbench

Încărcat de

aguinaldo6690Drepturi de autor:

Formate disponibile

WO R KS H O P

Traditional Workbench BY LAR RY O KR EN D

An heirloom project to build on

Building a traditional workbench is a challenge

that employs all of your woodworking skills, but

the result can last a lifetime and will serve you

like no other project can.

traditional cabinetmakers definitely stood the test of time: I the job more convenient.

A bench is much more than

a work surface its really

the biggest tool in your workshop.

It clamps, aligns, supports and

designed and built it about 16 years

ago, and it has been the functional

centerpiece of my shop ever since.

Youll need about 80 bf of 12/4

(3-in.) hard maple or a similar hard,

heavy and moderately stable wood.

(Light-colored wood creates a work

holds project pieces from start to Gather tools and materials surface thats easier on your eyes.) If

finish. Its also furniture for your Building this workbench requires you cant find thick stock, you can

shop. And like any good furniture, intermediate to advanced wood- glue thinner pieces together. An-

it should be sturdy, square and du- working skills and a good selection other alternative is to buy a manu-

rable after all, it must withstand of tools. If youre a dedicated wood- factured bench top online or from

great physical demands. worker, you may already have what a local lumber dealer. However, the

You can build a workbench that you need: a band saw, a table saw, tops size and thickness may differ

will serve all of these purposes. Its a jointer, a planer, a plunge router, from these plans, so you may need

a fairly ambitious project that takes a biscuit joiner and various hand to modify the size of the base and

about 30 to 60 hours to complete, tools. Depending on your preferred the way the vise hardware mounts.

but the time you invest in making work methods, you may be able to Be sure to purchase all of the hard-

it will pay off in years of service. build the bench with fewer tools ware before you start construction

The bench shown in this article has the array suggested simply makes to ensure a proper fit.

PHOTOGRAPHY BY MICHAEL ANDERSON

4 HANDY D E C E M B E R 2 0 1 1 / J A N U A R Y 2 0 1 2

11-12-Workshop.indd 4 11/1/11 12:53 PM

TRADITIONAL

WORKBENCH 2-1/4" 6" (10 spaces) 1" 1-1/4" 2-1/4"

1" B A E

1-1/8" 3/4"

dia. 1" 3/4" 1" deep slots Biscuit 7/8"

B A 87 1"

1" (typical) slot

2"

1-1/4" 3/8" DETAIL 2, BENCH TOP

dia.

3/8" dia. 2" 5/8"

3/4" I Tail vise

B A (see text)

1-1/4" dia.

1-1/2"

A E

DETAIL 1, END CAP E

No. 20

biscuit

1-1/4"

7/8"

2 87

No. 4

5" x 5/8"

Vise bracket fhws

I

5 1/2 x

B

4" 3-3/4"

(typ.) 1" spring

1"

D F

BENCH-TOP DOG

1 F

Elongate

C Sand

rear holes Vise flat 1" dia.

collar

3/8 x 4" bolt, I

washer and 3 1/2" 3/4"

nut (2 reqd.) rad. H

5-3/4" 1/2 x

4-1/4"

H

spring

3/8 x 4"

lag screw G

3/4" dia.

and washer F VISE-JAW DOG

(2 reqd.)

F 4

1-1/4" 1/8" 1/8"

F

3/8 x 4"

lag screw 1-1/8" deep hole

3/4" H 1/4"

and washer

(3 reqd.) 10-1/2" 4-1/2"

1-1/8" dia. 1-1/4"

10-1/2" tenon

25/64" dia. 1/2" H 1/4"

3/8 x 5" bolt,

washer and

nut (4 reqd.) 2-5/8" 1"

DETAIL 4

tenon

LEGS / STRETCHER

G 3

F 5-3/16" 6-11/16" 13/16"

1/2" C

3/4"

F 1-1/4" 1-5/8"

1/2" 1/4" 1/4"

1-1/4" dia. 9-1/2"

3/4" G 2-3/4" 1" 3/8"

1-1/4" Locate dado positions from bench top

1-1/4"

3/8" dia. 1"

C

5/8" (G)

G,I 1/4" 4-3/4"

1/2" (I)

3" 5" 7-1/2"

DETAIL 3, FEET / LEGS / RAILS DETAIL 5, FRONT VISE BENCH SLEEVE

ILLUSTRATION BY GABRIEL GRAPHICS

6 HANDY D E C E M B E R 2 0 1 1 / J A N U A R Y 2 0 1 2

11-12-Workshop.indd 6 11/1/11 12:53 PM

I used a large, traditional Veritas

single-screw front vise and a Veritas

twin-screw tail vise (see illustration,

opposite, and SOURCES ONLINE).

The twin-screw design prevents the

vise jaw from racking to maintain

even pressure on the workpiece.

Although I made my own bench

dogs, you can save some time by

buying them. If you do, be sure to

Biscuit grooves

size the dog holes accordingly.

Rough out the parts

For the parts to fit together prop-

erly, its essential that they be

straight, flat and square. If youre

starting with rough stock, use a

band saw to resaw the lumber to ap-

proximate size for the bench parts. Right-side jig

The pieces should be oversize to al-

low for milling waste. Sawing often

releases tension in the wood, which

can cause the stock to bow or twist.

1 2

Use a jig (see illustration, p. 10) and a Use a plate joiner to cut biscuit grooves

Let the wood sit for at least a few

router with a straight bit and a guide in the bench-top laminations. The biscuits

days in your shop to stabilize before

bushing to cut the bench-dog holes in the dont add strength; they align the pieces to

milling it to size.

two outside bench-top laminations. make assembly and milling much easier.

To make a bench top that is

strong, wears well and experiences

minimal wood movement, you

should mill the parts so that the

Router edge guide

annual rings run vertically (typi-

cally referred to as quartersawn

wood). This puts the fine, tight

grain on the top and bottom of the

bench; the wide-grain (plain-sawn)

sides are glued together. The same

principle holds true for the stand:

For stability, orient the quartersawn

sides vertically (feet, stretchers and

top rails) or toward the front (legs).

Make the top

3

The top is the most important and After squaring the end of the assembled top, cut the groove for the end cap (B) with a

time-consuming part of the work- router outfitted with a straight bit and an edge guide. Make multiple passes to achieve

bench to make. To keep waste to the required dimensions.

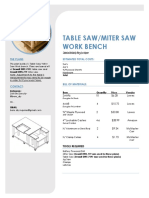

CUTTING LIST (all parts maple) SHOPPING LIST

KEY NO. DESCRIPTION SIZE Front vise (see SOURCES ONLINE)

Top Tail vise (see SOURCES ONLINE)

A 9 Bench-top laminations 2-11/16 x 3 x 66 in.* Bench stops (see SOURCES ONLINE)

B 1 Bench end cap 2-3/4 x 3 x 24 in. 80 bf of 12/4 maple

C 1 Front-vise bench sleeve 2 x 3 x 19 in. No. 20 plate-joining biscuits

D 1 Front-vise jaw 2-1/2 x 6 x 19 in. 3/8 x 4-in. bolts (2)

E 2 Tail-vise jaws 2 x 6-3/4 x 24 in. 3/8 x 5-in. bolts (4)

Stand 3/8-in. nuts (6)

F 4 Legs 2-3/4 x 3-1/4 x 27 in. 3/8-in. washers (17)

G 2 Feet 3 x 3-1/2 x 23 in. 3/8 x 4-in. lag screws (5)

H 2 Stretchers 1-1/4 x 5 x 51 in. Bench dogs, including 1/2 x 3-3/4-in. springs.

I 2 Top rails 2-3/4 x 3 x 18 in. 1/2 x 4-1/4-in. springs

*2-11/16-in. dimension is nominal; total width of stacked bench-top laminations is 24 in. No. 4 x 5/8-in. fhws

WWW.HANDYMANCLUB.COM DECEMBER 2011/JANUARY 2012 HANDY 7

11-12-Workshop.indd 7 11/1/11 12:53 PM

4

Once youve cut the end-cap groove in the top, cut the mating tongue in the end cap on

a table saw. Make the cut on the outside of the blade, not against the fence, to avoid

kickback. (The blade guard has been removed for photo clarity.)

Foot-mortise jig

5

Cut the leg mortises in the feet for the leg tenons with a router outfitted with a straight

bit and guide bushing. Use a jig (see illustration, below) to guide the cut. Youll cut the

contours in the feet after making the mortises.

Foot contour pattern

6

Make a hardboard pattern for the foot contours; then trace the shapes onto the work-

piece. Mark all sides so you can cut and sand to the line on both sides.

a minimum and produce a flat top in the cutting list. Mill the bench

that needs little sanding or planing, end cap (B) at the same time.

follow the steps outlined below. Next, arrange the pieces in the

First, joint and plane the bench- order that they should be assem-

top laminations (A) to their exact bled, and mark them so they dont

thickness and width but about get mixed up. Then mark the posi-

1/16 in. longer than the length tions of the plate-joining biscuits

11-12-Workshop.indd 8 11/1/11 12:53 PM

on all of the pieces, and mark the

dog-hole positions on the outside

pieces (see illustration, p. 6).

The best way to quickly cut the

square dog holes is with a couple

of simple router jigs one for the

left side and one for the right side

(see illustration, p. 10). These can

be nothing more than two pieces of

1/2-in. plywood nailed to scrap-

wood blocks that fit snugly against

the workpieces. Use a straight bit for

the cut and a router template bush-

ing to ride against the plywood.

(The space between the plywood

pieces depends on the diameter of

the bit and the size of the template

bushing.) The holes are angled to-

ward the tail vise so the dogs can

get a better bite on the workpiece. If

this is too much work, you can opt

for round dog holes.

Next, cut the kerfs for the plate-

joining biscuits in the bench-top

laminations. (The biscuits keep

the parts perfectly aligned during

assembly.) If you dont have a plate

joiner, use strips of 1/4-in. plywood

and cut the grooves with a router.

Rather than attempting to glue

all of the bench-top pieces to-

gether at once, I assembled them

in three sections and then glued

those sections together. This made

the procedure less rushed and

more accurate.

Sand or scrape off any glue

squeeze-out to level the top. Then

clamp a straightedge fence to the

top and use a straight bit to square

the ends of the top. Rout the groove

for the bench end cap in the left

end of the top using an edge guide

and a straight bit. (A spiral-cut end

mill works well.) You can do this

with the top resting flat (see photo

3, p. 7) or with it standing on end.

Drill the counterbores and holes

for the bolts in the end cap; then

cut the tongue to match the groove

in the top (see photo 4, opposite).

Rout the slotted holes that are op-

posite the bolt holes in the bottom

of the bench top (see illustration,

detail 1). Position the end cap; then

drill holes into the top using the

end-cap holes as guides. Elongate

the rear (left) hole in the top to al-

low for wood movement. Install the

WWW.HANDYMANCLUB.COM DECEMBER 2011/JANUARY 2012 HANDY 9

11-12-Workshop.indd 9 11/1/11 12:53 PM

4-1/2"

15-5/8"

ROUTER JIGS 5/8"

3"

3-7/8" 9/16"

13-1/4"

Right side

Right and left

dog jigs 1-1/2"

12"

6" 1-1/2"

Left side 3" 2-1/2"

1-3/4" (mirror of right side) 2-3/4"

1-3/8" 3/32" 3" 1-3/8"

87

4-3/4" Foot-mortise jig

8-1/4"

1"

4-5/8"

3"

19-1/8"

1-1/8"

Leg-mortise jig

1-1/8" 6-1/4"

3/4"

3-1/4"

1-1/2"

end cap by bolting it to the top. (Do

not use glue.)

Installing the vises varies accord-

ing to the models you purchase. (If

you use the same ones that are on

this bench, use the illustration as

a guide.) The Veritas twin-screw

vise I installed necessitated that I

use round bench dogs rather than

7 Cut the foot contours with a band saw. To prevent the blade from binding

in the cut or burning the stock, make several relief cuts to the contour line.

the square ones I used for the top.

Thats because the required 2-in.-

thick jaw isnt quite wide enough to

accommodate the angled holes for

the square dogs. Although a little

quirky, its only an aesthetic com-

promise, not a functional one.

Dont rush through installing

the vises they must be mounted

and adjusted properly to work ef-

fectively. Getting a vise to work

smoothly can be tricky and re-

quires patience. Be sure not to

cover any dog holes with the front-

vise-mounting bracket. To ensure a

good grip, use a hand plane to taper

the front-vise jaw slightly so its a

8 little thicker on the top than on the

bottom. Once the jaw is mounted

and working smoothly, plane the

Before finishing the stand joinery, test fit the legs, feet and top rails to ensure a good top edge so its flush with the top

fit. Make necessary adjustments with a sharp chisel. of the bench.

ILLUSTRATION BY MICHAEL ANDERSON

10 HANDY D E C E M B E R 2 0 1 1 / J A N U A R Y 2 0 1 2

11-12-Workshop.indd 10 11/1/11 12:54 PM

CUSTOM TOUCHES

9

The mortises in the legs that accept the stretchers (H) can be cut with a router and jig.

The joints should be snug but not too tight.

Although its not shown in the plan, this

Use a router jig to make the slots in

simple tray mounted to the workbench

the stretchers for the knockdown

top provides ready access to frequently

hardware (nuts and bolts.) You can

used small tools such as a tape mea-

assemble this stand without glue for

sure, pencils and a utility knife. You can

easier storage and transporting.

make the tray any size to accommodate

your needs.

Clearance

dado

10

Make the stand of the bench. Place them wherever

A sturdy set of legs for the bench is theyll do the most good.

Mounting the front vise takes patience essential, so build the stand care- You can buy bench dogs or you

and precision. Be sure to pay attention to fully. If youre familiar with mak- can make your own. It doesnt take

details such as the clearance dados for ing mortise-and-tenon joints, con- long to make them, and its a relax-

the bench dogs in the front-vise bench structing the stand shouldnt be ing break after building this bench.

sleeve (see illustration). Also take care difficult. I used a router to cut the See the illustration for details.

in tapering the jaws to achieve a secure mortises; then I cut the tenons on Finishing is optional, but it will

grip (see text). a table saw. enhance the appearance of the

The procedure for boring the bolt bench and offer some protection.

holes in the legs (F) and stretchers I used a clear water-base finish for

(H) is essentially the same one used the stand and Danish oil on the top

for boring holes to attach the end because it can be easily renewed.

cap to the bench top. If you want Be sure to apply oil to all surfaces

a stand that can be disassembled, of the top. Dont worry about oc-

dont glue the stretcher/leg joints. casional nicks and dings after

Bench stop Before you assemble the stand, bore all, this is a workbench, and the re-

all of the holes, including those in sulting patina shows admirers that

the top rails (I) that are needed to youre a real woodworker.

A mortised bench stop (see SOURCES bolt the stand to the bench top.

ONLINE) can be a useful device to brace Once youve completed the

workpieces perpendicular to the length SOURCES ONLINE

stand and attached the top, cut

For online information, go to www.HandymanClub.com

of the bench top. To mount a stop, simply mortises for the optional bench and click on WEB EXTRAS.

bore a hole for the screw-down mecha- stops (see SOURCES ONLINE). Lee Valley

nism and cut a shallow mortise with a (Veritas twin-screw vise, Veritas large front vise,

These are useful for bracing work- mortised bench stops), 800-871-8158

chisel or router. pieces perpendicular to the length www.leevalley.com

WWW.HANDYMANCLUB.COM DECEMBER 2011/JANUARY 2012 HANDY 13

11-12-Workshop.indd 13 11/1/11 1:06 PM

S-ar putea să vă placă și

- Book Case (Mission Style)Document8 paginiBook Case (Mission Style)khunchaiyai100% (3)

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsDe la EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsEvaluare: 5 din 5 stele5/5 (2)

- Wood Working Plans - Portable Router Station PDFDocument8 paginiWood Working Plans - Portable Router Station PDFBen GerezÎncă nu există evaluări

- Jig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsDocument6 paginiJig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsJd Diaz100% (1)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDe la EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersEvaluare: 3.5 din 5 stele3.5/5 (2)

- A Heavy Duty WorkbenchDocument16 paginiA Heavy Duty Workbenchjohnflory123445100% (1)

- Carpinteria - Manual Del TornoDocument147 paginiCarpinteria - Manual Del TornoPedro ZafraÎncă nu există evaluări

- Mission Furniture How to Make It, Part IDe la EverandMission Furniture How to Make It, Part IÎncă nu există evaluări

- Split-Top Roubo WorkbenchDocument29 paginiSplit-Top Roubo WorkbenchamelieÎncă nu există evaluări

- A Collection of Woodwork Projects; Designs for the Making of Furniture, Furnishings and Accessories for the HomeDe la EverandA Collection of Woodwork Projects; Designs for the Making of Furniture, Furnishings and Accessories for the HomeÎncă nu există evaluări

- Shop Drawings: Shaker-Style WorkbenchDocument29 paginiShop Drawings: Shaker-Style WorkbenchamelieÎncă nu există evaluări

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesDe la EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesEvaluare: 5 din 5 stele5/5 (1)

- Hybrid Roubo - Nicholson WorkbenchDocument22 paginiHybrid Roubo - Nicholson WorkbenchElisif DeFair100% (1)

- Intarsia Woodworking Projects: 21 Original Designs with Full-Size Plans and Expert Instruction for All Skill LevelsDe la EverandIntarsia Woodworking Projects: 21 Original Designs with Full-Size Plans and Expert Instruction for All Skill LevelsÎncă nu există evaluări

- Classic Plan: Artist's EaselDocument5 paginiClassic Plan: Artist's Easelwhorne240% (1)

- Creating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesDe la EverandCreating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesÎncă nu există evaluări

- Bench - Build A Classic Porch Glider - PopMecDocument8 paginiBench - Build A Classic Porch Glider - PopMecvdbroger100% (1)

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.De la EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Încă nu există evaluări

- Handwork Issue 5Document131 paginiHandwork Issue 5andrew_phelps100% (1)

- Traditional Workbench WoodSmith Volume 29 No. 173Document13 paginiTraditional Workbench WoodSmith Volume 29 No. 173Karen Rathbun100% (6)

- Streamlined Workbench: Photos by Carl Duguay Illustration by James ProvostDocument7 paginiStreamlined Workbench: Photos by Carl Duguay Illustration by James Provostrhinorod100% (1)

- Drawer Book-Runners Guides KickersDocument12 paginiDrawer Book-Runners Guides KickersDillon HartsykerÎncă nu există evaluări

- Mackintosh Inspiration On California's CoastDocument9 paginiMackintosh Inspiration On California's CoastpanáÎncă nu există evaluări

- Building The Holtz A PFF ElDocument42 paginiBuilding The Holtz A PFF ElguiferviÎncă nu există evaluări

- 0906workshop DoubleAdirondackDocument3 pagini0906workshop DoubleAdirondackkacey001Încă nu există evaluări

- Woodworking For Am 00 Gri FialaDocument136 paginiWoodworking For Am 00 Gri FialaIvan BaićÎncă nu există evaluări

- Traditional FurnitureDocument130 paginiTraditional Furniturearquivoslivros100% (2)

- Bancada MarceneiroDocument2 paginiBancada MarceneiroSérgio Paiva100% (1)

- Free Plan Small CabinetDocument9 paginiFree Plan Small CabinetAlexandre R. PeixotoÎncă nu există evaluări

- Popular Woodworking - 016 - 1984 PDFDocument52 paginiPopular Woodworking - 016 - 1984 PDFKawchhar Ahammed100% (1)

- Olde Forge Adirondack Chair PLANS PDFDocument49 paginiOlde Forge Adirondack Chair PLANS PDFjlct2009Încă nu există evaluări

- Benchcrafted Moxon ViseDocument12 paginiBenchcrafted Moxon VisexlotoxÎncă nu există evaluări

- Lie-Nielsen Studio BenchDocument2 paginiLie-Nielsen Studio BenchSameh SamehÎncă nu există evaluări

- Shaker FurnitureDocument25 paginiShaker Furniturevictor100% (1)

- Woodworking Plans - Entertainment CenterDocument12 paginiWoodworking Plans - Entertainment Centerapi-3822020100% (6)

- Sept2007 WM2 PDFDocument49 paginiSept2007 WM2 PDFBaSzar100% (1)

- Moxon's Ingenious Bench Vise: Jig JournalDocument2 paginiMoxon's Ingenious Bench Vise: Jig Journaloqab18100% (1)

- Wooden JointsDocument14 paginiWooden JointsAparna KulshresthaÎncă nu există evaluări

- Timber Frame ShedDocument5 paginiTimber Frame Shedpawkom100% (5)

- Selección de Los Mejores Dispositivos y Trucos para La Sierra CircularDocument24 paginiSelección de Los Mejores Dispositivos y Trucos para La Sierra CircularPierre799es100% (6)

- Work Bench Plans AdvancedDocument9 paginiWork Bench Plans AdvancedStevie Visser100% (1)

- Çalışma Tezgahı PlanıDocument14 paginiÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Chisel CabinetDocument3 paginiChisel CabinetErika Ramirez100% (4)

- Folding Sun LoungerDocument14 paginiFolding Sun LoungerKrespov100% (1)

- Building ShelvesDocument14 paginiBuilding ShelvesZoran MladenovicÎncă nu există evaluări

- HowWoodWords PDFDocument4 paginiHowWoodWords PDFJavier D100% (1)

- Kitchen Facelift PDFDocument21 paginiKitchen Facelift PDFBrian PriceÎncă nu există evaluări

- 032Document30 pagini032sergio100% (2)

- Raised Panels Three WaysDocument4 paginiRaised Panels Three WaysMiguel Ángel LJ0% (2)

- Champion The Lumber HorseDocument3 paginiChampion The Lumber HorseRowina Wamani67% (3)

- Your Guide To Shaker Furniture: 3 Classic ProjectsDocument25 paginiYour Guide To Shaker Furniture: 3 Classic Projectsjpl.guedes6842100% (1)

- FW RoutersRouterTables Excerpt-1Document78 paginiFW RoutersRouterTables Excerpt-1iacob_gilberto6473100% (8)

- Craftsman Bookcase - American WoodworkingDocument17 paginiCraftsman Bookcase - American WoodworkingRoberto Landa100% (2)

- Showcase Cabinets: The Delicate Interplay of Glass and WoodDocument7 paginiShowcase Cabinets: The Delicate Interplay of Glass and WoodAdrian Cocis100% (1)

- ChippendaleLeg FWW0135Document7 paginiChippendaleLeg FWW0135TAANGTAWAN007100% (1)

- Jack PlaneDocument6 paginiJack Planestuckinthestudio100% (1)

- Contoured Park Bench 2d DocumentationDocument1 paginăContoured Park Bench 2d DocumentationDusan SupeljakovicÎncă nu există evaluări

- 200 Personal Woodworking Plans and Projects PDFDocument985 pagini200 Personal Woodworking Plans and Projects PDFAlexsandro Pereira Dos Reis100% (5)

- Piano Stool PDFDocument16 paginiPiano Stool PDFaguinaldo6690Încă nu există evaluări

- 4169b enDocument2 pagini4169b enaguinaldo6690Încă nu există evaluări

- WP Plans2Document1 paginăWP Plans2aguinaldo6690Încă nu există evaluări

- 6317 Playground EquipmentDocument5 pagini6317 Playground Equipmentucme5600Încă nu există evaluări

- Woodwork - PlansDocument102 paginiWoodwork - Plansaguinaldo6690Încă nu există evaluări

- 54 Pediment Options 1Document1 pagină54 Pediment Options 1aguinaldo6690Încă nu există evaluări

- AbajurDocument11 paginiAbajuraguinaldo6690Încă nu există evaluări

- ListDocument1 paginăListaguinaldo6690Încă nu există evaluări

- FW1124 SideTableDocument7 paginiFW1124 SideTableaguinaldo6690Încă nu există evaluări

- Esab 22139 - 6Document1 paginăEsab 22139 - 6aguinaldo6690Încă nu există evaluări

- Birdfeeder ListofmaterialsDocument2 paginiBirdfeeder Listofmaterialsaguinaldo6690Încă nu există evaluări

- 2003 Vintage Model AirplaneDocument9 pagini2003 Vintage Model AirplanehosseinshafighÎncă nu există evaluări

- AbajurDocument11 paginiAbajuraguinaldo6690Încă nu există evaluări

- Nad T743 GBDocument32 paginiNad T743 GBemehranÎncă nu există evaluări

- Kanguru Duplicator User GuideDocument89 paginiKanguru Duplicator User Guideajpomales1Încă nu există evaluări

- 2023-06-28 KEI Wires Price ListDocument1 pagină2023-06-28 KEI Wires Price ListCpgeorge JohnÎncă nu există evaluări

- Electrical ApplicationDocument4 paginiElectrical Applicationengineer86Încă nu există evaluări

- Loader Assembly: Capsule Hopper: Chapter - 17 Parts ManualDocument7 paginiLoader Assembly: Capsule Hopper: Chapter - 17 Parts ManualSangram KendreÎncă nu există evaluări

- Clamping ToolsDocument190 paginiClamping ToolsИван РадивојевићÎncă nu există evaluări

- Example (Pty) LTD: Asset Set-UpDocument25 paginiExample (Pty) LTD: Asset Set-UpMichaelszAndreyÎncă nu există evaluări

- Ata 24 Learjet BateriaDocument4 paginiAta 24 Learjet BateriaJosueFerreiraÎncă nu există evaluări

- How To Splice Electrical Wires: By: Raymar M. BaquilarDocument18 paginiHow To Splice Electrical Wires: By: Raymar M. BaquilarShema MerchsÎncă nu există evaluări

- Basic Parts of A ComputerDocument36 paginiBasic Parts of A ComputerOtencianoÎncă nu există evaluări

- Shahan Tower Boosters-Booster Pump Floor - B6Document1 paginăShahan Tower Boosters-Booster Pump Floor - B6naseer lateeÎncă nu există evaluări

- Material ReceivedDocument31 paginiMaterial ReceivedAjay MedikondaÎncă nu există evaluări

- MCQ For Production and MachiningDocument8 paginiMCQ For Production and MachiningSaed ELkelanyÎncă nu există evaluări

- 321e 2825 641814 (CM9980)Document9 pagini321e 2825 641814 (CM9980)avant comercialÎncă nu există evaluări

- BearingsDocument98 paginiBearingsJohn SmithÎncă nu există evaluări

- Crimping Tools AssesmentDocument3 paginiCrimping Tools AssesmentAbhishekprasad royÎncă nu există evaluări

- Pipe Support IndexDocument4 paginiPipe Support IndexxkokarcaxÎncă nu există evaluări

- Group 5 Swing Device: 1. Removal and Install of MotorDocument25 paginiGroup 5 Swing Device: 1. Removal and Install of MotorMustofa TofaÎncă nu există evaluări

- Acoustasonic 100, 150Document20 paginiAcoustasonic 100, 150fluidaimaginacionÎncă nu există evaluări

- PVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListDocument11 paginiPVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListpauloÎncă nu există evaluări

- Ballscrew Product Specifications 13 14Document2 paginiBallscrew Product Specifications 13 14harryÎncă nu există evaluări

- Spare Parts Catalogue: Separation Unit 851Document122 paginiSpare Parts Catalogue: Separation Unit 851Pedro Gallego MartínezÎncă nu există evaluări

- Ball Bearing Nom PDFDocument1 paginăBall Bearing Nom PDFramanshriÎncă nu există evaluări

- Makita N1900B UGDocument12 paginiMakita N1900B UGnorthpolebcsÎncă nu există evaluări

- C01 C117Document117 paginiC01 C117HENRY DAVID PURUNCAJAS PAUCARÎncă nu există evaluări

- Sony D Ej725 ManualDocument24 paginiSony D Ej725 ManualJora MormontÎncă nu există evaluări

- ZF5HP19Document132 paginiZF5HP19TammyWest100% (2)

- Fire Pump and Jockey Pump With Accessories (Within Pump Room)Document1 paginăFire Pump and Jockey Pump With Accessories (Within Pump Room)John Paul Inovero JavierÎncă nu există evaluări

- Lada Trany ScriptDocument4 paginiLada Trany ScriptPisti BarcsiÎncă nu există evaluări

- Owner'S Manual and Installation Manual: HRV (Heat Recovery Ventilation)Document21 paginiOwner'S Manual and Installation Manual: HRV (Heat Recovery Ventilation)Flavio RicÎncă nu există evaluări