Documente Academic

Documente Profesional

Documente Cultură

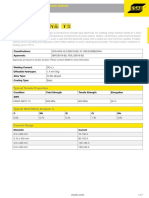

253 PDS Ai

Încărcat de

Achraf Boudaya0 evaluări0% au considerat acest document util (0 voturi)

143 vizualizări4 paginiAmeron

Titlu original

253_PDS_AI

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAmeron

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

143 vizualizări4 pagini253 PDS Ai

Încărcat de

Achraf BoudayaAmeron

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Amercoat 253

Performance Coatings & Finishes

Epoxy novolac tank lining

Product Data/ Physical Data

Finish Semigloss

Application Instructions Color Gray, white, pastel red

Components 2

(For Marine & Offshore use) Curing mechanism Solvent release and chemical

reaction between components

Exceptional resistance to a wide range of chemicals and Volume solids (calculated) 72% 3%

solvents Dry film thickness per coat 5-6 mils (125-150 microns)

Provides exceptional resistance over a wide range of Coats 2 or 3

temperatures and pressures Total minimum DFT

Practical application properties and cure schedules ships tanks 10-12 mils (250-300 microns)

Does not require baking to cure Maximum total DFT 18 mils (450 microns)

Theoretical coverage ft2/gal m2/L

High volume solids; two coat system 1 mil (25 microns) 1155 28.4

4 mils (100 microns) 5289 57.1

Typical Uses VOC lb/gal g/L

mixed 1.67 200

Cargo tanks in chemical tankers and barges

High pressure crude oil pipe and separation tanks Temperature resistance Wet Dry

Protective coating for highly corrosive environments Refer to Standard F C

System 2 stripe coats on all sharp edges, cutouts and Resistance List 300 149

welds. Flash point (SETA) F C

2 coats of Amercoat 253 Lining, 5-6 mils (125 to Amercoat 253 converter 5118 48

150 microns) per coat. Use contrasting colors for Amercoat 253 base 5108 42

each coat and strip coat. T-10 80 27

Amercoat 12 552 -17

Note: The maximum dry film thickness of the Amercoat

253 system is 18 mils (450 microns). Dry film thickness Application Data

above 18 mils (450 microns) could reduce the service life of Applied over Prepared steel, concrete,

the coating. aluminum

Surface preparation

Chemical Resistance steel SSPC-SP5 or 10

concrete ASTM D4259 or 4260

For a comprehensive listing of chemical resistance see the aluminum Light abrasive blast

latest Chemical Resistance List.

Method Airless or conventional spray

Mixing ratio (by volume) 4 parts base to

1 part converter

Induction time 15 minutes @ 70F (21C)

Thinner T-10

Equipment cleaner Thinner or Amercoat 12

Formerly Devchem 253

Pacific Southwest Supply, Inc. Page 1 of 4

www.pacificsouthwest.net

(562) 691-9600

Typical Properties Application Equipment

Property Method Result The following is a guide; suitable equipment from other

Abrasion ASTM D 4060, CS-17 90 mg loss manufacturers may be used. Changes in pressure, hose

Resistance 1000 gram load, 1000 cycles and tip size may be needed for proper spray characteris-

Adhesion ASTM D 4541 900-1100 psi tics.

Exterior Exposed in Florida facing 45 No effect on film Airless spray Standard equipment, such as Graco

Exposure integrity or adhesion. Bulldog Hydra-Spray, or larger, with a 0.017- to 0.025-inch

Film yellow. orifice.

Humidity ASTM D 2247, 1000 hours No effect on film Conventional spray - Industrial equipment, such as

Resistance integrity or adhesion. DeVilbiss MBC or JGA spray gun, and a pressure material

Less than 1/32 inch pot with mechanical agitator. A moisture and oil trap in the

rust creepage at main air supply and separate regulators for air and fluid

scribe and less than

0.5% rust at edges.

pressure are required.

Impact Power mixer Jiffy mixer powered by an air or explosion-

Resistance ASTM D 2794 70 inch-pounds proof electric motor.

Moisture

Permeability ASTM D 96 0.7 perms Environmental Conditions

Pencil

Hardness ASTM D 3363 6H Temperature F C

air 50 to 100 10 to 43

Salt Fog ASTM B 117 No effect on film

Resistance integrity or adhesion.

surface 50 to 120 10 to 49

Less than 1/16 inch Surface temperature must be at least 5F (3C) above dew

rust creepage at point to prevent condensation.

scribe and less than

0.5% rust at edges.

Tensile Application Procedure

Strength ASTM D 2379 1741 psi

1.Flush all equipment with thinner or Amercoat 12 cleaner

Modulus ASTM D 2370 192,400 psi before use.

Flexural

Strength

2.Stir base component thoroughly, then add converter to

(Yield Strength) ASTM D 790 3487 psi resin and mix until uniform. Induction time 15 minutes @

Hardness

70F (21C). Amercoat 253 is packaged in the proper

(Durometer) ASTM D 2240 (Type D) 83 mixing proportions of base and converter. Do not mix

Water

more material than will be used within pot life time.

Immersion ASTM D 1308, 2 years No effect Pot life (hours) F/C

100/38 90/30 70/21 50/10

Adhere to all instructions, precautions, conditions, and lim- 1 2 4 6

itations to obtain maximum performance. For conditions 3.If necessary for workability, use no more than 12 pint of

outside the requirements or limitations described contact

your Ameron representative. thinner per gallon of Amercoat 253 for airless or conven-

tional equipment.

Surface Preparation Thinner T-10

Coating performance is, in general, proportional to the 4.When applying by conventional spray, use adequate air

degree of surface preparation. All surfaces must be clean, pressure and volume to ensure proper atomization.

dry and free of all contamination, including salt deposits 5.Apply a wet coat in even parallel passes; overlap 50 per-

before applying coating. cent to avoid holidays, bare areas and pinholes and to

Steel New without pits or depressions blast SSPC-SP10(Sa achieve a dry film thickness of 5-6 mils (100-150

21/2). microns).

Rusted or pitted blast SSPC-SP5(Sa 3). Drying time (ASTM D1640) (hours) F/C

Blast to achieve a 11/2 mils (37 microns) minimum profile

as determined with a Keane-Tator Surface Profile 100/38 90/32 70/21 50/10

Comparator, Testex Tape or similar device. Remove abra- hard 2 6 15 26

sive residue or dust from surface. through 6 12 22 36

Apply coating as soon as possible to prevent rusting. Keep recoat

moisture, oil, grease or other organic matter off surface minimum 3 4 10 24

before coating. Spot blast to remove any contamination, maximum 18 24 96 144

solvent wiping is not adequate. Roughen surface if maximum recoat time is exceeded.

Fill small holes or voids with Nu-Klad 114A after applying Curing time for immersion service*

the first coat of Amercoat 253. Steel substrate Ambient cure

Concrete Clean concrete and masonry surfaces; abrasive Temperature Heat cure 12 mils/300 18 mils/450

blast (ASTM D4259) or acid etch (ASTM D4260). F C hours days days

Fill small holes or voids with Nu-Klad 114A before apply- 160 171 14 NA NA

140 160 18 NA NA

ing Amercoat 253. 122 150 24 NA NA

Aluminum Remove oil, grease or soap film with neutral 104 140 96 NA NA

detergent or emulsion cleaner; blast lightly with fine abra- 186 130 NA 14 16

sive. 170 121 NA 17 91/2

159 115 NA 10 13

150 110 NA 14 19

* After application and during the above curing schedule tanks must be ventilated to

prevent solvent entrapment.

253 PDS/AI Page 2 of 4

Ventilation It is very important for the safety of the Shipping Data

applicator and the proper performance of the Amercoat Packaging units 1 gal 5 gal

253 coating that good ventilation be provided to all converter 0.20 gal in 1-qt can 1 gal in 1-gal can

portions of the enclosed area. Recommended tank base 0.80 gal in 1-gal can 4 gal in 5-gal can

ventilation involves two important phases.Phase one is to Shipping weight (approx) lb kg

pump fresh, dehumidified air into all areas of the 1-gal unit

tank, especially dead air areas. Phase two is to exhaust, converter 1.9 0.9

via an explosion proof exhaust fan, the solvent vapors base 10.4 4.7

from the lowest portion of the tank. This practice of 5-gal unit

pumping fresh air into the tank and exhausting solvent converter 10.4 4.7

vapors out of the lowest part of the tank should be base 51.8 23.5

provided throughout the application and curing

processes. This practice is to insure than all solvents are Shelf life when stored indoors at 40 to 100F (4 to 38C)

removed from the coating. Tanks must be cured 7 days at 1 year from shipment date

70F (21C) with ventilation before being put into service. Numerical values are subject to normal manufacturing tolerances, color and

testing variances. Allow for application losses and surface irregularities. See

At lower temperatures, longer cure times are required. application instructions for complete information and safety precautions.

6.Check dry film thickness using nondestructive dry film The mixed product is photochemically reactive as defined by South Coast

thickness gauge such as Mikrotest or Elcometer. If less Air Quality Management Districts Rule 102 or equivalent regulations.

than the specified thickness, apply additional material.

Total dry film thickness must not exceed 18 mils (450

microns) in 2 coats, and must not be less than 8 mils Warranty

(200 microns). Ameron warrants its products to be free from defects in

7.When a pinhole-free coating is required, check continuity material and workmanship. Amerons sole obligation and

of dry but uncured coating with a nondestructive holiday Buyers exclusive remedy in connection with the products

detector such as Tinker-Rasor Model M-l. Apply shall be limited, at Amerons option, to either replacement

additional coats to areas requiring touch-up. of products not conforming to this Warranty or credit to

8.After use, clean equipment immediately with thinner or Buyers account in the invoiced amount of the nonconform-

Amercoat 12. ing products. Any claim under this Warranty must be made

by Buyer to Ameron in writing within five (5) days of

Buyers discovery of the claimed defect, but in no event

Safety Precautions later than the expiration of the applicable shelf life, or one

Read each components material safety data sheet before year from the delivery date, whichever is earlier. Buyers

use. Mixed material has hazards of each component. Safety failure to notify Ameron of such nonconformance as

precautions must be strictly followed during storage, han- required herein shall bar Buyer from recovery under this

dling, and use. Warranty.

CAUTION Improper use and handling of this product Ameron makes no other warranties concerning the

can be hazardous to health and cause fire or explosion. product. No other warranties, whether express, implied,

or statutory, such as warranties of merchantability or

Do not use this product without first taking all appropri- fitness for a particular purpose, shall apply. In no event

ate safety measures to prevent property damage and shall Ameron be liable for consequential or incidental

injuries. These measures may include, without limita- damages.

tion: implementation of proper ventilation, use of proper Any recommendation or suggestion relating to the use of

lamps, wearing of proper protective clothing and masks, the products made by Ameron, whether in its technical lit-

tenting and proper separation of application areas. erature, or in response to specific inquiry, or otherwise, is

Consult your supervisor. Proper ventilation and protec- based on data believed to be reliable; however, the prod-

tive measures must be provided during application and ucts and information are intended for use by Buyers having

drying to keep solvent vapor concentrations within safe requisite skill and know-how in the industry, and therefore

it is for Buyer to satisfy itself of the suitability of the prod-

limits and to protect against toxic hazards. Necessary ucts for its own particular use and it shall be deemed that

safety equipment must be used and ventilation require- Buyer has done so, at its sole discretion and risk. Variation

ments carefully observed, especially in confined or in environment, changes in procedures of use, or extrapo-

enclosed spaces, such as tank interiors and buildings. lation of data may cause unsatisfactory results.

This product is to be used by those knowledgeable about

proper application methods. Ameron makes no

recommendation about the types of safety measures Limitation of Liability

that may need to be adopted because these depend on Amerons liability on any claim of any kind, including

application and space, of which Ameron is unaware and claims based upon Amerons negligence or strict liability,

over which it has no control. for any loss or damage arising out of, connected with, or

If you do not fully understand the warnings and instruc- resulting from the use of the products, shall in no case

tions or if you cannot strictly comply with them, do not exceed the purchase price allocable to the products or part

use the product. thereof which give rise to the claim. In no event shall

Ameron be liable for consequential or incidental dam-

Note: Consult Code of Federal Regulations Title 29, Labor, ages.

parts 1910 and1915 concerning occupational safety and

health standards and regulations, as well as any other

applicable federal, state and local regulations on safe prac-

tices in coating operations.

This product is for industrial use only. Not for residen-

tial use.

Page 3 of 4 253 PDS/AI

Ameron U.S.A. 13010 Morris Rd, Suite 400, Alpharetta, GA 30004 (678) 393-0653

Ameron B.V. J. F. Kennedylaan 7, 4191 MZ Geldermalsen, The Netherlands (31) 345-587-587

253 PDS/AI Page 4 of 4 1999 Ameron Printed in U.S.A. R2/02 supersedes R8/00

S-ar putea să vă placă și

- 253 PDS AiDocument4 pagini253 PDS AiHrvoje RuzicÎncă nu există evaluări

- PPG Amercoat 370 Data SheetDocument3 paginiPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Amercoat 450H: Product Data/ Application InstructionsDocument4 paginiAmercoat 450H: Product Data/ Application InstructionsjoshÎncă nu există evaluări

- Chersterton Arc 982 PDFDocument2 paginiChersterton Arc 982 PDFMohamed NouzerÎncă nu există evaluări

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 paginiCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadÎncă nu există evaluări

- Sikaflex 252 TDSDocument3 paginiSikaflex 252 TDSxingobuilderÎncă nu există evaluări

- 9HS PDS AiDocument4 pagini9HS PDS AiHrvoje RuzicÎncă nu există evaluări

- Amercoat-235-Data Sheet PDFDocument4 paginiAmercoat-235-Data Sheet PDFPubcrawlÎncă nu există evaluări

- HereShield TDSDocument5 paginiHereShield TDSMahdi BagheriÎncă nu există evaluări

- Product Data: Engineered Siloxane CoatingDocument2 paginiProduct Data: Engineered Siloxane Coatinggk80823Încă nu există evaluări

- Amerlock 2Document3 paginiAmerlock 2Justan MendezÎncă nu există evaluări

- TDS - Ew 6325H - enDocument2 paginiTDS - Ew 6325H - enAnthony GalindoÎncă nu există evaluări

- Tideguard 182: Product Data/ Application InstructionsDocument2 paginiTideguard 182: Product Data/ Application InstructionsPablo Ahumada G.Încă nu există evaluări

- Product Information: Kemperol V210Document3 paginiProduct Information: Kemperol V210sri projectssÎncă nu există evaluări

- Epoxy Coating Solvent Free TDSDocument3 paginiEpoxy Coating Solvent Free TDSMohamed MagdiÎncă nu există evaluări

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 paginiControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUIÎncă nu există evaluări

- Pro Mastic Ste 87Document4 paginiPro Mastic Ste 87ahmedyahea181Încă nu există evaluări

- PPA 571 EsDocument4 paginiPPA 571 EsRohit Sangwan0% (1)

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 paginiTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranÎncă nu există evaluări

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 paginiDTM Bonding Primer: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- FT Grease 22Document2 paginiFT Grease 22Edgar Leonel CortésÎncă nu există evaluări

- Epoxy Coating Basf-Masterprotect-100 Sewer StructureDocument3 paginiEpoxy Coating Basf-Masterprotect-100 Sewer StructuresatheeshvmÎncă nu există evaluări

- PN78HBCDocument4 paginiPN78HBCLassadÎncă nu există evaluări

- NC-558 TDS enDocument2 paginiNC-558 TDS enniteshacharya100% (1)

- Flowcrete Asia Deckshield Ed Rapide May2020 TdsDocument2 paginiFlowcrete Asia Deckshield Ed Rapide May2020 TdsbidiecÎncă nu există evaluări

- Seal-Guard+ECF TDS EnglishDocument1 paginăSeal-Guard+ECF TDS Englishabbas ansariÎncă nu există evaluări

- Flowchem EPN - ENGDocument2 paginiFlowchem EPN - ENGbassem kooliÎncă nu există evaluări

- DTM Acrylic Pimer Finish B66W1Document4 paginiDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaÎncă nu există evaluări

- Henk Loctite Superflex Red TdsDocument2 paginiHenk Loctite Superflex Red TdsMariano DomenechÎncă nu există evaluări

- Technical Data: P/S 870 Class B Corrosion Inhibitive SealantDocument2 paginiTechnical Data: P/S 870 Class B Corrosion Inhibitive Sealantlucas laraÎncă nu există evaluări

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 paginiIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 paginiProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraÎncă nu există evaluări

- Carboguard 893 SG MIO PDSDocument4 paginiCarboguard 893 SG MIO PDSMuthuKumarÎncă nu există evaluări

- FlorosparticDocument3 paginiFlorosparticCarlos Rojas HandalÎncă nu există evaluări

- 395 PDSDocument2 pagini395 PDSNorman Mokoginta,ST,MBAÎncă nu există evaluări

- Powercrete R95 Application Instructions Cartridge Spray Guide April 2021 V1Document8 paginiPowercrete R95 Application Instructions Cartridge Spray Guide April 2021 V1Pammy JainÎncă nu există evaluări

- En GBDocument3 paginiEn GBAndrea Pamela León AlgarañazÎncă nu există evaluări

- Urethane Coating 165 PWDocument3 paginiUrethane Coating 165 PWANIBALLOPEZVEGAÎncă nu există evaluări

- Hi Solid PolyurethaneDocument4 paginiHi Solid PolyurethaneafvasquezÎncă nu există evaluări

- Technical Datasheet: MAXGUARD™ GT // HF/SF Premium Tooling GelcoatsDocument2 paginiTechnical Datasheet: MAXGUARD™ GT // HF/SF Premium Tooling GelcoatsMarjan ArhÎncă nu există evaluări

- Cooltherm Tc-2002 Thermally Conductive Structural Adhesive: Technical Data SheetDocument2 paginiCooltherm Tc-2002 Thermally Conductive Structural Adhesive: Technical Data SheetpronavÎncă nu există evaluări

- 5.1 Sumatane HSDocument4 pagini5.1 Sumatane HSjnu6mnju6njÎncă nu există evaluări

- Dow Corning 3165Document3 paginiDow Corning 3165Morlin BungkeriÎncă nu există evaluări

- Resutile Topcoat SD System Guide SWDocument4 paginiResutile Topcoat SD System Guide SWServandoÎncă nu există evaluări

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 paginiProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraÎncă nu există evaluări

- Carboline Carboguard 890 PDSDocument2 paginiCarboline Carboguard 890 PDSSamÎncă nu există evaluări

- Scotch-Weld: Structural AdhesiveDocument4 paginiScotch-Weld: Structural AdhesiveAfzal ImamÎncă nu există evaluări

- Crestomer, Adhesivo Estructural de Alta ResistenciaDocument3 paginiCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasÎncă nu există evaluări

- Carbocoat 8239: Selection & Specification DataDocument4 paginiCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINÎncă nu există evaluări

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 paginiFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnÎncă nu există evaluări

- SW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFDocument2 paginiSW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFtienÎncă nu există evaluări

- Electronics: Dow CorningDocument3 paginiElectronics: Dow CorningWandyy GonçalvesÎncă nu există evaluări

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 paginiFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezÎncă nu există evaluări

- FLEXICOAT PU (I) LatestDocument3 paginiFLEXICOAT PU (I) Latestmathewsujith31Încă nu există evaluări

- TDS - Premix Marine ThixotropeDocument3 paginiTDS - Premix Marine ThixotropegmÎncă nu există evaluări

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pagini3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanÎncă nu există evaluări

- Thermo Lag - 3000 SP - PDS FireproofingDocument4 paginiThermo Lag - 3000 SP - PDS FireproofingAdil KhanÎncă nu există evaluări

- Interline 984+br+eng PDFDocument2 paginiInterline 984+br+eng PDFMohamed NouzerÎncă nu există evaluări

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 paginiSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaÎncă nu există evaluări

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocument8 paginiSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaÎncă nu există evaluări

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocument4 paginiModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaÎncă nu există evaluări

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 paginiSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaÎncă nu există evaluări

- Sprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataDocument38 paginiSprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataAchraf BoudayaÎncă nu există evaluări

- Series LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorDocument6 paginiSeries LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorAchraf BoudayaÎncă nu există evaluări

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocument4 paginiSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaÎncă nu există evaluări

- Style 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationDocument4 paginiStyle 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationAchraf BoudayaÎncă nu există evaluări

- Rociador Ty LDocument8 paginiRociador Ty LOscar Fernandez SanchezÎncă nu există evaluări

- Majestic Optima: Technical Data SheetDocument3 paginiMajestic Optima: Technical Data Sheetaditarian .pÎncă nu există evaluări

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocument4 paginiModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaÎncă nu există evaluări

- Flyer TycoDocument8 paginiFlyer TycoAchraf BoudayaÎncă nu există evaluări

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocument4 paginiInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaÎncă nu există evaluări

- Jotaplast (ID) : Technical Data SheetDocument3 paginiJotaplast (ID) : Technical Data SheetBilher SihombingÎncă nu există evaluări

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 paginăClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaÎncă nu există evaluări

- Jotashield Flex: Technical Data SheetDocument3 paginiJotashield Flex: Technical Data SheetAchraf BoudayaÎncă nu există evaluări

- Jotun Essence Easy Clean Matt: Technical Data SheetDocument3 paginiJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaÎncă nu există evaluări

- Esab Pipeweld 6010R: Classifications: ApprovalsDocument1 paginăEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaÎncă nu există evaluări

- Weld-On Brackets Type 35Document1 paginăWeld-On Brackets Type 35Achraf BoudayaÎncă nu există evaluări

- Jotashield Extreme: Technical Data SheetDocument3 paginiJotashield Extreme: Technical Data SheetAchraf BoudayaÎncă nu există evaluări

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 paginăClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaÎncă nu există evaluări

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocument1 paginăTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaÎncă nu există evaluări

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 paginăClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaÎncă nu există evaluări

- Snubbers Type 31Document1 paginăSnubbers Type 31Achraf BoudayaÎncă nu există evaluări

- Installation Extensions Type 33Document1 paginăInstallation Extensions Type 33Achraf BoudayaÎncă nu există evaluări

- Telescopic Spring Supports Type 29Document1 paginăTelescopic Spring Supports Type 29Achraf BoudayaÎncă nu există evaluări

- Energy Absorber Type 32Document1 paginăEnergy Absorber Type 32Achraf BoudayaÎncă nu există evaluări

- Snubbers Type 30Document1 paginăSnubbers Type 30Achraf BoudayaÎncă nu există evaluări

- Rigid Struts Type 39Document1 paginăRigid Struts Type 39Achraf BoudayaÎncă nu există evaluări

- Sway Braces Type 27Document1 paginăSway Braces Type 27Achraf BoudayaÎncă nu există evaluări

- 1974 - Roncaglia - The Reduction of Complex LabourDocument12 pagini1974 - Roncaglia - The Reduction of Complex LabourRichardÎncă nu există evaluări

- DYCONEX Materials en 2020 ScreenDocument2 paginiDYCONEX Materials en 2020 ScreenhhaiddaoÎncă nu există evaluări

- Torrent - WSCC - Windows System Control Center 7.0.5.7 Commercial (x64 x86) - TeamOS - Team OS - Your Only Destination To Custom OS !!Document5 paginiTorrent - WSCC - Windows System Control Center 7.0.5.7 Commercial (x64 x86) - TeamOS - Team OS - Your Only Destination To Custom OS !!moustafaÎncă nu există evaluări

- DJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Document7 paginiDJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Lokhman HakimÎncă nu există evaluări

- Sta404 07Document71 paginiSta404 07Ibnu Iyar0% (1)

- AIF User Guide PDFDocument631 paginiAIF User Guide PDFÖzgün Alkın ŞensoyÎncă nu există evaluări

- U2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciDocument6 paginiU2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciELVIN MANUEL CONDOR CERVANTESÎncă nu există evaluări

- Research Paper On N Queen ProblemDocument7 paginiResearch Paper On N Queen Problemxvrdskrif100% (1)

- Concrete Lab ManualDocument20 paginiConcrete Lab ManualkelmazodroÎncă nu există evaluări

- Social Science PedagogyDocument4 paginiSocial Science PedagogyrajendraÎncă nu există evaluări

- SL 4001Document2 paginiSL 4001ardiÎncă nu există evaluări

- Jungles & SavannasDocument80 paginiJungles & SavannasJessica100% (1)

- Gauss' Law: F A FADocument14 paginiGauss' Law: F A FAValentina DuarteÎncă nu există evaluări

- Handbook+for+Participants+ +GCC+TeenDocument59 paginiHandbook+for+Participants+ +GCC+Teenchloe.2021164Încă nu există evaluări

- Power-Miser 12 Water Heater ManualDocument32 paginiPower-Miser 12 Water Heater ManualClaudeVanDammÎncă nu există evaluări

- High Performance Vector Control SE2 Series InverterDocument9 paginiHigh Performance Vector Control SE2 Series InverterhanazahrÎncă nu există evaluări

- Risk Assessment For Harmonic Measurement Study ProcedureDocument13 paginiRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanÎncă nu există evaluări

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Document3 paginiAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarÎncă nu există evaluări

- APPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListDocument824 paginiAPPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListReviewKeys.comÎncă nu există evaluări

- DICKSON KT800/802/803/804/856: Getting StartedDocument6 paginiDICKSON KT800/802/803/804/856: Getting StartedkmpoulosÎncă nu există evaluări

- Sim Educ101Document101 paginiSim Educ101Rolando AmadÎncă nu există evaluări

- Machine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDocument26 paginiMachine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDull PersonÎncă nu există evaluări

- Introduction To SCRDocument19 paginiIntroduction To SCRAlbin RobinÎncă nu există evaluări

- Contoh Label Sensus 2022Document313 paginiContoh Label Sensus 2022Ajenk SablackÎncă nu există evaluări

- Jazz PrepaidDocument4 paginiJazz PrepaidHoney BunnyÎncă nu există evaluări

- Dady - Piernas LargasDocument12 paginiDady - Piernas LargasSarha NietoÎncă nu există evaluări

- Ahmed Amr P2Document8 paginiAhmed Amr P2Ahmed AmrÎncă nu există evaluări

- IVISOR Mentor IVISOR Mentor QVGADocument2 paginiIVISOR Mentor IVISOR Mentor QVGAwoulkanÎncă nu există evaluări

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pagini2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusÎncă nu există evaluări

- Pressure-Dependent Leak Detection Model and Its Application To A District Water SystemDocument13 paginiPressure-Dependent Leak Detection Model and Its Application To A District Water SystemManjul KothariÎncă nu există evaluări