Documente Academic

Documente Profesional

Documente Cultură

Serie TMR 140 Brochure

Încărcat de

Marcelo VizcayaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Serie TMR 140 Brochure

Încărcat de

Marcelo VizcayaDrepturi de autor:

Formate disponibile

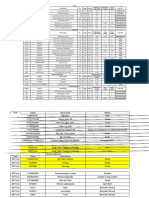

MEMBRAY Specifications

Module Type TMR140-050S TMR140-100S TMR140-200W TMR140-200D TMR140-400DW

MEMBRAY

Flow Capacity m3/day* 8 53 15 105 30 210 30 210 60 420 TM

gal/day* 2,100 14,000 4,000 27,700 7,900 55,500 7,900 55,500 15,900 111,000 TMR0140 Series

Number of Membrane Elements 50 100 200 200 400

Submerged Flat Sheet Membrane Module for MBR

Total Membrane Area m 2

70 140 280 280 560

sq.ft. 750 1,510 3,010 3,010 6,030

Dimensions Width mm 810 810 840 810 840

inch 31.9 31.9 33.1 31.9 33.1

Length mm 950 1,620 3,260 1,620 3,260

inch 37.4 63.8 128.3 63.8 128.3

Height mm 2,100 2,100 2,100 4,160 4,160

inch 82.7 82.7 82.7 163.8 163.8

Weight (dry) Module kg 400 695 1,430 1,365 2,690

lb. 882 1,532 3,153 3,009 5,930

Materials Diffuser, Frame,

304 stainless steel (316 stainless steel is available as option)

Permeated Water Manifold

* These are reference values with typical municipal wastewater, not guaranteed values.

Specifications subject to change without notice due to technical modifications or production changes.

TORAY satisfies global water treatment needs.

Global Website: http://www.toraywater.com/

ASIA (JAPAN)

Toray Industries, Inc. Head Office

MF & UF Membrane Products Dept., Water Treatment Division

1-1, Nihonbashi-muromachi 2-chome, Chuo-ku, Tokyo 103-8666, JAPAN

TEL: +81-3-3245-4557 FAX: +81-3-3245-4913

ASIA (SINGAPORE)

URL: http://www.toray.com/

Toray Asia Pte. Ltd.

NORTH AMERICA 111 Somerset Road, #14-01 Devonshire Wing,

Toray Membrane USA, Inc. Singapore Power Building, Singapore 238164

13435 Danielson Street, Poway, CA 92064, U.S.A. Tel: +65-6226-0525 Fax: +65-6226-0509

Tel: +1-858-218-2390 Fax: +1-858-486-3063

ASIA (CHINA)

EUROPE Toray Membrane (Beijing) Co., Ltd.

Toray Membrane Europe AG Room 918, Beijing Fortune Building, 5 Dongsanhuan Beilu,

Grabenackerstrasse 8b, CH-4142 Munchenstein 1, Switzerland Chao Yang District, Beijing 100004, China

Tel: +41-61-415-8710 Fax: +41-61-415-8720 Tel: +86-10-6590-8365 Fax: +86-10-6590-8611

MIDDLE EAST ASIA (KOREA)

Toray Membrane Europe (Middle East Branch) Toray International (Korea), Inc.

Armada Tower P2 Suite 1206 Jumeirah Lakes Towers 10F, LG Mapo Bldg. 275, Gongdeok-dong, Mapo-gu,

P.O. Box 17978, Dubai, United Arab Emirates Seoul, 121-721, Republic of Korea

Tel: +971-4-392-8811 Fax: +971-395-8639 Tel: +82-2-3273-8974 Fax: +82-2-3273-8360

About Toray

MEMBRAY improves

TM

Established in 1926, Toray is a worldwide leader in chemical manufacturing and related products. Leveraging decades of experience in

synthetic fibers and textiles, Toray has expanded into many other fields such as carbon fiber and its composites, plastics, fine chemicals

and innovative water treatment technologies. MBR system performance.

Toray is committed to achieving sustainable growth and environmental preservation, while meeting the diverse needs of its customers

worldwide. Toray constantly strives to contribute to the countries and communities in which it operates, not only through superior products

and services, but by acting as a concerned corporate citizen. In this way, Toray seeks to play its part in building a better society for all the

people of the world.

MEMBRAY is a trademark of Toray Industries, Inc.

Torays advanced membrane separation technology and

nanotechnology create better MBR modules.

The MEMBRAY submerged flat sheet membrane module, when used as a The MEMBRAY module configuration comprises an element block and an

component of a membrane bioreactor (MBR) system, effectively removes aeration block. The element block contains a number of membrane

suspended solids. This innovative microfiltration module in a plate- elements stacked at equal intervals, each of which has flat sheet membranes

and-frame configuration with flat sheet membranes was developed thanks attached on both sides of a supporting panel. Each element is connected via

to over 25 years of experience in high-quality membrane products and our a tube to a permeated water manifold. The aeration block consists of air

non-compromise R&D, manufacturing and application expertise. diffusers used to supply air.

Module Conceptual drawing of filtration Element

Conventional wastewater treatment system MBR system using MEMBRAY

Tube Permeated water

manifold

Permeated water

MEMBRAY Permeated

water nozzle

Wastewater Treated water Wastewater

Membrane

Activated Supporting Membrane

sludge panel

Element block Supporting

Permeated panel

water

RO Reuse Water/Air flow Water/Air flow Specifications (TSP-50150)

Aeration block Effective Membrane Area: 1.4m2

Activated sludge tank Sedimentation tank MBR tank Membrane Dimensions (W x H x T): 515 x 1,608 x 13.5mm

Bubbles

Membrane: PVDF and PET non-woven fabric

Air diffuser Aeration Supporting Panel: ABS resin

MBR with MEMBRAY Submerged Flat Sheet Membrane Module Why MEMBRAY performance ranks with the best.

MBR technology enhances Smaller footprint Fewer chemical cleaning Guaranteed high water Unique membrane structure Better membrane materials

wastewater treatment efficiency requirements and coarse screen permeability and high effluent

The module can be submerged Numerous small-diameter pores are Using PVDF (polyvinylidene fluoride)

pretreatment quality

Using membranes to separate directly in an activated sludge tank distributed evenly throughout the for the functional layer of the

sludge ensures much higher quality for combining biological treatment The plate-and-frame configuration Many 0.08 micron pores on the membrane surface with a narrow membrane and PET (polyester)

for treated water free from and membrane separation. It that employs flat sheet membranes membrane surface effectively diameter distribution. This structure non-woven fabric as the base layer

suspended solids. Combination with eliminates the sedimentation or is inherently stronger against fouling eliminate 0.1 micron+ particles to ensures higher treated water quality allows the membrane to exhibit

RO membranes allows producing sludge concentration process. than the hollow fiber membrane improve effluent quality. and minimizes membrane fouling superior physical strength and

water quality as good as potable More effective biological treatment configuration. Therefore, it results in Uniform pore size results in and pore clogging for consistently chemical stability.

water. allows activated sludge tank size to fewer chemical cleaning consistently high permeability with high water permeability.

Membranes can retain activated be reduced. requirements. minimal pore clogging. Flat sheet type membrane with

sludge at high concentrations, Reduced module fouling from modified surface nature

FE-SEM of membrane surface Pore size distribution

allowing BOD as well as nitrogen to human hair and other obstructive 1.5 The membrane has a simple flat

be removed more efficiently. substances allows coarse screening sheet configuration. This configuration

Number of pores (1012/m2)

Toray membrane

Unique membrane configuration as a pretreatment process. and the modified membrane surface

1.0

having an immense number of MBR SYSTEM nature allow very effective cleaning by

minuscule pores delivers stable high Energy efficient Other membrane a stream of water generated upward

water permeability with minimal MEMBRAY consumes less energy 0.5

as scouring air is diffused below it.

That of

clogging and higher permeated conventional compared to hollow fiber This mechanism provides extremely

water quality. method membrane due to more effective 0 stable filtration as the membrane

3.0 micron 3.0 micron

scouring aeration and lower Toray membrane Other membrane

0 0.2 0.4 0.6 0.8

does not allow sludge to adhere to its

Pore diameter (microns)

trans-membrane pressure. surface.

S-ar putea să vă placă și

- TDS ANCHOR BAR 900 - 1100 DP - Rev07 20151016 - ItaDocument1 paginăTDS ANCHOR BAR 900 - 1100 DP - Rev07 20151016 - ItacarminecasellaÎncă nu există evaluări

- 10 Schede Tecniche Lamiere Grecate COPERALL PDFDocument16 pagini10 Schede Tecniche Lamiere Grecate COPERALL PDFAlessio de IulisÎncă nu există evaluări

- 10 Schede Tecniche Lamiere Grecate COPERALL PDFDocument16 pagini10 Schede Tecniche Lamiere Grecate COPERALL PDFAlessio de IulisÎncă nu există evaluări

- TDS ANCHOR BAR RBS - Rev20 20170201 - ItaDocument1 paginăTDS ANCHOR BAR RBS - Rev20 20170201 - ItacarminecasellaÎncă nu există evaluări

- 01 Catalogo 2016 CompletoDocument56 pagini01 Catalogo 2016 CompletoMustdownÎncă nu există evaluări

- Raising Stones: ApplicationsDocument2 paginiRaising Stones: ApplicationsAdrian CarreraÎncă nu există evaluări

- Acoplamentos Trasco Es 033 PDFDocument10 paginiAcoplamentos Trasco Es 033 PDF3DLAB CAD/CAMÎncă nu există evaluări

- 328su ItDocument2 pagini328su Italessia olgiatiÎncă nu există evaluări

- AustrothermDocument7 paginiAustrothermSalvatoreDiGiacomoÎncă nu există evaluări

- TDS GBPHR Rev1Document2 paginiTDS GBPHR Rev1carminecasellaÎncă nu există evaluări

- The Science and Technology In: The Science and Technology In: The Science and Technology In: The Science and Technology inDocument50 paginiThe Science and Technology In: The Science and Technology In: The Science and Technology In: The Science and Technology inAndrea NobisÎncă nu există evaluări

- Calcoli 2Document65 paginiCalcoli 2Pasquale SabbatiniÎncă nu există evaluări

- CS 1.2379 StandardDocument1 paginăCS 1.2379 StandardWalid Ben AmirÎncă nu există evaluări

- Alutech Dach PDFDocument28 paginiAlutech Dach PDFEliyahu RockSteinÎncă nu există evaluări

- Serie FM: Frantumatori MeccaniciDocument2 paginiSerie FM: Frantumatori MeccaniciLa Taberna EspiritualÎncă nu există evaluări

- Filtri Per Taglio Plasma e OssitaglioDocument2 paginiFiltri Per Taglio Plasma e OssitaglioAlex SouzaÎncă nu există evaluări

- 4-106493 - Norm - Pav - Ponti - Quadro - Elettrico - HF Normes Pose Ponts ElevateurDocument2 pagini4-106493 - Norm - Pav - Ponti - Quadro - Elettrico - HF Normes Pose Ponts ElevateurpriceÎncă nu există evaluări

- Tenditore RoburDocument16 paginiTenditore RoburGiovanni BoscoloÎncă nu există evaluări

- Romani Components - Guide Lineari A RotelleDocument11 paginiRomani Components - Guide Lineari A RotelleFrancesco SpagnoloÎncă nu există evaluări

- Normative Uni enDocument13 paginiNormative Uni encapspugnaÎncă nu există evaluări

- LamieraDocument11 paginiLamieraMario BoveÎncă nu există evaluări

- CENOVNIK-METALNI-ORMANI-ABM-2020 Cjenovnik 2019Document2 paginiCENOVNIK-METALNI-ORMANI-ABM-2020 Cjenovnik 2019Dino BradaricÎncă nu există evaluări

- SANREMO - Scheda Tecnica - 4Document2 paginiSANREMO - Scheda Tecnica - 4Justin ReyesÎncă nu există evaluări

- Scheda Tecnica H2bp 3n32122Document6 paginiScheda Tecnica H2bp 3n32122dario.rtvitaliaÎncă nu există evaluări

- Caratteristiche Barre Filettate PDFDocument1 paginăCaratteristiche Barre Filettate PDFClaudioÎncă nu există evaluări

- ALUBEL - Isocoppo TekDocument9 paginiALUBEL - Isocoppo Tekwiwim20186Încă nu există evaluări

- Fibrangeo B 570 Scheda Tecnica Rev4Document2 paginiFibrangeo B 570 Scheda Tecnica Rev4viktor mickovskiÎncă nu există evaluări

- Mapetherm PF CamDocument4 paginiMapetherm PF CamricovivÎncă nu există evaluări

- Scheda Tecnica TUBO MULTISTRATODocument7 paginiScheda Tecnica TUBO MULTISTRATOatom7-2Încă nu există evaluări

- Scheda Tecnica H2BP24335Document3 paginiScheda Tecnica H2BP24335dario.rtvitaliaÎncă nu există evaluări

- Tefond Drain PlusDocument2 paginiTefond Drain PlusAilyn O. DungogÎncă nu există evaluări

- Catalogo ITADocument114 paginiCatalogo ITAMohammad AnwarÎncă nu există evaluări

- FB 01 SYS 003 IT 02 - SolaiDocument4 paginiFB 01 SYS 003 IT 02 - Solaic_passerino6572Încă nu există evaluări

- Norma Flanges PRFV PDFDocument33 paginiNorma Flanges PRFV PDFAlvaro RiverosÎncă nu există evaluări

- MapethermDocument4 paginiMapethermricovivÎncă nu există evaluări

- Weight of Di PipeDocument3 paginiWeight of Di PipeSuvam SwainÎncă nu există evaluări

- Euroslot - Quartino Backlack A4Document4 paginiEuroslot - Quartino Backlack A4Ruben PauwelsÎncă nu există evaluări

- Raccordi A Doppia OgivaDocument51 paginiRaccordi A Doppia Ogiva21n23mÎncă nu există evaluări

- 2332-Quantita' RevitDocument4 pagini2332-Quantita' RevitalbertopianarvtÎncă nu există evaluări

- EN10255 Caratteristiche Dei TubiDocument7 paginiEN10255 Caratteristiche Dei TubipindarelloÎncă nu există evaluări

- Lez DobsonDocument52 paginiLez Dobsonnongio27Încă nu există evaluări

- STZA Serrande Di Regolazione A Tenuta PDFDocument4 paginiSTZA Serrande Di Regolazione A Tenuta PDFEric NzalleÎncă nu există evaluări

- Alba Scheda TecnicaDocument3 paginiAlba Scheda TecnicassblackrockÎncă nu există evaluări

- Ischebeck TitanDocument4 paginiIschebeck Titanmoca89Încă nu există evaluări

- CATALOGODocument3 paginiCATALOGOAlvaro RJÎncă nu există evaluări

- BST Rev10Document6 paginiBST Rev10George 60Încă nu există evaluări

- Scheda Tecnica Stiferite Class SDocument3 paginiScheda Tecnica Stiferite Class SlorboÎncă nu există evaluări

- Strumenti Da Banco Sez.6Document24 paginiStrumenti Da Banco Sez.6Jacopo PintonÎncă nu există evaluări

- Catalogo-Tubi Rev13Document36 paginiCatalogo-Tubi Rev13testÎncă nu există evaluări

- Magnum - Tubo PE Corrugato SN4 DN ID Diametri InterniDocument3 paginiMagnum - Tubo PE Corrugato SN4 DN ID Diametri InterniGiuliano BrugnoliÎncă nu există evaluări

- Round Ingots: Lingotti TondiDocument6 paginiRound Ingots: Lingotti TondiAngelo Del PreteÎncă nu există evaluări

- All 106 1 Scheda Tecnica Benna Ripper Per Escavatori ID355 106Document2 paginiAll 106 1 Scheda Tecnica Benna Ripper Per Escavatori ID355 106Cleyton L. AlvesÎncă nu există evaluări

- Tabelle Tolleranze DimensionaliDocument4 paginiTabelle Tolleranze DimensionaliMicheleÎncă nu există evaluări

- Catalogos Grampo Pressao TesmecDocument1 paginăCatalogos Grampo Pressao TesmecAiese Cruz BarrosÎncă nu există evaluări

- Lamiere GrecateDocument2 paginiLamiere GrecatetizioÎncă nu există evaluări

- Filettature UNC PDFDocument1 paginăFilettature UNC PDFandreahankÎncă nu există evaluări

- Normative Uni enDocument13 paginiNormative Uni enZizuÎncă nu există evaluări

- TDS DTNET GL - Rev20 20151016 - ItaDocument2 paginiTDS DTNET GL - Rev20 20151016 - ItacarminecasellaÎncă nu există evaluări

- CT - Serie Fu e PZ - Rev2.1 - ItDocument3 paginiCT - Serie Fu e PZ - Rev2.1 - ItJuandaCabreraCoboÎncă nu există evaluări