Documente Academic

Documente Profesional

Documente Cultură

Nylon 66 Technical Data Sheet

Încărcat de

Rajeev BujjiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nylon 66 Technical Data Sheet

Încărcat de

Rajeev BujjiDrepturi de autor:

Formate disponibile

Technical Data Sheet for Nylon 66 Rod, Sheet & Tube

ERTALON 66 SA

PRODUCT DATA SHEET T

Material with a higher mechanical strength, stiffness, heat and wear resistance than Ertalon 6 SA. It also has a better

creep resistance but its impact strength and mechanical damping ability is reduced. Well suited for machining on

automatic lathes.

Please note that the Ertalon 66 SA natural rods over dia. 150 mm are made from a modified polyamide 66 resin (Ertalon

66 SA-C).

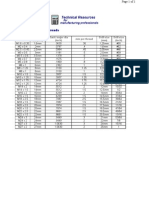

Physical properties (indicative values g)

PROPERTIES Test methods Units VALUES Legend:

Colour - - natural (cream)/

black + : values referring to dry material

++ : values referring to material in equilibrium with the standard

Density ISO 1183-1 g/cm 1.14

atmosphere 23 C / 50 % RH (mostly derived from literature)

Water absorption:

- after 24/96 h immersion in water of 23 C (1) ISO 62 mg 40 / 76 (1) According to method 1 of ISO 62 and done on discs 50 mm x 3

ISO 62 % 0.60 / 1.13 mm.

- at saturation in air of 23 C / 50 % RH - % 2.4 (2) The figures given for these properties are for the most part

- at saturation in water of 23 C - % 8 derived from raw material supplier data and other publications.

Thermal Properties (2) (3) Values for this property are only given here for amorphous

Melting temperature (DSC, 10 C/min) ISO 11357-1/-3 C 260 materials and not for semi-crystalline ones.

Glass transition temperature (DSC, 20 C/min) - (3) ISO 11357-1/-2 C - (4) Only for short time exposure (a few hours) in applications where

no or only a very low load is applied to the material.

Thermal conductivity at 23 C - W/(K.m) 0.28

(5) Temperature resistance over a period of 5,000/20,000 hours.

Coefficient of linear thermal expansion: After these periods of time, there is a decrease in tensile strength

- average value between 23 and 60 C - m/(m.K) 80 x 10-6 measured at 23 C of about 50 % as compared with the

- average value between 23 and 100 C - m/(m.K) 95 x 10-6 original value. The temperature values given here are thus based

Temperature of deflection under load: on the thermal-oxidative degradation which takes place and

- method A: 1.8 MPa + ISO 75-1/-2 C 85 causes a reduction in properties. Note, however, that the

Max. allowable service temperature in air: maximum allowable service temperature depends in many cases

- for short periods (4) - C 180 essentially on the duration and the magnitude of the mechanical

- continuously : for 5,000 / 20,000 h (5) - C 95 / 80 stresses to which the material is subjected.

(6) Impact strength decreasing with decreasing temperature, the

Min. service temperature (6) - C -30

minimum allowable service temperature is practically mainly

Flammability (7): determined by the extent to which the material is subjected to

- "Oxygen Index" ISO 4589-1/-2 % 26 impact. The value given here is based on unfavourable impact

- according to UL 94 (3 / 6 mm thickness) - - HB / HB conditions and may consequently not be considered as being the

Mechanical Properties at 23 C (8) absolute practical limit.

Tension test (9): (7) These estimated ratings, derived from raw material supplier data

- tensile stress at yield / tensile stress at break (10) + ISO 527-1/-2 MPa 90 / - and other publications, are not intended to reflect hazards

++ ISO 527-1/-2 MPa 55 / - presented by the material under actual fire conditions. There is no

ISO 527-1/-2 MPa 93 UL File Number available for Ertalon 66 SA stock shapes.

- tensile strength (10) +

(8) The figures given for the properties of dry material (+) are for the

- tensile strain at yield (10) + ISO 527-1/-2 % 5

most part average values of tests run on test specimens

- tensile strain at break (10) + ISO 527-1/-2 % 50 machined out of rods 40 - 60 mm. Except for the hardness

++ ISO 527-1/-2 % > 100 tests, the test specimens were then taken from an area mid

Copyright 2011 The Quadrant group of companies. All rights reserved. - Date of issue / revision: January 20, 2011

- tensile modulus of elasticity (11) + ISO 527-1/-2 MPa 3550 between centre and outside diameter, with their length in

++ ISO 527-1/-2 MPa 1700 longitudinal direction of the rod (parallel to the extrusion direction).

Compression test (12): (9) Test specimens: Type 1 B

- compressive stress at 1 / 2 / 5 % nominal strain (11) + ISO 604 MPa 32 / 62 / 100 (10) Test speed: 50 mm/min [chosen acc. to ISO 10350-1 as a

Charpy impact strength - Unnotched (13) + ISO 179-1/1eU kJ/m no break function of the ductile behaviour of the material (tough or brittle)]

Charpy impact strength - Notched + ISO 179-1/1eA kJ/m 4.5 (11) Test speed: 1 mm/min

(12) Test specimens: cylinders 8 mm x 16 mm

Ball indentation hardness (14) + ISO 2039-1 N/mm 160

(13) Pendulum used: 4 J

Rockwell hardness (14) + ISO 2039-2 - M 88 (14) Measured on 10 mm thick test specimens (discs), mid between

Electrical Properties at 23 C centre and outside diameter.

Electric strength (15) + IEC 60243-1 kV/mm 27 (15) Electrode configuration: 25 / 75 mm coaxial cylinders ; in

++ IEC 60243-1 kV/mm 18 transformer oil according to IEC 60296 ; 1 mm thick test

Volume resistivity + IEC 60093 Ohm.cm > 10 14 specimens.

++ IEC 60093 Ohm.cm > 10 12 Please note that the electric strength of Ertalon 66 SA black can

Surface resistivity + IEC 60093 Ohm > 10 13 be considerably lower than the figure listed in the table which

refers to natural material.

++ IEC 60093 Ohm > 10 12

Relative permittivity r : - at 100 Hz + IEC 60250 - 3.8 g

This table, mainly to be used for comparison purposes, is a

++ IEC 60250 - 7.4

valuable help in the choice of a material. The data listed here fall

Relative permittivity r : - at 1 MHz + IEC 60250 - 3.3 within the normal range of product properties. However, they are

++ IEC 60250 - 3.8 not guaranteed and they should not be used to establish

Dielectric dissipation factor tan : - at 100 Hz + IEC 60250 - 0.013 material specification limits nor used alone as the basis of

++ IEC 60250 - 0.13 design.

Dielectric dissipation factor tan : - at 1 MHz + IEC 60250 - 0.020

++ IEC 60250 - 0.06

Comparative tracking index (CTI) + IEC 60112 - 600

++ IEC 60112 - 600

Note: 1 g/cm = 1,000 kg/m ; 1 MPa = 1 N/mm ; 1 kV/mm = 1 MV/m.

Availablility: see "Guide to Diameter/Sheet Tolerances and Weights" or contact us

Ertalon is a registered trademark of the Quadrant Group.

This product data sheet and any data and specifications presented on our website shall provide promotional and general information about the Engineering Plastic Products (the "Products")

manufactured and offered by Quadrant Engineering Plastic Products ("Quadrant") and shall serve as a preliminary guide. All data and descriptions relating to the Products are of an indicative

nature only. Neither this data sheet nor any data and specifications presented on our website shall create or be implied to create any legal or contractual obligation.

Any illustration of the possible fields of application of the Products shall merely demonstrate the potential of these Products, but any such description does not constitute any kind of covenant

whatsoever. Irrespective of any tests that Quadrant may have carried out with respect to any Product, Quadrant does not possess expertise in evaluating the suitability of its materials or

Products for use in specific applications or products manufactured or offered by the customer respectively. The choice of the most suitable plastics material depends on available chemical

resistance data and practical experience, but often preliminary testing of the finished plastics part under actual service conditions (right chemical, concentration, temperature and contact time, as

well as other conditions) is required to assess its final suitability for the given application.

It thus remains the customer's sole responsibility to test and assess the suitability and compatibility of Quadrant's Products for its intended applications, processes and uses, and to choose those

Products which according to its assessment meet the requirements applicable to the specific use of the finished product. The customer undertakes all liability in respect of the application,

processing or use of the aforementioned information or product, or any consequence thereof, and shall verify its quality and other properties.

www.theplasticshop.co.uk

S-ar putea să vă placă și

- The Development of Armor-piercing Shells (With Suggestions for Their Improvement)De la EverandThe Development of Armor-piercing Shells (With Suggestions for Their Improvement)Încă nu există evaluări

- The Rifleman Series (Part 9)Document10 paginiThe Rifleman Series (Part 9)deolexrex100% (6)

- CQB Receiver - M4A1 Carbine With 10-Inch Upper ReceiverDocument21 paginiCQB Receiver - M4A1 Carbine With 10-Inch Upper ReceiverDoug EvansÎncă nu există evaluări

- M4 Carbine ImprovementsDocument1 paginăM4 Carbine ImprovementsNickchiosÎncă nu există evaluări

- About Hot Plate Welding PDFDocument5 paginiAbout Hot Plate Welding PDFmehdi7891Încă nu există evaluări

- Armalite AR-16 Battle RifleDocument3 paginiArmalite AR-16 Battle Rifleblowmeasshole1911Încă nu există evaluări

- M60English ManualDocument63 paginiM60English ManualJAG2011Încă nu există evaluări

- 2 Engineering MaterialsDocument14 pagini2 Engineering MaterialsPRASAD326100% (1)

- MOD 125 SniperDocument3 paginiMOD 125 SniperCarlos EduardoÎncă nu există evaluări

- Design and Modelling of ECM Rifling ToolDocument5 paginiDesign and Modelling of ECM Rifling Tooldavid2404100% (2)

- Result Page: Description of EP2309028 Print Copy Contact Us CloseDocument26 paginiResult Page: Description of EP2309028 Print Copy Contact Us CloseKaveri JainÎncă nu există evaluări

- US3779883 PentaDocument6 paginiUS3779883 PentaRuchita Poilkar100% (1)

- Heat Treatment and Hardness of Tool SteelDocument14 paginiHeat Treatment and Hardness of Tool SteelStephen MirdoÎncă nu există evaluări

- High Exp. Tech. & AppsDocument94 paginiHigh Exp. Tech. & AppsJ.c. MasonÎncă nu există evaluări

- Single Layer Winding of Three Phase Induction Motor: Enesi Asizehi YahayaDocument6 paginiSingle Layer Winding of Three Phase Induction Motor: Enesi Asizehi YahayaHuong Thao Le LuongÎncă nu există evaluări

- AR15 Improved Battle Sight ZeroDocument3 paginiAR15 Improved Battle Sight ZeroMattGryderÎncă nu există evaluări

- Bullets: Design and ManufactureDocument33 paginiBullets: Design and ManufactureaakasÎncă nu există evaluări

- Nitromet Liquid Ferritic NitrocarburizingDocument11 paginiNitromet Liquid Ferritic NitrocarburizingDoez AryanaÎncă nu există evaluări

- Thermore ENGLISHDocument12 paginiThermore ENGLISHdanieltsun20066817Încă nu există evaluări

- Pulse Detonation EngineDocument29 paginiPulse Detonation Enginev2brother100% (6)

- Shrinkage Values of PolymersDocument4 paginiShrinkage Values of PolymersVijaya SimhaÎncă nu există evaluări

- Orange PI ZeroDocument19 paginiOrange PI Zerosondaya86Încă nu există evaluări

- MIL-STD-1168A (Ammunition Lot Numbering) PDFDocument47 paginiMIL-STD-1168A (Ammunition Lot Numbering) PDFzorlon1100% (1)

- Chapter 4 - Casting ProcessesDocument40 paginiChapter 4 - Casting ProcessesErnawati ZailiÎncă nu există evaluări

- Computer Networks 12Document634 paginiComputer Networks 12SarzaminKhanÎncă nu există evaluări

- TM E9-206A - German 7.9-mm Dual Purpose Machine Gun MG34 1943 PDFDocument71 paginiTM E9-206A - German 7.9-mm Dual Purpose Machine Gun MG34 1943 PDFRobertLockieÎncă nu există evaluări

- Tap Chart - Metric ThreadsDocument1 paginăTap Chart - Metric ThreadssonytechoÎncă nu există evaluări

- Charge Design and Their Effect On Pressure Wave in GunDocument64 paginiCharge Design and Their Effect On Pressure Wave in GunIvan Dario Altamar CastellanosÎncă nu există evaluări

- MBD Annular SectionDocument4 paginiMBD Annular SectionCompra Venta De Maquinaria IndustrialÎncă nu există evaluări

- MAX11kManual Rev A PDFDocument12 paginiMAX11kManual Rev A PDFJorge Mercado NajeraÎncă nu există evaluări

- SVT40 ManualDocument23 paginiSVT40 Manualandy2205Încă nu există evaluări

- 4608 Eed 01Document29 pagini4608 Eed 01NickÎncă nu există evaluări

- Walther Introduces PPKS 22Document2 paginiWalther Introduces PPKS 22SukarmanÎncă nu există evaluări

- FNC Rifle: Kickintro - PPT - Page 1Document16 paginiFNC Rifle: Kickintro - PPT - Page 1محمد علىÎncă nu există evaluări

- Klashnikov (Ak-47)Document15 paginiKlashnikov (Ak-47)TonyVeneroÎncă nu există evaluări

- FX Black Powder PDFDocument18 paginiFX Black Powder PDFPijush SarkarÎncă nu există evaluări

- How2r1 DatasheetDocument3 paginiHow2r1 DatasheetMike PerezÎncă nu există evaluări

- Navy MIC PrimerDocument29 paginiNavy MIC PrimerDANIEL RONTEYÎncă nu există evaluări

- Pulsejet Ejector Thrust AugmentorDocument14 paginiPulsejet Ejector Thrust AugmentorTAMA_Încă nu există evaluări

- Hydroclear Spec SheetDocument4 paginiHydroclear Spec Sheetamitleck100% (1)

- Night Vision SightsDocument7 paginiNight Vision Sightsakms1982100% (1)

- Glock Magazine IdentificationDocument2 paginiGlock Magazine IdentificationSteve JohnsonÎncă nu există evaluări

- AK-47 Characteristics and FundamentalsDocument11 paginiAK-47 Characteristics and FundamentalsGeorge Drumm100% (4)

- Detail Specification, Rifle, 5.56 Millimeter, m1641 Mil-Dtl-32309Document57 paginiDetail Specification, Rifle, 5.56 Millimeter, m1641 Mil-Dtl-32309cjnjr1Încă nu există evaluări

- The Forensic Teacher Magazine: Issue 24Document50 paginiThe Forensic Teacher Magazine: Issue 24innoculatorÎncă nu există evaluări

- Germansportguns Gsg5Document34 paginiGermansportguns Gsg5Justin100% (1)

- Making and Using Reamers: Part 1Document50 paginiMaking and Using Reamers: Part 1angelines123Încă nu există evaluări

- Loperamide Hydrochloride FE7.0Document3 paginiLoperamide Hydrochloride FE7.0April ClineÎncă nu există evaluări

- High Speed CastingDocument7 paginiHigh Speed Castingferdlh9Încă nu există evaluări

- The Canadian Journal of Chemical Engineering Volume 93 Issue 1 2015Document10 paginiThe Canadian Journal of Chemical Engineering Volume 93 Issue 1 2015Widya Isti AriantiÎncă nu există evaluări

- Koch-2008-Propellants, Explosives, Pyrotechnics PDFDocument12 paginiKoch-2008-Propellants, Explosives, Pyrotechnics PDFmien nam100% (1)

- Sta - Cat 08 (LR)Document159 paginiSta - Cat 08 (LR)tintucinb100% (1)

- Revision B - 1982 PDFDocument34 paginiRevision B - 1982 PDFdududadamikeÎncă nu există evaluări

- Lightweight Ceramic Composite Armour SystemDocument5 paginiLightweight Ceramic Composite Armour SystemaamirmubÎncă nu există evaluări

- Ertalon 6PLA-ENDocument1 paginăErtalon 6PLA-ENEdwin TacoÎncă nu există evaluări

- Nylatron 66 SA FR PDS E 12072017Document1 paginăNylatron 66 SA FR PDS E 12072017TasfikÎncă nu există evaluări

- Glass Filled Nylon Technical Data SheetDocument1 paginăGlass Filled Nylon Technical Data SheetSyed MoinÎncă nu există evaluări

- ErtalyteDocument1 paginăErtalyteFlavio BertolaÎncă nu există evaluări

- Scheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317Document1 paginăScheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317wilderness_666Încă nu există evaluări

- Murtfeldt TK Murlubric Datasheet enDocument1 paginăMurtfeldt TK Murlubric Datasheet enPedro Henriques RamosÎncă nu există evaluări

- 113 B 22Document11 pagini113 B 22Rajeev BujjiÎncă nu există evaluări

- Nylon 66 Rod Diameter Tolerances and WeightsDocument1 paginăNylon 66 Rod Diameter Tolerances and WeightsRajeev BujjiÎncă nu există evaluări

- Dissertation Formatting GuideDocument7 paginiDissertation Formatting GuideRajeev BujjiÎncă nu există evaluări

- Samaveda Upakarma Saveca Aug31 11Document27 paginiSamaveda Upakarma Saveca Aug31 11Karthik DesaiÎncă nu există evaluări

- SaivamDocument90 paginiSaivamPavan Varma V100% (2)

- Postdoctoral Fellow - PDDocument3 paginiPostdoctoral Fellow - PDRajeev BujjiÎncă nu există evaluări

- FDP ScheduleDocument1 paginăFDP ScheduleRajeev BujjiÎncă nu există evaluări

- SHERA-Standards-IMPACT Strength of Boards (May 2011)Document1 paginăSHERA-Standards-IMPACT Strength of Boards (May 2011)Rajeev BujjiÎncă nu există evaluări

- Terms & ConditionsDocument14 paginiTerms & ConditionsRajeev BujjiÎncă nu există evaluări

- Terms & ConditionsDocument14 paginiTerms & ConditionsRajeev BujjiÎncă nu există evaluări

- BooksDocument1 paginăBooksbagmassÎncă nu există evaluări

- A Brief Guide To Designing Effective Figures For The Scientifi C PaperDocument4 paginiA Brief Guide To Designing Effective Figures For The Scientifi C PaperRajeev BujjiÎncă nu există evaluări

- Einstein Dissertation English PDFDocument15 paginiEinstein Dissertation English PDFlimberg_maytaÎncă nu există evaluări

- Terms & ConditionsDocument14 paginiTerms & ConditionsRajeev BujjiÎncă nu există evaluări

- RISE Announcement 2017-2018Document3 paginiRISE Announcement 2017-2018Rajeev BujjiÎncă nu există evaluări

- A Brief Guide To Designing Effective Figures For The Scientifi C PaperDocument4 paginiA Brief Guide To Designing Effective Figures For The Scientifi C PaperRajeev BujjiÎncă nu există evaluări

- List of Confused English Spellings Gr8AmbitionZDocument8 paginiList of Confused English Spellings Gr8AmbitionZsandeepkottemÎncă nu există evaluări

- ReportDocument36 paginiReportRajeev BujjiÎncă nu există evaluări

- Alluminio UkDocument1 paginăAlluminio UkRajeev BujjiÎncă nu există evaluări

- Terms & ConditionsDocument14 paginiTerms & ConditionsRajeev BujjiÎncă nu există evaluări

- Literature in Tabular FormatDocument9 paginiLiterature in Tabular FormatRajeev BujjiÎncă nu există evaluări

- BDocument1 paginăBRajeev BujjiÎncă nu există evaluări

- Cantilver Column (75 MM X 75 MM)Document1 paginăCantilver Column (75 MM X 75 MM)Rajeev BujjiÎncă nu există evaluări

- Is 1893 2016 New ProvisionsDocument61 paginiIs 1893 2016 New Provisionsdev_1989Încă nu există evaluări

- Ad 137b23a-B Lowres PDFDocument4 paginiAd 137b23a-B Lowres PDFRajeev BujjiÎncă nu există evaluări

- Ad 137b23a-B LowresDocument4 paginiAd 137b23a-B LowresRajeev BujjiÎncă nu există evaluări

- Precast Concrete Frames GuideDocument58 paginiPrecast Concrete Frames GuideHari Amudhan Ilanchezhian100% (9)

- Precast Concrete FloorslabDocument37 paginiPrecast Concrete FloorslabBanu Umashankar100% (3)

- Design of Steel Structures.1-10Document10 paginiDesign of Steel Structures.1-10Rajeev BujjiÎncă nu există evaluări

- BR1500691092Brochure Vasant MatsagarDocument2 paginiBR1500691092Brochure Vasant MatsagarRajeev BujjiÎncă nu există evaluări

- Adhesively Bonded Joints PDFDocument336 paginiAdhesively Bonded Joints PDFSantiago Molina100% (1)

- Brochure SupportiDocument12 paginiBrochure SupportiiceschelÎncă nu există evaluări

- Integral Bridge Design To EN 1992-2Document58 paginiIntegral Bridge Design To EN 1992-2Dem HasiÎncă nu există evaluări

- Mos Series 1 QP Set3Document2 paginiMos Series 1 QP Set3SijuKalladaÎncă nu există evaluări

- Behavior of Reinforced Concrete Sandwiched Panels (RCSPS) Under Blast Load (Abbas-2019)Document15 paginiBehavior of Reinforced Concrete Sandwiched Panels (RCSPS) Under Blast Load (Abbas-2019)juan diazÎncă nu există evaluări

- Static and Thermal Analysis of Piston and Piston RingsDocument8 paginiStatic and Thermal Analysis of Piston and Piston RingsNguyenÎncă nu există evaluări

- ME 2256 - Strength of Materials - Lab ManualDocument36 paginiME 2256 - Strength of Materials - Lab ManualMohan Prasad.M100% (22)

- ASTM A36 Steel, PlateDocument2 paginiASTM A36 Steel, PlateMuhammad Al FaqihÎncă nu există evaluări

- DFDGGGDGDGDDocument54 paginiDFDGGGDGDGDAnil MaliÎncă nu există evaluări

- API Gate Valve CalculationsDocument140 paginiAPI Gate Valve CalculationsFaraj KhalikovÎncă nu există evaluări

- Effect of CaCO3 On The Mechanical Properties of Polypropylene TapesDocument28 paginiEffect of CaCO3 On The Mechanical Properties of Polypropylene TapesJubril Sanusi DanlamiÎncă nu există evaluări

- GSI: A GEOLOGICALLY FRIENDLY TOOL FOR ROCK MASS STRENGTH ESTIMATION - Marinos & HoekDocument12 paginiGSI: A GEOLOGICALLY FRIENDLY TOOL FOR ROCK MASS STRENGTH ESTIMATION - Marinos & HoekJohan Van StaverenÎncă nu există evaluări

- Vol19b 0925Document17 paginiVol19b 0925Walaa Hassan Salem Abd El KareemÎncă nu există evaluări

- 4 Thick Cylinders AsgnDocument5 pagini4 Thick Cylinders AsgnHILMAN NAZRIÎncă nu există evaluări

- 04 Properties of Electroless Nickel PlateDocument27 pagini04 Properties of Electroless Nickel PlateSimi SolaÎncă nu există evaluări

- ES228 Mechanics of Deformable Bodies-SyllabusDocument9 paginiES228 Mechanics of Deformable Bodies-SyllabusJaypee BucatcatÎncă nu există evaluări

- M15 - HILTI Anchor Design Report With HST3 M10 Anchors - AD - 2017 - 2Document7 paginiM15 - HILTI Anchor Design Report With HST3 M10 Anchors - AD - 2017 - 2Rajeev DuaÎncă nu există evaluări

- 4 Shafts and Shaft ComponentsDocument7 pagini4 Shafts and Shaft ComponentsGino JardinicoÎncă nu există evaluări

- Compression Test em 327: Mechanics of Materials Laboratory: ObjectivesDocument5 paginiCompression Test em 327: Mechanics of Materials Laboratory: Objectivesrajenkoley88% (8)

- Rock Mechanics and Tunneling Course Outline: Part One Rock MechanicsDocument39 paginiRock Mechanics and Tunneling Course Outline: Part One Rock MechanicsMulugeta DefaruÎncă nu există evaluări

- rr321401 Principles of Machine DesignDocument8 paginirr321401 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- Ch9 Horizontally Curved Steel GirdersDocument43 paginiCh9 Horizontally Curved Steel GirdersErnie ErnieÎncă nu există evaluări

- Analysis and Testing of Bamboo Joint Series' SY.B.Tech. Minor Project ReportDocument40 paginiAnalysis and Testing of Bamboo Joint Series' SY.B.Tech. Minor Project ReportMr.Bhaskar WabhitkarÎncă nu există evaluări

- Abstract Number: 191 Finite Element Analysis of Geotextile Reinforced Highway Embankment Using Plaxis 3DDocument13 paginiAbstract Number: 191 Finite Element Analysis of Geotextile Reinforced Highway Embankment Using Plaxis 3DAnjali SharmaÎncă nu există evaluări

- D B Mall Projects LTD., BhopalDocument59 paginiD B Mall Projects LTD., BhopalDevendra SharmaÎncă nu există evaluări

- Early Age CrackingDocument4 paginiEarly Age CrackingAngga Fajar SetiawanÎncă nu există evaluări

- The Response of Honeycombsandwich Panels Under Low-Velocity Impact LoadingDocument25 paginiThe Response of Honeycombsandwich Panels Under Low-Velocity Impact LoadingMihaela NastaseÎncă nu există evaluări

- FRP Slab Flexure Strengthening With TYFO Fibrwrap System: Retrofitting of Anglo WarehouseDocument5 paginiFRP Slab Flexure Strengthening With TYFO Fibrwrap System: Retrofitting of Anglo Warehouseheherson juanÎncă nu există evaluări

- Adigrat UniversityDocument59 paginiAdigrat UniversitymikiaelehagossumÎncă nu există evaluări

- Doec Question Bank: Ut 2 and Yt 2)Document4 paginiDoec Question Bank: Ut 2 and Yt 2)Aditya DeshmukhÎncă nu există evaluări