Documente Academic

Documente Profesional

Documente Cultură

Dry ISE Service 060710

Încărcat de

Ivan Villena ChumanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dry ISE Service 060710

Încărcat de

Ivan Villena ChumanDrepturi de autor:

Formate disponibile

Service Manual

Vitalab Dry Electrode ISE

for

Vitalab Selectra E

Vitalab Selectra XL

Preface

CE

This instrument conforms to the provisions of the EU Directive on In Vitro Diagnostic Medical Devices

(98/79/EC) of the European Parliament and the Council of 27 October 1998.

The contents of this manual with all figures, tables and graphics are intellectual property of Vital Scientific.

Unauthorized commercial or non-commercial excerption or copying of contents and use of this manual (in

total or in parts) are strictly forbidden unless the editor gives written permission for it.

This manual was written and produced with the utmost care. However, errors cannot be fully excluded. Vital

Scientific do not take any responsibilities and accepts no liabilities for incidents of any kind that may occur

because of errors in the manual.

All product names are mentioned in this manual are registered trademarks. The manual describes the

analyzer system Dry ISE and the software version 1.0.

The Dry ISE has been conceptualized, manufactured and tested in accordance with the declaration of

conformity. This declaration is supplied with each device in a separate file.

Please call Technical Support if you need advice or you have any questions.

Manufacturer:

Vital Scientific N.V.

PO box 100

NL 6950 AC Dieren

The Netherlands

Telephone: +31 313 430 500

Telefax: +31 313 427 807

e-mail: info@vital.nl

Internet: www.vitalscientific.com

Article No.: 6002-580-450

Version: 01

Date: January 2006

1 Introduction ..................................................................................................................... 1-1

1.1 Scope of manual .................................................................................................. 1-1

1.2 Prerequisites ........................................................................................................ 1-1

1.3 Password protection ............................................................................................ 1-2

2 The bare minimum .......................................................................................................... 2-1

2.1 Does the unit run? ................................................................................................ 2-1

2.2 Is the ISE activated? ............................................................................................ 2-1

2.3 Does the unit Communicate? .............................................................................. 2-1

2.4 Is there reference liquid flowing? ........................................................................ 2-1

2.5 Is the sipper blocked? .......................................................................................... 2-1

3 The service screen ............................................................................................................ 3-1

3.1 Overview ............................................................................................................. 3-1

3.2 The service function keys .................................................................................... 3-2

3.3 Paged data ............................................................................................................ 3-2

3.4 Paged data format ................................................................................................ 3-3

3.5 F1 Measurement DATA ................................................................................... 3-4

3.6 F2 EEPROM DATA ........................................................................................ 3-7

3.7 F3 CALIBRATION DATA .............................................................................. 3-8

3.8 F4 BUBBLE-DETECTOR CALIBRATION DATA ....................................... 3-9

3.9 F5 PUMP TEST ............................................................................................. 3-10

3.10 F6 ADC TESTS .............................................................................................. 3-10

3.11 F7 VALVE TEST ........................................................................................... 3-12

3.12 F8 SIPPER TEST ........................................................................................... 3-12

4 Field service ...................................................................................................................... 4-1

4.1 Servicing an ISE .................................................................................................. 4-1

4.2 Service tools required .......................................................................................... 4-1

4.3 Servicing a trouble-free unit (6 months service) ................................................. 4-1

4.4 Servicing units with intermittent problems ......................................................... 4-1

4.5 Servicing a failed system ..................................................................................... 4-2

5 Communications testing .................................................................................................. 5-1

5.1 Testing presence of Dry-ISE ............................................................................... 5-1

5.2 Testing Selectra communications ........................................................................ 5-1

5.3 Testing ISE communications ............................................................................... 5-2

6 Troubleshooting tips ........................................................................................................ 6-1

6.1 Overview ............................................................................................................. 6-1

6.2 Observing waste flow .......................................................................................... 6-1

6.3 Trouble shooting a startup cycle ......................................................................... 6-2

6.4 Troubleshooting measurement cycle ................................................................... 6-3

6.5 Corrective actions ................................................................................................ 6-5

7 Component replacement ................................................................................................. 7-1

7.1 Opening-up the ISE ............................................................................................. 7-1

7.2 Replacing the power supply ................................................................................ 7-2

7.3 Replacing the main board .................................................................................... 7-3

7.4 Replacing the valve assembly ............................................................................. 7-5

7.5 Replacing the stepping motor .............................................................................. 7-6

7.6 Replacing the ground electrode ........................................................................... 7-6

7.7 Replacing the bubble-detector assembly ............................................................. 7-7

8 ISE firmware re-programming ...................................................................................... 8-1

8.1 Introduction ......................................................................................................... 8-1

8.2 Tools required ...................................................................................................... 8-1

VITAL SCIENTIFIC N.V. 1-1

8.3 Firmware download instructions ......................................................................... 8-1

8.4 Troubleshooting bootloader problems ................................................................. 8-2

9 Appendix .......................................................................................................................... 9-1

9.1 The Dry-ISE field QC test ................................................................................... 9-1

9.1.1 Overview ............................................................................................................. 9-1

9.1.2 Version Verify QC-Q1 ........................................................................................ 9-1

9.1.3 Pump Motor QC-Q2 ............................................................................................ 9-2

9.1.4 Valve QC-Q3 ....................................................................................................... 9-4

9.1.5 Simulated Sipper QC-Q4 ..................................................................................... 9-4

9.1.6 EEProm Read/Write QC-Q5 ............................................................................... 9-5

9.1.7 A/D Coverters QC-Q6 ......................................................................................... 9-5

9.1.8 Bubble-Detector QC-Q7 ...................................................................................... 9-6

9.1.9 Calibration QC-Q8 .............................................................................................. 9-7

9.1.10 Field QC Checkoff .............................................................................................. 9-8

9.2 Spare parts ........................................................................................................... 9-9

9.2.1 ISE Consumables ................................................................................................ 9-9

9.2.2 ISE Spare Parts .................................................................................................... 9-9

1-2 VITAL SCIENTIFIC N.V.

Introduction

Introduction

1.1 Scope of manual

This manual covers all subjects related to Servicing of a Dry-ISE module by a qualified Ser-

vice Technician. The following are areas covered by the manual:

Correct Operation and Interpretation of the Selectra Dry-ISE Service Screen.

Troubleshooting.

Component Replacement.

1.2 Prerequisites

It is assumed that Dry-ISE servicing will be carried out by a qualified technician who has

undergone the appropriate training in servicing a Dry-ISE module. It is also assumed that the

technician is familiar with the general operation of the Selectra system and with that of the

Dry-ISE module, and that they have read the appropriate User Manuals for each unit.

Fig. 1.2.0.1 The Dry-ISE Module

Attention!

Read the User manual

Information in the User Manual is not repeated in this Manual. It is important to read the User

Manual in combination with the Service Manual. Please be aware of all safety instructions in

the User Manual.

VITAL SCIENTIFIC N.V. 1-1

Introduction

1.3 Password protection

The Service Screen of the Selectra is password protected. The Service technician should

have received the Service area password during Service training. The Service area is

accessed from the main menu by pressing F5 / Service. Failure to enter the correct password

will prevent the technician from accessing the Service Screen.

1-2 VITAL SCIENTIFIC N.V.

The bare minimum

The bare minimum

2.1 Does the unit run?

In the event that a Dry-ISE module does not operate correctly, it is recommended that the unit

be observed during a Startup/Reset Cycle. On manual power-on the Dry-ISE should go

through a simple Startup/Reset cycle and the Peristaltic Motor should operate the pump. The

valves should switch, and Reference liquid should be pumped through the line and bubble-

detector within 25-30 seconds. Failure of any of these to occur is an indication that something

is not correct. Follow the instructions in the Troubleshooting Section (Section 6) to trouble-

shoot further.

2.2 Is the ISE activated?

A common problem encountered in troubleshooting Dry-ISE modules, is that the Dry-ISE

module has not been installed/activated within the Selectra-PC software.

To activate the Dry-ISE module on the Selectra system go to F5 Special Functions / F2

Install, then double click on the System Parameters selection in the left hand menu. The ISE

Installed box should have been checked. None of the ISE functions will be available unless

this box is checked.

2.3 Does the unit Communicate?

If there is no apparent problem observed during the Power-Up startup cycle, then the next

step is to attempt to Restart the Dry-ISE from the Selectra by going to the Special Functions /

ISE screen and pressing F1 ISE Reset. The Dry-ISE module should immediately Reset.

Next follow the Testing Presence of Dry ISE procedure in the Communications section of this

manual.

2.4 Is there reference liquid flowing?

Reference liquid is stored in the bottle contained in the recess on the left hand side of the Dry-

ISE module. This is the easiest source of liquid to use for system troubleshooting since the

movement of this liquid is exclusively under the control of the Dry-ISE module and does not

require the participation of the Selectra.

The following issues are sometime encountered:

The Reference reservoir is empty.

The lines become blocked - check the lines in the region of the pinch valves.

Check that the Reference interconnect lines are sealed onto the straws and the Reference

interface block.

Check that the straws in the Reference bottle are not blocked.

2.5 Is the sipper blocked?

Identify the Sipper on the Selectra bench. Very infrequently the end of the Sipper becomes

blocked. If this happens, blowing through the sample line (with the ISE disconnected) from

the Dry-ISE Sample connection point on the Selectra, can usually unblock the line (see the

User Manual for more details).

Serum should not be used as an initial discarded P6 measurement (after calibration). Rather,

use a LO-calibrator sample removed from the LO-calibrator position after calibration. It has

been found that the use of a serum P6 has major drawbacks. Users generally do not replen-

ish P6 frequently enough (especially over a weekend) and evaporation of the sample creates

a resulting P6 sample which is very viscous and prone to blocking the line.

Regular cleaning of the Dry-ISE and the use of a LO-cal P6 will prevent Sipper blockage in

most cases.

VITAL SCIENTIFIC N.V. 2-1

The bare minimum

2-2 VITAL SCIENTIFIC N.V.

The service screen

The service screen

3.1 Overview

The most important screen from the standpoint of servicing a Dry-ISE module is the Service

Screen. It contains a number of diagnostic screens and test functions which can rapidly allow

a Service Technician to converge in on any module problems. It is accessed by choosing the

ISE Arm / ISE Unit from the left hand menu (Fig. 3.1.0.1). The Service screen is password

protected and not available to the normal user.

There are two categories of Service Functions (designated with the letters D and T); the first

allows the Service Technician to access some of the important raw data which lie behind the

actual measurements and calibrations. Secondly, it is possible to directly test the high preci-

sion ADC (Analog to Digital Converter), the pump motor, the two valves, the Sipper Control

circuitry.

Fig. 3.1.0.1 The ISE Arm / ISE Unit Service Screen

VITAL SCIENTIFIC N.V. 3-1

The service screen

3.2 The service function keys

The Dry-ISE Service Screen has a set of 9 keys at the bottom of the screen (Figure 2), each

of which corresponds to a keyboard function key. The tests shown on each function key may

be carried out either by clicking on the screen key image with a mouse, or by pressing the

appropriate key on the keyboard

KEY TYPE DESCRIPTION ACTION PAGES

F1 D Measurement Data Data 13

F2 D EEPROM Data Data 6

F3 D Calibration Data Data 11

F4 D Flow (Bubble Detector) Data Data 9

F5 T Peristaltic Pump Test Test / Data 2

F6 T ADC Tests Test / Data 4

F7 T Valve Test Test / Data 1

F8 T Sipper Test Test / Data 2

F10 Return (to Main Menu) Return -

Table 1: The service Screen Function buttons

The exact function of each of the Service Screen keys is given in Table 1. The Service keys

F1..F4, designated with the letter D in the center of the button (D-Keys), are a method of

accessing important measurement and calibration data on the Dry-ISE module; the second

set F5..F8, designated with the letter T, are Test keys (T-Keys), which result in an action being

performed by the Dry-ISE and which also return data at the end of the test.

3.3 Paged data

A number of possible pages of data are available for all the Data buttons and some of the test

buttons. Each time a key is pressed a single action is performed (T-Keys) and a single data

page is returned to the Selectra screen (D-Keys, T-Keys). The pages are returned to the

Selectra in a wraparound fashion. As an example, the F1 key (measurement Data) returns a

total of 13 pages (Pages 0-12) of data to the screen, one page for each time the function key

is pressed. If the key is pressed for the 14th time, Page 0 will again be visible. Pressing any of

the other function key, resets the page counter to zero for all function buttons.

A number of the Service function keys return QC test information (PASS/FAIL) when a key is

first pressed. Subsequent key presses return more detailed information. Pressing the F10

button return the Selectra system to the main menu. There is no action performed on the Dry-

ISE when the F10 button is pressed.

Note that in the following manual pages, further details of each of the Data/Test

screens are given. Wherever it is appropriate, information on the possible data range

expected is given in curly brackets {...}.

3-2 VITAL SCIENTIFIC N.V.

The service screen

3.4 Paged data format

Each page of data consists of 5 lines (Figure 3) superimposed in the center of the Service

Screen. The first line is a title line which may also contain data (numbers). The other 4 lines

contain data in most cases. Refer to the following sections for more details on the meaning of

each screen.

Fig. 3.4.0.1 Paged Data Format Example

VITAL SCIENTIFIC N.V. 3-3

The service screen

3.5 F1 Measurement DATA

The function key F1 returns mostly measurement data. Pressing the key F1 for the first time

results in information on the last error encountered by the Dry-ISE. Subsequent key presses

display detailed background information on the last 6 measurements being returned to the

Selectra screen. It takes 2 pages of data to return the information for a single measurement.

The exact F1 page format is shown in Tables 2a-c.

The screens show detailed information on the last Dry-ISE measurement executed. The

actual values printed on the screen may be used by the Service Department to troubleshoot

measurement problems on the Dry-ISE.

PAGE SCREEN DATA FORMAT

0 Error Screen

LAST ERR

Error Text

subErr = xxxx

Proc = xxxx

Time = xxxx

see Table 2b

1 Measurement Screen M0A

MnA [ T1 , T2 ]

0 Meas0 Ffs0 Fco0 - [K]

1 Meas1 Ffs1 Fco1 - [Na]

2 Meas2 Ffs2 Fco2 - [Cl]

3 Meas3 Ffs3 Fco3 - [CO2]

see Table 2c

2 Measurement Screen M0B

MnB [ T3 , St ]

0 Ref0 Delta0 - [K]

1 Ref1 Delta1 - [Na]

2 Ref2 Delta2 - [Cl]

3 Ref3 Delta3 - [CO2]

3-4 VITAL SCIENTIFIC N.V.

The service screen

see Table 2c

Measurement Screen M1A

3 Same format as Pg 1

4 Measurement Screen Same format as Pg 2

5 Measurement Screen Same format as Pg 1

6 Measurement Screen Same format as Pg 2

7 Measurement Screen Same format as Pg 1

8 Measurement Screen Same format as Pg 2

9 Measurement Screen Same format as Pg 1

10 Measurement Screen Same format as Pg 2

11 Measurement Screen Same format as Pg 1

12 Measurement Screen Same format as Pg 2

These screens contain a great deal of valuable data which may be used by the Service engi-

neer to troubleshoot measurement inaccuracies.

Pages 1..12 give detailed information on the last six measurements carried out on the Dry-

ISE. This data set include measurement timing information (title line) and the raw voltage sig-

nals used in the final measurement calculation. The pages are labeled MnA, MnB in the title

line (n=0..5). There are two pages of data for each measurement (e.g. M0A, M0B), with the

data going back in time. Measurement n=0 is the most recent. The key to the abbreviation

used in Table 2a, are shown in Table 2b-c.

VITAL SCIENTIFIC N.V. 3-5

The service screen

ABBREVIATION DESCRIPTION

Error Text The 'Error text' will be one of the following:

Err: Not Ready

Err: Sequence

Err: Data

Err: Startup/Reset

Err: Insufficient Sample

Err: Bubble Detector

Err: Parameters Unavailable

Err: Calibration Unavailable

Err: Insufficient Reference

No Error

Sub-Error A numbered code which gives additional error information which

may be used by the manufacturer to troubleshoot the unit.

Process A numbered code which gives additional error information.

Time ISE Real-Time Clock (from last Reset or power-on)

ABBREVIATION DESCRIPTION

MnA or Mnb M Designates a Measurement

n The measurement number 0..5 (0-most recent)

A First page of data for measurement n

B Second page of data for measurement n

T1 Measurement time Marker (sec) local time to Dry-ISE

since startup/reset

T2 Time since last measurement (sec)

T3 Measurement Duration (sec accurate to 0.01 sec)

St Status info on exit

Meas Final measurement for component

Ffs# (# = 0..3) Factor, First Sample

Fco# (#=0..3) Factor, Carry Over

RefMV Raw voltage, Ref signal (mV)

DeltaMV Raw voltage, Measurement ( delta signal in mV)

3-6 VITAL SCIENTIFIC N.V.

The service screen

3.6 F2 EEPROM DATA

A full set of return data pages for the EEPROM function key are shown in Table 3.

The values shown in these pages should be identical to those listed in the Dry-ISE

Parameter Screen. If any of the values are different, consult the Service Department

for up-to-date information on the required values.

The first page gives QC information only. The first time the ISE is run (after burning

the software), a default set of EEPROM parameters are saved in EEPROM Flash

memory. This is checked with the Page 0 QC call.

PAGE SCREEN DATA FORMAT

0 EEPROM QC Information

EEPROM QC EEP-

ROM R/W - PASS/FAIL

ELC-ACTIVE - PASS/FAIL

CALIB PRMS - PASS/FAIL

SLOPE BNDS - PASS/FAIL

1 Control Parameters

CTRL PRMS

Act=xx - Active electrodes (right nibble)

TVO=xx - Time-out for Valves Open (min)

TRF=xx - Ref time (secs)

AGN=xx - Gain (not used at present)

2 Offset Parameters OFFSET PRMS

0 Offset Parameter [ K ]

1 Offset Parameter [ Na ]

2 Offset Parameter [ Cl ]

3 Offset Parameter [ CO2 ]

3 LO/HI-Calibrator Values LO/HI PRMS HI-Calibrator [ K ]

0 LO-Calibrator HI-Calibrator [ Na ]

1 LO-Calibrator HI-Calibrator [ Cl ]

2 LO-Calibrator HI-Calibrator [ CO2 ]

3 LO-Calibrator

4 Slopes Min/Max Parameters SLOPES MIN/MAX

0 Slope-Minimum Maximum [ K]

1 Slope-Minimum Maximum [ Na]

2 Slope-Minimum Maximum [ Cl ]

3 Slope-Minimum Maximum [ CO2 ]

5 Carry-Over/ First-Sample CO/FS PRMS

Parameters 0 Carryover First-Sample [ K ]

1 Carryover First-Sample [ Na ]

2 Carryover First-Sample [ Cl ]

3 Carryover First-Sample [ CO2 ]

VITAL SCIENTIFIC N.V. 3-7

The service screen

3.7 F3 CALIBRATION DATA

Calibration data is saved within the EEPROM of the Dry-ISE module. As well as the activate

calibration, a series of the 10 most recent calibrations (together with their voltage information)

are also saved within the EEPROM permanent storage. These may be retrieved within this

section of the Service area. The information saved for each calibration is identical to the infor-

mation displayed on the Selectra screen at the end of the calibration step. If a calibration fails

for any reason, calibration values will not be saved within the Flash memory.

SCN SCREEN DATA RETURNED

0 Active Calibration

ACTIVE CAL #; KEY=xx

0 Mv-LO, mv-HI, Slope [ K ]

1 Mv-LO, mv-HI, Slope [ Na]

2 Mv-LO, mv-HI, Slope [Cl ]

3 Mv-LO, mv-HI, Slope [ CO2]

1 Previous Calibration 0

CAL0 T=t0

Mv-LO, mv-HI, Slope [ K ]

Mv-LO, mv-HI, Slope [ Na ]

Mv-LO, mv-HI, Slope [ Cl ]

Mv-LO, mv-HI, Slope [ CO2 ]

2 Previous Calibration 1 Same as above for CAL1

3 Previous Calibration 2 Same as above for CAL2

4 Previous Calibration 3 Same as above for CAL3

5 Previous Calibration 4 Same as above for CAL4

6 Previous Calibration 5 Same as above for CAL5

7 Previous Calibration 6 Same as above for CAL6

8 Previous Calibration 7 Same as above for CAL7

9 Previous Calibration 8 Same as above for CAL8

10 Previous Calibration 9 Same as above for CAL9

3-8 VITAL SCIENTIFIC N.V.

The service screen

3.8 F4 BUBBLE-DETECTOR CALIBRATION DATA

Pressing the F4 service button gives important information on the bubble-detector calibration.

The first screen is for QC purposes only. These numbers are important in troubleshooting a

possible problem with the bubble detector. This function key is also used to retrieve detailed

timing information on the previous 6 measurements.

SCN SCREEN DATA RETURNED

0 Bubble Detector QC BUBBLE-DET QC

TRIG LL PASS/FAIL

MAX DET PASS/FAIL

MIN DET PASS/FAIL

DET DIF PASS/FAIL [ DDIF ]

DDIF difference value

1 BBL-Det Calibration BBL-DET CAL

BBL-TRIG - Bubble-Detector Trigger Level (RAM)

BBL-MAX - Bubble-Detector Maximum Signal (RAM)

BBL-MIN - Bubble-Detector Minimum Signal (RAM)

BBL-AVG - Bubble-Detector Present Signal (RAM)

2 Stored Calibration BBL-DET EEPROM

Bubble-Detector Trigger Level (EEPROM)

Bubble-Detector Maximum Signal (EEPROM)

Bubble-Detector Minimum Signal (EEPROM)

Bubble-Detector Key (EEPROM)

3 Timing for M0 M# TIMING [xx]

BS=xx.x - Begin Sample (sec)

ES=xx.x - End Sample (sec)

BR=xx.x - Begin Ref (sec)

TD=xx.x - Total Time sec)

M0 is the most recent measurement

4 Timing for M1 Same as M0 (page 3)

5 Timing for M2 Same as M0 (page 3)

6 Timing for M3 Same as M0 (page 3)

7 Timing for M4 Same as M0 (page 3)

8 Timing for M5 Same as M0 (page 3)

VITAL SCIENTIFIC N.V. 3-9

The service screen

3.9 F5 PUMP TEST

Pressing the F5 button results in the stepping motor being exercised on both the Fast and

Slow settings (the slow setting is determined as part of calibration initialization). The first page

is a QC test. The second pages returns more detailed motor timing information. The most

important effect of pressing this button is that the Dry-ISE motor should rotate for a period of

at least 10 seconds. This is a simple test which gives instant feedback that the Selectra and

the Dry-ISE are talking to each other.

SCN SCREEN DATA RETURNED

0 MOTOR TEST / RESULTS

PUMP QC

DIRN. (F) PASS/FAIL

COUNT (F) PASS/FSIL

DURN. (S) - PASS/FAIL

COUNT (S) - PASS/FAIL

F -fast, S -slow

1

PUMP QC

DIRN. (F) - xx.xx (Duration sec)

COUNT (F) - xxxx (count s)

DURN. (S) - xx.xx (Duration, sec)

COUNT (S) - xxxx (counts)

F -fast, S -slow

3.10 F6 ADC TESTS

Pressing the F6 key exercise the Dry-ISE ADCs (A/D Converters). The first page is a general

and comprehensive QC test (see Table 7). This test requires correct operation of the valves

and pump motor and puts the ISE electrodes in a wet state before measuring. The PASS cri-

teria are indicated in Table 7. Note that the Reference liquid reservoir has to be connected for

the QC test to work correctly. The QC page returns two numbers which are the largest Volt-

age values and Standard Deviation measured in the test.

The second F6 page returns more detailed measurement information from the page 0 test.

The third pressing of F6, triggers a multiplexed reading of the processor internal 10-bit ADC.

Three numbers are returned, which verify the operation of the 10-Bit

ADC, together with the running average of the bubble detector measurement..

The final F6 page is the raw register readings for the 16 ADC1243 registers (Register

0..15). Non-zero values in some of these registers, demonstrates that the chip-to-chip

SPI interface communications is working correctly on the main Dry-ISE PC board.

3-10 VITAL SCIENTIFIC N.V.

The service screen

PAGE SCREEN DATA RETURNED

0 Full ADC QC ADC QC

10B RNGE PASS/FAIL (10bit ADC range)

24B DURN PASS/FAIL (24bit meas. Durn.)

24B MAXV PASS/FAIL (24-bit Max Volts)

24B MXSD PASS/FAIL (24-bit Max StdDev)

10bit RNGE; values in range 0 to 1024. 24B

DURN: measurement time in range 4.5 to 6.0

secs 24B MAXV: all voltages < 1.0 V.

24B MXSD: All standard deviations <0.003.

1 ADC Test Data ADC1243 DATA; dT=xxx

(corresponding to Page 0) 0 Meas StdDev NumPts [ K ]

1 Meas StdDev NumPts [ Na ]

2 Meas StdDev NumPts [ Cl ]

3 Meas StdDev NumPts [ CO2 ]

Meas measurement (volts)

StdDev Standard Deviation

NumPts - Number of measured Points

2 10-BIT ADC Test 10-BIT READ

0: 10-Bit Read { 0-1023 }

10: 10-Bit Read { 0-1023 }

19: 10-Bit Read { 0-1023 }

B: 10-Bit Average Read { 0-1023*20 }

1 ADC1243 Registers ADC1243 REGS

Registers Read 0, 1, 2, 3

Registers Read 4, 5, 6, 7

Registers Read 8, 9, 10, 11

Registers Read 12, 13, 14, 15

VITAL SCIENTIFIC N.V. 3-11

The service screen

3.11 F7 VALVE TEST

Pressing the F7 button results in the two valves on the Dry-ISE module being

exercised. First the upper (Reference valve) is pulses on and off 5 times, followed by

the Sample valve. If the lower valve is seen to pulse first, the valves have probably

been mounted incorrectly.

PAGE SCREEN DATA RETURNED

0 Valve QC See text to left

3.12 F8 SIPPER TEST

Pressing the F8 button results in the Sipper control interface being exercised and tested on

the Dry-ISE module. Please note that due to the override of the Sipper control mechanism by

the Selectra, it is not possible to observe the Sipper actually moving.

The state of the Sipper interface control line, as sensed by the Selectra, is shown on the dia-

gram at the top of the Selectra Dry-ISE Service screen. Below the diagram, the state of the

ISE ARM CONTROL is indicated. After pressing F8, the following should be observed on the

screen: ISE ARM CONTROL: Down

At the end of the test the line should return to the Up mode and the message in Table 8,

should be observed on the screen. The time delay for the complete test is measured by the

processor internal clock. The value should be extremely close to 5.2-5.4 seconds. A second

pressing of the F8 key returns the Sipper test duration to the screen.

3-12 VITAL SCIENTIFIC N.V.

The service screen

PAGE SCREEN DATA RETURNED

0 Sipper QC See text

1 Sipper QC See text (Duration in secs)

VITAL SCIENTIFIC N.V. 3-13

The service screen

3-14 VITAL SCIENTIFIC N.V.

Field service

Field service

4.1 Servicing an ISE

It is expected that the servicing calls related to an ISE will fall into three broad categories:

1. Regular 6 monthly service visit; Trouble-Free System

2. Servicing as system which has experienced intermittent measurement problems.

3. Servicing a system which has undergone complete system failure.

The second servicing call will probably be the most difficult for the Service Engineer to trou-

bleshoot.

4.2 Service tools required

We recommend the following tools be available:

A full set of tools including metric Allen wrenches.

A laptop computer with a terminal emulator such as. HyperTerminal( Microsoft Corpora-

tion).

A female-female crossover RS232 cable (sometimes referred to as a null modem cable).

4.3 Servicing a trouble-free unit (6 months service)

The Dry-ISE system requires the following servicing steps:

1. Replacement of electrodes.

2. Replacement of tubing assemblies (utilize correct Fluid-Accessories kit).

3. Replacement of internal Sipper to ISE tubing (internal to Selectra).

4. Full functional check (Selectra ISE Service Area).

5. Calibration and Normal/Abnormal check.

4.4 Servicing units with intermittent problems

Intermittent measurement problems represent the most difficult of any type of problem for the

service engineer to troubleshoot. We recommend the following approach:

1. Review the calibration data for the time period in question.

2. Review the abnormal/normal logs for the time period in question.

3. Review the reagents and other fluids used on the analyzer.

4. Inspect the tubing set for damage and replace tubing assemblies where necessary.

5. Run a calibration and 3 normal/abnormal samples and observe carefully the operation of

the analyzer.

6. If necessary (under instructions from Service Department), retrieve the raw measurement

data for the 3 Normal/Abnormal samples using the Service Screen/F1.

7. Refer to the troubleshooting guide in the Appendix for any possible measurement prob-

lems.

VITAL SCIENTIFIC N.V. 4-1

Field service

4.5 Servicing a failed system

A failed system is defined as one which will never pass calibration or which will not respond to

any communications from the Selectra. A failed ISE system should be returned to the manu-

facturer for repair. However, before this is done, a few simple steps should be taken to look for

obvious communications problems.

Carry out the following in order:

1. Make sure that the ISE is activated in the Selectra Installation menu.

2. Go into ISE Screen and press F1, ISE Reset. Observe that the Reset Cycle is correct.

3. If there is no communication at this point, we recommend carrying out the communications

tests described below.

4. Go into Service menu (you will need to enter Service password) and go to ISE Arm / ISE

Unit screen.

5. Press F2, EEPROM Data and observe the QC information.

6. Press F5, Pump Test and observe the Dry-ISE motor turning for 20 seconds; observe the

QC information.

7. Press F6, ADC Test and observe the QC information.

8. Press F7, Valve Test and observe the Ref and then the Sample valves pulsing.

9. Press F8, Sipper Test and confirm the screen information that the Sipper has been acti-

vated.

4-2 VITAL SCIENTIFIC N.V.

Communications testing

Communications testing

5.1 Testing presence of Dry-ISE

The following two simple tests indicate correct communications between the Selectra and the

Dry-ISE.

1. Go to the installation Screen and double click on the Release option on the lefthand-side.

One of the boxes is labeled ISE Unit. The Version Number of the ISE software should

appear in this box (Figure 4).

2. A second simple method of testing Selectra to Dry-ISE communications is to carry out the

F5 Pump Test on the Selectra ISE Arm / ISE Unit option on Service Screen (see above).

If these tests fail, we recommend testing the Selectra and / or the Dry-ISE serial communica-

tions separately as discussed in the next sections.

Fig. 5.1.0.1 The Release Screen

5.2 Testing Selectra communications

If there is no obvious communications between the Selectra and the Dry-ISE we recommend

carrying out the following test:

1. Disconnect the Dry-ISE unit and hook up a female-female RS232 cable from side of

Selectra to the laptop RS232 port.

2. Run HyperTerminal ( 9600 + N + 8 + 1 and disable handshake control).

3. Press the ISE Reset button and observe the data string displayed on the HyperTerminal

screen.

4. Failure to see data may point at the Selectra communications as the culprit.

VITAL SCIENTIFIC N.V. 5-1

Communications testing

5.3 Testing ISE communications

The following simple test is recommended to test the communications of the Dry-ISE module:

1. Connect the Dry-ISE module to the RS232 port of a computer with a male-female RS232

interface cable.

2. Run HyperTerminal ( 9600 + N + 8 +1 and disable handshake control).

3. Power-up the Dry-ISE.

4. Wait for 54 seconds. Characters should appear on the HyperTerminal ( screen at the end

of the startup cycle.

5-2 VITAL SCIENTIFIC N.V.

Troubleshooting tips

Troubleshooting tips

6.1 Overview

Like many other apparently simple devices, nothing beats experience in being able to trouble-

shoot the system in order to make it be able to reach it's full measurement potential. This sec-

tion is an attempt to lay down some simple indicators which can allow a technician to

troubleshoot a system in the minimum time possible. The layout of the fluidic system is shown

in Fig. 6.2.0.1.

The most important indicator of system health is to observe liquid flow in the system in the dif-

ferent cycles of operation. We lay out below, some of the simple indicators of system health.

Possible problems, once identified from these tables should be fixed as recommended by the

appropriate corrective action CA1 etc.

6.2 Observing waste flow

The flow of liquid in the waste line, can given important indicators of Dry-ISE system health.

There are two states in which the waste liquid can reside; the first is a uniform liquid column;

the second is column consisting mostly of air, with intermittent liquid bubbles. Typically the

bubbles are 3-6 mm apart.

Note that, due to the finite volume of the fluid lines, the observations listed below, will require

approximately 5-10 seconds to be seen in the waste tube, once the state of the ISE module is

changed. As an example, when Ref liquid flows through the system, the uniform liquid flow

will take some time to reach the waste tube. Similarly when air is pumped through the Sample

line, it will take some time for bubbles to be observed at the level of the Waste Line.

Fig. 6.2.0.1 Overview of Tubing Assemblies

(For Part Number information, refer to ISE User manual)

VITAL SCIENTIFIC N.V. 6-1

Troubleshooting tips

OBSERVE CONDITION CA #

Uniform homogenous Should only occur when liquid is being pumped OK

liquid flow (no bubbles) through both the Sample and Reference Lines.

Uniform Bubble Flow Should be observed when liquid is being pumped OK

through Ref line and air is being pumped through

Sample line.

Non-uniform (pulsed Usually indicates that there is a blockage in the line. a) CA1

or jerky) bubble flow Possible reasons (in order of likely occurrence): a) b) CA2

with no net movement The Sipper tube is blocked. b) The Reference tube c) CA3

of liquid is blocked under the Reference valves. c) The Sam-

ple tube is blocked under sample valve.

Movement of liquid in This may indicate a pressure buildup in the waste CA4

waste line when the system. This can have a negative effect on the

pump is not activated operation of the ISE.

6.3 Trouble shooting a startup cycle

The startup cycle offers valuable information in being able to troubleshoot a Dry-ISE system.

The startup cycle which is initiated after system power-up or as a result of an ISE-Reset.

STEP TIME OBSERVE CONDITION CA #

secs

1 20 PUMP OUT SAMPLE LINE WITH

AIR

Sample Valve Open, Ref Valve Correct opera- OK

Closed. Any liquid in sample line tion

should flow through the system at

uniform speed.

Evidence of non-uniform flow of any blocked Sam- CA3

liquid in sample line (if there is ple line

some present)

Ref valve does not close Ref Valve failure CA6

At end of step 1, when the Sample Blocked Sipper CA1

Valve Closes and the Ref opens,

observation of extremely fast liquid

flow

2 0 PUMP REFERENCE LIQUID

TROUGH ELECTRODES

Sample Valve Closed, Ref Valve Correct opera- OK

Open. There should be a uniform tion OK

flow of Ref liquid through Bubble

Detector.

No Ref Liquid Observed on either Ref liquid has CA5

side of the Ref valve run-out

The Ref liquid does not flow Blocked Refer- CA2

through system even though there ence Line

is liquid in the Ref liquid bottle. (under Valve)

6-2 VITAL SCIENTIFIC N.V.

Troubleshooting tips

Sample valve does not close. Sample Valve CA6

has failed

At end of step 2, when the Refer- Blocked Sipper CA1

ence Valve closes and the Pump

stops, observation of extremely fast

liquid flow back through the system

NOTES:

1. The final cycles of Dry-ISE startup are a repeat of the first cycles; nothing more can be

learnt from observing these cycles.

2. The observed errors may also trigger an error at level of the Selectra, depending on

whether the action of Reset was initiated by the Selectra or not.

6.4 Troubleshooting measurement cycle

Note that from the standpoint of the Dry-ISE, the measurement of a sample, or the measure-

ment of a calibration standard are identical. Thus, this section applies to both and either may

be observed in an effort to troubleshoot the system.

STEP TIME OBSERVE CONDITION CA #

secs

1 10 to 14 PUMP SAMPLE TO ELECTRODES

The following sequence should Correct Operation OK

be observed:

1. Sipper plunges into sample

cup for approx. 5 seconds.

2. Observe liquid uniformly

moving through sample line and

up to detector in approx. 12-14

seconds.

3. Liquid should move through

Bubble detector and stop very

soon after liquid exits the bubble

detector. The bubble detector

light should indicate red

(absence of liquid)

Bubbles occur at front end of Contaminated Diluent CA7

Sample liquid stream

Sample does not reach detector Blocked Sipper CA1

and moves very slowly through

the tubing, slowing down as it

goes.

Blocked Sample Line CA3

(under Sample Valve)

2 5 to 7 SAMPLE READING

Both valves are closed; the Dry- Correct Operation OK

ISE is accumulating an accurate

voltage reading

VITAL SCIENTIFIC N.V. 6-3

Troubleshooting tips

The liquid stream in the elec- Tubing Problem CA8

trodes is seen to move during

this cycle.

3 5 to 7 PUMP REFERENCE LIQUID THRU ELECTRODES

1. The sample valve is closed, Correct Operation OK

the Ref valve opens.

2. Ref liquid is pumped through

electrodes for 4 seconds.

3. Both valves are then closed.

No Ref Liquid Observed on Ref liquid has run-out CA5

either side of the Ref valve

The Ref liquid does not flow Blocked Reference CA2

through system even though Line (under Valve)

there is liquid in the Ref liquid

bottle.

Sample valve does not close. Sample Valve has CA6

failed

At end of step 2, when the Ref- Blocked Sipper CA1

erence Valve closes and the

Pump stops, observation of

extremely fast liquid flow back

through the system.

4 5 to 7 REFERENCE READING

Both valves are closed; the Dry- Correct Operation OK

ISE is accumulating an accurate

voltage reading

The liquid stream in the elec- Tubing Problem CA8

trodes is seen to move during

this cycle.

NOTES:

1. Observing the final steps of Dry-ISE measurement will not greatly add to system trouble-

shooting.

2. If an internal error is triggered by the Selectra based on the absence of fluids at critical times,

the unit will go into an automatic flush cycl and send the appropriate error code to the Selectra

module.

6-4 VITAL SCIENTIFIC N.V.

Troubleshooting tips

6.5 Corrective actions

We have indicated some possible corrective actions based on some of the diagnoses listed

above. Each corrective action is indicated by a Corrective Action number (e.g. CA5).

CA # DIAGNOSED PROB- CORRECTIVE ACTION

LEM

CA1 Blocked Sipper Remove Sample line from Selectra.

Substitute line connected to retracted syringe.

Gently push on syringe and blow out line.

Replace Sample line and reset.

CA2 Blocked Reference Power-down ISE.

Line (under Valve) Remove Ref line from valve.

Observe state of line (there may be obvious signs of

blockage or line fusion a thin white band across tube

at position of electrode).

Gently roll the tubing between fingers, the fused tub-

ing will relax and return to the normal state.

Replace tubing in Ref valve.

CA3 Blocked Sample Line Power-down ISE.

(under Valve) Remove Sample line from valve.

Observe state of line (there may be obvious signs of

blockage or line fusion a thin white band across tube

at position of electrode).

Gently roll the tubing between fingers, the fused tub-

ing will relax and return to the normal state.

Replace tubing in Sample valve.

CA4 Waste Pressure Blow- Remove cap from Waste container, and gently

back from Selectra replace, taking care to leave slightly loose.

CA5 Ref Liquid has run-out Replace Ref bottle with a new one

CA6 Ref. Valve Failure Contact Customer Service

Sample Valve Failure

CA7 Contaminated diluent Replace diluent

Initiate Selectra wash

CA8 Tubing Problem Check all tubing connections to ensure they are

sealed correctly.

Check tubing for possible holes or other mechanical

damage. Replace tubing if necessary.

VITAL SCIENTIFIC N.V. 6-5

Troubleshooting tips

6-6 VITAL SCIENTIFIC N.V.

Component replacement

Component replacement

7.1 Opening-up the ISE

The following steps need to be followed in gaining access to the Dry-ISE main chamber.

1. Switch the Dry-ISE system off and unplug the power cable.

2. Remove the Ref bottle connections in the Ref bottle recess.

3. Remove the Sample-In and Waste-Out connections on the Selectra Interface block on the

bottom of the ISE main plate.

4. Unscrew the 4 hex screws holding the main plate on to the instrument body (Fig. 7.1.0.1).

5. Gently move the plate away from the main body.

6. Unplug the following cables from the Dry-ISE main electronics board (Fig. 7.1.0.2):

a) Unplug the power supply from the main board.

b) Unplug the power indicator cable at the main board.

c) Unplug the Selectra interface (RS232) 3M 10-pin ribbon connector from the main board.

d) Unplug the ground line from the ground-lug on the main plate.

7. The main plate should now separate from the Dry-ISE body (Fig. 7.1.0.3).

Fig. 7.1.0.1 Removing the screws

Fig. 7.1.0.2 Disconnecting the internal cables

VITAL SCIENTIFIC N.V. 7-1

Component replacement

Fig. 7.1.0.3 The front plate removed

7.2 Replacing the power supply

To replace the Dry-ISE power supply (Figure 7) the following steps need to be followed:

1. Open up the Dry-ISE unit as described earlier.

2. Remove the following connections:

a) Power cable from power input module.

b) Fan power cable (24V).

c) Power cable to main board.

3. Remove the 4 hex bolts holding the power supply onto the instrument case.

4. Replace the power supply with a new one and fix firmly to instrument case.

5. Replace all cables and re-install main plate.

Fig. 7.2.0.1 Removing the Power Supply

7-2 VITAL SCIENTIFIC N.V.

Component replacement

7.3 Replacing the main board

To replace the Dry-ISE main board the following steps need to be followed:

1. Open up the Dry-ISE unit as described earlier.

2. Take the main plate with the affixed main board and remove all electricalconnectors.

3. Carefully remove the back protection plate off the back of the main board (Fig. 7.3.0.1).

4. Remove the electrode PC board cover assembly which protects the upper part of the main

board (Fig. 7.3.0.4).

5. Unscrew the mounting bar off the main plate (Fig. 7.3.0.5). The board plus mounting bar

should now come off as a single assembly.

6. Remove the mounting bar from the PC board (Fig. 7.3.0.6).

7. Take a new board and reverse each of the steps above.

Fig. 7.3.0.1 Remove Protection Plate

Fig. 7.3.0.2 Remove the PC Board Cover - A

VITAL SCIENTIFIC N.V. 7-3

Component replacement

Fig. 7.3.0.3 Remove the PC Board Cover - B

Fig. 7.3.0.4 Remove the PC Board Cover - C

Fig. 7.3.0.5 Remove PC Board Mounting Bar

7-4 VITAL SCIENTIFIC N.V.

Component replacement

Fig. 7.3.0.6 Remove Mounting Bar from PC Board

7.4 Replacing the valve assembly

To replace the Dry-ISE main board the following steps need to be followed:

1. Open up the Dry-ISE unit as described earlier.

2. Remove the valve assembly connector off the main board.

3. Remove each of the valves by unscrewing the two retaining screws off the main

plate (Fig. 7.4.0.1).

4. Remove the Valves play the wiring harness as a single assembly. Be sure to mark

which valve was the Reference valve (towards top of instrument).

5. Replace the Valve assembly and be careful to do the following:

a) Test the connections and replace the valve assembly with the valves in the

correct orientation.

b) Orient the valves with the valve slit pointed towards the electrode assembly.

6. Reverse each of the steps above.

7. Switch the unit on and make sure that at system startup the Sample Valve is Open

and the Ref valve closed. If this is not the case, reverse the positions of the valves.

Fig. 7.4.0.1 Valve and motor replacement

VITAL SCIENTIFIC N.V. 7-5

Component replacement

7.5 Replacing the stepping motor

To replace the Dry-ISE Stepping Motor the following steps need to be followed:

1. Open up the Dry-ISE unit as described earlier.

2. Take the main plate and disconnect the Stepping Motor connector off the main board.

3. Remove the spindle off the stepping motor shaft.

4. Remove the stepping motor by unscrewing the 4 retaining screws.

5. Replace with a new motor and reverse each of the steps above.

7.6 Replacing the ground electrode

The ground electrode is part of the main electrode assembly and does not require the main

plate to be removed. To replace the ground electrode, follow these steps:

1. Switch the Dry-ISE unit off and remove the Main Cover to expose the Main Plate.

2. Remove the electrode EM shield by unscrewing the two knurled nuts.

3. Remove the 3 connecting tubes that are connected to the electrode assembly.

4. Slide the electrode assembly sideways off the electrical pins which connect the electrodes

to the main board (Figure 10).

5. Remove the Dry-ISE electrode assembly and disconnect all electrodes from the ground

electrode.

6. Replace the ground electrode with a new one and reverse each of the steps described

above.

Fig. 7.6.0.1 The Electrode Pack

7-6 VITAL SCIENTIFIC N.V.

Component replacement

7.7 Replacing the bubble-detector assembly

To replace the Dry-ISE Bubble Detector assembly the following steps need to be followed:

1. Open up the Dry-ISE unit as described earlier.

2. Disconnect the Bubble-Detector cable from the main board (Fig. 7.7.0.1).

3. Take the main Plate and disconnect the Bubble Detector electronic board by removing the

two screws and gently pulling the board and source/detector assembly off the bubble

detector mechanical assembly (Fig. 7.7.0.1).

4. If necessary replace the Bubble-Detector mechanical assembly.

5. Mount a new board on the mechanical assembly and make sure that it fits correctly down

inside the assembly.

6. Reverse each of the steps above to re-assemble the system.

Fig. 7.7.0.1 Replacing Bubble Detector

VITAL SCIENTIFIC N.V. 7-7

Component replacement

7-8 VITAL SCIENTIFIC N.V.

ISE firmware re-programming

ISE firmware re-programming

8.1 Introduction

Dry-ISE Modules may now be programmed in the field through the serial interface without the

need to return the units to the factory. It is expected that Service Engineer has already

received the appropriate training necessary to carry out a Firmware upgrade. Firmware soft-

ware version prior to V1.1.1 do not include the Serial bootloader. These units have to be

returned to the factory for Firmware reprogramming.

8.2 Tools required

1. Null modem interface (DB9-AME, Asynchronous modem eliminator - Black Box ME211).

Note that a null-modem (F-F) RS232 cable may be substituted.

2. ISE_Loader.exe program contained on the Selectra program disk.

8.3 Firmware download instructions

The following steps necessary to reprogram the ISE should take less than 3 minutes to per-

form.

1. Turn ISE off.

2. Remove Reference bottle from ISE (very important).

3. Remove interface cable from Selectra and connect through null modem interface to laptop

serial port.

4. Run the ISE-LOADER program.

5. If necessary change the COM port.

6. Switch on the ISE and wait until the message ISE Ready (ISUFFICENT REFERENCE

message) appears; this takes approximately 45-50 seconds.(Fig. 8.3.0.1).

7. Press Get ISE Firmware Version and make note of the version number presently installed

on the ISE.

8. Press Place ISE in Load Software Mode button and wait for ISE Turn unit off/on.

response.

9. Turn ISE off/on and wait for ISE Bootloader Ready message.

10.We recommend you check the Erase Parameter EPROM box.

11. Press Transmit .s19 File button and locate and select the file ISEProg4BL.s19.

12.A number of messages will appear on screen and a bar will show the progress of the

download (Fig. 8.4.0.1).

13.. Once the message **File Download Complete appears followed by the instruction to

Switch the system off/on, carry out that instruction and wait for the message ISE Ready

(ISUFFICENT REFERENCE message) to reappear (45-50 seconds) AS IN Fig. 8.4.0.2.

14.Press Get ISE Firmware Version to verify that the version number has been updated.

15.Switch the unit off, return the interface cable to the Selectra, switch ISE unit on and oper-

ate as normal. Remember to reconnect the Reference bottle.

VITAL SCIENTIFIC N.V. 8-1

ISE firmware re-programming

Fig. 8.3.0.1 The ISE Loader Program

8.4 Troubleshooting bootloader problems

1. If no text appears on the ISE_Loader program screen after 54 seconds, after switching the

ISE unit off/on (and seeing the startup sequence taking place, including the motor turning),

then it is likely that the cabling, interconnection between the ISE and the laptop is incor-

rect.

2. If steps 1..7 proceed as expected, but step 8 does not send the correct response, then it is

possible that the ISE does not contain a serial bootloader. Please make note of the pres-

ently installed Firmware version in step 7 and contact Customer Service. The unit may

have to be sent back to the factory for upgrade to a bootloader friendly version.

3. For all other problems, contact Customer Service.

Fig. 8.4.0.1 Select the ISEProg4EDL.s19 file

8-2 VITAL SCIENTIFIC N.V.

ISE firmware re-programming

Fig. 8.4.0.2 A successful firmware update

VITAL SCIENTIFIC N.V. 8-3

ISE firmware re-programming

8-4 VITAL SCIENTIFIC N.V.

Appendix

Appendix

9.1 The Dry-ISE field QC test

9.1.1 Overview

The series of QC tests Q1..Q8 listed in Table A1, are a means of quickly documenting the

health of a Dry-ISE module once any Service work has been performed. We recommend that

any unit which is serviced by a Service Engineer, is quickly put through this series of tests and

the testing documented using Table A2 at the end of this document (together with appended

data). This information should become part of the permanent service file of the unit.

Table A1: Dry-ISE QC Tests

# Screen DESCRIPTION TIME TABLE

Q1 Release Version Verify QC 15 secs Q1

Q2 Service Pump Motor QC 25 secs Q2

Q3 Service Valve QC 15 secs Q3

Q4 Service Sipper QC 10 secs Q4

Q5 Service EPROM Read/Write QC 10 secs Q5

Q6 Service A/D Converters QC 54 secs Q6

Q7 Service Bubble DetectorQC 10 secs Q7

Q8 Calibration Calibration QC 10 minutes Q8

Total time to QC a single instrument should not exceed: 15 minutes

9.1.2 Version Verify QC-Q1

Table Q1: Version Verify QC

TITLE COMMENT

SCREEN Release

ROUTE F10 ; F5; F2 Double click Release in left window.

EXECUTE Double click on Release

PASS The Dry-ISE version number (e.g. V1.0.7) will be returned in the ISE

Unit box

FAIL No version number returned

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial

2 Write version Num in First value.

QC FAIL ACTION 3 Check connections.

4 Check that the unit is powered up.

5 If 1 & 2 fail, contact engineering.

VITAL SCIENTIFIC N.V. 9-1

Appendix

9.1.3 Pump Motor QC-Q2

Table Q2: Pump Motor QC

TITLE COMMENT

SCREEN Service

ROUTE

EXECUTE Press F5: Pump Test

PASS 1 Observe the motor rotating CCW (counter-clockwise) followed by a

short pause and then running again (speed may be slower or equal to

the speed observed in the first period). Take approx twenty seconds.

2 PASS Displayed on 4 lines.

FAIL 1 Motor does not rotate

2 Motor does not turn CCW.

3 FAIL displayed on any of the 4 lines.

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial.

QC FAIL 1 Press F5 and write down numbers on screen.

ACTION 2 Replace motor assembly.

9-2 VITAL SCIENTIFIC N.V.

Appendix

Fig. 9.1.3.1 Motor QC

Fig. 9.1.3.2 Valves QC

VITAL SCIENTIFIC N.V. 9-3

Appendix

9.1.4 Valve QC-Q3

Table Q3: Valve QC

TITLE COMMENT

SCREEN Service Screen

EXECUTE Press F7: Valve Test to initiate testing.

PASS 1 Reference Valve (Figure 5) opens and closes 5 times.

2 Sample Valve (Figure 5) opens and closes 5 times

FAIL 1 Either or both valves do not switch.

2 The valves switch in the wrong order.

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial

QC FAIL ACTION Replace valve assembly.

9.1.5 Simulated Sipper QC-Q4

Table Q4: Sipper QC

TITLE COMMENT

SCREEN Service Screen

EXECUTE Press F8: Sipper Test to initiate testing.

PASS 1 PASS displayed

2 Screen indicates a Down state.

FAIL 1 FAIL displayed

2 Screen does not indicate a Down state

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial

QC FAIL ACTION 1 Check cable.

2 Replace cable.

3 Service Selectra Sipper control electronics.

N.B. The Sipper on Selectra does not move because of the Selectra override of the Sipper control.

This is a simulation only to detect the proper operation of the ISE Sipper control communications.

9-4 VITAL SCIENTIFIC N.V.

Appendix

9.1.6 EEProm Read/Write QC-Q5

Table Q5: EEPROM QC

STATE DESCRIPTION

SCREEN Service Screen (see previous test)

EXECUTE Press F2

PASS All 4 lines indicate PASS

FAIL One or more lines indicates FAIL

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial

QC FAIL ACTION 1 Press F2 5 times and write down the numbers that appear on each

page. And write down numbers on screen.

2 Contact Customer Service.

9.1.7 A/D Coverters QC-Q6

Table Q7: Flow Data Verify

TITLE COMMENT

SCREEN Service Screen

EXECUTE Press F4

PASS All 4 lines indicate PASS

FAIL One or more lines indicates FAIL

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial.

2 Write DET DIFF as First value.

QC FAIL ACTION 1 Press F4 and write down the numbers that appear on the returned

page.

2 Replace bubble-detector assembly.

VITAL SCIENTIFIC N.V. 9-5

Appendix

9.1.8 Bubble-Detector QC-Q7

Table Q7: Flow Data Verify

TITLE COMMENT

SCREEN Service Screen

EXECUTE Press F4

PASS All 4 lines indicate PASS

FAIL One or more lines indicates FAIL

SCREEN O/P

QC DOC. 1 Fill in Pass/Fail column and initial.

2 Write DET DIFF as First value.

QC FAIL ACTION 1 Press F4 and write down the numbers that appear on the returned

page.

2 Replace bubble-detector assembly.

9-6 VITAL SCIENTIFIC N.V.

Appendix

9.1.9 Calibration QC-Q8

Table Q8: Calibration QC (K, Na, Cl, CO2)

STATE DESCRIPTION

SCREEN Calibration

EXECUTE 1. Double click ISE 2 point calibration1 .

2. Press F2: Calib.

PASS 1. Slopes for each of the active electrodes lie within the acceptable

range at the end of C3 (at end of First Full Calibration cycle).

2. Absence of Calibration Error Message on Selectra Screen.

FAIL Failure of at least one of the pass criteria (Repeat Q8 one more time if

necessary; append failure results)

SCREEN O/P

QC DOC. 1. Fill in Pass/Fail column and initial

2. Staple printed calibration results to QC form

QC FAIL ACTION 1. Contact engineering with data.

NOTES

1) Note that all Reagents and Calibration Fluids must be correctly positioned on the instrument

prior to this QC test being performed. Consult the User Manuals for the Selectra and the Dry-ISE

for further details on system Calibration and Operation.

VITAL SCIENTIFIC N.V. 9-7

Appendix

9.1.10 Field QC Checkoff

Each QC step should be documented at the end of the individual QC step. It is recommended

to carry out all the test sequence Q1..Q7 even if one of them fails. Do not proceed to Q8

unless Q1..Q7 have all passed.

Table A2: Field QC Checkoff

# DESCRIPTION PASS/ FIRST VALUE SECOND INITIALS

FAIL VALUE

Q1 Version Verify QC

Q2 Pump QC

Q3 Valve QC

Q4 Sipper QC

Q5 EPROM QC

Q6 A/D Converters QC

Q7 Bubble Detector QC

Q8 Calibration QC (C3) PRINT PAGE

(only if Q1..Q7 all pass)

ISE SN: PASS/FAIL:

SIGNATURE: DATE:

Service QC Version 0.99.10

9-8 VITAL SCIENTIFIC N.V.

Appendix

9.2 Spare parts

9.2.1 ISE Consumables

For a comprehensive list of ISE Consumables consult the ISE User Manual (Appendix).

9.2.2 ISE Spare Parts

Table 2: ISE Spare Parts

QTY DESCRIPTION PART (EU)1 PART (US)

1 Line Filter 3315-276 3315-276

1 Power Supply 3359-041 3359-041

1 Power cable 3374-170 3374-170

1 Interface cable 3374-111 3374-111

1 Main Board 3367-084 3367-084

2 Valve 3366-923 3366-923

1 Valve Cable 3374-168 3374-168

1 Roller Assembly (Pump) 8002-554 8002-554

1 Motor Assembly 8002-555 8002-555

1 Pump Bracket 4802-434 4802-434

1 Bubble Detector Assembly 8002-558 8002-558

1 Cover Assembly 8002-559 8002-559

5 Tube Clamps 4100-787 4100-787

1 EMC Plate 4803-578 4803-578

1 Fan Unit 8002-561 8002-561

1 Accessory Kit (Power, Serial, fuses) 8002-564 8002-564

1 Ground Electrode 8002-551 8002-551

2 Knurled Nut 3019-109 3019-109

1. International Customers should use the EU Part Numbers

VITAL SCIENTIFIC N.V. 9-9

Appendix

9-10 VITAL SCIENTIFIC N.V.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Vertical Labarotory Steam SterilizerDocument2 paginiVertical Labarotory Steam SterilizerIvan Villena ChumanÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Nüve - Ot 32VS Service ManualDocument50 paginiNüve - Ot 32VS Service ManualIvan Villena Chuman100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Roche Omni C - Service Manual PDFDocument184 paginiRoche Omni C - Service Manual PDFIvan Villena ChumanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- TC220 Manual Tenico V1.15Document147 paginiTC220 Manual Tenico V1.15Ivan Villena ChumanÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Ot 32vs-User ManualDocument27 paginiOt 32vs-User ManualIvan Villena Chuman0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- D Mqwave ManualDocument64 paginiD Mqwave ManualIvan Villena ChumanÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Diatron Abacus Junior Hematology Analyzer - Service Manual PDFDocument159 paginiDiatron Abacus Junior Hematology Analyzer - Service Manual PDFCharlymsps75% (8)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Runyes Autoclave - Service ManualDocument21 paginiRunyes Autoclave - Service Manualvoica andreea67% (15)

- MNM-81035-01-B Service Minitecno New RevBDocument23 paginiMNM-81035-01-B Service Minitecno New RevBIvan Villena Chuman100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Chemistry URIT-810Document2 paginiChemistry URIT-810Monero SasonoÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Ð ÑƒÐºÐ Ð Ð Ð Ñ Ñ Ð Ð Ð¿Ð Poskom PXP60-HF Ра Ð°Ð Ð Ð Ð Ð Ñ ÐºÐ Ð Ñ Ð Ñ ÐºÐDocument37 paginiÐ ÑƒÐºÐ Ð Ð Ð Ñ Ñ Ð Ð Ð¿Ð Poskom PXP60-HF Ра Ð°Ð Ð Ð Ð Ð Ñ ÐºÐ Ð Ñ Ð Ñ ÐºÐTulus Arisono100% (3)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Rt-7200 Manual ServicioDocument24 paginiRt-7200 Manual ServicioIvan Villena Chuman80% (5)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Behringer CMD DC1 VirtualDJ 8 Operation GuideDocument7 paginiBehringer CMD DC1 VirtualDJ 8 Operation GuideIvan Villena ChumanÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- BLL01 Memmert Waterbath WNB 10.enDocument3 paginiBLL01 Memmert Waterbath WNB 10.enIvan Villena ChumanÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- USHIO Lamparas Equipos MedicosDocument16 paginiUSHIO Lamparas Equipos MedicosIvan Villena ChumanÎncă nu există evaluări

- Sinnowa BS3000M-User ManualDocument32 paginiSinnowa BS3000M-User ManualIvan Villena Chuman65% (20)

- R02 BC Scale SM ENDocument160 paginiR02 BC Scale SM ENIvan Villena ChumanÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Bomba de Vacio Vacuubrand Me2ntDocument88 paginiBomba de Vacio Vacuubrand Me2ntIvan Villena ChumanÎncă nu există evaluări

- CS-400 Service ManualDocument173 paginiCS-400 Service ManualIvan Villena Chuman50% (4)

- Zero Data Loss Recovery Appliance: Administrator's Guide Release 12.1Document322 paginiZero Data Loss Recovery Appliance: Administrator's Guide Release 12.1enrico rampazzoÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- A320LEAP1A-B12-0008.5 Cont&Ind R1 220517Document78 paginiA320LEAP1A-B12-0008.5 Cont&Ind R1 220517simsimsomÎncă nu există evaluări

- A New Method For Encryption Using Fuzzy Set TheoryDocument7 paginiA New Method For Encryption Using Fuzzy Set TheoryAgus S'toÎncă nu există evaluări

- Study of Possibilities of Joint Application of Pareto Analysis and Risk Analysis During Corrective ActionsDocument4 paginiStudy of Possibilities of Joint Application of Pareto Analysis and Risk Analysis During Corrective ActionsJoanna Gabrielle Cariño TrillesÎncă nu există evaluări

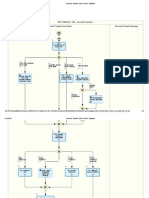

- Accounts Payable (J60) - Process DiagramsDocument16 paginiAccounts Payable (J60) - Process Diagramsgobasha100% (1)

- Full Multisim 14 PDFDocument365 paginiFull Multisim 14 PDFHafiz PGÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Appendix B: Technical InformationDocument11 paginiAppendix B: Technical InformationOnTa OnTa60% (5)

- Ultra-Low Standby Power SRAM With Adaptive Data-Retention-Voltage-Regulating SchemeDocument4 paginiUltra-Low Standby Power SRAM With Adaptive Data-Retention-Voltage-Regulating SchemeTasmiyaÎncă nu există evaluări

- HTTPS: - WWW - Whois.com - Whois - Tech-Al - InfoDocument4 paginiHTTPS: - WWW - Whois.com - Whois - Tech-Al - InfoΛουκάςÎncă nu există evaluări

- Proposal SampleDocument33 paginiProposal SampleMichael MesfinÎncă nu există evaluări

- Iedscout: Versatile Software Tool For Working With Iec 61850 DevicesDocument12 paginiIedscout: Versatile Software Tool For Working With Iec 61850 DeviceshmhaidarÎncă nu există evaluări

- Quadro Mobile Line Card n18 11x8.5 r4 HRDocument1 paginăQuadro Mobile Line Card n18 11x8.5 r4 HREka S. PaongananÎncă nu există evaluări

- DevOps Tools InstallationDocument4 paginiDevOps Tools InstallationNitin MandloiÎncă nu există evaluări

- LM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Document17 paginiLM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Pravin MevadaÎncă nu există evaluări

- Book PDF Reliability Maintainability and Risk Practical Methods For Engineers PDF Full ChapterDocument18 paginiBook PDF Reliability Maintainability and Risk Practical Methods For Engineers PDF Full Chaptermary.turner669100% (8)

- 012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)Document61 pagini012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)buts101100% (5)

- Lecture 6 NormalizationDocument54 paginiLecture 6 NormalizationAndrea BatholomeoÎncă nu există evaluări

- CS201 Introduction To Programming Solved MID Term Paper 03Document4 paginiCS201 Introduction To Programming Solved MID Term Paper 03ayesharahimÎncă nu există evaluări

- Chicago Citation: Chicago Notes-Bibliography Style GuideDocument4 paginiChicago Citation: Chicago Notes-Bibliography Style GuideElizaÎncă nu există evaluări

- Agenda: - What's A Microcontroller?Document38 paginiAgenda: - What's A Microcontroller?Hoang Dung SonÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Flipkart CategoriesDocument15 paginiFlipkart Categoriesramanjaneya reddyÎncă nu există evaluări

- Water: Use of Decision Tables To Simulate Management in SWAT+Document10 paginiWater: Use of Decision Tables To Simulate Management in SWAT+Hugo Lenin SanchezÎncă nu există evaluări

- Hipaa Information and Consent FormDocument1 paginăHipaa Information and Consent FormJake HennemanÎncă nu există evaluări

- Air Compressor Daisy Chain Termination - Rev 0Document1 paginăAir Compressor Daisy Chain Termination - Rev 0mounrÎncă nu există evaluări

- 0 Dumpacore 3rd Com - Samsung.android - App.contactsDocument161 pagini0 Dumpacore 3rd Com - Samsung.android - App.contactsJosé “José” CanÎncă nu există evaluări

- I Need Free Serial Key of Acrobat Xi Pro - FixyaDocument3 paginiI Need Free Serial Key of Acrobat Xi Pro - FixyaRamesh Gowda33% (3)

- Use Case Specifications For Stock Maintenance SystemDocument10 paginiUse Case Specifications For Stock Maintenance SystemAnup PatwariÎncă nu există evaluări

- RS232STATUSMONDocument1 paginăRS232STATUSMONashish.boradÎncă nu există evaluări

- SketchBook User ManualDocument57 paginiSketchBook User ManualJCM100% (1)

- HeliTrim Manual en PDFDocument9 paginiHeliTrim Manual en PDFJuan Pablo100% (1)