Documente Academic

Documente Profesional

Documente Cultură

Diverter S

Încărcat de

Sasan Abbasi0 evaluări0% au considerat acest document util (0 voturi)

284 vizualizări12 paginihydril diverter

Titlu original

Diverter s

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenthydril diverter

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

284 vizualizări12 paginiDiverter S

Încărcat de

Sasan Abbasihydril diverter

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 12

°Y HYDRIL

Diverters

Te | a) |

el

Te)

Features and Benefits

subsea, anay tom ng and personne. ght

Purpose. A diverter is a safety system which reroutes a well fluid

flow away from the rig. Shallow gas is permitted to flow until

depleted, or unti the well is bridged over or Killed by pumping in

heavy mud. Ready during upper hole operations, a diverter is

intended for use when there is a danger of penetrating a

pressurized gas zone, while the casing shoe strength may not be

sufficient to contain shut-in pressures.

Critical need. Diverters safeguard the rig and personnel during

the most dangerous phase of driling. A preponderance of

blowouts has occurred at shallow driling depths where gas

charged sediments lie. Much of the diverter equipment now in

the field was installed before the availabilty of systems properly

designed for diverting. A rash of diverter malfunctions from overly

complex systems has led to serious accidents. Loss of lives and

‘equipment has brought about the design of systems that are

simple, durable, and avoid risk caused by too many parts and

sequential activations.

Rig survivability. Massive flows of gas and sand can quickly

destroy a rig's diverter system. Hyd diverters are stout to resist

erosive cutout, high thrust and impact loads. They are

fundamentally simple. Bends that induce turbulence are

minimized. Valves, insert cartridges, linkages, and the

sequencing process that frequently cause malfunction are

completely eliminated.

‘Cover: FS 21-500 Marine Riser Dvoror

‘nd ts housing for oating oferoe ciling Hos.

Copyright © Hycet Company 1991

Rig marketability. With growing

emphasis on safety, the best equipped

rigs get the most work. Field proven

Hycirl diverter systems have earned

testimonials of satisfied users and

recommendations of safety authorities.

Hydril diverter systems make rigs more

attractive to operating companies,

Economical, easily installed and

maintained. Significant safety

enhancement, rig protection, and

marketability are important practical

considerations. Hydril options offer

attractive ways to upgrade. Handling

and tig time consumed are minimal.

Quick connects, scope and spacer

spools, and overshot subs that run

through a 37 1/2 inch rotary table enable

easy nipple-up and down. Hyd

diverters use dependable annular

packing elements. They are routinely

maintained and handled in the same

manner as BOP’s on the rig

Hydtil is a single source for all parts,

including handlingitest tools, overshots,

spoo's, and rubber goods. This

simplifies procurement, installation,

operation, maintenance, and stocking of

spare parts. Field service is available

worldwide.

tng ofshalow 9a

Hydril diverter equipment can be tailored to any rig, bottom

founded, floating, or tethered. Arrangements can be made to

permit diverting at the surface andlor subsea. Full redundancy of

surface-subsea options can significantly enhance reliability.

sore (

ing elements used in.

‘lose on any size pipe or open hole. Mereover, Hy rubbars renowned for

fandiong if Every packng unt saci tested n a BOP. Tho cried te

italy aninepeetor, means the unt meets ya's ngorus sana. 1

in i used nthe SXVISP Dvere/BOP

SXV/MSP Diverter/BOP System

‘SXVIMSP DiverionBOP System

For Bottom Founded and Floating Offshore

Drilling Rigs

‘The SXVIMSP system combines the SXV exhaust valve with the

MSP blowout preventer. As companion pieces to the 30 inch,

29 1/2 inch, and 21 1/4 inch annular BOP’s, they provide the

protection of a blowout preventer, as well as a diverter with surface

or subsea options. In addition, the SXV/MSP can be integrated

within a subsea stack for floating offshore rigs. Shear ram BOP's

canbe included in the subsea stack to provide valuable options.

‘The MSP 30-1000, with the largest bore of three models, is

compatible with 30 inch conductor pipe, yet it can still close on

open hole.

‘The SXV 30-1000 responds to the same control signal as the

MSP unit, Internal view.

[tthe surface, ls safely diverted

annular BOP for exhausting flow in the diverting mode. Itis

‘compatible with 30 inch casing, and can be nippled-up directly to

the annular BOP at the surface or be positioned subsea. It

features an integral vent vaive for diverting. As the annular BOP

is closed for diverting, the SXV vent line is opened simultaneously

for exhaust. When converting the system from divert to the BOP

‘mode, the SXV spool outlets are simply blinded off

No flowline valve is needed. Closure of the MSP unit

automatically stops flow to the shale shaker, since the flowline is

above the annular BOP, connected to the bell nipple. Cartridge

type diverters require sequential operation of a number of valves,

including the flowline valve before the annulus can be closed.

Safety Valve Feature. The SXV is designed to open to vent as,

the MSP closes upward flow. In the remote event that the SXV

does not open on command, building of internal pressure within

the SXV wil lf its annular piston and allow the fluid to vent, if no

closing fluid is applied to the SXV.

Upgrade is economical, since it can be made without cost of

large bore valves. The SXV unit can use existing annular BOP's

from various manufacturers.

The SXV avoids solids jamming. Clean shutoff at the bore

combats valve jamming by stagnant mud caking or ice formation.

Quick nipple-up. The SXV unit can be fitted with high strength

quick connects for the top, bottom, and side outlets.

Big vent outlets. The SXV unit can be fitted with one or more

outlets of 12, 14, or 16 inch nominal size. Expensive and fragile

vent valves are eliminated

FS 21-500 Marine Riser Diverter

2 i

FsDverter

rig, the vavesoeve

‘Selector trough

povtorstarboerd

it Pipe

or open hole. The chance for human error is increased by

cartridge type diverters which require fetching, installing, and

latching cartridge inserts.

Open hole closure. The annular packing unit seals on open

hole, eliminating a serious safety gap caused by cartridge inserts.

The FS Diverter allows stripping while diverting, and it seals

on the kelly, drill pipe, casing, or dill collars.

Minimal running time. The diverter assembly will run through a

49 1/2 inch rotary table with the handling-test tool which is

capable of supporting the diverter, riser, and BOP stack

Reduced downtime. The design eliminates line disconnections

and reconnection at each installation. The diverter assembly is

laiched into the permanent housing supported by the rotary

beams. Permanent attachments to the housing include flowline,

ventline, filup line, overflow line, and hydraulic function

connection. The FS unit is designed for fast installation and,

removal.

Extended packing unit life. The FS packing unit is

manufactured by Hydril Rubber Operations where it undergoes

Hydril’s thorough testing and quality assurance measures.

Simple, safe pressure testing. The handling tool allows tests to

{ull working pressure. Itis not possible to leave the testing tool in

place inadvertently, since access to the wellbore is blocked by its

presence.

Pua

fs

Housing

US. Patents

4ausaon

‘36.002

4456083

uring the normal iting mod, hm

FS Diverter Engineering Data

FS 21-500 Marine Riser Diverter

i

¢

;

FS 21-500 Marine Risor Diverter

For Floating Offshore Drilling Rigs

The FS 21-500 is a diverter with a 21 inch bore and 500 psi

working pressure rating. Drilships and semrisubmersibles employ

a diverter for venting gas flows encountered while driling top hole

through the 30 inch casing. The diverter also serves as the

‘support for the upper flex joint and the inner barrel of the riser

telescopic joint, so the diverter is in place whenever the riser isin

service. On a floating rig, the diverter is never used as a BOP, so

its pressure rating is 500 psi. Its bore accommodates the riser

bore

The FS diverter is fundamentally simple. ts design avoids the

functional complexities which increase chance for human error

FS 21-500 Marine Riser

Diverter, internal view.

‘Running the divertor and

tser. sr era

Marine Fiser

and equipment breakdown, the causes of diverter malfunctions,

rig damage, and injury to personnel.

The patented integral valve design elirinates equipment such

as vent valves, flowiine valves, filup valves, and interconnecting

Circuitry. There is no sequencing.

The single control function applies a solitary hydraulic signal

which moves the piston up and closes the annular packing unit.

Allat once, the signal opens the vent line, stops upward flow,

shuts off the flowline to the shaker, and shuts off the filup line.

Fast response time is ensured since there is no waiting tor

remote valve functions or sequencing.

Built to endure the brutal beating of a shallow gas kick, the FS

design avoids the structural problems that so frequently cause

malfunction. It is rugged, and there are no external valves,

linkages, or other fragile parts to break. The FS units fited wth

abig bore vent outlet to handle large flow volume.

The vent line is always open and clear since there are no

valves to obstruct the vent line. Flow is always allowed. There is

no closed position. Even during actuation of the flow selector, the

vent line is open.

There is no stagnant vent line space to allow caking of solids

or ice formation that could obstruct or shut off the flow. The flow

is opened immediately because of the integral piston-vent design.

Always ready. Cartridge inserts are not needed to close on pipe

FSP 28-2000 Diverter/BOP System

igure 2 Figues

arrangement of BOP’s and diiling spools as driling progresses.

‘Simple, safe testing is ensured since the packing unit does not

directly contact hydraulic fluid during actuation, eliminating the

dangers of rupturing packers and losing critically needed control

fluid. The packing unit is pressure tested while the handling test

tools in place for installation. Removal of the tool leaves the

entire system unaltered, in safe operating condition. There is no

need to override a control sequence to test, which risks the

forgetting to restore it to correct functional mode. The FSP can

be tested to full working pressure rating in either the divert or BOP

mode.

Extended packing unit life is the result of years of rubber

manufacturing, testing, and designing at Hydril Rubber

Operations. Bonded steel segments in the packing unit provide

rigidity and strength to resist thrust and impact. The unit is a

member of Hydril's GX annular packing unit family which limits

stresses in the rubber material, improving closure cycle and

stripping lite

H2S service. The FSP Diverter is equipped with trim that meets

NAGE requirements for H2S service.

‘A. 26" drill bit passes through the open annular packer.

Versatile handling-test tool. The handling-test tool has a

design load exceeding 500,000 lbs. The axial bore of the tool is

the channel through which pressure is conducted to test the FSP

Diverter packing unit

Bel

Npote|

a

Poe

FS 28.2000 Diverter/BOP in diverting mode. "

re anna packing unt aroun

orm eling mode, mus ek Now op Brough the

FSP Engineering Data

Pack

one"?

US. Patents

a so4a%e

4456088

FSP 28-2000 Diverter/BOP System

FSP 20.2000 Diverter OP

For Bottom Founded Offshore Drilling Rigs

‘The FSP 28-2000 is a diverter/blowout preventer with a 28 inch

bore and 2000 psi working pressure rating for platform, jackup,

and submersible rigs. Its used as a diverter while driling the

upper hole. After cementing the conductor pipe, it can be used as

a blowout preventer.

Reliability is especially important for a bottom-founded rig,

since, unlike floating rigs, it cannot be moved off location to avoid

a gas plume. A biowout at the casing shoe could erode the

seatloor sufficiently to topple the rig

Simplicity means safety. No system is simpler than the FSP

Diverter. On command, one hydraulic signal to one component

reroutes the flow of a well kick. With the integral valve design, the

piston movement closes the upward flow path and opens the vent

line for well fuid. Its single control feature eliminates the need for

external valves, actuators, and interconnecting control circuitry

Even when closed on large diameter pipe, the vent path is fully

open.

Fast response time is ensured by its simplicity. There is no

waiting for valve functions or sequencing,

Ruggedness and high strength characterize Hydril diverters.

‘They are designed to withstand violent thrust loads and erosive

forces. There are no extemal valves, linkages, limit switches,

interconnecting control lines, or other fragile parts to break.

Fue 1

The vent line is always open and clear. There are no valves to

obstruct the vent line, The Hydril Flow Selector, which permits

manual choice of port or starboard venting, allows vent flow even

during position changing, and itis never closed.

There is no stagnant vent line space to permit caking of solids

or formation of ice that could obstruct or shut off the flow, or jam a

valve. The flow is opened immediately when the piston moves up

the cylindrical wall of the diverter.

There is no worry about packer inserts, which are necessary in

cartridge type diverters. Fetching, instaling, and latching the

packer insert cartridge can be overlooked. Without an insert

installed, the diverter won't work. If the insert cartridge is in place

but not properly latched down, it can be a dangerous projectile.

Open hole closure is permitted by the annular packing unit

which shuts off even while there is no pipe in the hole, eliminating

a serious gap in safety. Typically, cartridge type diverters cannot

close on open hole.

Closing around drill pipe, kelly, casing, and most other tools is

provided by annular packing unit design.

Stripping. The FSP annular packing unit permits stripping of

pipe into the hole while diverting well fluids.

Quick installation and versatility is forded by high strength

quick-connect couplings for fast nipple up and down. Scope

spools are custom built with variable length to accommodate any

6

Features and Benefits

Simplicity of function derives

from patented integral valve

design which eliminates

extraneous valves, inter-

connections, and sequencing,

‘One command, one hydraulic

FS 21-600

521-500 Marine Riser Diverter

Marine Riser Diverter

signal does it all. Upward motion

‘of one component, the piston,

stops upward flow of well fluid

and opens the vent line. Fast

response time is ensured, since

there is no waiting for valve

functions. Risk from malfunction

uring sequencing of compon-

ents is significantly decreased

Ruggedness and durability.

Hydrildiverters are built to

endure the brutal biast of fluid,

sand and rocks. All diverters at

Hydril undergo rigorous testing,

including acoustic emission

testing which Hydril pioneered in

the BOP industry. Sound waves

are used to detect any micro-

defects in the steel that could

decrease service life. The Hyd

system facilitates elimination of

ordinary valves, tees, elbows,

land supports which could be

destroyed by impact, thrust, and

erosion.

=i

For floating rigs;

‘Subsea diverting provides significant safety advantages. By

dissipating destructive forces into the sea, remote from the rig,

Surface support is spared from impact and erosion. Safety of

personnel and rig is significantly enhanced.

Hyde divertor 1 snot vent

| tnntegrt

Valve tntions

ine smitenable

Inger

1

srt ssten

‘A Hydril divertor system significantly decreases risk of malfunction ‘010

tps upward fw "board ven eimutansousiy, Saquental ve

fancing steps which eres ohances

sons tho overboard vent

valves and inkages mith

FS Maine iser Dverto

Long life packing units are manufactured by Hydril Rubber

Operations, and are renowned for their extended cycle lite and

endurance. Continuous research and development, decades of

manufacturing experience, and rigorous testing ensure

dependability.

Since the 1930's, Hydril has manufactured annular BOP’s which

have a distinguished service record. Hydril developed the

annular blowout preventer and pioneered the technology for well

control systems. In that tradition, Hydril has developed a new

‘generation of sate, simple, and durable diverter systems using

annular BOP technology as a basis, coupled with high standards

‘of manufacturing and quality assurance.

| Hydril engineers have a CAD package that optimally sizes

spools and accessories to custom fit any rig. Finite Element

Analysis is used to design critical components.

Field proven. Hyciil diverters have logged many rig-years in

service, as attested by numerous satisfied users and regulatory

authorities.

,

SXV/MSP Diverter/BOP System

BOP’ can be added to subsea stack

nearing pipe 9 move of facavon.

Simple control system. A single hydraulic command executes

the entire divert mode. Typically, diverters require the sequential

operation of several valves before the annulus can be closed.

‘The SXV/MSP system simplifies hydraulic controls since there is

no need for insert cartridge lockdown dogs, diverter lockdown

dogs, and flow line seal energizing.

‘There is no need for cartridges. Annular packing units can

close and seal on any size pipe in the hole without worry of

remembering to insert a packer after the BHA enters the hole.

This also eliminates potential for human error from incorrect

latching of the cartridge, which, if not properly secured, could

become a dangerous projectile in the event of a kick.

Open hole closure is provided by the annular packer design.

Unlike cartridge type diverters, installed annulars are always

ready to protect the crew and rig from shallow gas hazard.

Fast response time is ensured since there is no waiting for valve

functions or sequencing. There is only a small operating fluid

requirement

Structural strength. Annular BOP’s are typically massive and

very well secured. They can better resist thrust. impact loads,

and erosion. The SXV is built to withstand severe flows.

‘Subsea diverting provides significant safety measures.

Flows are discharged away from the rig and personnel. The

surface piping is not subjected to erosion, high impact flow, or

frictional heating. Ignition chances are greatly reduced. Flow is

dispersed and diluted in the sea.

‘The SxvIMSP 30

Ine row trough

el

‘Nipple

Qvershot ~

SUD

Us. Patents

546828

Casing ~ ‘26028

592,126

L

1000 syste closes the bore with the MSP annular un, ard vents

the SxV exaust ave ne BOP

nes

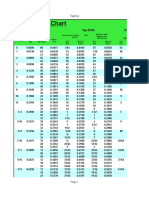

SKVIMSP_Engineering

font sae wanes | as mi Eom sare

Jccosina pnessune | so0a0o0 e3 RZ | x atoso% esi] A" | rseosam Ps) RA

mance | EBT [| meee [a | age |

BOS Sime | Venton [thy | Tweuien | ing] to outer

RSIS one [8 CAL) hy |v enone Ea | re LOS] He

BRR ine [een hy | «| — [AN

use wessaT veawo iss [rwcane] easooias | "yg? | szsooxss | 44?

rein | aeeae | — [amar] - Paamel -

fesaaceren, | pusoette, | - [pezmmnicee| — [UR Rade -

a

lesceerten | Zemeeetn, | — | RSQ Aas| — [eed]

Eee 7 fae =

ABBE | tem woo | ee | woe | BP

sfamicor | em en sem | a] sem |B

© heehecut | ma wy was | ae fms | ae

[RSP | wean om [a wer | ae

Flow Selector

Flow Selector

The patented Flow Selector is a rugged switchable target

designed to keep the discharge line always open. Itis switchable

so that a downwind line can be preselected,

It replaces a target and two valves which can be unintentionally

shut.in and can restrict flow area. It eliminates parts and controls

sequencing, and thus reduces potential for malfunction.

The vent path is always open, even during actuation, to avoid

system shutin, There is no closed postion. During fluid flow, the

Flow Selector can be switched to redirect flow from one side to

another,

‘The hardened steel target resists erosion and provides long flow

life. Cross sectional flow area is large diameter for minimum

pressure drop.

In any physical orientation, itis operable. Hydraulic operator

cyaling alternates discharge lines. Actuation is impervious to

jamming by solids. Jet nozzle ports can facilitate break up

gumbo. It has accommodation for strong structural support.

Upgrade. The Flow Selector can upgrade the diverter system of

any rig, new or old.

10

US Patont

14.565.404

:

Flow Selector Engineering Data

ces

SYSTEN OF

SE a

WERT casos | 202 KG | 7500188 | 0100 KG

| DIMENSION D 7600 (IN) | 406 MM | 18.00 (IN) wn

Fault Tree Comparison

Hydril diverter systems are dependable because of their

simplicity. Hydril designs enhance system safety. Design

features such as integral valve function, annular packer

operation, and single command control greatly improve reliability

Most diverter problems occur because of human error. Extra

valves, linkages, interconnected functions, packer inserts, and

) sequencing result in higher risks. They increase potential for

human error and offer more chance for parts breakage, sequence

abort, and vent obstruction.

‘Sequential diverter systems are general complex Exra valves packer san, sequencing

function risks oven more. Since ho force ot

cing an surface equement. may

‘Subsea Mydril systems 32

is nave been a

Hydrit systems which divert at the surface 2101 maunciion, Sequencing

Caridge related lunctons, and extra vales, have boen elmira

"1

Worldwide Sales, Service, and Manufacturing

Canada, Alberta, Calgary

Sales Office

Hy Canadian Company, Li.

Suite 1640 Aqutaine Tower

‘540 5th Avenue SW.

Calgary. Abeta 12° OM

Canada

Telephone: (405) 31-1590

FAK: (403) 266-0585

Tx 038-21858

Canada,

Alberta, ‘Edmonton

Sales Office, Field Service,

‘Manutacturing Plant

Hy Canacian Company, Lid

602-13 Avenue

P.O, Box 202

Nsku, Aberta TOs 260,

Canada

Telephone: (400) 955-2045

FAX: 405) 955.7627

Mexico, Mexico City

Sales Oice, Field Service

HyorlSA de Cx.

Hamburgo 213, 12 Piso

186500 Mexico, OF.

Telephone: «26) 208-7088,

Telephone. +525) 208-7148,

Telephone: +525) 208-7268,

“Telephone: 1525) 208-7208

FAK (625) 208-7861

Mexico, Veracruz

Manufacturing Plant

Hycil SA oe Ox.

‘Av Framboyanes Lote 4.8

Marana 1

aj Indust! Bru Paghis

Verso, Veracruz

Mexico

Telephone: +52-20-810019

152-20-010233

Fax: 452-29.810702

Netherlands, The Hague

Sales Omics

Hyd Company

on Jutanapien $093,

595 AA Dan Haag

Netelands

Telephone: +31-70-2476635,

FAX: 631-70-3476121

To. 21604

Nigeria, Port Harcourt

Sales Office, Field Service

Hyd Aiea TOPS

4 Evergreen Stas

Niger

Teleprone: #254-64:582261

Nigeria, Warri

Service Center

Hyd Aton TOPS

F2t laugboe Estate

(Ogun, Wa

Noera

Telephone: 4234-53-252565,

posite dooce | ut artic

Bennie YA, Ale, Ach

Be eee | Sma

pits ‘rom ns

rete Uk, Cao

Telephone: +65-861-6933. a

Los hae

‘TUX (786) 26608 HYSGSL peony |

Switzerland, Fribourg Cosme CA SOiE-408

‘rornaona Tour eaer mes Toupbow 19-80

iponea rac oro 0-008

tpoodaS U.S.A, California, Oxnard

bs7O9F Sie tee, See Srter

tonne De Benen sl Corey

(CH-1700 Fribourg oa

ae Grea CAS

Telopnone: (85) 488-3654

Telephone: +41-27-821281 Bre dealon

FAK: 041-97-249165,

eer

Sites trase gaan ee

Sales Office, Field Service, ‘Hyd Company

Manufacturing Plant eee

Brome LA ros18 0506

Nyt UI i Teoprone (10 6075654

‘Attens Industrial Estate Pe

sowaoon ABT U.S.A, Louisiana,

Seater New Grieans

Tegan: +4-24-879p4 Sos Oe, Serve Center

Tax aceaoaoe rye Company

Fat cat geneoees ‘Yoo Tao Ae Sue 240

be gen ror New onan A 70112

United Kingdom, ee ee

Andover, England ear

‘tomatic 04 Toke, USA, Louisiana,

fos orce, Manufacturing Pant Westviego.

‘out conany Manctotieng Plant

era ay tra comoary

Winer ntl atte Pleo 29

Xicsr HoratreSP'0S8W etapa, A 7008

troand mre

Teepone: 442048501 Westueg, LA 7%

Fax sans res “Tape (6s) au aie

he gen eter Fre p00) 48 3500

United Kingdom, U.S.A, Oklahoma,

London, England ‘Oklahoma City

Sas one Sates mee, id Serie

Ft Un inte frat Company

orton aise ‘tonsa

foment Pond Chana oy, 7127509

gram Srey e0080 Tepe 8 s.090 Tab

Eoin Toupone (3 98-355 Mech

Tetehone: 44284-9577 Fro os tot2

Totophone: 44784438280 Direct

FAK: +88-765-490562

Headquarters

Hye Company

P.O, Box 60458

Houston, Texas 77205-0458

{3300 Norh Sam Houston Parkway East

Houston, Texas 77032-3411

Telephone: (713) 449-2000

FAK: (719) 985-2063

TLE 168905 HYDRILCSO HOU

*y HYORIL

1-800-999-1601

USA, Texas,

Corpus Christi

Sales Ortce

Hyde Company

730-F Diamond Cut Road

Corpus Chit, 1X 78400

Telephone: (512) 288-5031 - Mech

Telephone: (52) 269-5034 - Tub

Fae (12) 289.0258,

U.S.A, Texas, Houston

yar Rubber Operations

Hyer Company

7.0, drawer 1808

Humble, 1X 77347-1608

18000 Eastex Freeway,

Humble, TX 77296

Telephone: (713) 446-0083

FAK (719) 446-4700

U.S.A, Texas, Houston

Moers fc. Manufacturing

Hyail Company

8641 Moers Read

Houston Texas 77075-1546

Telephone: (13) 041-6639

FAK: (779) 941-5862

U.SA,, Texas, Houston

Hydell Technology Center,

Solos Office, Field Service,

-Manetacturing Plant

Hyer Company

P.O. Box 60458

Houston, Texas 77208-0458,

300 N. Sam Houston Parkway East

Houston, Texas 77032-3411

“Telepnone: (713) 440-2000

FAK (719) 985-2959,

“TOs: 168605 HYDRIL CS HOU

U.S.A, Texas, Odessa

Hyde Company

18000 West Highaay 0, East

(Odessa, Tx 70768

Telephone: (15) 563-3730

Fa 915) 963.5426,

U.S.A,, Wyoming, Casper

Sales Otic, Service Canter

Hyd Company

P.O. Box 124

(Caspar, Wy 82602

£501 North Poplar

‘Gaspar, WY 82601

Telephone: (37) 268-2120

Fax 7) 2042182

Puerto La Cruz

HydriCompary

‘x. Constiticon EDF

Parque Mar 5A Puerto La Cruz

Edo Anzoategi Mal Box 22

6003 Venezuaia

Telephone: 359-61-761271

FAX: +50-81-670800

ned Unto Stes

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Logan Welded Cup Junk SubsDocument2 paginiLogan Welded Cup Junk SubsSasan AbbasiÎncă nu există evaluări

- Optimist Tuning GuideDocument9 paginiOptimist Tuning GuideSasan AbbasiÎncă nu există evaluări

- PRE-RECORDED SHEET DATADocument7 paginiPRE-RECORDED SHEET DATASasan AbbasiÎncă nu există evaluări

- Drill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsDocument7 paginiDrill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsSasan AbbasiÎncă nu există evaluări

- LaMOT RD CatalogDocument20 paginiLaMOT RD CatalogSasan Abbasi0% (1)

- U BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealDocument1 paginăU BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealSasan AbbasiÎncă nu există evaluări

- Corrosion AllowanceDocument35 paginiCorrosion AllowanceReni Mutiara Sari50% (2)

- 1930PA Reversible Impact Wrench with Adjustable Torque SettingsDocument1 pagină1930PA Reversible Impact Wrench with Adjustable Torque SettingsSasan Abbasi100% (1)

- Tap Drill CalculatorDocument1 paginăTap Drill CalculatorSasan AbbasiÎncă nu există evaluări

- Guide To Contamination StandardsDocument8 paginiGuide To Contamination StandardsCarlos MejíaÎncă nu există evaluări

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 paginioEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiÎncă nu există evaluări

- Assistant Barge Supervisor 9-16-04Document3 paginiAssistant Barge Supervisor 9-16-04Sasan AbbasiÎncă nu există evaluări

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 paginioEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiÎncă nu există evaluări

- 77 3001 TypeDDocument8 pagini77 3001 TypeDSasan AbbasiÎncă nu există evaluări

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 paginioEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiÎncă nu există evaluări

- Guide To Contamination StandardsDocument8 paginiGuide To Contamination StandardsCarlos MejíaÎncă nu există evaluări

- Ifu 5902152 Emgy DSCNT DviceDocument12 paginiIfu 5902152 Emgy DSCNT DviceSasan AbbasiÎncă nu există evaluări

- BOP Dimensions 13stackDocument3 paginiBOP Dimensions 13stackSasan AbbasiÎncă nu există evaluări

- Cylinder Adaptors Connect Gas Cylinders to RegulatorsDocument2 paginiCylinder Adaptors Connect Gas Cylinders to RegulatorsSasan AbbasiÎncă nu există evaluări

- Hard Versus Soft Shut inDocument15 paginiHard Versus Soft Shut inAgus AlexandriÎncă nu există evaluări

- Pipe Racking System OJTDocument20 paginiPipe Racking System OJTDanang PrasetioÎncă nu există evaluări

- Rig MoveDocument10 paginiRig MoveSasan AbbasiÎncă nu există evaluări

- Bit Breakers PDFDocument2 paginiBit Breakers PDFSasan AbbasiÎncă nu există evaluări

- Bit Breakers PDFDocument2 paginiBit Breakers PDFSasan AbbasiÎncă nu există evaluări

- Imperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)Document1 paginăImperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)OSCAR BUSTOSÎncă nu există evaluări

- 4 - Figures and Tables - Fluid FlowDocument22 pagini4 - Figures and Tables - Fluid FlowCarlosCD17Încă nu există evaluări

- Bit Breakers PDFDocument2 paginiBit Breakers PDFSasan AbbasiÎncă nu există evaluări

- Draw WorksDocument32 paginiDraw WorksSasan AbbasiÎncă nu există evaluări

- 0080A-60.3118 PublicationDocument1 pagină0080A-60.3118 PublicationSasan AbbasiÎncă nu există evaluări