Documente Academic

Documente Profesional

Documente Cultură

Resolusion A800 (19) 23.11.1995

Încărcat de

CostinRotaru0 evaluări0% au considerat acest document util (0 voturi)

82 vizualizări44 paginiRevised Guidelines for approval of sprinkles system ref to SOLAS

Titlu original

Resolusion A800(19) 23.11.1995

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentRevised Guidelines for approval of sprinkles system ref to SOLAS

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

82 vizualizări44 paginiResolusion A800 (19) 23.11.1995

Încărcat de

CostinRotaruRevised Guidelines for approval of sprinkles system ref to SOLAS

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 44

Resolution A.800(19)

adopted on 23 November 1995

(Agenda item 10)

REVISED GUIDELINES FOR APPROVAL OF SPRINKLER SYSTEMS

EQUIVALENT TO THAT REFERRED TO IN SOLAS REGULATION I1-2/12

THe Assesuy,

RECALLING Aticle 15() of the Convention on the Intemational Martime Organization concering the

functions of the Assembly in relation to regulations and guidelines concerning maritime safety,

NOTING the significance of the performance and reliability of the sprinkler systems approved under the

‘provisions of regulation 2/12 ofthe International Convention for the Safety of ie at Sea (SOLAS), 1974,

DESIROUS of Keeping abreast of the advancement of sprinkler technology and further improving fire

protection on board ships,

HAVING CONSIDERED the recommendation made by the Maritime Safety Commitee at its sbayfourth

session,

1. ADOPTS the Revised Guidelines for Approval of Sprinkler Systems Equivalent to that Referred to in

SOLAS Regulation IL2/12 set out in the annex to the present resolution;

2. _ INVITES Governments to apply the Guideines witen approving equivalent sprinkler systems;

3. _REQUISTS the Markie Safety Commitee to Keep the Guldelins under review and to amend them as

necessary

4. REVOKES resolution A755(18)

‘Annex

REVISED GUIDELINES FOR APPROVAL OF SPRINKLER SYSTEMS

EQUIVALENT TO THAT REFERRED TO IN SOLAS REGULATION I1-2/12

1 GENERAL

Equivalent sprinkler systems must have the sane characteristics which have been identified as sigiicant to

‘the performance and relabilty of automatic sprinter systems approved under the requirements of SOLAS

regulation th2/12.

2 DEFINITIONS

2.4 Antifeeze system A wet pipe sprinter systern employing automatic sprinklers attached toa piping

system containing an antifreeze solution and connected to a ater supply. The antifreeze sokuton

Cscharged, folowed by water, Inmediately upon uperaiun of sprinklers opened by heat om a fre

Resolution 4.00/19) ~ 119

2.2 Deluge system. A sprinkles syste employing open sprinklers atached oa piping stem connected

‘to. water supply through a valve thats opened bythe operation of a detection system installed inthe same

areas as the sprinklers, When this valve opers, water fows ino the piping system and discharges from all

sprinklers auached thereto.

23D pipe system: A sprinkler system employing automatic sprinklers attached to a piping system

Containing ar oF nitrogen under pressure, the release of which as from the opening of a sprinkler) permits

the water pressure to open a valve known asa dry pipe valve. The water then flows ino the ping system

and out of the opened sprinklers.

24 Freaction system: A sprinkler system employing automatic sprinklers attached ta piping system

Containing air that may or may not be under pressure, with a sunplemetal detection system installed in the

same area asthe sprinklers. Actuation ofthe detection system opens a valve that permis water to Howe into

the sprinkle piping «stem and to be discharged from any sprinklers that may be open,

2.5 Waterbasod extinguishing medium: Fesh water or seawater with or without adives mined to

‘enhance fre-exinguishing capability.

2.6 Wet pipe system: A sprinkler system employing automatic sprinklers attached 10a piping system

containing water and connected to a wales supply so that water discharges immeclatelyffom sprinklers

‘opened by heat from a fre.

3 PRINCIPAL REQUIREMENTS FOR THE SYSTEM.

3.1 The system should be automatic in operation, with no human action necessary t9 set tin operation

3.2. The system should be capable of both detecting the fre and acting to contol or suppress the fhe

‘wth a waterbased exingulshing medium.

33. The sprinkler system should be capable of continuously supplying the water-based extinguishing

‘medium for a minimum of 30 min. A pressure tank should be prowded to meet the functional requitement

stipulated in SOLAS regulation 1r2/12.4.1

3.4 The system should be of the wet pipe type but small exposed sections may be of the dy pipe,

reaction, deluge, antireeze or other type tothe satisfaction of the Administration where ths is necessary.

35 __Thesystem should be capable offre contra or suppression under a wide variety of fe loading, fuel

arrangement, room geometry and ventilation conditions.

3.6 The system and equipment should be stably designed to withstand ambient temperature changes,

vibration, humidity, shock, impact, clogging and corrasian nermlly encaunteced in ships

3.7 The system and its components should be designed and installed in accordance with international

Hlandarde acceptable to the Organization” and manufactured and tested to the slisfction of the

‘Administration in accordance with the requirements given in appendices 1 and 2 to these Guidelines,

3.8 The system should be provided with both main and emergency sources of power.

3.9. The system should be provided with a redundant means of pumping or otherwise supplying a water:

based extinguishing medium tothe sprinkle system,

+ Peng he deepen of teats! standards acceptable tothe Organization naoral sandals as prescribed by the

‘Adminstaton sul be sop.

120 Resolution A.800(19)

3.10. The system should be fited with @ permanent sea inlet and be capable of continuous operation

using seawater

3.11 Tho piping systom should be sized in accordance with a hydrate calulation technique”

3.12 Sprinklers should be grouped into separate sections. Any section should not serve more than two

‘decks of one main vertical zone,

3.13 _ ach section of sprinklers shouldbe capable of being isolated by one stop valve only. The stop valve

in each section should be realy accessible and its location should be clearly and permanent indicated

“Means should be provided for preventing the stop valves being operated by an unauthorized person

3.14 Sprinkler piping sould not be used for any other purpose.

3.15 The sprinkler system supply components should be outside category A machinery spaces

3.16 A means for testing the automatic operation ofthe sytem for assuring the required pressure and

low should be provided.

3.17 Each sprinkler section should be provided with a means for giving a visual and audible alarm at a

‘ontinuously manned central contol station within one minut offow rom one or more sprinklers, check

valve, pressure gauge, and atest connection with a means of drainage

3.18 A sprinkle control plan should be splayed at each centally manned contrt station,

3.19. Installation plans and operating manuals should be supplied tothe hip and be readily available on

board. Alt or plan should be dplayed showing the spaces covered and the location ofthe zone n respect

‘of each section. Instructions for testing and maintenance should sho be avaiable on bo2rd

2.20. Sprinklers should have fat rosponte characteristics at defined in ISO standard 618241

3.21 In accommodation and service spaces the sprnkers should have a nominal temperature rating of

57°C to 79°C, except that in locations such as drying rooms, where high ambient temperatures might be

‘expected, the nominal temperature may be increased by not more than 30°C above the maximum

deckhead temperature,

3.22. Pumps and alternative supply components should be sized so as to be capable of maintaining the

equired flow tothe hydraulically most demanding area of not less than 280 m:. For appcaion to a small

ship with a total protected area oles than 280 m*, the Administration may specify the appropiate area for

Sizing of pumps and alternative supply components

* Whore th Hazan Wiams math se he allowing values othe iin facto Cor diferent pipe ype ahich may be

For spaces fam 12 m up to SO me

“For paces over 30 m*

3 DEHNITIONS

3.1. Fie suppression: Sharply ceducing the heat release rate of a fire and preventing its regrowth by

‘means ofa dtect and sufcien application of water trough the fire plume tothe buring fuel surtace [2]

3.2. Fite convo: Umitng the size ofa fre by dstibutlon of water so as ro decrease the heat release rate

and prewet adjacent combustibles, wile controling celing gas temperatures avoid structural damage [2

Kesoluvon ASUOTY) — 145

3.3. Fire source: Fire source s defined as the combustible material in which the fre i set and the

‘combustible material covering walls and celing

32.4 Igniter: The device used to ignite the fire source.

4 GENERAL REQUIREMENTS,

4.1 Nozzle positioning

Ihe tesung organization shouldbe responsible or assuring that the nozzles foreach fice test ae installed in

accordance with the manufacturer's design and instalation instructions. The tests should be performed at

the maximum specified spacings, installation height and distances below the celine. In addition, Hf the

testing organization finds it necessary, selected fire tests should also be conducted at minimum specified

spacings, installation hejght and distances below the ceiling,

42 Water presure and flow rates

‘The testing organization should he responce for asuring that ale tests are condictad atthe operating

pressure and flow rates specified by the manufacture,

43. Temperature measurements

‘Temperatures should be measured as described in detail under each chapter. Chromelelamel not

‘exceeding 0.5 mm diameter welded together and chromelalumel 0.8 mm should be used. The 0.0 mmo

thermocouple wires shouldbe twisted three times, have the end remaining wie cu off and be heated with

an oxyacetylene 1orch to melt and form a small bal. The temperatures should be measured continuous, at

Teast once every two seconds Uroughout Ue test

4 Fmvizonmental conditions

‘The test hall should have an ambient temperature of between 10°C and 30°C atthe start of each tes.

43° Tolerances

Unless otherwise stated, the following tolerances should apph:

1 bength 22% of value

2 Volume 5% of value

3 Pressu 53% of value

4 Temperature 5% of value

‘Those tolerances are in accordance with ISO standard 6182-1, Fabruary 1994 elton (4)

46 Observations

‘The following observations should be made during and after each test

time of ignition;

activation time of each nozzle;

time winen water flow is shut of

damage to the fie source:

temperature recordings;

system flow rate and pressure;

total number of operating nozzles.

Weber

146 ~ Resolution 4.000419)

47° Fire sources

‘Ure requirement for fire surees specified in the folowing sections ofthis test method cannot be fufiled,

Is the responsibilty of the test laboratory to show that allemative materials used have burning

characterises sar to those of specified materials.

4.8 Produce and documentation requirements

‘A daft copy of the desig, installation and operating Instruction manu should be furnished for use as a

uid rv dhe testing ofthe fre protection system devies.

‘The instructions should reference the limitations of each device and should include at least the following

description and operating details of each device and all accestory equipment, including

Senicaton of eningusting system componens oF acesory equipment by pat oF model

nozzle design recommendation and limitations for each fre type:

‘ype and pressure rating of pipe, tubing and ftings to be used

equivalent longth values of al iting: and al system components through which water flows;

2

3

4

3

ischarge nozzle limitations, including maximum dimensional and area coverage, minimum

and maximum instalation height limitations, and nozzle permited location in the protected

volume:

6 range of filing capacities for each size storage container;

17 details forthe proper installation of each device inching all component equipment;

.B reference to the specific types of detection and contol panels (f applicable 1 he connected ta

the equipment:

9 operating pressure ranges ofthe system;

method of sizing plpe oF tubing:

11 recommended orientation of tee Stings and the spliting of lows through tees

12. maximum difference in operating (lowing) pressure between the hydraulically Closest and most

remote nozzle.

5 CABIN AND CORRIDOR FIRE TESTS

5.1 Test arrangement

SA The fe tess should be conducted in 4 3m x 4m, 24m high cabin connected to the centre of

115 m x 12m long condor, 2-4 m high with both ends open,

5.1.2 The cabin shouldbe fited with one doorway opening, 0.8 wide and 22 high, wich provides

fora 0.2 mint! above the opening,

5.1.3. The walls of the cabin should be constructed from an inner layer of nominally 12 nm thick Horr

Combustible wall board with a nominally 4 mm thick mineral woo! ner. The walls and ceting of the

Cotrdor and celng of the cabin should be constructed of nominally 12 mm thick non-combustible wal)

boards, The cabin should be provided with a window In the wall opposite the como for observation

purposes during the fie tess

Resolution A 800(19) ~ 147

5.14 The cabin and comidor celing should be covered with cellulosic acoustical panels. The acoustical

anes should be nominafy 12 mm to 15 mm thick and should not ignite when tested in accordance with

IMO resolution A.653(16).

5.1.5 Plywood panels should be placed on the cabin and condor wals. The panels should be

approximately 3 mm thick The ignition time of the panel should not be more than 35 s and the flame

Spread time at 350 mm postion should not be mote than 100 $38 measured in accordance with IMO.

resolution A653(16)

5.2 Instrumentation

Dring each fe test the flowing temperatures should be measured using thermocouples of dlameter not

exceeding 0.5 mm:

1 the cling surface temperature above the ignition source ia the cabin should be measures with

a thermocouple embeded inthe ceiling materia from above such thatthe thermocouple bead

Fe fash wth the celingsurtace;

2 the celing gas temperature should be measured with a thermocouple 75:41 mn below the

ceiling inthe conte of the cabin:

3 the celing surface temperature in the cenire of the corridor, directly opposite the cabin

“doorway, should be measured with a thermocouple embedded inthe ceiling materia such that

the thermocouple bead is flush withthe celing (see gure 1)

53. Nozzle positioning

“The nozzes should be insaled to protect the cabin and coridor in accordance with the manufacturer's

design and instalation instructions subject tothe following

41 itonly one nozze is installed inthe cabin it may not be placed in the shaded areas in figure 2

and

2 comidor nozzies should not be placed close to the centreline ofthe cabin doorway than one

half the maximum spacing recommended bythe manufacturer. An exception i systems where

nozzles are required to be placed outside each doorway.

5A Fire sources

BALI Cabin test fire source

Two pullmantype bunk beds having an upper and lower berth should be installed along the opposite side

walls ofthe cabin (see figure 1). Each bunk bed shouldbe fted with 20 m by 0.8 m by 0.1 m polyether

‘mattresses having a cotton fabric cover. Plows measuring 0.5 m by 0.8 m by 0.1 m should be cut from the

mattresses. The cut edge should be postioned towards the doorway. A thied matress should form a

bharkrect forthe lower bunk hed, The hackrestchowld he attached in upright postion in & way thal prevents

it from faling over (see figure 3),

“The mattresses should be made of nonfreretardant polyether and they should have a density of

‘approximately 33 kg/m’. The cotton fabric should not be fre retardant treated and it should have an area

‘elaht of 140 g/t 160 gl’. When tested according to ISO 5660-1 [ASTM E1354), the polyther foam

Should give results as given inthe table below. The frame of the bunk beds should be of sect nominally

2 mm thick

148 — Resolution 200119)

180 5660, Cone calorimeter test

Test conditione:Iradiance 35 kW/m’. Horizontal position,

Sample thickness SOmm. No frame retainer should be use

Test results Foam

Time to ignition (s) 2-6

3 minute average HR, gio kW/m?) 270+50

Effective heat of combustion (MI/ka) 2x3

Total heat release (Ml/m") Sox12

52. Condor test re source

“The cotidor re tests should be conducted using cit pled polyether mattress pieces measuring Om >

(0.4 m x 0.1 mas specified in 5.4.1, without fabric covers. The ple should be placed on a stand, 0.25 m

high, ord ina tec test basket 0 prevent the pile from fling over (see gure 4)

5.5 Test method

‘The folowing sels offre tess should be performed with automatic activation of the nozze(s) installed in

the cabin and/or corridor as indicated. Each fre should be ignited with a lighted match using an igniter

made of some porous materal, eg pieces of insulating floreboard. The igniter may be ether square or

‘ylindrcal, 60 mm square or 75 mm in diameter. The length should be 75 mm. Prioe to the test the igniter

Should be soaked in 120 ml of heptane and wrapped in aplastic bag and postioned as indicated for each

‘abin fre test For the corior fie tests, the igniter should be located inthe centre atthe base ofthe ple of|

the mattress pieces, and on ane side ofthe test stand atthe base ofthe pile of the mates pieces,

1 Lower bunk bed tes Fre arranged in one lower bunk bed and ignited withthe igniter located

a the front towards door) centreline of the plow.

2 Upper bunk bed tes Fire aranged in one upper bunk bed withthe igniter located atthe font

(towards door cenreine ofthe pile

3 Avsonis test Fre aranged by spreading 1 of white spirit evenly over one lower bunk bed and

backrest 20 prior to ignition. The igniter should be locate inthe lower bunk bed a the front

(towards door} centreline ofthe pillow.

4 Disabled nozzle test. The nozzles inthe cabin should be disabled. Fire arranged in one lower

bunk bed and ignited with the igniter located atthe ffont (towards door) centrelie of the

pilow.

nozzles Inthe cabin are linked with nozzles) the coridor such that a malfunction would

affect them ala cabin and condor nozzles inked should be disabled

5 Corridor test. Fire source located against the wall ofthe covidor under one nozzle,

6 Corridor test. Fie source located against the wall of the coridor between two nozzles.

“The fre tat shouldbe condliced fr 10 min after the activation of the fret anzzle nl any reining fe

should be extinguished manualy.

5.6 Acceptance criteria

‘Based on the measurements, a maximum 30 s average value should be calculated for each measuring point

‘which forms the temperature acceptance extra,

Resolution A 800(19) — 149

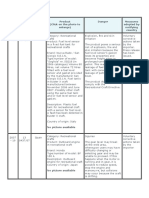

‘Acceptance criteria for the cabin and corridor tests

‘Maximum 30 ‘Maximum 30 s[ Maximum

snerage lg | org |main| Sceiaie

surace Surface | damage on

temperature |PE'SPPC.) temperature | maresses(%) | Other extra

inthe cabin | *"¢-8 igthe comdor | Lower [Upper

co CO" | bun | nk

Tower

360 320 120 | 40 | 10 | Nonozzes n

bank cogor

allowed to

Cabin Upper ‘

‘este | Yoo NA | 40 | “opeate

ed

Arsonist] NA NA 120 [NA [NA | NA

Corridor NA NA 120" NA Ony wo

independent

nozzles in

ride

allowed 12

operate

Disabled nazele | NA NA 400? NA NA

"tn each es the emperature shoud be measured above he fe source

2 The ee Yeo owed to propagate lng the condor beyond the ozzes closest tothe door opening,

2 not apple, ean nolo) ar ied 9 como no

“Not appable, condor nozzle) are hed eget.

Note: After the test the fie sources should be examined visually to determine compliance with the

requiced maximum damage. The damages should be estimated using the folowing formula:

‘Damage to lower bunk bed = (damage to horizontal matress (%) +0225 x damage to plow (7%) +

damage to backrest (%)/2.25

‘Damage to upper bunk bed ~ (damage to horizontal mattress (4) +0.25 x damage to pillow (%)]/

125

IC is not clearly obvious by visual examination whether the criteria are fulfled or not the test

should be repeated,

6 LUXURY CABIN FIRE TESTS

6.1 Test arrangement

‘These fre tests should be condycted ina 2.4 m high room having equal sides and a floor area of atleast,

25 m:, but not exceeding 80 m’. The room shouldbe fited with two doorway openings, in cross Comers

‘opposite the fie source. Each opening should be 0.8 m wide and 2.2 m high, which provides for @ 0.2 m

Intel above te openings Wals and clings shoul be mde of noncombusl, ominaly 12 mm ick

‘The test room celing should be covered 2.4 m out from the corer with cellulosic acoustical panels. The

Acoustical panels should be nominally 12 mm to 15 mm thick, and should not ignite when tested in

Accordance with IMO resolution A.53(16),

150 ~ Resolution A800(18)

Piywood panels should be placed on two ofthe test room walls and extending, 2.4 m out from the comer

‘wth the fre source. The panels should be approximately 3 mm thick, The Ignition me ofthe panel should

not be more than 35 $ and the fame spread time at 350 mm positon should not be more than 100 s as

measured in accordance with IMO resolution A.653(16) (see gure 5).

62 Instrumentation

During the ire tests the fllowing temperatures should be measured. Note thatthe instrumentation may be

dferent, dependent on which of two types of fre sources are Used

A. The ceiling material temperature above the ignition source should he measured using 30.8 mm

thermocouple embedded inthe caling. 6.50.5 mm from the surface.

2 The celing gas temperature should be measured using a 08 mm thermocouple located

754 1 mm below the celing within 0.2 m horizontally from the closest nozzle to the comer

3 The cceling surface temperature above the ignition source should be measured using a

thermocouple wth ameter not exceeding 05 mm embedded in the celing material such that

the thermocouple bead i sh withthe ceing surface.

4 The celing gas temperature should be measured using a 0.5 mm thermocouple located

75:1 mm below the celng within 02 m horizontal from the closest nozzle to the commer.

Measurements a accordance with 1 and 2 should apply when a fire source in accordance with 64. i

‘used and 3 and 4 when afr cource in accordance with 6.4.2 is used (se figure 5)

63 Nozzle positioning

The distance between the outer nozzle and the walls should be one half the maximum nozzle spacing

specified by the manufacturer. The distance between nozzles should be equal to the maximum spacing

Spee by the mance

"Nozzles should be positioned with their fame arms parallel and perpendicular withthe walls ofthe cabin.

(0F for nozzles without fame arms, so that the lightest cscharge density willbe directed towards the te

1¥ nonuniform instalation i selected by the manufacturer, the maximum spacing is established in the open

public space scenario.

64 Fire source

‘The fre source should consist of a wood crib and a simulated funiture ie, UL 1626 Residential Sprinkler

fuel package (7) or, alternatively, an upholstered chair (e. FM 2030 Residential fuel package [8

GALT Wood cribjimulated farture description

The wood cb should weigh approximately 6 ke and should be dimensioned 0:3 m x03 m x 03 m. The

cb should consist of eight alternate layers of four rade size nominal 38 mm x 38 mm klndlied spruce or

fr lumber 0.3 m long. The alteate layers of the lumber should be placed at right anglas tothe adiacent

layers. The indhidual wood members in each layer should be evenly spaced along the length of the

previous layer of wood members and stapled together.

After the wood crib is assembled, it shauld be conditioned ata temperature of 50:43°C for not less than

16h. Following the conditioning the moisture content of the rb thould be measured at various locations

with a probetype moisture meter The moisture content of the crip should not exceed 5% prior tothe fre

test The orb should be placed on top ofa 0.3 m x 0.2m, 0.1 mhigh steel et tay and positioned 25mm

from each wall

Resolution A.800(19) ~ 151

‘The simulated furniture should consist of two 76 mm thick uncavered polyether foam cushions having &

density of 16 kg/m’ to 20 ke/m?, 2 compressive strength of 147 N to 160 N, measuring 0.9 m x 1.0 m,

teh attached to 4 wood support ame. The wood suppaxt fame should havea rectangolar plywood face

‘measuring approximately 810 mm x_760 mm ono Which the foam cushions are applied. The cushions

should be stretched and stapled onto plywood panels which extend perpendicular tothe face towards the

‘opposite end of ihe frame by approximately 180 mm. Each cushion should overlap the 1p of the wood

frame by approximately 150 mm and the sides of the wood fame by approximately 180 mm.

This fuel package hes an uleafast fire growth, @ maximum heat relese in excess of 2.5 MW and a growth

time (time to reach 1 MW) of 80:10 s (see figure 5).

642. Uphoistered chair description

‘The fuel package consists ofthe following tems (se figure 6)

Tem Code No. of unis ‘Dimensions and description

Simulated sofa end s 1 19 mm plywood structure, open top and

otto, 610 mm x 914 mm, 610 mm

high

‘Chai recline c 1 (Customamade reclining. chair approx:

mately 760 rmx 314 rm, 990 mm

high. ll new materials consisting of vinyl

covering with cotton backing (4.54 kg

polyurethane fom (seat 2.27 hg, 127 mm

thick}; polyurethane (arms, 1.36 kg,

25 mm thick) pine structure; tora weight

23.8 ky, bull by Old Brussels of Stu

bridge, Massachusetts

nd tate E 1 Table wp: 19 mm panicle board,

1660 mmx 495 mm; table legs are

Softwood, Le pine, fr, etc, 38 mm x

38 mm, 314 mm high

Cunains ow 4 2 panes, rod pocket panels (1,016 mm

x_1/629 mm) fabric blend: 50% poly

ester, 50% cotton

2 panels sheer rod pocket panels

(1.016 mm x 1,829 mm), (100% pol.

ester batt)

“An equate cht may e spaced as 2 e source wh amu heat release ae Of 1.5 MW, 2 Regured Deleted

Const oS nln ads gow re (ne reach Y Mussa socond power pont ma) ofa TOE

65 Test method

‘The fie tests should be conducted fr 10 min after the acvaton of the rst nozzle, and any emaining ke

should be extinguished manual.

65:1 Wood crb/simulated furiture

0.2 of heptane should be placed on a 5 mm water base inthe test tray positioned directly below the wood

crib. Approximately 120 total of excesior (wood woo!) should be pulled apart and loosely positioned on

the Noor with approximately 60 g adjacent to each section of the smulatedfuriture.

The heptane should be ignited and 40 «later the excelsir should also be ignited,

152 — Resolution A.800(19)

65.2 Upholstered chair

Ignition should ake place using alighted match a the centre of two horizontal axially parallel and adjacent

103 mlong cotton wicks, each 9.3 mm in diameter, saturated with 25d of ethyl alcohol. The wick should be

positioned atthe bate of the chai as described in figure 6, within 2 min prior to ignition,

66 Acceptance criteria

Based on the measurements a maximum of 30 s average value should be calculated for each measuring

Point which forms the temperature acceptance erteria,

‘Max. 30. average ceiling | Max 30 average calling

Fire source smaterial/surace temperature ‘gs temperature

to ce)

As per 6.41 I 260 320

AS per 64.2 260 320

7 PUBLIC SPACE FIRE TESTS

7.1 Test atrangements

The fie tests should be conducted in a wellvented building under aceling fat least 80 min area with no

dimensionless than 8 m, There should be atleast a1 m space between the perimeter of the celing and any

wal ofthe test bulding. The cling height should be set at 25 m and 5.0 m respectively

wo diferent tess should be conducted as per 71.1 and 7.1.2

7.4.1 Open public space test

‘The fre source should be poskioned under the cente of the open celing so that there s an unobstructed

flow of gases across the ceiing The celing should be constructed from a non-combustible material

7A2_ Comer publi space test

The test should be conducted in a comer constructed by two at least 3.6 m wide, pominaly 12 ram thick,

noncombustible wall bard

Plywood panel should be placad on the wall, The panels should be approximately 3 mm thick The

Ignition time of the panel should not be more than 33 sand the fame spread time at 350 mm position

should not be more than 100 s measured in accordance with IMO resolution A(653(16),

The ceiling shouldbe covered, 3.6 m out from the corer, with cellulosic acoustical panels. The acoustical

panels should be nominally 12 mm to 15 mm thick and should not ignite when tested in accordance with

IMO resolution A.653(16)

7.2 Instrumentation

During each fie tes, the following temperatures should be measured using thermocouples with diameter

not exceeding 05 mm,

7.21 Open public space test

1 The calling surface temperature above the ignition source should be meatuted using a

‘thermocouple embedded in the coling material such thatthe thermocouple bead is fush with

the celng surlace

Resolution A.800(19) ~ 153

2 The ceiling gas temperature should be measured using a thermocouple located 75:1 mm

below the ceing 1.8 m from Ignition.

72.2 Comer public space test

1 The celing surface temperature above the ignition source should be measured using a

thermocouple embedded in the celing material such that the thermocouple bead is Mush with

the ceting surface.

2 The celng gas temperature should be measured using a thermocouple located 75.¢1 mm

below the celing wid 0.2 mn Inxizontally Irn Ure closes noel to Be corner

73. Noule positioning

For nozzles with rame arms, tess should be conducted with the frame arms positioned both perpendiculr

and parle! with the edges of the ceiling oc corner walls for nozrles without framed acm, the nozzles

should be oriented so tht the lightest discharge density will be diected towards the fe area,

74 Fire sources

74.1 Open public space

‘The fire source should consst of four sofas mad of mattresses as specified in 54.1 installed in ste! fame

‘sofas The sofas shouldbe positioned as shown in figure 7 spaced 25 mm apart.

‘One of the middle sofas should be Ignited, centric and atthe bottom ofthe backrest, with an igniter as

described in 5.5

7.2. Comer public space test

The fie source should consist ofa sofa 85 specified in 7.4.1, placed with the backrest 25 mm from the right

hand wall and close up to the lft hand wall. target soa shouldbe placed along the righthand wall with

the seat cushion 0.1 m from the frst sofa and another target sofa should be placed 05 m from it on the left

hand side. The sofa should be ignited using an igniter, as described in 5.5, that shoul be placed a the far

left of the comer sofa, at the base ofthe backrest, near the lft hand wall (see figure 8).

7.5 Test method

“The fire tess should be conducted for 10 min after the activation ofthe fist nozzle, and any remaining fire

should be extinguished manual.

7.5. Open public space sts

Fire tests should be conducted withthe ignition centred under one. between two and below four nozzles.

75.2 Comer public space test

‘Two fire tere should be conducted with at leat four nozzles arranged in a2 x 2 matin. For the second fe

test, the nozzle closest o the comer should be disabled

7.6 Acceptance criteria

‘Based on the measurements, maximum 30 s average value should be calculated for each meseuring point

which forms the temperature acceptance crite

154 — Resolution A.200(19)

7.6.1. Acceptance rteria forthe public space tests

| Maximum 30s] — Maximum 308

MU 30S simu ceptable

surtace temperate gutemperstume | dame on matiewee

ro co

Open space 360 2207 50/35"

rma x0 20 5075 ron st)

comer No char trget ss

(tied vont | __NA NA 0 gst)

507% 8 te upper fo any sgl est. 3576 he upper forth average of the publi space tess aque in 7 and 9

fect clog Right ads Be Sasicd sper meee

Tig stomp ule mene i lt potion andthe eon thread on ehh

INA. Not aplisbe

8 SHOPPING AND STORAGE AREA FIRE TESTS

8.1 Test arrangements

[As per 7:1 but with 2.5 m celing height only

82 Instrumentation

No temperature measurements are required.

23 Nowe positioning

As per 73.

84 Fire source

The fie source should consst of two central, 1.5 m high, solid piled stacks of cardboard boxes packed with

polystyrene unexpanded plasic cups with a 0.3 m flue space. Each stack should be approximately 1.6 m

fong and 1.1 m to 1.2 m wide

‘A suitable plastic commodity is the FMRC standard plastic commodity [9]. Similar commodities might be

used if they are designed in a similar way and are proven to have the same burning characteristics and

suppressablity

The fie source shouldbe sus ouncded by sx 1.5 high sold piled stacks of empty cardboard boxe fori

a target aray to determine the fe wl jump the alse. The boxes should be atached to each other, or

‘@ample by staples, 10 prevent them trom fling over {see figure 9)

5 Test method

Fie tests should be conducted with te ignition centred under one, between two and below four nozzles,

ach fre shouldbe ignited with alighted match using rwo Igners as described In 55. The ignites should be

located placed on the Moor, each against the base of one of the two cenval stacks and: Ignited

simultaneous)

‘The fire teste should be conducted fr 10 min after the activation ofthe fet nozzle, and any reining fine

should be extinguished manual

Resolution A.800/19) ~ 135

86 Acceptance criteria

4

2 No more than 50% ofthe cartons filed with plastic cups should be consumed.

9 VENTILATION TesT

‘One corner public space es 7 and the coridar space test which has given the worst result among those

in 5.42 should be repeated with the ambient aie having 2 minimum velaciy of 0.3 m/s

‘The ambiont air velocity inthe public space ests should be measured 1 above the for and 1m below

the colng ata location 5 m out rom the comer, midway between the enclosure walls Ar veloc nthe

corridor should be measured atthe micsheght.

9.1 Acceptance criteria

‘The fre should not progress to the edge ofthe combustible wall or ceiling.

10 REFERENCED PUBLICATIONS

IN] Interaonal Convention forte Sole fife at Se (SOLAS, tration Matime Orgarzaton

London.

(2) Solomon, Robert £, Automatic Sprinkler Systems Handbook, National Fire Protection Association,

Rattorymarch Park, Quiney, MA. USA, Sth edition, 1991,

IB] ANSVUL 723, Surface Burning Characteristics of Building Materia

[4] 150 6182/1, February 1994 edition.

[5], 150 56601, Fe Tests - Reaction to Fire Rate of Hoat Release fom Building Products (Cone

(Calorimeter Method}, 1st eon, 1993

[6] Babrauskas, Vand Wetterund, 1, Instructions for Cone Calorimeter Testing of Furniture Samples,

(CBUF Consort, SPAR 1999: 63, Bris, Sweden, 1993

17] Standard for Resienta Sprinklers for Fe-Proection Service, UL 1626, Underwsters Laboratories Inc,

Northbrook, IL, USA, December 28, 1990 revision,

[8] Approval Standard for Residental and Limited Water Supply Automatic Sprinklers, Class 2030, Factory

‘Mutual Research Corporation, Norwood, MA, USA, January 27, 1993,

[9] Chicarelo, Peter), and Troup, Joan, MA, Fire Products Collector Test Procedure for Determining the

‘Commodity Classicaion of Ordinary Combustible Products, Factory Mutual Research Corporation,

Nonwood, MA, USA, August 1990

156 — Resolution A.800(19)

Figure 1

is

Figure 2

Resolution 20019) ~ 157

sera

158 ~ Resolution A 80019)

Cling metoria temp, thermocouple

Lzsom

60m) | Cling gos ome, messoremens

= 1 mm below cating. 18 m

= ‘

| _

| a

ome

ae

unl leg

i

, iL

Figure §

(shown with wood crib/simulated furniture)

Resolution A.800(19) — 159

l!

wt

——

I

Bik

Pi

me

Ly i

Lot hand,

target sof

| Celing sutac temo.

thermocouple

‘joe robe

‘poe io

>

Plan view

|| ee

AA

Figure 8

Resolution A 800/19) — 161,

25m

i |

[il carsboard cartons packed with polstvrene plastic cups

[Lemony boxes as target arrays

Figure 9

162 ~ Resolution 4.80018)

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Consolidated TEXT: ConslegDocument34 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- En 1998L0041 Do 001 PDFDocument9 paginiEn 1998L0041 Do 001 PDFCostinRotaruÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Consolidated TEXT: ConslegDocument21 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Consolidated TEXT: ConslegDocument18 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- En 2002R0417 Do 001 PDFDocument10 paginiEn 2002R0417 Do 001 PDFCostinRotaruÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- En 1997L0070 Do 001 PDFDocument42 paginiEn 1997L0070 Do 001 PDFCostinRotaruÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- En 1996L0098 Do 001 PDFDocument71 paginiEn 1996L0098 Do 001 PDFCostinRotaruÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- En 1996D0587 Do 001 PDFDocument4 paginiEn 1996D0587 Do 001 PDFCostinRotaruÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Consolidated TEXT: ConslegDocument6 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Consolidated TEXT: ConslegDocument9 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- ICSMS Exchange Information SystemDocument24 paginiICSMS Exchange Information SystemCostinRotaruÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Consolidated TEXT: ConslegDocument31 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- Consolidated TEXT: ConslegDocument15 paginiConsolidated TEXT: ConslegCostinRotaruÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- ETSI ETS 300 067 Ed (1) .1 (1990-11)Document53 paginiETSI ETS 300 067 Ed (1) .1 (1990-11)CostinRotaruÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- 40 CFR 94 PDFDocument81 pagini40 CFR 94 PDFCostinRotaruÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Placing On The Market - IMEC GuideDocument4 paginiPlacing On The Market - IMEC GuideCostinRotaruÎncă nu există evaluări

- EN EN: Commission of The European CommunitiesDocument26 paginiEN EN: Commission of The European CommunitiesCostinRotaruÎncă nu există evaluări

- MSC 1151-1175 PDFDocument255 paginiMSC 1151-1175 PDFCostinRotaruÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- ICOMIA Standard No (1) - 46 98Document4 paginiICOMIA Standard No (1) - 46 98CostinRotaruÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Koelbel - Boat Design Reflected - 1999Document3 paginiKoelbel - Boat Design Reflected - 1999CostinRotaruÎncă nu există evaluări

- COUNCIL DIRECTIVE 96/98/EC of 20 December 1996 On Marine EquipmentDocument71 paginiCOUNCIL DIRECTIVE 96/98/EC of 20 December 1996 On Marine EquipmentCostinRotaruÎncă nu există evaluări

- EUROPEAN RECREATIONAL INLAND NAVIGATION NETWORK Resolution No. 52Document5 paginiEUROPEAN RECREATIONAL INLAND NAVIGATION NETWORK Resolution No. 52CostinRotaruÎncă nu există evaluări

- Economic Impact Analysis of Recreational Boating in Canada: 2001Document4 paginiEconomic Impact Analysis of Recreational Boating in Canada: 2001CostinRotaruÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- IMO Res (1) - MSC.36 (63) Chapter 8Document10 paginiIMO Res (1) - MSC.36 (63) Chapter 8CostinRotaruÎncă nu există evaluări

- 2007 RAPEX AgrementDocument3 pagini2007 RAPEX AgrementCostinRotaruÎncă nu există evaluări

- 1998 Machinery Directive 98/37/EC GuideDocument266 pagini1998 Machinery Directive 98/37/EC GuideCostinRotaruÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)