Documente Academic

Documente Profesional

Documente Cultură

New Catalyst Could Split Water Cheaply

Încărcat de

Bruna RodriguesDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

New Catalyst Could Split Water Cheaply

Încărcat de

Bruna RodriguesDrepturi de autor:

Formate disponibile

New Catalyst Could Split Water Cheaply

Umair Irfan,ClimateWire

The mysterious workings of a new catalyst could help produce fuels from water and

improve fuel cells, scientists say.

Splitting water into its constituent hydrogen and oxygen elements is an important

starting point for the development of clean renewable fuels. Producing hydrogen from

water could also become a method to store excess renewable energy.

Its a process plants have already mastered via photosynthesis and humans are now

working to replicate.

While photosynthesis is extremely good at oxidizing water, the truth is many man-

made processes of doing these things are not that good, said Thomas Jaramillo, a

researcher at the SUNCAT Center for Interface Science and Catalysis in Stanford

Universitys Department of Chemical Engineering.

Many of the artificial methods of making hydrogen and oxygen from water require

materials that are too expensive, require too much energy or break down too quickly in

real-world conditions, like the acidic electrolytes in fuel cells.

But splitting water to generate hydrogen may be an important way to cut greenhouse

gas emissions. Jaramillo observed that the world produces more than 50 billion

kilograms of hydrogen each year and more than 95 percent of it comes from fossil fuels

through processes like steam reforming methane.

Jaramillo and his collaborators sought to develop a catalyst for the oxygen evolution

reaction, the notoriously slow half of the water-splitting process. A catalyst is a

substance that speeds up a chemical reaction or lowers the energy required to get it

started without getting used up itself. Making these materials last longer, work faster

and use less energy would cut prices and improve efficiency in producing renewable

hydrogen.

In a paper published last week in the journal Science, the research team presented an

oxygen evolution catalyst that worked in harsh conditions and beat all of its

competitors.

The biggest achievement in this paper is that we were able to find a stable catalyst that

works in acid, said co-author Yasuyuki Hikita, a staff scientist at SLAC National

Accelerator Laboratory. The activity that we found has been record-breaking.

In an oxygen evolution reaction catalyst, one of the key benchmarks is the

overpotential, or the amount of electricity needed to drive the reaction. The past record

was 320 millivolts, but the new catalysts only needed between 270 and 290 millivolts of

overpotential to reach the same level of oxygen production.

Hikita said this is a huge improvement in efficiency and would drastically cut the

energy needed in a potential hydrogen production plant that would run around the clock.

The catalyst in this case was a thin film crystal, grown to be as flat as possible, with one

layer made from iridium oxide and another layer made from strontium iridium oxide.

With a flat, thin crystal, researchers had a better standard of comparison for their

simulations.

Iridium oxide is the only known catalyst that works in acid, Hikita said.

In their experiments, the researchers also found that the catalysts performance

improved over time. Measurements showed that the surface of the catalyst changed, but

the mechanism thats sped up oxygen evolution is unclear. Microscopically, were not

sure why at this point, Hikita said. Part of the strontium goes out into the solution.

The researchers are now working to make their oxygen evolution catalyst more efficient

and less expensive, as well as teasing out the physics of what makes the material work

so well. Iridium is still a very expensive metal, Hikita said. How much can we

reduce the amount of iridium to achieve the same results? For practical industrial

applications, we need to go much, much lower.

Theres much further room ahead than there is behind in terms of developing a better

catalyst, Jaramillo said. You can imagine a catalyst a million times better than the one

we made.

S-ar putea să vă placă și

- Scientists Discover A New, Sustainable Way To Make Hydrogen For Fuel Cells and FertilizersDocument3 paginiScientists Discover A New, Sustainable Way To Make Hydrogen For Fuel Cells and FertilizersParthaÎncă nu există evaluări

- Catalyst Energy FuelDocument2 paginiCatalyst Energy Fuelapi-319565214Încă nu există evaluări

- The Biggest Clean Energy Advances in 2016Document5 paginiThe Biggest Clean Energy Advances in 2016Javier A MoraÎncă nu există evaluări

- Meeg 442 Term Paper - Turning Over A New LeafDocument17 paginiMeeg 442 Term Paper - Turning Over A New Leafapi-233129849Încă nu există evaluări

- Bionic LeafDocument24 paginiBionic LeafJHuvieCLaireÎncă nu există evaluări

- Visual Encyclopedia of Chemical Engineering Catalysts: General InformationDocument7 paginiVisual Encyclopedia of Chemical Engineering Catalysts: General InformationVanÎncă nu există evaluări

- Reading Two PDFDocument2 paginiReading Two PDFindah muliaÎncă nu există evaluări

- Researchers Solve A Major Hurdle in Producing Clean Hydrogen - by Faisal Khan - Technicity - Aug, 2021 - MediumDocument4 paginiResearchers Solve A Major Hurdle in Producing Clean Hydrogen - by Faisal Khan - Technicity - Aug, 2021 - Mediumpang sai siong pang sai siongÎncă nu există evaluări

- Auto HydrogenDocument57 paginiAuto HydrogenRealSolutionÎncă nu există evaluări

- Single-Atom Catalysis: A Forthcoming Revolution in ChemistryDe la EverandSingle-Atom Catalysis: A Forthcoming Revolution in ChemistryÎncă nu există evaluări

- NoceraCatalyst073108 PDFDocument2 paginiNoceraCatalyst073108 PDFGopi KrishnaÎncă nu există evaluări

- Literature Review Hydrogen Fuel CellDocument7 paginiLiterature Review Hydrogen Fuel Cellc5rga5h2100% (1)

- Research Paper On Green Engine Technology PDFDocument6 paginiResearch Paper On Green Engine Technology PDFwpuzxcbkf100% (1)

- Magnetic Nanoparticle Based CatalystDocument3 paginiMagnetic Nanoparticle Based CatalystIsabel GarcíaÎncă nu există evaluări

- Chemistry ArticlesDocument4 paginiChemistry ArticlesMatthew EbertÎncă nu există evaluări

- Zeolite PHD ThesisDocument5 paginiZeolite PHD Thesisdwtcn1jq100% (2)

- Artificial Photosynthesis Final 1 Ppt-1Document18 paginiArtificial Photosynthesis Final 1 Ppt-1Vipul0% (1)

- PEMFC Research Proposal Final 2010Document13 paginiPEMFC Research Proposal Final 2010Bradley Hallier100% (1)

- Membrane Reactor Configuration For Separation of H2S CO2 and H2Document56 paginiMembrane Reactor Configuration For Separation of H2S CO2 and H2AbdelSamed MohamedÎncă nu există evaluări

- CHE June09 - CHM Progress in Underground Coal GasificationDocument4 paginiCHE June09 - CHM Progress in Underground Coal GasificationJUÎncă nu există evaluări

- Modification of I C Engine To Run With Water As Supplement Fuel To Increase Its Efficiency Using HHO KitDocument5 paginiModification of I C Engine To Run With Water As Supplement Fuel To Increase Its Efficiency Using HHO KitNam stareÎncă nu există evaluări

- The Future of Hydrogen Fuel UNSW Researchers Develop Technique To Analyse Hydrogen Fuel Cell StabilityDocument4 paginiThe Future of Hydrogen Fuel UNSW Researchers Develop Technique To Analyse Hydrogen Fuel Cell StabilitySab-Win DamadÎncă nu există evaluări

- By Anji Reddy Thatiparthy 11011D8012 M.Tech (Mechatronics)Document23 paginiBy Anji Reddy Thatiparthy 11011D8012 M.Tech (Mechatronics)anji_thatiparthyÎncă nu există evaluări

- Inoraganic AssignmnetDocument2 paginiInoraganic AssignmnetJlibran QamarÎncă nu există evaluări

- Artificial PhotosynthesisDocument16 paginiArtificial PhotosynthesisNoli Frias Claridad0% (1)

- Air Pollution by Grade 6Document4 paginiAir Pollution by Grade 6Eljay VinsonÎncă nu există evaluări

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationDe la EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationÎncă nu există evaluări

- Urea Electrolysis: Schematic Representation of The Direct Urea To Hydrogen ProcessDocument4 paginiUrea Electrolysis: Schematic Representation of The Direct Urea To Hydrogen Processramnadh803181Încă nu există evaluări

- Development of New Sorption Materials For Refrigeration PurposeDocument7 paginiDevelopment of New Sorption Materials For Refrigeration PurposeMaheshÎncă nu există evaluări

- 2012 Petruccietal Afeasibilitystudy CETDocument7 pagini2012 Petruccietal Afeasibilitystudy CETMuhammad RehanÎncă nu există evaluări

- Ref 3 RDDocument8 paginiRef 3 RDFerdi habibÎncă nu există evaluări

- Explainer - What Is A Catalyst - Science NewsDocument2 paginiExplainer - What Is A Catalyst - Science NewsJerwynn LauÎncă nu există evaluări

- Solar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationDe la EverandSolar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationÎncă nu există evaluări

- Enviroeconomic and Exergoeconomic Based Analytical Study of Double Slope Solar Distiller Unit Using Al2O3 NanoparticlesDocument15 paginiEnviroeconomic and Exergoeconomic Based Analytical Study of Double Slope Solar Distiller Unit Using Al2O3 NanoparticlesIJRASETPublicationsÎncă nu există evaluări

- RRLDocument3 paginiRRLArianne Rose TalledoÎncă nu există evaluări

- ADVANCES in Solar Energy Vol 17Document337 paginiADVANCES in Solar Energy Vol 17proleceo11Încă nu există evaluări

- Kanarev Water EnergyDocument11 paginiKanarev Water EnergyharishkumarsinghÎncă nu există evaluări

- (2019-11p) IOP MSE - Subcritical Water...Document7 pagini(2019-11p) IOP MSE - Subcritical Water...ClearyÎncă nu există evaluări

- Hydrogen PDFDocument8 paginiHydrogen PDFbrumbrumÎncă nu există evaluări

- Effective Utilization of By-Product Oxygen From Electrolysis Hydrogen ProductionDocument19 paginiEffective Utilization of By-Product Oxygen From Electrolysis Hydrogen ProductionJafar JilaniÎncă nu există evaluări

- Advanced Oxidation Processes For Wastewater TreatmDocument5 paginiAdvanced Oxidation Processes For Wastewater TreatmhusseinhshÎncă nu există evaluări

- Hydrogen Production by A PEM ElectrolyserDocument7 paginiHydrogen Production by A PEM ElectrolyserAdrián HerreroÎncă nu există evaluări

- Hydrogen Energy: Challenges and Solutions for a Cleaner FutureDe la EverandHydrogen Energy: Challenges and Solutions for a Cleaner FutureÎncă nu există evaluări

- How To Make The Most Of: Carbon DioxideDocument3 paginiHow To Make The Most Of: Carbon Dioxidetorta1Încă nu există evaluări

- Breathing Battery' Advance Holds Promise For Long-Range Electric CarsDocument4 paginiBreathing Battery' Advance Holds Promise For Long-Range Electric CarsRavi Kanth M NÎncă nu există evaluări

- Literature Review PyrolysisDocument8 paginiLiterature Review Pyrolysisafmznqfsclmgbe100% (1)

- ICESEN37 AjatSudrajatDocument18 paginiICESEN37 AjatSudrajatPeter DouseÎncă nu există evaluări

- Research Papers On Fuel CellsDocument5 paginiResearch Papers On Fuel Cellsxkcwaaqlg100% (1)

- Hydrogen Peroxide From Fuel CellDocument12 paginiHydrogen Peroxide From Fuel CellAnnas FauzyÎncă nu există evaluări

- Analysis and Assessment of A Novel Hydrogen Liquefaction ProcessDocument10 paginiAnalysis and Assessment of A Novel Hydrogen Liquefaction ProcessDilla WahabÎncă nu există evaluări

- Nitrogen Fixation Research PaperDocument5 paginiNitrogen Fixation Research Papergvzz4v44100% (1)

- What Is Nanotechnology?Document4 paginiWhat Is Nanotechnology?janine mujeÎncă nu există evaluări

- Hydrogen Storage in MG Based AlloysDocument110 paginiHydrogen Storage in MG Based AlloysCindy FengÎncă nu există evaluări

- T421 Prospects of Ammonia Based Ocean Thermal Energy ConversionDocument20 paginiT421 Prospects of Ammonia Based Ocean Thermal Energy ConversionBenito Antonio Formoso LouroÎncă nu există evaluări

- Chemistry Breakthroughs in The Last 10 Years 1500 WordsDocument6 paginiChemistry Breakthroughs in The Last 10 Years 1500 WordsIrungu MugiÎncă nu există evaluări

- Activated Carbon ThesisDocument7 paginiActivated Carbon Thesischristinabergercolumbia100% (1)

- Internship Report NML Nikita RajDocument30 paginiInternship Report NML Nikita RajAVINASH KUMAR100% (1)

- Aqua CatDocument4 paginiAqua Catlonely3Încă nu există evaluări

- Impact Fall06Document8 paginiImpact Fall06Steven RankineÎncă nu există evaluări

- How The Suburbs Could Help Save BiodiversityDocument5 paginiHow The Suburbs Could Help Save BiodiversityBruna RodriguesÎncă nu există evaluări

- The Future of Meat (EpDocument31 paginiThe Future of Meat (EpBruna RodriguesÎncă nu există evaluări

- Rethinking The Infamous Milgram Experiment in Authoritarian TimesDocument3 paginiRethinking The Infamous Milgram Experiment in Authoritarian TimesBruna RodriguesÎncă nu există evaluări

- The Zero-Minute Workout (EpDocument23 paginiThe Zero-Minute Workout (EpBruna RodriguesÎncă nu există evaluări

- Notes From An Imperfect Paradise (EpDocument30 paginiNotes From An Imperfect Paradise (EpBruna RodriguesÎncă nu există evaluări

- Theranos and Elizabeth Holmes Charged With Fraud - Scientific AmericanDocument8 paginiTheranos and Elizabeth Holmes Charged With Fraud - Scientific AmericanBruna RodriguesÎncă nu există evaluări

- Does Parkinson's Begin in The GutDocument7 paginiDoes Parkinson's Begin in The GutBruna RodriguesÎncă nu există evaluări

- Eye EssayDocument6 paginiEye Essayppggihnbf100% (2)

- Lab ManualDocument96 paginiLab ManualASWANI RAJAN50% (2)

- The Dark Side of NTPC PDFDocument50 paginiThe Dark Side of NTPC PDFCFA IndiaÎncă nu există evaluări

- Heat ExchangerDocument11 paginiHeat ExchangerMangesh MandgeÎncă nu există evaluări

- Science 8 WorkbookDocument46 paginiScience 8 WorkbookPradeep WalaweÎncă nu există evaluări

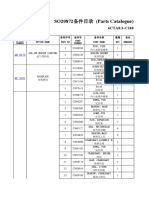

- 6CTA8.3-C240 FRO CLG862 40c0273en Parts CatalogueDocument80 pagini6CTA8.3-C240 FRO CLG862 40c0273en Parts CataloguePurnama AbhieÎncă nu există evaluări

- KCA Bladder Tanks en 2010Document11 paginiKCA Bladder Tanks en 2010NovancyÎncă nu există evaluări

- Liebert Gxt4 5kva 10kvaDocument50 paginiLiebert Gxt4 5kva 10kvaAllamÎncă nu există evaluări

- ZF AVS Automatic Gearbox ManualDocument67 paginiZF AVS Automatic Gearbox Manualdaniel_ting_191% (22)

- NIT Patna Department of Mechanical Engineering Subject-Turbo MachinesDocument26 paginiNIT Patna Department of Mechanical Engineering Subject-Turbo MachinesAjitKumarPandeyÎncă nu există evaluări

- Mid Term Exam Preparation SeatworkDocument1 paginăMid Term Exam Preparation SeatworkFour AyesÎncă nu există evaluări

- Thornycroft90 108 PDFDocument42 paginiThornycroft90 108 PDFvadim vadimÎncă nu există evaluări

- G5 Low Profile Unit Cooler Ver 2.0Document10 paginiG5 Low Profile Unit Cooler Ver 2.0Wawan NuryanaÎncă nu există evaluări

- Resin Infusion MoldingDocument111 paginiResin Infusion MoldingAnkitChoudhary100% (2)

- Scroll SolenoidDocument11 paginiScroll SolenoidRauf AlirzayevÎncă nu există evaluări

- 0705 Oil ReportDocument12 pagini0705 Oil ReportAnonymous oUJSCyZÎncă nu există evaluări

- Partial Discharge Theory and Applications To Electrical SystemsDocument15 paginiPartial Discharge Theory and Applications To Electrical SystemsjonathanmartinÎncă nu există evaluări

- AH-RESI DatasheetDocument2 paginiAH-RESI DatasheetRahul ShelkeÎncă nu există evaluări

- P & I DiagramsDocument26 paginiP & I Diagramsengrfarhansiddiqui100% (3)

- Instruction Manual For 4 Stroke, 4 Cylinder, Mpfi Petrol Engine Test RIGDocument47 paginiInstruction Manual For 4 Stroke, 4 Cylinder, Mpfi Petrol Engine Test RIGAbhishek ShuklaÎncă nu există evaluări

- Apb Calculation (Natural Gas)Document8 paginiApb Calculation (Natural Gas)Nasrul HazimÎncă nu există evaluări

- WAG-9 at A GlanceDocument29 paginiWAG-9 at A GlancePrem VeerÎncă nu există evaluări

- Energy Valorization of Biogas in Santa CatarinaDocument10 paginiEnergy Valorization of Biogas in Santa CatarinagrimdorlfÎncă nu există evaluări

- Soil Colloid AVIDocument5 paginiSoil Colloid AVIMonika KshetriÎncă nu există evaluări

- Recent Advances in Enhanced Flooded Battery For Smart Mild Hybrid Power TrainsDocument29 paginiRecent Advances in Enhanced Flooded Battery For Smart Mild Hybrid Power Trains3 GamerÎncă nu există evaluări

- EN 16407 HOIS PresentationDocument26 paginiEN 16407 HOIS PresentationEsin DenizÎncă nu există evaluări

- 1-Field Life CycleDocument18 pagini1-Field Life CycleAlberto100% (2)

- Sealing For Hydropower EquipmentDocument28 paginiSealing For Hydropower EquipmentJenny Cecilia Ureña ZuriÎncă nu există evaluări

- Chapter8-Kaplon Turbine10Document10 paginiChapter8-Kaplon Turbine10fazarbadhushaÎncă nu există evaluări

- Shielding Design GeneralDocument22 paginiShielding Design GeneralAbu OmarÎncă nu există evaluări