Documente Academic

Documente Profesional

Documente Cultură

Issue 6 June 2011 - Conveyor Belt Tensioning and Take Up Guide PDF

Încărcat de

Petros IosifidisTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Issue 6 June 2011 - Conveyor Belt Tensioning and Take Up Guide PDF

Încărcat de

Petros IosifidisDrepturi de autor:

Formate disponibile

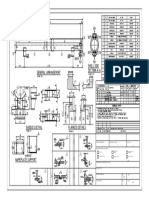

TekBulletin

June 2011 Issue 6 Page 1

Conveyor Belt Tensioning Systems

The conveyor belt distance of the conveyor and the

type of belt (see calculation).

tensioning system

The screw take-up on shorter

or take-up device is belts is normally located at the

a vital component in tail end. Tracking of the belt with

the screw take-up should only be

ensuring optimium performed as a last resort as it may

belt performance. cause permanent belt stretch.

associated tracking problems.

The GTU performs best located The GTU should be protected

The role of the take-up device close to the drive drum. The GTU with a return belt plough and

is to create and maintain bend pulleys will have a minimum must be adequately guarded.

adequate pre-tension to allow diameter based on the belt

the conveyor drive pulley to specification. Movement of the GTU

drive the belt under all running on both the vertical and horizontal

conditions (empty or loaded). axis should be limited to 10mm

to avoid excessive movement and

Generally there are two main

types of take-up. The fixed type

(normally refered to as a screw

take-up STU) and the automatic

or Gravity take-up (GTU).

The screw take-up is normally used

on short conveyors up to a length

of 50m. Over 50m an automatic

take-up system should be used

to ensure constant pre-tension.

The length of the take-up

depends on the both the centre

TekTip The GTU length can store spare belt to ConveyorTek Limited

facilitate the replacement of a vulcanised Unit 1 Ballinderry Industrial Estate

2a Glenavy Road

splice without the need for additional belting Upper Ballinderry

Lisburn, County Antrim, BT28 2EU

Tel UK: 028 92 652666 Tel ROI: 048 92 652666 Email: sales@conveyortek.com

Fax UK: 028 92 652555 Fax ROI: 048 92 652555

www.conveyortek.com

Appointed conveyor belt distributors for

A MEMBER OF THE SEMPERIT-GROUP

TekBulletin

June 2011 Issue 6 Page 2

Conveyor Belt Tensioning Systems

For fabric belts the following calculation may be

used to estimate the length of take-up required.

Recommended minimum take-up distance:

*Ltu = L x 1.5% Where

Ltu = Take-up length

100 L = Centre distance

*For conveyors L< 10m add approximately 100-200mm to Ltu

The possibility of adjusting the would have a minimum conveyor maintain a constant belt sag

belt tension under normal running take-up length (Ltu) of 1.8m from between the idlers (normally q/s

conditions should be around 0.8% to the calculation above. Therefore = 1- 2%) hence calculating the

1.2%. This is important in estimating adequate provision should be made correct weight is important.

the position of the take-up especially for an adjustment of 0.96m-1.44m

A GTU underweight will lead

during the installation of a new belt. (0.8-1.2%) when positioning the GTU.

to excessive belt sag thus

For example, a conveyor with a GTU Weight and Belt Sag (q/s) increasing belt bend resistance

centre distance length of 120m The weight of the GTU should and reducing overall belt and

idler life. A GTU overweight will

lead to excessive belt tension

resulting in belt and joint stretch.

To calculate the correct

weight please contact your

Belt Sag q/s= 1-2% Top Run Idlers ConveyorTek Engineer.

TekTip Ensure all take-up ConveyorTek Limited

Unit 1 Ballinderry Industrial Estate

devices are adequately guarded. 2a Glenavy Road

Upper Ballinderry

Lisburn, County Antrim, BT28 2EU

Tel UK: 028 92 652666 Tel ROI: 048 92 652666 Email: sales@conveyortek.com

Fax UK: 028 92 652555 Fax ROI: 048 92 652555

www.conveyortek.com

Appointed conveyor belt distributors for

A MEMBER OF THE SEMPERIT-GROUP

S-ar putea să vă placă și

- C3048 PNJ CAL B 0002 B Conveyor 11 CV 01Document30 paginiC3048 PNJ CAL B 0002 B Conveyor 11 CV 01Joel MooreÎncă nu există evaluări

- DR Dusan Ilic BE MECH PHD MIEAust Transfer Chute Analysis Techniques Including Continuum Modelling and The Discrete Element Method DEMDocument20 paginiDR Dusan Ilic BE MECH PHD MIEAust Transfer Chute Analysis Techniques Including Continuum Modelling and The Discrete Element Method DEMPaul Ticla PuenteÎncă nu există evaluări

- Conveyor Pulleys AGS 051Document36 paginiConveyor Pulleys AGS 051jonodo890% (1)

- Manual de Uso de Chute MavenDocument33 paginiManual de Uso de Chute MavenMiguel FarahÎncă nu există evaluări

- Product List: 1 Potech Conveyor 2Document3 paginiProduct List: 1 Potech Conveyor 2Ratumas Maharani SaskiaÎncă nu există evaluări

- Impumelelo PDFDocument13 paginiImpumelelo PDFsigitÎncă nu există evaluări

- Alimentador VibratorioDocument24 paginiAlimentador VibratoriojgarciacochachiÎncă nu există evaluări

- Belt ConveyorsDocument7 paginiBelt ConveyorsPMA1Încă nu există evaluări

- Brochure Transfer Point l3649 Transfer PointDocument20 paginiBrochure Transfer Point l3649 Transfer PointEdson MirandaÎncă nu există evaluări

- Ansys WorkbenchDocument3 paginiAnsys WorkbenchAditya DandekarÎncă nu există evaluări

- Addressing Plugging Wear Spillage TransferchutesDocument43 paginiAddressing Plugging Wear Spillage Transferchutesmishra_1982Încă nu există evaluări

- Feeder or Conveyor: What's The Difference and Why Does It Matter?Document4 paginiFeeder or Conveyor: What's The Difference and Why Does It Matter?Neeraj AgrawalÎncă nu există evaluări

- As 3638-1993 Test Sieving ProceduresDocument7 paginiAs 3638-1993 Test Sieving ProceduresSAI Global - APACÎncă nu există evaluări

- Slurry Pumps MCU Introduction (English)Document33 paginiSlurry Pumps MCU Introduction (English)Jose Antonio RojasÎncă nu există evaluări

- Solutions For Detecting Rips in ConveyorDocument10 paginiSolutions For Detecting Rips in ConveyorJuan CarlosÎncă nu există evaluări

- Transfer Station DesignDocument5 paginiTransfer Station DesignJakesÎncă nu există evaluări

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersDocument5 paginiPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsanioseÎncă nu există evaluări

- Chute Design Jenike - Complex Calcs PDFDocument5 paginiChute Design Jenike - Complex Calcs PDFGeorge McMullinÎncă nu există evaluări

- Correa de SacrificioDocument22 paginiCorrea de Sacrificiomatias vargas apablazaÎncă nu există evaluări

- Conveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliDocument35 paginiConveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliRichmond YarrickÎncă nu există evaluări

- Chalcobamba P00142 PFS Independent Peer Review June 2018 Final Report Rev 0 CompiledDocument82 paginiChalcobamba P00142 PFS Independent Peer Review June 2018 Final Report Rev 0 CompiledVíctor Rojas Pasten100% (1)

- Loeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700Document5 paginiLoeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700mkpasha55mpÎncă nu există evaluări

- Non-Linear Dynamics Belt ConveyorsDocument6 paginiNon-Linear Dynamics Belt ConveyorsAndrew PeterÎncă nu există evaluări

- Transport Cross-Beam For Roll Units: Machine Manual en-PM - RUN.101.ADocument45 paginiTransport Cross-Beam For Roll Units: Machine Manual en-PM - RUN.101.AYinder Vega OsorioÎncă nu există evaluări

- Artigo - Rocky Dem and Ansys CFD CouplingDocument2 paginiArtigo - Rocky Dem and Ansys CFD CouplingEruaro Guerra CarvajalÎncă nu există evaluări

- 600-EQ-014 Operation Manual Stripping Machine PDFDocument90 pagini600-EQ-014 Operation Manual Stripping Machine PDFcorasaulÎncă nu există evaluări

- S-Class / Ty-Speed Body Components: LinerDocument6 paginiS-Class / Ty-Speed Body Components: Lineryolimar escorciaÎncă nu există evaluări

- White Paper On Conveyor Belt CapacityDocument3 paginiWhite Paper On Conveyor Belt Capacityhimangshu mandal100% (1)

- Fenner Friction Belts PDFDocument54 paginiFenner Friction Belts PDFchagar_harshÎncă nu există evaluări

- Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ®Document26 paginiInstallation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ® Installation and Parts Replacement Manual For ®Carlos RiosÎncă nu există evaluări

- Secondary and Tertiary Cone CrushersDocument4 paginiSecondary and Tertiary Cone CrushersDanielSantosÎncă nu există evaluări

- Ypt Paletli Brosur 3 PDFDocument4 paginiYpt Paletli Brosur 3 PDFarsanioseÎncă nu există evaluări

- Data Sheet For Rotary Calciner - TEPLDocument2 paginiData Sheet For Rotary Calciner - TEPLpuneet gehlotÎncă nu există evaluări

- T11M408 I1 Takraf 03910 Vdcme02 P1me01 004Document42 paginiT11M408 I1 Takraf 03910 Vdcme02 P1me01 004manuelarranoÎncă nu există evaluări

- Apron Feeder PDFDocument3 paginiApron Feeder PDFabdulloh_99100% (1)

- Power Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsDocument9 paginiPower Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsRajeshÎncă nu există evaluări

- Lats Cad T.S. en Ver1.0Document23 paginiLats Cad T.S. en Ver1.0DIÊGO NASCIMENTO0% (1)

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 paginiGearless Drives For Medium-Power Belt Conveyors: MotionchalogdÎncă nu există evaluări

- Modelling of In-Pit Crusher Conveyor AlternativesDocument8 paginiModelling of In-Pit Crusher Conveyor AlternativesJosue GonzalezÎncă nu există evaluări

- Servicio de Fabricación E Instalación de Nuevos Chutes en Fajas OverlandDocument18 paginiServicio de Fabricación E Instalación de Nuevos Chutes en Fajas OverlandRodolfo Humbert Zurita CruzÎncă nu există evaluări

- Belt Feeder Using Dem (Discrete Element Modelling) PDFDocument32 paginiBelt Feeder Using Dem (Discrete Element Modelling) PDFEmerson Ferreira100% (1)

- Belt Rope Chain Drives PDFDocument45 paginiBelt Rope Chain Drives PDFVivekÎncă nu există evaluări

- RME Data Sheet - RUSSELL Mill Relining MachineDocument1 paginăRME Data Sheet - RUSSELL Mill Relining MachineСергейÎncă nu există evaluări

- Expandable MandrelsDocument3 paginiExpandable Mandrelsali-masoodÎncă nu există evaluări

- Pipe Conveyor Belts: With Steel Cord and Fabric ReinforcementDocument5 paginiPipe Conveyor Belts: With Steel Cord and Fabric ReinforcementEugenepaccelli Kolandai SamyÎncă nu există evaluări

- Helix Delta-T6 Sample Report01Document29 paginiHelix Delta-T6 Sample Report01Khaleel PashaÎncă nu există evaluări

- Chute Calculation ExampleDocument1 paginăChute Calculation ExampleBimal DeyÎncă nu există evaluări

- Allis Saga Brochure-EN-V4.0Document26 paginiAllis Saga Brochure-EN-V4.0Benjamin Murphy100% (1)

- Kubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingDocument5 paginiKubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingtonyÎncă nu există evaluări

- Warman Competition Rules 2017 - Ver1.0Document30 paginiWarman Competition Rules 2017 - Ver1.0Ng QingarnÎncă nu există evaluări

- 8531Document3 pagini8531Srinivas VenkateshÎncă nu există evaluări

- 5 Rene Orellana Codelco (Modulo II)Document18 pagini5 Rene Orellana Codelco (Modulo II)Rodrigo BartoloÎncă nu există evaluări

- Paper # 1 - Simulation As A Tool To Enable World's Best Mill Relining PracticeDocument10 paginiPaper # 1 - Simulation As A Tool To Enable World's Best Mill Relining PracticeEdú BrizuelaÎncă nu există evaluări

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 paginiBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosÎncă nu există evaluări

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaDocument47 paginiTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaSubhransu MohapatraÎncă nu există evaluări

- 3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Document10 pagini3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Cristian CanazaÎncă nu există evaluări

- Issue 6 June 2011 - Conveyor Belt Tensioning and Take Up Guide PDFDocument2 paginiIssue 6 June 2011 - Conveyor Belt Tensioning and Take Up Guide PDFmkiani2Încă nu există evaluări

- Belt Drive Chapter 2Document51 paginiBelt Drive Chapter 2Raja SekarÎncă nu există evaluări

- Specs - Belt Conveyor 1 ProjectDocument7 paginiSpecs - Belt Conveyor 1 ProjectEdson Valter VillalunaÎncă nu există evaluări

- A Review Paper On Mechanical Power Transmission SystemDocument17 paginiA Review Paper On Mechanical Power Transmission SystemRoshan TiwariÎncă nu există evaluări

- Pipe ClassDocument5 paginiPipe Classmokie305100% (1)

- Sag16 Pipe Spans ChartDocument1 paginăSag16 Pipe Spans ChartPetros IosifidisÎncă nu există evaluări

- Corrugated Web BeamDocument67 paginiCorrugated Web BeampsewagÎncă nu există evaluări

- Sag16 Pipe Spans ChartDocument1 paginăSag16 Pipe Spans ChartPetros IosifidisÎncă nu există evaluări

- Murcia 09 S. VerstichelDocument48 paginiMurcia 09 S. VerstichelPetros IosifidisÎncă nu există evaluări

- Help Logitrace PDFDocument70 paginiHelp Logitrace PDFvhmaturaÎncă nu există evaluări

- Pipe ClassDocument5 paginiPipe Classmokie305100% (1)

- Walter Tech Bulletin 03ENDocument8 paginiWalter Tech Bulletin 03ENPetros IosifidisÎncă nu există evaluări

- History of Stainless SteelDocument65 paginiHistory of Stainless SteelMayank100% (1)

- Report 2014 SfogliabileDocument92 paginiReport 2014 SfogliabilePetros IosifidisÎncă nu există evaluări

- 13 Outokumpu Supra Range Datasheet May 2015Document12 pagini13 Outokumpu Supra Range Datasheet May 2015Petros IosifidisÎncă nu există evaluări

- Protego Er/V: Self Closing Emergency Pressure Relief ValveDocument2 paginiProtego Er/V: Self Closing Emergency Pressure Relief ValvePetros IosifidisÎncă nu există evaluări

- Stainless Steel PassivationDocument9 paginiStainless Steel Passivationpiyusharora1964100% (1)

- Report 2014 SfogliabileDocument92 paginiReport 2014 SfogliabilePetros IosifidisÎncă nu există evaluări

- Cold Formed Heads PDFDocument0 paginiCold Formed Heads PDFDumitru SorinaÎncă nu există evaluări

- Inspection of Unfired Pressure VesselsDocument35 paginiInspection of Unfired Pressure Vesselstbmari100% (7)

- Griffin LauraDocument103 paginiGriffin LauraPetros IosifidisÎncă nu există evaluări

- B 2804 e 7754Document14 paginiB 2804 e 7754Petros IosifidisÎncă nu există evaluări

- Ijetae 0113 77Document5 paginiIjetae 0113 77Petros IosifidisÎncă nu există evaluări

- Design Variations in ASP Systems S-Gamble CH2M HillDocument20 paginiDesign Variations in ASP Systems S-Gamble CH2M HillPetros IosifidisÎncă nu există evaluări

- Anaerobic DigestionDocument12 paginiAnaerobic DigestionPetros IosifidisÎncă nu există evaluări

- Man Wrt1900ac 8820-01897 Reva00 en Fr-CA ComprehensiveDocument108 paginiMan Wrt1900ac 8820-01897 Reva00 en Fr-CA ComprehensivePetros IosifidisÎncă nu există evaluări

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Document7 paginiDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- Equipments / Tags No. Purchase Ordener No. Project No.: Rejected Reviewed With Commets Reviewed Without CommentsDocument1 paginăEquipments / Tags No. Purchase Ordener No. Project No.: Rejected Reviewed With Commets Reviewed Without CommentsPetros IosifidisÎncă nu există evaluări

- Pulse Jet Bag Filters PDFDocument12 paginiPulse Jet Bag Filters PDFPetros IosifidisÎncă nu există evaluări

- Kapitel 01 DINO Techn TeilDocument12 paginiKapitel 01 DINO Techn TeilPetros IosifidisÎncă nu există evaluări

- Dust Collection Technical HandbookDocument106 paginiDust Collection Technical HandbookcassindromeÎncă nu există evaluări

- 3D PV 2017 BrochureDocument4 pagini3D PV 2017 BrochurePetros Iosifidis100% (1)

- LPPJFF RL - Envi - 2013 04 04Document10 paginiLPPJFF RL - Envi - 2013 04 04Petros IosifidisÎncă nu există evaluări

- Demag Wheels PDFDocument20 paginiDemag Wheels PDFPetros IosifidisÎncă nu există evaluări

- Alufix Slab Formwork Tim PDFDocument18 paginiAlufix Slab Formwork Tim PDFMae FalcunitinÎncă nu există evaluări

- Albert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Document19 paginiAlbert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Ilias Asimakis100% (1)

- Introduction of ProtozoaDocument31 paginiIntroduction of ProtozoaEINSTEIN2D100% (2)

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocument16 paginiBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- History of Drilling PDFDocument9 paginiHistory of Drilling PDFNguyen Van TinhÎncă nu există evaluări

- HYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev ADocument33 paginiHYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev Azulu80Încă nu există evaluări

- FM Testbank-Ch18Document9 paginiFM Testbank-Ch18David LarryÎncă nu există evaluări

- How To Make An Effective PowerPoint PresentationDocument12 paginiHow To Make An Effective PowerPoint PresentationZach Hansen100% (1)

- Crusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabDocument3 paginiCrusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabErika CalistroÎncă nu există evaluări

- Altos Easystore Users ManualDocument169 paginiAltos Easystore Users ManualSebÎncă nu există evaluări

- Deloitte - Introduction To TS&A - CloudDocument2 paginiDeloitte - Introduction To TS&A - Cloudsatyam100% (1)

- Merging Shapes - 10 Minutes To Better Painting - Episode 1Document12 paginiMerging Shapes - 10 Minutes To Better Painting - Episode 1Nguyên HàÎncă nu există evaluări

- BBAG MPR and STR LISTSDocument25 paginiBBAG MPR and STR LISTShimanshu ranjanÎncă nu există evaluări

- Financial Management of Public Sector Unit (PSU) - NotesDocument23 paginiFinancial Management of Public Sector Unit (PSU) - Notesbiz19100% (1)

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocument8 paginiTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaÎncă nu există evaluări

- ABHIGYAN 2020 E-InvitationDocument2 paginiABHIGYAN 2020 E-Invitationchirag sabhayaÎncă nu există evaluări

- Pepperberg Notes On The Learning ApproachDocument3 paginiPepperberg Notes On The Learning ApproachCristina GherardiÎncă nu există evaluări

- Different Principles Tools and Techniques in Creating A BusinessDocument5 paginiDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaÎncă nu există evaluări

- Chapter 3 Depreciation - Sum of The Years Digit MethodPart 4Document8 paginiChapter 3 Depreciation - Sum of The Years Digit MethodPart 4Tor GineÎncă nu există evaluări

- Java Edition Data Values - Official Minecraft WikiDocument140 paginiJava Edition Data Values - Official Minecraft WikiCristian Rene SuárezÎncă nu există evaluări

- Preblending of Raw Materia1Document26 paginiPreblending of Raw Materia1Mohammed Abdo100% (1)

- Edtpa Lesson 3Document3 paginiEdtpa Lesson 3api-299319227Încă nu există evaluări

- Aashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraDocument291 paginiAashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraMohammed NasserÎncă nu există evaluări

- MBA-7002-20169108-68 MarksDocument17 paginiMBA-7002-20169108-68 MarksN GÎncă nu există evaluări

- PEA Comp Study - Estate Planning For Private Equity Fund Managers (ITaback, JWaxenberg 10 - 10)Document13 paginiPEA Comp Study - Estate Planning For Private Equity Fund Managers (ITaback, JWaxenberg 10 - 10)lbaker2009Încă nu există evaluări

- Department of Education: Republic of The PhilippinesDocument1 paginăDepartment of Education: Republic of The PhilippinesKlaribelle VillaceranÎncă nu există evaluări

- Iroquois Clothes and WampumDocument3 paginiIroquois Clothes and Wampumapi-254323856Încă nu există evaluări

- Understanding Culture Society, and PoliticsDocument3 paginiUnderstanding Culture Society, and PoliticsVanito SwabeÎncă nu există evaluări

- Presentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadDocument14 paginiPresentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadAndres EduardoÎncă nu există evaluări

- Training Course For 2 Class Boiler Proficiency Certificate (Gujarat Ibr)Document3 paginiTraining Course For 2 Class Boiler Proficiency Certificate (Gujarat Ibr)JAY PARIKHÎncă nu există evaluări