Documente Academic

Documente Profesional

Documente Cultură

1999v05 Welding Requirements PDF

Încărcat de

danemsalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1999v05 Welding Requirements PDF

Încărcat de

danemsalDrepturi de autor:

Formate disponibile

WHAT EVERY STEEL

ERECTOR SHOULD KNOW

ABOUT WELDING

REQUIREMENTS

(BEFORE THE AUDITORS ARRIVE)

goals of the program are to increase

T

HE AISC E RECTOR C ERTIFICATION

PROGRAM HAS BEEN ESTABLISHED TO awareness of quality and safety issues

ENHANCE THE QUALITY OF STRUCTUR- in erector organizations and to provided

AL STEEL ERECTION. Contractors are cer- an incentive to comply with quality

tified based on their demonstrated expe- requirements. A commitment from

rience, capability and awareness of management to become a certified erec-

sound erection practices. Included in tor in 99 will prove to be a wise deci-

the program are certain welding sion.

requirements. These provisions are not The authors hope to provide some

new and, in most cases, have been code helpful insight into the welding require-

requirements for many years; however, ments associated with the AISC Erector

some additional documentation may be Certification Program, as well as some

imposed. Any contractor doing work in of the code requirements. This paper is

accordance with AWS D1.1 or D1.5 is not intended to be comprehensive, but

already required to comply with these will address several key issues. A thor-

code provisions. ough review of the AISC Erector

The Structural Welding Code is a Certification Program and applicable

consensus document that represents codes is recommended.

the collective wisdom of designers, fabri-

cators, inspectors, educators and consul-

tants, acquired over decades of experi- Common Misconceptions

ence (Post, J.W., "Welding Solutions:

Duane K. Miller Put Things in Perspective with the AWS

(top) is Manager of D1.1 Code 1998 National Steel In the realm of steel erection, there are

Engineering Construction Conference Proceedings). several misconceptions related to weld-

Services and R. ing requirements. To obtain certifica-

It is not just a book of rules; rather it is

Scott Funderburk is

Welding Design a document that promotes quality work. tion, erectors must first move beyond the

Engineer with The The erector certification program following fallacies and address the root

Lincoln Electric focuses on quality and safety, both of problems in the industry.

Company in which are key to the success of a project

Cleveland. and directly influence the cost effective- Misconception #1:

ness of steel erection. Now is the time The AWS D1.1 Structural Welding

for all erectors to get on board and join Code applies to shop fabrication

the ranks of certified erectors. In a only.

learning curve analogous to that experi-

enced by certified building and bridge The D1.1 Code specifically states that

fabricators more than 20 years ago, this code contains the requirements

steel erectors will also need to expand for fabricating and erecting welded

their comfort zone as they embrace this steel structures (emphasis added,

program. Eventually, it is expected that AWS D1.1-98, para. 1.1). The Code

the program will be end-user driven contains provisions, such as joint tol-

through contract specifications. The erances and fitup (AWS D1.1-98, para

Modern Steel Construction / May 1999

5.22), that must be followed regard- formed as necessary prior to assem-

The authors would

less of where the welding is done. In bly, during assembly, during welding,

fact, many of the sections were writ- and after welding to ensure that like to thank Tom

ten with field erection in mind. For material and workmanship meet the

example, if the root opening on a requirements of the contract docu- Schlafly of AISC,

groove weld exceeds the as-fit toler- ments. Fabrication/erection inspec-

ances, the Code provides options for tion and testing are the responsibili- Inc. and Farnham

resolution of this problem (AWS ties of the contractor unless

D1.1-98, para. 5.22.4.3 and 5.22.4.4). otherwise provided in the contract Jarrard, Clare

It is speculated that these provisions documents(AWS D1.1-98, para.

are used more frequently in the field 6.1.2.1). AWS D1.5 mandates that Ulstad and Art

than in the shop. the Quality Control (QC) function is

The D1.1 Code is equally applicable the responsibility of the erector (AWS Arndt of the Quality

to both shop fabrication and field con- D1.5-96, para. 6.1.1.1), and the QC

struction. Inspector works on behalf of the erec- Auditing Company,

tor for inspection, testing and quality

Misconception #2: matters (AWS D1.5-96, para. 6.1.2.1). Inc. for their valu-

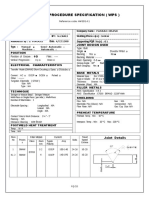

If a prequalified welding proce- For many field projects, the contract

dure is used, then a written WPS will require Verification or Quality able input on this

is not required. Assurance (QA) Inspection, often

paper, as well as for

stipulating that NDT be performed

The D1.1 Code mandates that all by the Verification Inspector (AWS

their diligent contri-

prequalified WPSs shall be written D1.1-98, 6.1.2.2). This does not, how-

(D1.1-98, para. 3.1). Welding ever, preclude or replace the QC butions to the

Procedure Specifications are the com- Inspection that is required by the

munication tool that gives the welder Code. For more information on this structural steel

instructions on how to make the issue, the authors recommend

weld. Items such as minimum pre- Ensuring Weld Quality in Structural industry for many

heat temperature, maximum inter- Applications: The Roles of Engineers,

pass temperature and bead place- Fabricators and Inspectors (Part I of years.

ment are listed on the WPS and must III) (Miller, NASCC 1996).

be maintained to obtain the required The contractor is responsible for erec-

weld soundness and mechanical prop- tion inspection and testing, unless

erties. More information on WPS specifically exempted by the contract

development is included in in documents.

"Reviewing and Approving Welding

Procedure Specifications" (Miller and Misconception #4:

Funderburk, NSCC 1998) and "What The union hall takes care of all

Every Engineer Needs to Know About the welder qualification issues.

Welding Procedures" (Miller, NSCC

1997). Indeed, unions do provide a valuable

Written WPSs are required for all service to the industry through their

welding, including prequalified proce- welder training and testing pro-

dures. grams. Welders can even become cer-

tified welders through the AWS

Misconception #3: Welder Certification Program.

Quality Assurance will handle all However, in terms of the AWS D1.1

of the field inspection issues the Code, it is the contractors responsi-

contractor does not need to do bility to qualify all welders, welding

any inspection. operators, stud welders and tack

welders (AWS D1.1-98, para. 4.1.2.2

Both the AWS D1.1 and D1.5 Codes and 7.7.4). If a welder was qualified

specifically define inspection respon- on a previous job, that performance

sibilities for the contractor. D1.1 qualification may be acceptable pro-

names the Fabrication/Erection vided that proper documentation and

Inspector as the designated person evidence has been maintained and

who acts on behalf of the contractor that the Engineer, not the contractor,

with regard to all inspection and approves it (AWS D1.1-98, para.

quality matters (AWS D1.1-98, para. 4.1.2.1).

6.1.3.1). D1.1 also says that fabrica- Welder qualification is the contrac-

tion/erection inspection shall be per- tors responsibility.

Modern Steel Construction / May 1999

To improve quality and safety, use by the welders and ready for Code does not say that the

it is important that these mis- submission. It also makes good welder must keep the WPS with

conceptions be exposed and cor- business sense, because complete him at all times. However, the

rected. These misunderstand- and proper WPSs generally welder should have quick access

ings can lead to other problems, encourage quality and productiv- to it. On most job sites, the field

such as those discussed below, if ity. office trailer is an adequate loca-

they are not addressed. tion for storage of the WPSs. On

No steel specification or grade some projects, however, the trail-

was listed on the WPS. er may be too far away for the

welding crew to readily retrieve

Specific Audit In this case, the WPS was sub- the documents. In this case, it

Problems mitted, but it was incomplete. may be more appropriate to

One of the essential variables is issue a set of WPSs to each crew.

the base metal specification and The WPS is intended to control

grade (AWS D1.1-98, para. the welding. To do the work

The acceptance criteria of the 4.7.3); this information must be properly, the welders need the

audit are categorized in three explicitly stated on the WPS. information recorded on the

areas: Application (Ap), Other examples of incomplete WPS, including the allowable

Management (Mg) and or incorrect WPSs are the follow- tolerances.

Operations (Op). These criteria ing: polarity not listed, no date

have requirements related to all shown, backing to be used with- The WPS listed 225 degree F

aspects of steel erection, includ- out the backing material desig- minimum preheat temperature,

ing welding. Based on results nated, no supporting PQRs for and the welder was using a 150

from initial audits, nonconfor- qualified procedures, and pre- degree F crayon.

mance has been found in the fol- qualified status declared with a

lowing: Welding Procedure non-prequalified process (e.g., The WPS must be properly

Specifications, quality control, GMAW short circuiting). followed, and the welder must

welder qualification and other use the right tools (the correct

miscellaneous welding issues. Are approved written temperature indicating crayon in

To aid the erector in the certifi- welding procedures in this case). Here, the welder does

cation process, each problem close proximity to and not know if the steel is above the

item is quoted from the AISC used by the welders? minimum specified preheat tem-

Certified Advanced Steel Erector (AISC, Advanced Program perature of 225 degree F. He

Evaluation Checklist with exam- Only Op444) only knows if it is above 150

ples of auditor citations of specif- degree F, and he can not main-

ic requirements. A few of the The WPS was for E7018, and tain the minimum specified pre-

requirements are for Advanced the welder was using E71T-8. heat temperature.

Certification only, and these are Several other things could

noted in the applicable sections In this example, either the happen if the WPS is not fol-

below. welder had the wrong WPS or he lowed, including: improper weld

was violating the WPS he was size, maximum interpass tem-

WELDING PROCEDURE using. Whichever was the case, perature exceeded, wrong elec-

SPECIFICATIONS what the welder was doing did trode, incorrect travel speed, and

not match the requirements of other problems. The result could

Are representative weld the WPS. The auditors will be inadequate structural perfor-

procedures submitted? often verify that the actual weld- mance, hydrogen cracking,

(AISC, Ap10) ing is in conformance with the lamellar tearing, increased cost,

WPS. timely repairs and schedule

Erector did not submit any over-runs.

WPSs. The WPSs were not at the job

site apparently they are kept The welder was running on

The contractor must have at the home office. the wrong polarity and did not

WPSs that cover every weld to know the difference between DC

be made on the job, and the erec- The home office is not in close positive and negative.

tor must submit several to the proximity to the welder. One of

auditors for review. Also, an the key objectives for WPSs is to The auditors expect the

inspector or the Engineer could clearly communicate the require- welder to understand the funda-

ask to review the WPSs at any ments to the welder and inspec- mental issues covered by the

time (AWS D1.1-98, para. 4.1.1, tors. This can not effectively WPS, including electrode polari-

4.2.3 and 6.3.1). Therefore, take place with the instructions ty. The welder should also have

WPSs should be kept current, in filed away at the office. The a basic understanding, for exam-

Modern Steel Construction / May 1999

ple, of welding processes (e.g., (AISC, Op17) There is little benefit in giving

FCAW vs. SMAW), visual accep- responsibility to someone who

tance criteria, joint and weld The welding foreman did not can not authorize the work to be

types (e.g., butt joint with a sin- know what the AWS D1.1 Code done.

gle-bevel groove weld), joint fit- was.

up tolerances, and position (e.g., Do the welders under-

2F and 6G). No one expects the job super- stand, comply with, and

intendent or the foreman to check their welds against

know all the applicable code pro- the workmanship and

QUALITY CONTROL visions from memory, but they technique requirements of

should at least know what the AISC, AASHTO, or AWS?

If welding is required, is a code is and where to find (AISC, Op35)

competent welding techni- answers to common code ques-

cian (such as a CWI or tions. For example, the auditor The welder was making welds

ACWI) employed by the may ask the foreman to show with unacceptable undercut and

applicant? (AISC, him the code provisions for didnt know what was wrong.

Advanced Program Only allowable porosity levels. The

Mg166) foreman should be able to fairly The Code says that, the con-

quickly open the AWS D1.1 Code tractor shall be responsible for

Erector had no welding and turn to Chapter 6 - visual inspection and necessary

inspector. Inspection to find the answer. correction of all deficiencies in

materials and workmanship in

It is important to have person- Has a key person been accordance with the require-

nel available to the job site who assigned the responsibility ments of this code (AWS D1.1-

have training in welding, includ- of bolting or welding joints 98, para. 6.6.1). This includes

ing the AWS D1 Welding Codes, in accordance with the the following issues: cracks,

welding processes, inspection applicable specifications? weld/base metal fusion, craters,

technology and quality accep- (AISC, Op30) weld profiles, weld size, under-

tance criteria. The Certified cut, and porosity (AWS D1.1-98,

Welding Inspector (CWI) pro- No one knew who was in Table 6.1). This code provision

gram sponsored by AWS charge of welding. establishes the basis for the

requires the participants to requirement that the welders

demonstrate their knowledge of At the heart of this require- must understand, comply with,

these issues through job experi- ment are two issues: responsi- and check their work.

ence and examination. Having a bility and specifications. To According to the auditors note

CWI on staff is no guarantee achieve high quality, key people in this example, the welder

against problems, but it does must ensure that the work con- apparently didnt know what

provide some level of confidence forms to the standards estab- undercut was, or that there were

when trouble arises. The D1.1 lished in the specifications (e.g., unacceptable limits. Since the

Code does not require a AWS AWS D1.1 and contract docu- contractor is responsible for visu-

CWI; there are other acceptable ments). Along with responsibili- al inspection, having the welders

qualification bases such as the ty must come the motivation to check to make sure that their

Canadian Welding Bureau CWI do the right thing and to see work meets the visual inspection

(AWS D1.1-98, para. 6.1.4.1). things through to completion. criteria is an effective first step.

Since quality is a core objective Responsibility also encourages

of the AISC Erector Certification pride of workmanship, owner-

Program, incorporating qualified ship, the understanding that it WELDER QUALIFICATION

people is fundamental. A CWI is has to be done correctly and that Does the applicant have a

not essential to obtaining a cer- it is up to the individual to record of the craft workers

tificate but there must be some- accomplish the goal. This person who are certified welders?

one available who has demon- can be the one responsible for (AISC, Mg7c)

strated awareness of welding assuring quality of the work, but

and code issues. he must know the criteria and be No Welder Performance

active on the site. If this respon- Qualification Records (WPQRs)

Are job site superinten- sibility is not given to one specif- were available.

dents and foremen conver- ic person, the likelihood of con-

sant with current work- formance to the workmanship In this example, records were

manship requirements standards in the specifications is inadequate to prove the qualifi-

such as those contained in low. The person in charge of cation of the welders. AWS D1.1

AWS, AREA, AISC, welding must also have the states that the Welding

AASHTO, specifications? authority to make decisions. Performance Qualification

Modern Steel Construction / May 1999

Record (WPQR) shall serve as AWS D1.1 have been violated. mance be conducted every year

written verification and shall list The Code states that changes (AWS D1.5-96, para. 5.5), and

all of the essential variables of beyond the limitation of essen- the erector must maintain copies

Table 4.10 (AWS D1.1-98, para. tial variables for welders... of the most current certificates.

4.21). shown in Table 4.10 shall The Structural Code states that

Another situation is that the require requalification (AWS when requested by the

erector may have the qualifica- D1.1-98, para. 4.22). The weld- Engineer, the contractor or fabri-

tion records, but the results of ing process (e.g., FCAW, SMAW, cator shall furnish certification

mechanical, visual and NDT are GMAW and GTAW) used during that the electrode or electrode-

not listed. Without test results, qualification is the first essential flux combination will meet the

the qualification may be suspect. variable listed in Table 4.10 of requirements of the classifica-

To make the qualification credi- the Code. This table states that tion (AWS D1.1-98, para.

ble, this information must be if the welder is going to change 5.3.1.1). AWS A5.01-87 Filler

recorded and retained. As a to a process for which he is not Metal Procurement Guidelines

matter of reference, the D1.1 qualified, he must qualify for have several schedules that per-

Code has an example WPQR that process as well. mit re-certification of electrodes

form in Annex E with space Other essential variables are to different time periods. For

included for the visual, destruc- SMAW F-number, non-approved example, Schedule G calls for re-

tive and radiographic test results electrodes/shielding medium in certification on an annual basis,

(AWS D1.1-98, pg. 305). the AWS A5 filler metal specifi- while Schedule F allows for the

Additionally, the date and an cations, position, material thick- use of the manufacturers stan-

authorized signature must be on ness, vertical progression, omis- dard testing levels. Some manu-

the WPQR. The Code says that sion of backing and number of facturers use a three year period

the welders qualification shall electrodes (AWS D1.1-98, Table for products unlikely to be used

be considered as remaining in 4.10). on bridge projects where D1.5

effect indefinitely unless ... the requires annual re-certification.

welder is not engaged in a given

process of welding for which the OTHER WELDING PROBLEMS Are flux and rod ovens

welder ... is qualified for a period In the event the applicant adequate and close enough

exceeding six months... (AWS purchases weld wire, steel to where the work is being

D1.1-98, para. 4.2.3.1). This material, paint, castings, performed and are they

means that as long as the welder etc., are the manufactur- operating per the latest

welds with the process for which ers test reports or certifi- AWS requirements? (AISC,

he is qualified at least once every cates of compliance on file Op36)

six months, his qualification last at the location where the Rod ovens on site, but the

forever unless there is reason to material is being utilized? temperature inside the oven was

question his ability. The key to (AISC, Advanced Program only 100 degrees F.

this requirement is that the date Only Op40))

must be recorded on the WPQR Electrode storage ovens must

form when the welder was first No welding electrode be available on site, the tempera-

qualified. Also, a log must be Certificates of Conformance were ture inside the oven must be

kept to verify that the welder on file. maintained to at least 250

remains current in his qualifica- degrees F, and the oven must be

tion. The welding consumables (i.e., reasonably close to where the

To make record keeping easi- electrode, electrode/flux combi- welding is actually done. The

er, many erectors use commer- nation, or electrode/shielding D1.1 Code requires that imme-

cially available computer soft- gas) used on the job site must diately after opening the hermet-

ware packages to track welder conform to the provisions of the ically sealed container, elec-

qualification. appropriate AWS A5 filler metal trodes shall be stored in ovens

specifications. Filler metal tests held at a temperature of at least

Are welders qualified per of conformance are conducted by 250 degrees F (120 degrees C)

the project requirements the welding consumable manu- (AWS D1.1-98, para. 5.3.2.1).

(i.e., AWS, AASHTO, facturer. The results of these Problems can arise if the con-

ASME)? (AISC, Op34) tests are reported on a certificate sumables are not properly main-

of conformance. Copies of the tained. For example, when weld-

Some welders were welding certificates of conformance must ing a higher strength steel,

with FCAW but were only quali- be kept at the job site for each delayed cracking can occur even

fied for SMAW. consumable used for the with low hydrogen electrodes if

Advanced Certification Program. they are not stored and handled

The problem here is that the The Bridge Code requires that properly. Major rework may

welder qualification provisions of the filler metal tests of confor- result, and cracking is a poten-

tial consequence if this require-

ment is not followed. The pur-

pose of the rod oven is to keep

the electrodes dry to help mini-

mize the chances for problems of

this nature. Make sure that the

rod ovens (1) are on the job site,

(2) work properly, and (3) are

close to the location of welding.

SUMMARY

In the form of the D1.1

Structural Welding Code and the

D1.5 Bridge Welding Code, steel

erectors have been given a

readymade two-part blueprint

for excellence that will serve

them well in meeting the

requirements of AISCs Erector

Certification Program.

This paper is part of the 1999

North American Steel

Construction Conference session:

What Every Steel Erector

Should Know About Welding

Requirements (Before The

Auditors Arrive!).

Modern Steel Construction / May 1999

S-ar putea să vă placă și

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDocument7 paginiWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalÎncă nu există evaluări

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 paginiWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasÎncă nu există evaluări

- 208 4Document35 pagini208 4danemsalÎncă nu există evaluări

- Fundamentals - ValvesDocument52 paginiFundamentals - Valvesapi-3808778100% (2)

- Psrao Welding DefectsDocument35 paginiPsrao Welding DefectsdanemsalÎncă nu există evaluări

- Buried PipeDocument83 paginiBuried PipePlalvarezcelis100% (3)

- Παρουσίαση EC3 Connections Και ΙNSTANT Steel 2012Document28 paginiΠαρουσίαση EC3 Connections Και ΙNSTANT Steel 2012danemsalÎncă nu există evaluări

- ZorcDocument6 paginiZorcdanemsalÎncă nu există evaluări

- 4 1 Sirin ManuscriptDocument6 pagini4 1 Sirin ManuscriptdanemsalÎncă nu există evaluări

- Yongxu Yang 2Document164 paginiYongxu Yang 2danemsalÎncă nu există evaluări

- Ultrasonic SolutionDocument46 paginiUltrasonic Solutionsoumyadev86% (14)

- ThickWalledCylinder and PressShrinkFit ShigDocument17 paginiThickWalledCylinder and PressShrinkFit ShigArooj WaniÎncă nu există evaluări

- WPS Smaw1gDocument1 paginăWPS Smaw1gDanem HalasÎncă nu există evaluări

- Bts Roc Methodes 2002 PDFDocument36 paginiBts Roc Methodes 2002 PDFdanemsalÎncă nu există evaluări

- A - SeriesDocument18 paginiA - SeriesdanemsalÎncă nu există evaluări

- B Section 202 To 212Document11 paginiB Section 202 To 212joshua_tan_31Încă nu există evaluări

- Causes and Cures of Common Welding Defects: Blow HolesDocument12 paginiCauses and Cures of Common Welding Defects: Blow HolesDeepak GuptaÎncă nu există evaluări

- StructEngII Connections 276-327Document52 paginiStructEngII Connections 276-327danemsalÎncă nu există evaluări

- Psrao Welding DefectsDocument35 paginiPsrao Welding DefectsdanemsalÎncă nu există evaluări

- Bts Roc Methodes 2009Document31 paginiBts Roc Methodes 2009Med Ali MaatougÎncă nu există evaluări

- 4 1 Sirin ManuscriptDocument6 pagini4 1 Sirin ManuscriptdanemsalÎncă nu există evaluări

- Calculate HVL Material Attenuation CoefficientDocument4 paginiCalculate HVL Material Attenuation CoefficientdanemsalÎncă nu există evaluări

- Welding Processes: Basic Ideas, Terminology, Properties of The Welding ArcDocument38 paginiWelding Processes: Basic Ideas, Terminology, Properties of The Welding ArcdanemsalÎncă nu există evaluări

- CDC UP Test Plan TemplateDocument20 paginiCDC UP Test Plan TemplatedanemsalÎncă nu există evaluări

- Course Module 9Document10 paginiCourse Module 9danemsalÎncă nu există evaluări

- B Section 202 To 212Document11 paginiB Section 202 To 212joshua_tan_31Încă nu există evaluări

- Ultrasonic SolutionDocument46 paginiUltrasonic Solutionsoumyadev86% (14)

- Arccosts PDFDocument27 paginiArccosts PDFharry_1981Încă nu există evaluări

- A - SeriesDocument18 paginiA - SeriesdanemsalÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Quiz 1Document3 paginiQuiz 1JULIANNE BAYHONÎncă nu există evaluări

- 31 Legacy of Ancient Greece (Contributions)Document10 pagini31 Legacy of Ancient Greece (Contributions)LyreÎncă nu există evaluări

- Lab Report 1Document8 paginiLab Report 1Hammad SattiÎncă nu există evaluări

- Amber ToolsDocument309 paginiAmber ToolshkmydreamsÎncă nu există evaluări

- READING 4.1 - Language and The Perception of Space, Motion, and TimeDocument10 paginiREADING 4.1 - Language and The Perception of Space, Motion, and TimeBan MaiÎncă nu există evaluări

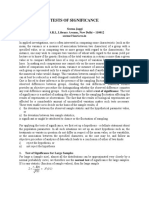

- 5 Tests of Significance SeemaDocument8 pagini5 Tests of Significance SeemaFinance dmsrdeÎncă nu există evaluări

- Unit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDocument15 paginiUnit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDoc Joey100% (3)

- Daftar PustakaDocument3 paginiDaftar PustakaNurha ZizahÎncă nu există evaluări

- Unit 3.1 - Hydrostatic ForcesDocument29 paginiUnit 3.1 - Hydrostatic ForcesIshmael MvunyiswaÎncă nu există evaluări

- Lecture 6-Design For ShearDocument14 paginiLecture 6-Design For ShearMarkos DanielÎncă nu există evaluări

- Spectro Xepos Brochure 2016Document8 paginiSpectro Xepos Brochure 2016Mary100% (1)

- The Critical Need For Software Engineering EducationDocument5 paginiThe Critical Need For Software Engineering EducationGaurang TandonÎncă nu există evaluări

- University Reserch Worksheet PDFDocument7 paginiUniversity Reserch Worksheet PDFapi-410567922Încă nu există evaluări

- Smell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaDocument35 paginiSmell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaUniversity of Washington PressÎncă nu există evaluări

- CH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Document16 paginiCH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Muhammad Fariz IbrahimÎncă nu există evaluări

- ECE Laws and Ethics NotesDocument29 paginiECE Laws and Ethics Notesmars100% (1)

- CHEE319 Tutorial 4 SolnDocument13 paginiCHEE319 Tutorial 4 SolnyeshiduÎncă nu există evaluări

- Empowerment Technology - Week 2Document3 paginiEmpowerment Technology - Week 2yahgieÎncă nu există evaluări

- Giraffe Juice GamesDocument32 paginiGiraffe Juice Gamesgwyn022100% (3)

- Mil B 49430BDocument36 paginiMil B 49430Bparam.vennelaÎncă nu există evaluări

- Design and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABDocument5 paginiDesign and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABJeannot MpianaÎncă nu există evaluări

- What Is A Lecher AntennaDocument4 paginiWhat Is A Lecher AntennaPt AkaashÎncă nu există evaluări

- Course-PM SSY135 Wireless Communications 21-22Document7 paginiCourse-PM SSY135 Wireless Communications 21-22Amirhossein MohsenianÎncă nu există evaluări

- Tithi PRAVESHADocument38 paginiTithi PRAVESHAdbbircs100% (1)

- ADL MATRIX STRATEGY FOR BPCL'S GROWTHDocument17 paginiADL MATRIX STRATEGY FOR BPCL'S GROWTHSachin Nagar100% (1)

- Superficial ConclusionDocument49 paginiSuperficial ConclusionIngrid ParissÎncă nu există evaluări

- Chemical Engineering Assignment SubmissionDocument10 paginiChemical Engineering Assignment SubmissionFahad KamranÎncă nu există evaluări

- Guimaras State CollegeDocument5 paginiGuimaras State CollegeBabarianCocBermejoÎncă nu există evaluări

- Ninja's Guide To OnenoteDocument13 paginiNinja's Guide To Onenotesunil100% (1)

- Kavanaugh On Philosophical EnterpriseDocument9 paginiKavanaugh On Philosophical EnterprisePauline Zoi RabagoÎncă nu există evaluări