Documente Academic

Documente Profesional

Documente Cultură

Articulo Sobre Escalamiento PDF

Încărcat de

sofad1693Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Articulo Sobre Escalamiento PDF

Încărcat de

sofad1693Drepturi de autor:

Formate disponibile

DIMENSIONAL ANALYSIS

How to Scale Up

Scientifically

Michael Levin

A

rational approach to scale-up has

been used in the physical sciences

for quite some time. This ap-

proach, called dimensional analysis, is

a proven method of developing func-

tional relationships that describe any

given process in a dimensionless form

to facilitate modeling and scale-up or

scale-down. This short article reviews

and demonstrates the dimensional

COMSTOCK

analysis method as applied to pharma-

ceutical processes and includes refer-

ences to works that have become clas-

The author reviews sics in the field of granulation scale-up.

dimensional analysis as a

What is dimensional analysis?

straight-forward approach

Dimensional analysis is a method for

to scale up. producing dimensionless numbers

and deriving functional relationships

among them that completely charac-

terize the process. The analysis can be

applied even when the equations gov-

erning the process are not known.

Imagine a dimensionless space in

which you have no mass, no length,

Michael Levin is president and no time. It is obvious that in such

and CEO of Metropolitan a space, there are no scale-up prob-

Computing Corporation,

tel. 973.887.7800,

lems because there is no scale.

fax 973.887.8447, Dimensional analytical procedure

michael.levin@mcc-online.com. was first systematically applied to fluid

s4 Pharmaceutical Technology SCALING UP MANUFACTURING 2005 www.phar mtech.com

DIMENSIONAL ANALYSIS

flow 90 years ago by Lord Rayleigh (1), has been described for powder blend-

on the basis of the principle of simil- ing (3) and was suggested as a criterion

itude referred to by Newton in one of for dynamic similarity as well as a scale-

his early works. up parameter in wet granulation (4).

The mechanics of the phenomenon

Dimensionless numbers was described as an interplay of the

Physical quantities such as force or centrifugal force (pushing the particles

speed have the basic dimensional qual- against the mixer wall) and the cen-

ities of length (L), mass (M), time (T), tripetal force produced by the wall,

and so forth. For example, speed has thereby creating a compaction zone.

dimensions of L/T, and force has a di- The Reynolds number, which re-

mensional composition of ML/T 2. lates the inertial force to the viscous

Unlike the regular physical quan- force, is frequently used to describe

tities, dimensionless numbers have mixing processes (5), especially in

no dimensions. Such numbers are chemical engineering, for example, for

frequently used to describe the ra- problems of waterair mixing in ves-

tios of various physical quantities. sels equipped with turbine stirrers

Most relevant to the forthcoming where scale-up can range from 2.5 to

discussion are Newton (Ne, power), 906 L, which is a scale-up factor of

Froude (Fr), and Reynolds (Re) 1:71 (see, for example, Reference 6).

numbers, which, respectively, are ex-

pressed as Theory of models

Ne 5 P/(rn d ) 3 5 Scale-up, then, is simple: Express the

Fr 5 n2d/g process using a complete set of dimen-

Re 5 d2nr/h sionless numbers and try to match

them at various scales. This dimen-

in which P is the power consumption sionless space in which the measure-

(ML2/T 3), r is the specific density of ments are presented or measured will

particles (M/L3), n is the impeller speed make the process scale invariant.

(T 21), d is the impeller diameter (L), g According to the modeling theory,

is the gravitational constant (L/T 2), two processes are considered similar

and h is the dynamic viscosity (M/LT). if there is a geometrical, kinematic,

The Newton (power) number, and dynamic similarity (7). Two sys-

which relates the drag force acting on tems are called geometrically similar if

a unit area of the impeller and the in- they have the same ratio of character-

ertial stress, is a measure of the power istic linear dimensions. For example,

required to overcome friction in fluid two cylindrical mixing vessels are geo-

flow in a stirred reactor. In mixer- metrically similar if they have the same

granulation applications, this number ration of height to diameter. Two geo-

can be calculated from the power con- metrically similar systems are called

sumption of the impeller. kinematically similar if they have the

The Froude number, first introduced same ratio of velocities between cor-

to quantify the resistance of ships (2), responding points. Two kinematically

s6 Pharmaceutical Technology SCALING UP MANUFACTURING 2005 www.phar mtech.com

similar systems are dynamically simi- further subdivided as geometric, phys-

lar when they have the same ratio of ical, or operational. Each relevance list

forces between corresponding points. should include only one target (i.e.,

For any two dynamically similar sys- dependent response) variable.

tems, all the dimensionless numbers Pitfalls of dimensional analysis often

necessary to describe the process have relate to selecting the reference list, tar-

the same numerical value (8). get variable, or measurement errors

Lack of geometrical similarity is (e.g., friction losses of the same order

often the main obstacle when apply- of magnitude as the power consump-

ing dimensional analysis to solve scale- tion of a motor). The larger the scale-

up problems. It has been shown, for up factor, the more precise the meas-

example, that Collette Gral 10, 75, and urements of the small scale must be (8).

300 are not geometrically similar (4).

In such cases, a proper correction to Dimensional matrix

the resulting equations is required. Dimensional analysis can be simpli-

fied by arranging all relevant variables

Buckinghams P theorem from the relevance list into a matrix,

The fundamental theorem of the di- with a subsequent transformation

mensional analysis, the P theorem, yielding the required dimensionless

states: Every physical relationship be- numbers. The dimensional matrix

tween n dimensional variables and con- consists of a square core matrix and a

stants can be reduced to a relationship residual matrix. The rows of the ma-

between m = n 2 r mutually independ- trix consist of the basic dimensions,

ent dimensionless groups, in which r is whereas the columns represent the

the number of dimensions; that is, fun- physical quantities from the relevance

damental dimensional units (rank of list. The most important physical

the dimensional matrix). The theorem properties and process-related param-

is universally ascribed to Buckingham, eters, as well as the target variable (i.e.,

who introduced the term and popular- the one we would like to predict on

ized it in the United States (9), although the basis of other variables) are placed

it was proven earlier by others. in one of the columns of the residual

matrix.

It starts with a relevance list The core matrix is linearly trans-

Dimensional analysis starts with a rel- formed into a matrix of unity in which

evance list, which is a list of all vari- the main diagonal consists only of

ables thought to be crucial for the ones and the remaining elements are

process being analyzed. To set up a rel- all zero. The dimensionless numbers

evance list for a process, one needs to are then created as a ratio of columns

compile a complete set of all dimen- in the residual matrix and the core

sional relevant and mutually inde- matrix, with the exponents indicated

pendent variables and constants that in the residual matrix. The following

affect the process. The word complete examples illustrate this rather simple

is crucial. All entries in the list can be process.

Pharmaceutical Technology SCALING UP MANUFACTURING 2005 s7

DIMENSIONAL ANALYSIS

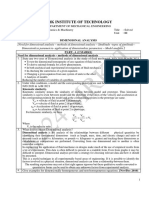

Case study I Table I: Variables used in dimensional analysis.

Hans Leuenberger

Quantity Symbol Units Dimensions

et al. proposed a

Power consumption P Watt ML2/T 3

theory of granula-

tion end point de- Specific density r kg/m3 M/L3

termination and Blade diameter d m L

scale up using di- Blade speed n rev/s T 21

mensional analysis, Binder amount m kg M

starting with the

Bowl volume Vb m3 L3

relevance list in

Table I (7, 10, 11). Gravitational constant g m/s2 L/T 2

The list reflects cer- Bowl height h m L

tain assumptions

that are used to simplify the model;

Core matrix Residual matrix

namely, that there are short range in- r d n P m V g h

teractions only and no viscosity factor Mass M 1 0 0 1 1 0 0 0

b

(and therefore, no Reynolds number). Length L 3 1 0 2 0 3 1 1

Why is the gravitational constant Time T 0 0 1 3 0 0 2 0

included? Well, imagine the same

process to be done on the moon. Figure 1: Initial dimensional matrix for

Would you expect any difference? case study I.

One target variable (power con-

sumption) and seven process variables

Unity matrix Residual matrix

or constants thus represent the num-

r d n P m V g h

ber n 5 8 of the P theorem, and there

b

M 1 0 0 1 1 0 0 0

are three basic dimensions (r); namely, 3M 1 L 0 1 0 5 3 3 1 1

M, L, and T. According to the theo- 2T 0 0 1 3 0 0 2 0

rem, the process can be reduced to a

relationship between m 5 n 2 r 5 8 Figure 2: Initial dimensional matrix after

2 3 5 5 mutually independent di- one linear transformation.

mensionless groups.

To find these groups, or numbers, shown in the residual matrix.

form the dimensional matrix shown in The residual matrix contains five

Figure 1. One transformation changes columns, therefore five dimensionless

the 23 in the L-row, r-column to 0. P groups (numbers) are formed (see

Subsequent multiplication of the T- Table II).

row by 21 transfers the 21 of the n- The end result of the dimensional

column to 11 (see Figure 2). Five di- analysis is an expression of the form

mensionless groups are formed from P0 = f (P1, P2, P3, P4)

the five columns of the residual matrix

by dividing each element of the resid- Assuming that the groups P2, P3,

ual matrix by the column headers of and P4 are essentially constant, the

the unity matrix, with the exponents P-space can be reduced to a simple re-

s8 Pharmaceutical Technology SCALING UP MANUFACTURING 2005 www.phar mtech.com

DIMENSIONAL ANALYSIS

Leuenberger and his

Table II: Dimensionless P groups for case study I. group empirically estab-

P group Expression Definition lished that the amount

of binder required to

Newton (power)

P0 P/(r1d 5n 3) 5 Ne reach a desired end-

number

point (as expressed by

Specific amount the absolute value of

of liquid Vp is Ne) is essentially pro-

volume of particles, portional to the batch

q /(r1d 3n0) 5

P1 q is the binder size (see Figure 3), thus

qt /(Vpr)

addition rate, and t specifying the functional

is the binder dependence f and estab-

addition time lishing a rational basis

t/(r0d3n0) 5 Fractional particle for granulation scale-up.

P2

(Vp /Vb)21 volume According to Leuen-

P3 g/(r0d 1n 2) 5 Fr21 Froude number berger, the correct

amount of granulating

P4 h/(r0d 1n 0) 5 h/d Ratio of lengths

liquid per batch is a

scale-up invariable, pro-

vided that the binder is mixed in as a

dry powder and then water is added

at a constant rate. This functionality

Binder amount

was shown for nonviscous binders.

The ratio of quantity of granulat-

S 3 ing liquid to batch size at the inflec-

tion point S3 of power versus time

curve is constant, irrespective of batch

Batch size

size and type of machine. Moreover,

for a constant rate of low viscosity

Figure 3: Binder amount versus batch binder addition proportional to the

size. Adapted from Reference 11. batch size, the rate of change (slope or

time derivative) of the torque or power

lationship P0 = f(P1); that is, the value consumption curve is linearly related

of Newton number Ne at any point in to the batch size for a wide spectrum of

the process is a function of the specific high-shear and planetary mixers. In

amount of granulating liquid. other words, the process end point, as

Up to this point, all considerations determined in a certain region of the

were rather theoretical. From the the- curve, is a practically proven scale-up

ory of modeling, we know that the parameter for moving the product from

above dimensional groups are func- laboratory to production mixers of var-

tionally related. The form of this func- ious sizes and manufacturers.

tional relationship f, however, can be Different vessel and blade geome-

established only through experiments. tries will contribute to differences in

s10 Pharmaceutical Technology SCALING UP MANUFACTURING 2005 www.phar mtech.com

absolute values of the signals, but the

signal profile of a given granulate com- Core matrix Residual matrix

position in a high-shear mixer is very r d n h g h

P

similar to one obtained in a planetary Mass M 1 0 0 1 1 0 0

mixer. Length L 3 1 0 2 1 1 1

To calculate Ne, the power of the Time T 0 0 1 3 1 2 0

load on the impeller rather than the

mixer motor should be used. Before Figure 4: Dimensional matrix for case

attempting to use dimensional analy- study II.

sis, one must measure or estimate

power losses for empty-bowl mixing. Unity matrix Residual matrix

This baseline, however, does not stay r d n P h g h

constant; it changes significantly with M 1 0 0 1 1 0 0

load, mixer condition, or motor effi- 3M + L 0 1 0 5 2 1 1

T 0 0 1 3 1 2 0

ciency, which may present inherent

difficulties in using power meters in-

stead of torque. Torque, of course, is Figure 5: Matrix for case study II after

directly proportional to the power linear transformation.

drawn by the impeller so that the

power number can be calculated from The dimensional matrix and the

the torque and speed measurements. matrix after the already familiar linear

transformation are shown in Figures

Case study II 4 and 5, respectively. The residual ma-

Scale-up in fixed-bowl mixer granu- trix contains four columns, therefore

lators has been studied using the clas- four dimensionless P groups (num-

sical dimensionless numbers of New- bers) are formed in accordance with

ton (power), Reynolds, and Froude to the P-theorem (see Table IV). Under

predict end-points in geometrically the assumed condition of dynamic

similar, high-shear Fielder PMA 25-, similarity, therefore, Ne = f(Re, Fr, h/d).

100-, and 600-L machines (12). When corrections for gross vortex-

The relevance list included power ing, geometric dissimilarities, and

consumption of the impeller (as a re- powder-bed height variation are made,

sponse) and six factor quantities: spe- data correlations from all mixers allow

cific density, impeller diameter, im- predictions of optimum end-point

peller speed, gravitational constant, conditions. The linear regression of

vessel height (all with units and di- the Newton number (power) on the

mensions shown in Table I), and vis- adjusted Reynolds number (in log/log

cosity of the wet mass (h, units of Pa- domain) yields Ne 5 7.96 3 102 (Re

s, dimensions M/LT). Dynamic Fr h/d)20.732 (see Figure 6).

viscosity has replaced the binder The 0.7854 correlation coefficient

amount and bowl volume of Leuen- for the final curve-fitting effort, how-

bergers relevance list, thus making it ever, indicates the presence of many

applicable to viscous binders. unexplained outlier points. To main-

Pharmaceutical Technology SCALING UP MANUFACTURING 2005 s11

DIMENSIONAL ANALYSIS

Table IV: Dimensionless P groups for Case study II.

P group Expression Definition

1 5 3

P0 P/(r d n ) 5 Ne Newton (power) number

1 2 1 21

P1 h/(r d n ) 5 Re Reynolds number

0 1 2 21

P2 g/(r d n ) 5 Fr Froude number

P3 h/(r0d 1n 0) 5 h/d Ratio of lengths

m, dimensions of L). As a meas-

100 PMA 25 ure of power consumption, net

10

PMA 100

impeller power consumption DP

PMA 600

(motor power consumption

Me

1 minus the dry blending baseline

0.1

level was used. Dimensional

100 1000 10000 100000 analysis and application of the

Re* Fr* h/d

Buckingham theorem indicated

Figure 6: Power number versus dimensionless that Ne, Re, Fr, and h/d (propor-

processing factors. Adapted from Reference (12). tional to the fill ratio) adequately

described the process. A relation-

tain the geometric similarity between ship Ne 5 k[ReFr (h/d)]2r was postu-

mixers, it is important to keep the lated and the constants k and r were

batch size in proportion to the over- found empirically with a good correla-

all shape of the mixer and especially tion (.0.92) between the observed and

its bowl height. A special considera- predicted numbers.

tion is required when using torque val- Once the process similarity is estab-

ues from mixer torque rheometers for lished or the appropriate corrections are

the viscosity of wet granulation, be- made, scale-up problems can be greatly

cause these values are proportional to reduced or even completely eliminated,

kinematic viscosity n 5 h/r rather because the same equation predicts the

than dynamic viscosity h required to power number of the granulation

calculate the Reynolds numbers. process regardless of the batch size.

Case study III References

Fraure et al. applied this same approach 1. Lord Rayleigh, The Principle of Simili-

tude, Nature 95, 6668 (18 March 1915).

to a planetary Hobart AE240 mixer with

2. C.W. Merrifield The Experiments Re-

two interchangeable bowls (13). The cently Proposed on the Resistance of

relevance list, assuming the absence of Ships, Trans. Inst. Naval Arch. (London)

chemical reaction and heat transfer, in- 11, 8093 (1870).

cluded power consumption, specific 3. J.Y. Oldshue,Mixing Processes, in Scale-

Up of Chemical Processes: Conversion from

density, blade diameter, blade speed, dy- Laboratory-Scale Tests to Successful Com-

namic viscosity, gravitational constant, mercial-Size Design, A. Bisio and R.L.

and wet powder bed height (h, units of Kabel, Eds. (Wiley, New York, NY, 1985).

s12 Pharmaceutical Technology SCALING UP MANUFACTURING 2005 www.phar mtech.com

4. G.J.B. Horsthuis et al., Studies on Up-

scaling Parameters of the Gral High-

Shear Granulation Process, Int. J.

Pharm. 92 (143), (1993).

5. O. Reynolds, An Experimental Investi-

gation of the Circumstances which De-

termine Whether the Motion of Water

Shall Be Direct or Sinusous and of the

Law of Resistance in Parallel Channels,

Philos Trans. R. Soc. London 174,

935982 (1883).

6. M. Zlokarnik, Problems in the Appli-

cation of Dimensional Analysis and

Scale-Up of Mixing Operations, Chem.

Eng. Sci. 53 (17), 30233030 (1998).

7. H. Leuenberger, Scale-Up of Granula-

tion Processes with Reference to Process

Monitoring, Acta Pharm. Technol. 29

(4), 274280 (1983).

8. M. Zlokarnik, Dimensional Analysis and

Scale-Up in Chemical Engineering

(Springer-Verlag, 1991).

9. E. Buckingham, On Physically Similar

Systems; Illustrations of the Use of Di-

mensional Equations, Phys. Rev. NY 4,

345376 (1914).

10. H. Leuenberger, H.P. Bier, and H.B.

Sucker, Theory of the Granulating-

Liquid Requirement in the Conventional

Granulation Process, Pharm. Technol.

6, 6168 (1979).

11. H.P. Bier, H. Leuenberger, and H. Sucker,

Determination of the Uncritical Quan-

tity of Granulating Liquid by Power

Measurements on Planetary Mixers,

Pharm. Ind. 4, 375380 (1979).

12. M. Landin et al., Scale-Up of a Phar-

maceutical Granulation in Fixed Bowl

MixerGranulators, Int. J. Pharm. 133,

127131 (1996).

13. A. Faure et al., A Methodology for the

Optimization of Wet Granulation in a

Model Planetary Mixer, Pharm. Dev.

Technol. 3 (3), 413422 (1998). PT

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Functional Safety - IEC 61511 Introduction: New Plymouth, 11 April 2013Document74 paginiFunctional Safety - IEC 61511 Introduction: New Plymouth, 11 April 2013sofad1693Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Functional Safety - IEC 61511 Introduction: New Plymouth, 11 April 2013Document74 paginiFunctional Safety - IEC 61511 Introduction: New Plymouth, 11 April 2013sofad1693Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- C-Bacterial Metabolism-Springer-Verlag New York (1986)Document370 paginiC-Bacterial Metabolism-Springer-Verlag New York (1986)xuantra100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Biochemical Engineering Journal: Susana Cortez, Ana Nicolau, Michael C. Flickinger, Manuel MotaDocument13 paginiBiochemical Engineering Journal: Susana Cortez, Ana Nicolau, Michael C. Flickinger, Manuel Motasofad1693Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- C-Bacterial Metabolism-Springer-Verlag New York (1986)Document370 paginiC-Bacterial Metabolism-Springer-Verlag New York (1986)xuantra100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- BioreactorsDocument0 paginiBioreactorsPaulo SouzaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Visualizing The MacCabe Thiele Diagram PDFDocument9 paginiVisualizing The MacCabe Thiele Diagram PDFMayank SinhaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- CE Evap Selection PDFDocument8 paginiCE Evap Selection PDFBharadwaj RangarajanÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Articulo 3 PDFDocument10 paginiArticulo 3 PDFsofad1693Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Deborah and Weissenberg Numbers ExplainedDocument9 paginiThe Deborah and Weissenberg Numbers ExplainedHanifrahmawan SudibyoÎncă nu există evaluări

- Rta PosterDocument1 paginăRta PosterJohn HomeÎncă nu există evaluări

- Process Engineering CDocument202 paginiProcess Engineering Cleman quliyevaÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- S 7517Document32 paginiS 7517JDavid NavaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Ad 0299980Document68 paginiAd 0299980alexÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Fluid Flow - Lecture Note - 9Document6 paginiFluid Flow - Lecture Note - 9Ikegbule AdaezeÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Design of Shell and Tube Heat Exchangers - A Review (2019)Document17 paginiThe Design of Shell and Tube Heat Exchangers - A Review (2019)David C. SouzaÎncă nu există evaluări

- Optimization of Shell and Tube Heat ExchangerDocument29 paginiOptimization of Shell and Tube Heat ExchangerAna QuintanaÎncă nu există evaluări

- A Modern Course in Transport Phenomena by Venerus OttingerDocument538 paginiA Modern Course in Transport Phenomena by Venerus OttingerJoshelyn Mariangela Paredes ZavalaÎncă nu există evaluări

- Fluid Mechanics Fundamentals and Applications 3rd Edition Cengel Solutions ManualDocument25 paginiFluid Mechanics Fundamentals and Applications 3rd Edition Cengel Solutions ManualDanielNelsonipzr100% (56)

- Letter Aeronautical Sciences: Symbols ForDocument30 paginiLetter Aeronautical Sciences: Symbols ForMadhu MadhuÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Assessing Flowability of Small Quantities of Cohesive Powder Using Distinct Element ModellingDocument4 paginiAssessing Flowability of Small Quantities of Cohesive Powder Using Distinct Element ModellingYadeÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Mechanical Properties of Solids - AR MCQSDocument12 paginiMechanical Properties of Solids - AR MCQSShobha SinghÎncă nu există evaluări

- Convective Mass TransferDocument26 paginiConvective Mass TransferJorge Alberto Cuellar BolivarÎncă nu există evaluări

- Title: Unit V Turbulence and SimilarityDocument64 paginiTitle: Unit V Turbulence and SimilarityRishi Gethu MassÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- WindandDocument17 paginiWindandjose manuel gomez jimenezÎncă nu există evaluări

- Transport Phenomena (CHE-345) : Interphase Transport and Transfer Coefficients Ismail TosunDocument21 paginiTransport Phenomena (CHE-345) : Interphase Transport and Transfer Coefficients Ismail Tosunmuhammad shahadat awanÎncă nu există evaluări

- Xi CH 1Document33 paginiXi CH 1Sajid UllahÎncă nu există evaluări

- Homeworks 1-10 PDFDocument95 paginiHomeworks 1-10 PDFWendy LinÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- MATCHING RESERVOIR PROPERTIES WITH TYPE CURVESDocument57 paginiMATCHING RESERVOIR PROPERTIES WITH TYPE CURVESDEAF BOY TOMAHUÎncă nu există evaluări

- Surface Tension ExplainedDocument23 paginiSurface Tension ExplainedSwagBeast SKJJÎncă nu există evaluări

- ISEC 1996 Proceedings Vol1Document862 paginiISEC 1996 Proceedings Vol1Ashish KotwalÎncă nu există evaluări

- Class 10 Free Span AnalysisDocument37 paginiClass 10 Free Span AnalysisLK AnhDungÎncă nu există evaluări

- FMM - Unit Iii QBDocument50 paginiFMM - Unit Iii QBThiruvasagamoorthy KaÎncă nu există evaluări

- Unitops CH 1Document13 paginiUnitops CH 1Arturo TorresÎncă nu există evaluări

- H81HMT Heat Transfer Notes Section 2Document44 paginiH81HMT Heat Transfer Notes Section 2محمد سالمÎncă nu există evaluări

- 11 - Convection & Reynolds NumberDocument19 pagini11 - Convection & Reynolds NumberMahir MahmoodÎncă nu există evaluări

- Topic 4 Dimensional Analysis Similititude Modelling 1Document78 paginiTopic 4 Dimensional Analysis Similititude Modelling 1Riker SiÎncă nu există evaluări

- Engineering Fluid Mechanics 10th Edition Elger Solutions Manual Full Chapter PDFDocument67 paginiEngineering Fluid Mechanics 10th Edition Elger Solutions Manual Full Chapter PDFaffreightlaurer5isc100% (13)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)