Documente Academic

Documente Profesional

Documente Cultură

Oil Circulation Tank 674 GB Register 7

Încărcat de

hendraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oil Circulation Tank 674 GB Register 7

Încărcat de

hendraDrepturi de autor:

Formate disponibile

Fittings for oil

Weishaupt oil circulation tank

1. General information

The oil circulation tank is a packaged unit The second oil meter in the return, as well as For fuel oil EL the pipe connections at the unit

offering oil metering for burners, in particular the safety valve to bypass the oil meter in the can be reduced by the installer, i.e. by using

those having spill type nozzles. return are no longer required. reducers. For fuel oil S however, it could be

the opposite and in some cases, they may

Previously, two oil meters one in the burner need to be increased in diameter.

The oil circulation tank contains a shut off flow and one in the return, were needed to

valve, an oil filter, an oil meter and a safety calculate the actual consumption using the The oil circulation tanks oil pipe connections

valve. The connection of an oil additive mixing difference between the two. are plain ends, suitable for either welding or

unit is possible. other numerous fitting possibilities, employing

The oil circulation device considerably reduces screwed or flanged components.

The oil meters used have a measurement installation work.

tolerance of 1% from the measurement

value and an accuracy of 2% within the The oil meter is not approved for precise oil

minimum and maximum throughputs given in throughput calculations.

the table to the right.

The pipe connections for burner and ring main

are dimensioned for residual oil. The additional

pipe layout is carried out to the dimensions

given in work sheets (6-2.1 to 6.2.4).

2. Description

The oil circulation tank consists of two bubbles prior to starting the venting Pressure setting ring main

completely separated chambers, which are process at the ball valve. Initial venting The pressure is set at the pressure regulating

connected by the ball valve, the filter and the should be carried out as described in the valve in the ring main. Pressure is shown

oil meter. Therefore only the oil actually used installation instructions given in point d (oil on the pressure gauge at the intake of the

by the burner is metered. meter installation and removal). burner pump. (Measurement only during

To protect the oil meter after draining, carry burner operation at full load).

The safety valve fitted relieves any excess on as follows:

The ball valve should only opened a Table

pressure caused due to temperature increase

during burner shut down when the ball valve is fraction, so that the oil under pressure a) Fuel oil S

closed. slowly fills the filter, oil meter and the

upper chamber of the oil circulation tank, Atomising Required

as well as the lines to the burner pump. temperature C excess pressure bar

Venting is extremely important for the reliable

operation of the oil circulation tank. Venting is Rapid filling will damage the measuring 125 2.5

carried out via ball valve. accuracy of the oil meter. Only open the 130 2.7

ball valve fully once the venting process 135 3.2

This ball valve has to be opened until the has been completed.

system has been vented following first 140 3.8

The oil/air mixture exiting at the ball valve 145 4.4

commissioning, after every service, or when (during the venting process) flows through the

exchanging oil hoses and nozzles and when oil meter and is indicated. This measured

disturbing the oil lines etc. b) Fuel oil EL ________1.5-2.0 bar

quantity is not an actual burner consumption.

Please note that venting should be activated Venting should also be carried out, if air has For supply systems with multiple burners the

when the burner is shut down (burner pump) accumulated in the circulation chamber connection line should be fitted with a

and relative to the oil supply pressure following prolonged operation. A sure sign of restrictor valve for equalisation (only with

available. this are irregular noises from the burner oil M+S).

When first venting a new oil supply or after pump.

Filter maintenance

it has been re-filled, the ball valve should The oil circulation tank must only be operated By manually rotating the spindle and therefore

initially be fully closed. The oil ring main with a pressurised supply. The supply pres- the filter bundle (depending on degree of

and the lines branching off to the oil sure for oil EL should be a minimum of1.5 bar. soiling in the fuel oil) any debris is removed

circulation tank, as well as the lower from the filtering edges.

chamber of the oil circulation tank must For fuel oil M and S the pressure The debris falls to the base of the housing.

first be filled with oil and the ring main depends on the oil preheat temperature set This can be removed periodically by removing

pumps must be operating for a few (see table). the drainage plug.

minutes, so that the oil is free from

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, May 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 1

Fittings for oil

Weishaupt oil circulation tank

Installation information:

a) Installation position f) Flange connections:

The oil circulation tank only works in one position with the flow connection to the If flange connections are required, the following parts must also be ordered:

burner vertically upwards. For W-OC 180:

1 x welding flange set DN32 for W-OC-S135 No.: 10900008212

b) Flow direction

The flow direction within the ring main connections can be in any direction. For W-OC 1000/2000:

The flow direction in the flow and return to the burner must be observed. 1 x welding flange set DN65 for W-OC-S135 No.: 10900009182

The flanges must be welded on on site.

c) Heating:

The heating must only be electrically energised once the oil circulation tank has g) Trace heating:

been filled with oil and vented. If trace heating is required, the following parts must also be ordered:

Trace heating set 230V W-OC-S

d) Fitting and removing the oil meter: (heating capacity 1 x 192W and 1 x 350W) No.: 10900009192

When delivered, the oil circulation device is fitted with double nipple (instead of the

oil meter). The oil meter and the seals required are supplied loose. Replacement parts:

The oil meter must only be mounted after venting and once the system is completely Filter insert for W-OC-L 1000 EF, W-OC-L 2000 EF 100m No.: 453528

filled. To mount the oil meter, close the ball valve with an SW17 wrench. Drain Filter insert for W-OC-S 1000 EF and W-OC-S 2000 EF 200m No.: 493531

sufficient oil through the drain plug to allow the double nipple to be removed and the Filter insert for W-OC-L 180 SF, W-OC-L 1000 SF

oil meter with new seals to be fitted . and W-OC-L 1500 SF 100m No.: 493536

The system must be vented after every drainage. Set of seals for filter for W-OC-L and W-OC-S No.: 493537

Heating cartridge 230V 55W (filter) No.: 10900006182

e) Additive injection Heating cartridge 230V 110W (container) No.: 10900006212

Connect supply line of the additive mixing unit with G 1/4 to

connection 2 (page 2).

Description Filter Meter Oil type Oil throughput Voltage Order No.

W-OC-L 180 SF Star filter 100m VZO 8 Fuel oil L 4 - 180 L/h 10900008012

W-OC-L 180 SF Star filter 100m VZO 8 RE 1 Fuel oil L 4 - 180 L/h 10900008022

W-OC-L 180 SF Star filter 100m VZO 8 RE 0.00311 Fuel oil L 4 - 180 L/h 10900008032

W-OC-L 1000 SF Star filter 100m VZO 20 Fuel oil L 30 - 1000 L/h 10900009102

W-OC-L 1000 SF Star filter 100m VZO 20 RV 1 Fuel oil L 30 - 1000 L/h 10900009112

W-OC-L 1000 SF Star filter 100m VZO 20 IN 0.01 Fuel oil L 30 - 1000 L/h 10900009122

W-OC-L 1500 SF Star filter 100m VZO 25 Fuel oil L 75 - 1500 L/h 10900010102

W-OC-L 1500 SF Star filter 100m VZO 25 RV 1 Fuel oil L 75 - 1500 L/h 10900010112

W-OC-L 1500 SF Star filter 100m VZO 25 IN 0.1 Fuel oil L 75 - 1500 L/h 10900010122

W-OC-L 1000 EF Edge filter 100m VZO 20 Fuel oil L 30 - 1000 L/h 10900009012

W-OC-L 1000 EF Edge filter 100m VZO 20 RV 1 Fuel oil L 30 - 1000 L/h 10900009022

W-OC-L 1000 EF Edge filter 100m VZO 20 IN 0.01 Fuel oil L 30 - 1000 L/h 10900009032

W-OC-L 2000 EF Edge filter 100m VZO 25 Fuel oil L 75 - 2000 L/h 10900010012

W-OC-L 2000 EF Edge filter 100m VZO 25 RV 1 Fuel oil L 75 - 2000 L/h 10900010022

W-OC-L 2000 EF Edge filter 100m VZO 25 IN 0.1 Fuel oil L 75 - 2000 L/h 10900010032

W-OC-S 1000 EF Edge filter 200m VZO 20 Fuel oil S 30 - 1000 L/h 230V 10900009042

W-OC-S 1000 EF Edge filter 200m VZO 20 Fuel oil S 30 - 1000 L/h 110V 10900009072

W-OC-S 1000 EF Edge filter 200m VZO 20 RV 1 Fuel oil S 30 - 1000 L/h 230V 10900009052

W-OC-S 1000 EF Edge filter 200m VZO 20 RV 1 Fuel oil S 30 - 1000 L/h 110V 10900009082

W-OC-S 1000 EF Edge filter 200m VZO 20 IN 0.01 Fuel oil S 30 - 1000 L/h 230V 10900009062

W-OC-S 1000 EF Edge filter 200m VZO 20 IN 0.01 Fuel oil S 30 - 1000 L/h 110V 10900009092

W-OC-S 2000 EF Edge filter 200m VZO 25 Fuel oil S 75 - 2000 L/h 230V 10900010042

W-OC-S 2000 EF Edge filter 200m VZO 25 Fuel oil S 75 - 2000 L/h 110V 10900010072

W-OC-S 2000 EF Edge filter 200m VZO 25 RV1 Fuel oil S 75 - 2000 L/h 230V 10900010052

W-OC-S 2000 EF Edge filter 200m VZO 25 RV1 Fuel oil S 75 - 2000 L/h 110V 10900010082

W-OC-S 2000 EF Edge filter 200m VZO 25 IN 0.1 Fuel oil S 75 - 2000 L/h 230V 10900010062

W-OC-S 2000 EF Edge filter 200m VZO 25 IN 0.1 Fuel oil S 75 - 2000 L/h 110V 10900010092

Star filter : Cleaning during operation not possible

Edge filter : Cleaning during operation possible, integrated magnetic separator

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, May 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 2

Fittings for oil

Weishaupt oil circulation tank

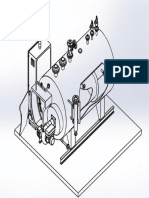

W-OC-L 180 SF with star filter and oil meter VZO 8 fuel oil L4 - 180 L/h

5 4 10 1

6 2

7 7

4 3 9

W-OC-L 1000 with star filter and oil meter VZO 20 fuel oil EL 30 - 1000 L/h

W-OC-L 1500 with star filter and oil meter VZO 25 fuel oil EL 75 - 1500 L/h

5 4 10 1

8

2

6

7 7

4 3 9

1 Burner supply Ball valve open Ball valve closed

2 Burner return

3 Safety valve

4 Ball valve

5 Oil meter

6 Star filter fuel oil EL 100m

7 Ring main

8 Ball valve for venting

9 Oil drainage plug filter (filter cleaning)

10 Connection for pressure gauge

Pressure gauge -1/+9 bar with shut off valve Order No. 12136485030

Screwed union KOR15-12 Order No. 452160

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, September 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 3

Fittings for oil

Weishaupt oil circulation tank

W-OC-L 1000 EF with edge filter oil meter VZO 20 fuel oil L 30 - 1000 L/h

W-OC-L 2000 EF with edge filter oil meter VZO 25 fuel oil L 75 - 2000 L/h

8 6 13 1

11

3

9

10 10

6 5 12

W-OC-S 1000 EF with edge filter oil meter VZO 20 fuel oil S 30 - 1000 L/h

W-OC-S 2000 EF with edge filter oil meter VZO 25 fuel oil S 75 - 2000 L/h

8 6 13 1

2 11

3

9

4

10 10

4

7 6 5 12

1 Burner supply

2 Connection for additive line G1/4

3 Burner return Ball valve open Ball valve closed

4 Heating (only for fuel oil S)

5 Safety valve

6 Ball valve

7 Terminal box (only for fuel oil S)

8 Oil meter

9 Edge filter

fuel oil EL 100m

fuel oil S 200m

10 Ring main

11 Ball valve for venting

12 Oil drainage plug filter (filter cleaning)

13 Connection for pressure gauge

Pressure gauge -1/+9 bar with shut off valve Order No. 12136485030

Screwed union KOR15-12 Order No. 452160

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, September 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 4

Fittings for oil

Weishaupt oil circulation tank

W-OC-L 180 SF with star filter and oil meter VZO 8 fuel oil L4 - 180 L/h

175 92

42.4

648

42.4

42.4

42.4

(423)

344

50

534 1036

1000

14

350

W-OC-L 1000 SF with star filter and oil meter VZO 20 fuel oil EL 30 - 1000 L/h

W-OC-L 1500 SF with star filter and oil meter VZO 25 fuel oil EL 75 - 1500 L/h

350

175

76.1

76.1

556

76.1

(423)

76.1

131.5

50

14

350

1000

1036

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, September 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 5

Fittings for oil

Weishaupt oil circulation tank

W-OC-L/S 1000 EF edge filter oil meter VZO 20 fuel oil L / S 30 - 1000 L/h

W-OC-L/S 2000 EF edge filter oil meter oil meter VZO 25 fuel oil L / S 75 - 2000 L/h

350

175

76.1

76.1

76.1

556

(463.5)

344

76.1

131.5 3

50

14

350

1036

Pipework system: Ring main for single burner:

Open ball valves (1). Set pressure regulating

valve to lowest pressure. Switch on ring main

pump. Fill ring main, oil circulation unit, supply

Burner pipework, burner etc. with oil and vent.

supply Close ball valves (1) and fit oil meter.

Pump station Open ball valves (1) and vent unit again. Set

Burner Venting

Ring main pressure regulating valve to pressure

return

given in table (measured at the burner pump

1

with the burner operating at full load setting).

Ring main for multiple burners:

Open ball valves (1). Set pressure regulating

valve to lowest pressure. Switch on ring main

pump. Fill ring main, oil circulation unit, supply

pipework, burner etc. with oil and vent.

Close ball valves (1) and fit oil meter.

Burner Burner Burner Open ball valves (1) and vent unit again. Set

supply supply supply pressure regulating valve to pressure

Burner Venting Burner Burner Venting given in table (measured at the burner pump

Pump station return return return with the burner operating at full load setting).

Ring main

1 1 1

For fuel oil S, a restrictor valve is required in

the connection pipework to the return of the

ring main to balance the flow resistances.

It is supplied fully open. During initial

commissioning, the restrictor valve is

adjusted in such a way that, at full load, the

Restrictor valve Restrictor valve connection pipework to all burners connected

fuel oil S only fuel oil S only to the system is supplied equally with oil and

kept warm.

Pressure regulating valve

Max Weishaupt GmbH, D-88475 Schwendi

Tel.: +49 7353 8 30, Fax: +49 7353 8 33 58

Technical folder 674 GB, May 2015

All rights reserved.

We reserve the right to make changes. 7-1.7 Sheet 6

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Installation and Operating Instructions W FM Comwithinput Output Add On ModuleDocument48 paginiInstallation and Operating Instructions W FM Comwithinput Output Add On ModuleCaZias EoiÎncă nu există evaluări

- Mod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot PlantDocument4 paginiMod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot Plantessam essÎncă nu există evaluări

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 paginiReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersÎncă nu există evaluări

- Solar Centaur 40 - Mechanical DriveDocument2 paginiSolar Centaur 40 - Mechanical Driverezzz7Încă nu există evaluări

- Altronic Iii: Ignition System For Industrial EnginesDocument4 paginiAltronic Iii: Ignition System For Industrial EnginesClever NegreteÎncă nu există evaluări

- Vacon 100 FLOW Application Manual DPD01083F UKDocument380 paginiVacon 100 FLOW Application Manual DPD01083F UKJoonki YunÎncă nu există evaluări

- PNEUMAX CatalogueDocument980 paginiPNEUMAX CatalogueZoran DjurdjevicÎncă nu există evaluări

- Sulzer MD 126 TdsDocument2 paginiSulzer MD 126 TdsJonasJonyÎncă nu există evaluări

- Steam Trap TesterDocument4 paginiSteam Trap TesterISMAEL RAMIREZÎncă nu există evaluări

- Atv31 (E)Document220 paginiAtv31 (E)Santos Zosimo Ocas GoicocheaÎncă nu există evaluări

- Quemador Riello - RL - 70 - 100 - 130 - ManualDocument28 paginiQuemador Riello - RL - 70 - 100 - 130 - ManualCsr TorresÎncă nu există evaluări

- FlenderTechnical HandbookDocument79 paginiFlenderTechnical HandbookTom TamponÎncă nu există evaluări

- AIRTORQUEDocument20 paginiAIRTORQUEPaula MendesÎncă nu există evaluări

- Level Monitor DATUM SCU500 LOOPDocument20 paginiLevel Monitor DATUM SCU500 LOOPJose Manuel Vazquez ZarcoÎncă nu există evaluări

- Kinemax Gas or Oil Burners: Bulletin 4200Document26 paginiKinemax Gas or Oil Burners: Bulletin 4200agua1829Încă nu există evaluări

- Burner-Comparison - Uso InternoDocument1 paginăBurner-Comparison - Uso InternoRICARDO PINTOÎncă nu există evaluări

- TZ 200.01 Bending Device Gunt 1429 PDF 1 en GBDocument2 paginiTZ 200.01 Bending Device Gunt 1429 PDF 1 en GBJA C FÎncă nu există evaluări

- Flame Scanner Sensor PDFDocument36 paginiFlame Scanner Sensor PDFGhuna UcihaÎncă nu există evaluări

- General Specification For Electric Actuators - Integral Motor ControlDocument4 paginiGeneral Specification For Electric Actuators - Integral Motor ControlschgirlÎncă nu există evaluări

- Fuel Oil System P & ID1Document1 paginăFuel Oil System P & ID1Parmeshwar Nath TripathiÎncă nu există evaluări

- Boiler RoomDocument1 paginăBoiler RoomtylerstearnsÎncă nu există evaluări

- Modern Trends in Internal Combustion EnginesDocument15 paginiModern Trends in Internal Combustion EnginesMahmOud S. El-MashadÎncă nu există evaluări

- Grundfos CRCRNDocument73 paginiGrundfos CRCRNsmile4hariÎncă nu există evaluări

- ASCO SolenoidDocument10 paginiASCO Solenoidsharib26Încă nu există evaluări

- System GuideDocument218 paginiSystem Guidethanh_79Încă nu există evaluări

- Ec3X Burst Tester Instruction Manual: Bűchel B.VDocument45 paginiEc3X Burst Tester Instruction Manual: Bűchel B.Vmohamadreza1368Încă nu există evaluări

- Old Fan DesignDocument42 paginiOld Fan DesignRyan KurniaÎncă nu există evaluări

- GEA Ecoflex NT Serie EDocument2 paginiGEA Ecoflex NT Serie EVLASTAR0% (1)

- Nism GK567GBDocument16 paginiNism GK567GBsafwan azizÎncă nu există evaluări

- Compressors, Chillers & CondensersDocument113 paginiCompressors, Chillers & CondensersmicerinosÎncă nu există evaluări

- Nrs 1-50 GestraDocument28 paginiNrs 1-50 Gestramike tsakirisÎncă nu există evaluări

- Catalogo Catalogue Giuliani Anello 2015 FiltreDocument116 paginiCatalogo Catalogue Giuliani Anello 2015 Filtrekhabbab hussainÎncă nu există evaluări

- Olaer EhvDocument12 paginiOlaer EhvandinoÎncă nu există evaluări

- Woodward EG-3P, Proportional ActuatorDocument4 paginiWoodward EG-3P, Proportional ActuatorMohd Ridzuan AhmadÎncă nu există evaluări

- LDP Series Actuator - DEMBLADocument4 paginiLDP Series Actuator - DEMBLAKamitkumar PatelÎncă nu există evaluări

- MAS 711 Technical DataDocument8 paginiMAS 711 Technical DatarianandiyahooÎncă nu există evaluări

- ARCA Evolution160 240 enDocument2 paginiARCA Evolution160 240 enadyturÎncă nu există evaluări

- Sel Guide 1-15Document17 paginiSel Guide 1-15Ezequiel FinleyÎncă nu există evaluări

- ABB Navigator 600Document96 paginiABB Navigator 600lequydueu100% (1)

- SKF Pinion SolutionsDocument31 paginiSKF Pinion SolutionsLLÎncă nu există evaluări

- Depliant Brochure Marine en PDFDocument9 paginiDepliant Brochure Marine en PDFFadzil NorÎncă nu există evaluări

- Nor GrenDocument5 paginiNor GrenSarlo11Încă nu există evaluări

- Project ReportDocument36 paginiProject Reportvishi89Încă nu există evaluări

- Auto Drain ValveDocument2 paginiAuto Drain ValveRoopa MahtoÎncă nu există evaluări

- As Operating and Installation InstructionsDocument12 paginiAs Operating and Installation InstructionsmedjebÎncă nu există evaluări

- Burner Monoblockburners50 - 1200 - EN - 2018Document96 paginiBurner Monoblockburners50 - 1200 - EN - 2018Randy FajardoÎncă nu există evaluări

- Manual Wayne 3G7221P-8JKDocument96 paginiManual Wayne 3G7221P-8JKAlejandro AdriasolaÎncă nu există evaluări

- Pressure & Temperature Switch RT SeriesDocument4 paginiPressure & Temperature Switch RT SeriesVivek Vous AimeÎncă nu există evaluări

- Vu/Vhliquidringvacuumpumps: Technical DataDocument22 paginiVu/Vhliquidringvacuumpumps: Technical DataIMAM HARYADIÎncă nu există evaluări

- Instruction Manual GS PUMPDocument28 paginiInstruction Manual GS PUMPVu DangÎncă nu există evaluări

- Variable Frequency DrivesDocument54 paginiVariable Frequency DrivesAlessandro DamascenoÎncă nu există evaluări

- Pneumax VacuumTechnologyDocument124 paginiPneumax VacuumTechnologyMd MansoorÎncă nu există evaluări

- SPX Johnson Pump OverviewDocument8 paginiSPX Johnson Pump OverviewSLNSG - 李玟福Încă nu există evaluări

- Pub109-011!00!1114 Soldo Sy-Sw Switchbox FlyerDocument4 paginiPub109-011!00!1114 Soldo Sy-Sw Switchbox FlyerEric JohnsonÎncă nu există evaluări

- Oil Flushing Procedures For Steam Turbine & Generator Sets 1Document8 paginiOil Flushing Procedures For Steam Turbine & Generator Sets 1atul singhÎncă nu există evaluări

- Sezione 2 PDFDocument8 paginiSezione 2 PDFMAZZI1978100% (1)

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 paginiElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianÎncă nu există evaluări

- System Descr MAB ModulesDocument10 paginiSystem Descr MAB ModulesMareks LezevskisÎncă nu există evaluări

- Pompe Motorina VD - Carte TehnicaDocument6 paginiPompe Motorina VD - Carte Tehnicar_cristiÎncă nu există evaluări

- Table Steam 1Document1 paginăTable Steam 1hendraÎncă nu există evaluări

- Lesson 9 - Estimating & Comparing Weld Metal CostsDocument1 paginăLesson 9 - Estimating & Comparing Weld Metal CostshendraÎncă nu există evaluări

- Bono Thermal Oil HeatersDocument10 paginiBono Thermal Oil HeatershendraÎncă nu există evaluări

- Flange Tables - Compare Common FlangesDocument20 paginiFlange Tables - Compare Common FlangeshendraÎncă nu există evaluări

- Full Page PhotoDocument1 paginăFull Page PhotohendraÎncă nu există evaluări

- Boiler PDFDocument1 paginăBoiler PDFhendraÎncă nu există evaluări

- Overflow ValveDocument1 paginăOverflow ValvehendraÎncă nu există evaluări

- Industrial Steam Steam Flow Deaerator PDFDocument4 paginiIndustrial Steam Steam Flow Deaerator PDFhendraÎncă nu există evaluări

- Klinger Marine Valves & GasketsDocument279 paginiKlinger Marine Valves & GasketsAndy Luthor100% (1)

- Industrial Steam Steam Flow DeaeratorDocument4 paginiIndustrial Steam Steam Flow DeaeratorhendraÎncă nu există evaluări

- Simboli Cevovod SD230511-17Document1 paginăSimboli Cevovod SD230511-17tekijacÎncă nu există evaluări

- Simboli Cevovod SD230511-17Document1 paginăSimboli Cevovod SD230511-17tekijacÎncă nu există evaluări

- Natural Resources in The Philippines PresentationDocument19 paginiNatural Resources in The Philippines PresentationRaymond de Fiesta100% (1)

- YIY POWERWALL Engergy Storage System ConfigurationDocument3 paginiYIY POWERWALL Engergy Storage System ConfigurationIT TG CAPÎncă nu există evaluări

- NTPC KantiDocument33 paginiNTPC Kantivivek mahobiya100% (1)

- Psac2017 Grade6 Science PDFDocument16 paginiPsac2017 Grade6 Science PDFDefimediaÎncă nu există evaluări

- Power Units Based in Stirling EnginesDocument7 paginiPower Units Based in Stirling EnginesDïego Andrés NÎncă nu există evaluări

- Seychelles Africa RE SPDocument4 paginiSeychelles Africa RE SPstevenÎncă nu există evaluări

- Connect Nergy Olutions: RE E SDocument4 paginiConnect Nergy Olutions: RE E SSuresh ThevarÎncă nu există evaluări

- Pakistan Affairs 2021Document2 paginiPakistan Affairs 2021Naeem RehmanÎncă nu există evaluări

- Industrial Technologies Program: Ultra-Low Nox Burners With Flue Gas Recirculation and Partial ReformerDocument2 paginiIndustrial Technologies Program: Ultra-Low Nox Burners With Flue Gas Recirculation and Partial ReformerOA AooÎncă nu există evaluări

- IKEA (2015), Sustainability ReportDocument94 paginiIKEA (2015), Sustainability ReportDWotherspoon22Încă nu există evaluări

- POWER SYSTEMS Assignment Smart Micro GridDocument6 paginiPOWER SYSTEMS Assignment Smart Micro GridSafwan D. MasarikÎncă nu există evaluări

- Hyundai Dash 9 Posi Nega SytemDocument70 paginiHyundai Dash 9 Posi Nega SytemSomboonpanmaingam Paprom100% (3)

- Acetylene and Oxygen Safe Use For WeldingDocument16 paginiAcetylene and Oxygen Safe Use For WeldingShirishÎncă nu există evaluări

- GHG Emission India - Cement Tool FinalDocument75 paginiGHG Emission India - Cement Tool FinaljagrutÎncă nu există evaluări

- Airconditioning Feb 2018 Rev 4 Presentation-7Document59 paginiAirconditioning Feb 2018 Rev 4 Presentation-7darius james del mar86% (7)

- Iloilo City Has The Most Expensive Electricity in The CountryDocument7 paginiIloilo City Has The Most Expensive Electricity in The CountryKate Catherine RamosÎncă nu există evaluări

- DaihatsuDocument10 paginiDaihatsuMANIU RADU-GEORGIANÎncă nu există evaluări

- Egr BrochureDocument7 paginiEgr BrochureEcogreen1Încă nu există evaluări

- Doosan Basic EngineDocument67 paginiDoosan Basic EngineJuan Guzmán100% (4)

- MIA Market Report 2017Document45 paginiMIA Market Report 2017sanjeevÎncă nu există evaluări

- Spmd10yb ManualDocument50 paginiSpmd10yb ManualmeitixrecargedÎncă nu există evaluări

- International Baccalaureate Chemistry Higher Level Extended EssayDocument28 paginiInternational Baccalaureate Chemistry Higher Level Extended EssayGeorge GeorgiadisÎncă nu există evaluări

- Pump Storage WBSEDCLDocument33 paginiPump Storage WBSEDCLDave ChaudhuryÎncă nu există evaluări

- Thesis Statement For Solar PowerDocument8 paginiThesis Statement For Solar Powerafcnfajtd100% (2)

- Huafengdongli 495 4100 Series OperationmanualDocument73 paginiHuafengdongli 495 4100 Series OperationmanualHoang Vien DuÎncă nu există evaluări

- VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualDocument29 paginiVA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation ManualhoangduythanhqbÎncă nu există evaluări

- Properly Designing A Boiler Exhaust SystemDocument26 paginiProperly Designing A Boiler Exhaust SystemAndrivoka RheevooÎncă nu există evaluări

- Punjab Technical University: Theory of Machines-IDocument3 paginiPunjab Technical University: Theory of Machines-IdraculagurdeepÎncă nu există evaluări

- Decommissioning Strategy-IMP PDFDocument70 paginiDecommissioning Strategy-IMP PDFInaya GeorgeÎncă nu există evaluări

- POWER Magazine - May 2023-1Document43 paginiPOWER Magazine - May 2023-1MarcialgonzalezpÎncă nu există evaluări