Documente Academic

Documente Profesional

Documente Cultură

Torque Bridas PRFV

Încărcat de

Andres Camilo Galvis EspinelDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Torque Bridas PRFV

Încărcat de

Andres Camilo Galvis EspinelDrepturi de autor:

Formate disponibile

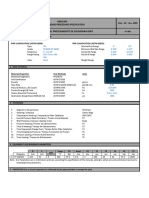

ASME RTP-12007

Fig. 4-10 Nozzle Flange Dimensions for Class 150 Bolting

+1/ in.

A 02in.

C

B

T

Flange face flatness

per Table 4-1.

F F At F, spot face for

L

Min. radius washers. See below.

1/ in.

4

t

hr

ANSI

B18.22.1

C, Min. T, Min. T, Min. Hub Type A Narrow

Size in. Type I Type II Reinforcement, Min. Min. No. Bolt Hole Bolt Washer Size Bolt

B, A, [Notes Laminates, Laminates, hr , t, L, of Diameter, Diameter, (O.D.), Torque,

in. in. (1)(3)] in. in. in. in. in. Bolts in. in. in. ft-lb

2 6 434 0.625 0.563 0.25 0.25 258 4 3

4 5

8 1516 25

3 712 6 0.625 0.563 0.283 0.25 278 4 3

4 5

8 1516 25

4 9 712 0.813 0.688 0.313 0.25 314 8 3

4 5

8 1516 25

6 11 912 0.938 0.688 0.313 0.25 31316 8 7

8 3

4 112 25

8 1312 1134 1.125 0.813 0.375 0.25 438 8 7

8 3

4 112 25

10 16 1414 1.25 0.938 0.5 0.25 438 12 1 7

8 134 25

12 19 17 1.438 1.063 0.625 0.25 41516 12 1 7

8 134 25

14 21 1834 1.438 1.063 0.688 0.313 5 12 118 1 2 30

16 2312 2114 1.563 1.188 0.813 0.313 5116 16 118 1 2 30

18 25 2234 1.625 1.25 0.75 0.375 512 16 114 118 214 35

20 2712 25 1.813 1.313 0.75 0.375 538 20 114 118 214 35

24 32 2912 2.125 1.5 0.813 0.438 538 20 138 114 238 40

GENERAL NOTES:

(a) Gaskets shall be 18-in. thick full-face elastomeric material having a hardness of Shore A60 5.

(b) Flange thicknesses are based on 1,800 psi design stress for Type I laminates and a 3,000 psi design stress for Type II laminates. A

design factor of 5:1 was used against ultimate tensile stress in both types of laminate construction.

(c) The nozzle neck thicknesses given are based on a Type II or equivalent strength filament wound Type X laminate with a design factor

of 10:1 against ultimate tensile strength and are the minimum thicknesses that may be used in all types of laminate construction. If

Type I hand lay-up laminates are utilized, the nozzle neck thicknesses must be increased for nozzle sizes 10 in. and up.

(d) The rating of all nozzle necks and flanges for all sizes given in this Table is 50 psi.

(e) Dimensions generally comparable to Class 150 welding-neck flanges.

NOTES:

(1) 0.06 in. (see ASME B16.5).

(2) 0.03 in. center to center of adjacent bolt holes (see ASME B16.5).

(3) Eccentricity between bolt holes and center of nozzle: for size 2 in., 0.03 in.; for size 3 in. and larger, 0.06 in.

48

S-ar putea să vă placă și

- Tabla de Equivalencias Pulgadas DiametralesDocument7 paginiTabla de Equivalencias Pulgadas DiametralesPaul Paredes Flores100% (1)

- Torqueo Pikotek PDFDocument4 paginiTorqueo Pikotek PDFjast111100% (1)

- Catalogo, Sockolet, Threadolet, Nippolet, Swaged NippleDocument3 paginiCatalogo, Sockolet, Threadolet, Nippolet, Swaged NippleD_carolina50% (2)

- QT 16Cr PDFDocument1 paginăQT 16Cr PDFYaroslav RuizÎncă nu există evaluări

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 paginăNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefÎncă nu există evaluări

- Tabla Limite de Retiro EspesoresDocument4 paginiTabla Limite de Retiro EspesoresVicent RojasÎncă nu există evaluări

- Tipicos Tuberia Ecopetrol PDFDocument141 paginiTipicos Tuberia Ecopetrol PDFJunior Oña OrdoñezÎncă nu există evaluări

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Document3 paginiDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Torque Spiral Wound GSKT TableDocument2 paginiTorque Spiral Wound GSKT TableCarlos Roberto Tamariz100% (1)

- Tabla de Torque - HdpeDocument3 paginiTabla de Torque - HdpeDevi SalcedoÎncă nu există evaluări

- Table 11 of API 5LDocument1 paginăTable 11 of API 5LBilly Kurniawan100% (1)

- Tapa Semieliptica: X 900 X 900 Y 15.875 Y 12.7 Z 50.8 Z 50.8Document3 paginiTapa Semieliptica: X 900 X 900 Y 15.875 Y 12.7 Z 50.8 Z 50.8eGnEsToMc100% (3)

- ASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblyDocument1 paginăASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblykhaireddinÎncă nu există evaluări

- MEDIDAS TURBINA Dresser Imtm MeretDocument3 paginiMEDIDAS TURBINA Dresser Imtm MeretronaldÎncă nu există evaluări

- Argus FK76MDocument2 paginiArgus FK76MFelipe Gamboa Gálvez100% (1)

- Calculo Espesores ASME B31.4Document13 paginiCalculo Espesores ASME B31.4Juan YepesÎncă nu există evaluări

- Tee GuiadaDocument1 paginăTee GuiadaDANIELCOLUNGAÎncă nu există evaluări

- B1a1 Pipe ClassDocument1 paginăB1a1 Pipe Classbrujula27Încă nu există evaluări

- Acsr SPLN 41-7 PDFDocument2 paginiAcsr SPLN 41-7 PDFDharta Wira100% (1)

- Engrasadora NEUMATICAFLOWSERVERDocument16 paginiEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarÎncă nu există evaluări

- Bolt Torque Chart: ASTM A307Document5 paginiBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- Denso Protal 7200Document2 paginiDenso Protal 7200min_one447065Încă nu există evaluări

- Lista para Materiales Valvulas 8 Enero2020Document806 paginiLista para Materiales Valvulas 8 Enero2020Luis GonzalezÎncă nu există evaluări

- Hidrante Seco Mod F0733Document1 paginăHidrante Seco Mod F0733Julio FloresÎncă nu există evaluări

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Document3 paginiButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesÎncă nu există evaluări

- Astm A270 PDFDocument1 paginăAstm A270 PDFgaminÎncă nu există evaluări

- Practica # 2 PRV2SIZE PDFDocument4 paginiPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaÎncă nu există evaluări

- Tabla Torque PikotekDocument2 paginiTabla Torque PikotekHernando Diaz100% (2)

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDocument2 paginiFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PLuis CarlosÎncă nu există evaluări

- Victaulic Procedure To Load Spec To AutoCAD Plant 3DDocument4 paginiVictaulic Procedure To Load Spec To AutoCAD Plant 3Dluiskar985Încă nu există evaluări

- Dimensions Weldolet® Size On Size STD MSS SP97Document2 paginiDimensions Weldolet® Size On Size STD MSS SP97Musslih Yulianto100% (1)

- Api 12BDocument2 paginiApi 12BLENIN GAMARRA100% (2)

- Tubos Astm A53Document1 paginăTubos Astm A53RAFAELÎncă nu există evaluări

- Torques Espiraladas PDFDocument4 paginiTorques Espiraladas PDFFabricio Mayta BenitezÎncă nu există evaluări

- LS Furmanite OyMDocument26 paginiLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- Weldolet DimensionDocument4 paginiWeldolet DimensionabhishekÎncă nu există evaluări

- 2.1 WPS - PipingDocument13 pagini2.1 WPS - PipingSheri DiĺlÎncă nu există evaluări

- Hdpe Bps Sab355Document1 paginăHdpe Bps Sab355Benjamin Enmanuel Mango DÎncă nu există evaluări

- Anexo T - API 650Document4 paginiAnexo T - API 650ChristiaanÎncă nu există evaluări

- Astm A126Document3 paginiAstm A126Amit PanchalÎncă nu există evaluări

- Torque Values KlingerDocument1 paginăTorque Values KlingerSầu ĐờiÎncă nu există evaluări

- Nozzle CatalogueDocument53 paginiNozzle CatalogueMike UpÎncă nu există evaluări

- HDPE Bolt Torque Flanged Joints HIERRO DUCTILDocument1 paginăHDPE Bolt Torque Flanged Joints HIERRO DUCTILRenato BarretoÎncă nu există evaluări

- C0208-PAM-EP-2011-ARB SMARTPRO Página No. 208Document7 paginiC0208-PAM-EP-2011-ARB SMARTPRO Página No. 208Jose Antonio EspinosaÎncă nu există evaluări

- Split Tee CatalogoDocument3 paginiSplit Tee Catalogobotella berÎncă nu există evaluări

- Asme B31.8 Nozzles CalcDocument16 paginiAsme B31.8 Nozzles CalcSAMER OSMANÎncă nu există evaluări

- Asme SB 862 Astm b862 PDFDocument14 paginiAsme SB 862 Astm b862 PDFp v krishnakantÎncă nu există evaluări

- ASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelDocument1 paginăASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelStan HonÎncă nu există evaluări

- Anvil Fig137 U-Bolt PDFDocument1 paginăAnvil Fig137 U-Bolt PDFAin AzmiÎncă nu există evaluări

- SS SUB 175 v01Document1 paginăSS SUB 175 v01mcohen LCIÎncă nu există evaluări

- Clevis Hangers CombinedDocument4 paginiClevis Hangers CombinedSaleem BashaÎncă nu există evaluări

- ASME B16.5 - 3 InchDocument1 paginăASME B16.5 - 3 InchRanjan KumarÎncă nu există evaluări

- Estojos - ASME B16 5-2009Document7 paginiEstojos - ASME B16 5-2009Kauê VelhoÎncă nu există evaluări

- Abracadeira Gota - 287 1Document1 paginăAbracadeira Gota - 287 1Robson CustódioÎncă nu există evaluări

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocument1 paginăFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsMarco AntonioÎncă nu există evaluări

- SS SUB 181 v01Document1 paginăSS SUB 181 v01mcohen LCIÎncă nu există evaluări

- Chatham Steel StructshapesDocument21 paginiChatham Steel Structshapesjalv.mendoza25Încă nu există evaluări

- SS SUB 171 v01Document1 paginăSS SUB 171 v01mcohen LCIÎncă nu există evaluări

- Pipe HangerDocument105 paginiPipe HangerYvan Nuñez EscobedoÎncă nu există evaluări

- Llustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Document48 paginiLlustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Michael RapinoÎncă nu există evaluări

- Makenna Resort: by Drucker ArchitectsDocument12 paginiMakenna Resort: by Drucker ArchitectsArvinth muthuÎncă nu există evaluări

- Serie 20 Sauer DanfossDocument18 paginiSerie 20 Sauer DanfossCristian100% (1)

- KIT REQUEST FORM - GradDocument2 paginiKIT REQUEST FORM - Graddamie aadamsÎncă nu există evaluări

- Norm TMT PDFDocument12 paginiNorm TMT PDFGustavoÎncă nu există evaluări

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument59 paginiFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny lieÎncă nu există evaluări

- Nguyen Ngoc-Phu's ResumeDocument2 paginiNguyen Ngoc-Phu's ResumeNgoc Phu NguyenÎncă nu există evaluări

- Bachelors - Project Report 1Document43 paginiBachelors - Project Report 1divyaÎncă nu există evaluări

- Pricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarDocument12 paginiPricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarGaurav ChauhanÎncă nu există evaluări

- SIP Project ProposalDocument2 paginiSIP Project ProposalDeep SutariaÎncă nu există evaluări

- Universal Human Values NotesDocument13 paginiUniversal Human Values NotesS RamÎncă nu există evaluări

- FMDS0102Document69 paginiFMDS0102hhÎncă nu există evaluări

- 3949-Article Text-8633-1-10-20180712Document10 pagini3949-Article Text-8633-1-10-20180712Volodymyr TarnavskyyÎncă nu există evaluări

- G120D Getting Started 0418 en-USDocument94 paginiG120D Getting Started 0418 en-USHamadi Ben SassiÎncă nu există evaluări

- Experiment #3 Venturi Meter: Home Unquantized ProjectsDocument7 paginiExperiment #3 Venturi Meter: Home Unquantized ProjectsEddy KimathiÎncă nu există evaluări

- International Trade SyllabusDocument3 paginiInternational Trade SyllabusDialee Flor Dael BaladjayÎncă nu există evaluări

- Neal Peres Da CostaDocument507 paginiNeal Peres Da CostaNoMoPoMo576100% (1)

- Student Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaDocument14 paginiStudent Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaJoshua Perez-Luna67% (3)

- Final PaperDocument12 paginiFinal PaperReikooÎncă nu există evaluări

- 65° Panel Antenna: General SpecificationsDocument2 pagini65° Panel Antenna: General SpecificationsAnnBliss100% (2)

- 2022 05 141RBSF351652506386Document6 pagini2022 05 141RBSF351652506386tathagat jhaÎncă nu există evaluări

- Lab Session 8: To Develop and Understanding About Fatigue and To Draw S-N Curve For The Given Specimen: I. SteelDocument4 paginiLab Session 8: To Develop and Understanding About Fatigue and To Draw S-N Curve For The Given Specimen: I. SteelMehboob MeharÎncă nu există evaluări

- FINAL Shivani Confined Space PermitDocument1 paginăFINAL Shivani Confined Space PermitVimal SinghÎncă nu există evaluări

- Galaxy A8 User ManualDocument193 paginiGalaxy A8 User ManualHüseyin ACARÎncă nu există evaluări

- 01 Gyramatic-Operator Manual V2-4-1Document30 pagini01 Gyramatic-Operator Manual V2-4-1gytoman100% (2)

- Low Invasion CoringDocument4 paginiLow Invasion CoringKHALEDFEKAIRÎncă nu există evaluări

- Conventional and Box-Shaped Piled RaftsDocument6 paginiConventional and Box-Shaped Piled RaftsAdrian VechiuÎncă nu există evaluări

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocument7 paginiBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengÎncă nu există evaluări

- Consumer Behaviour ProjectDocument43 paginiConsumer Behaviour ProjectMuhammad UsmanÎncă nu există evaluări

- Job No. 25800: Quebrada Blanca Fase 2Document1 paginăJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozÎncă nu există evaluări

- Command Center Processing and Display System ReplacementDocument2 paginiCommand Center Processing and Display System ReplacementImranÎncă nu există evaluări

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDe la EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontEvaluare: 4.5 din 5 stele4.5/5 (18)

- Slow Violence and the Environmentalism of the PoorDe la EverandSlow Violence and the Environmentalism of the PoorEvaluare: 4 din 5 stele4/5 (5)

- The Cyanide Canary: A True Story of InjusticeDe la EverandThe Cyanide Canary: A True Story of InjusticeEvaluare: 4 din 5 stele4/5 (52)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDe la EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionEvaluare: 3 din 5 stele3/5 (1)

- Environmental Justice in New Mexico: Counting CoupDe la EverandEnvironmental Justice in New Mexico: Counting CoupÎncă nu există evaluări

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaDe la EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaEvaluare: 4 din 5 stele4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretDe la EverandWaste: One Woman’s Fight Against America’s Dirty SecretEvaluare: 5 din 5 stele5/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawDe la EverandPrinciples of direct and superior responsibility in international humanitarian lawÎncă nu există evaluări

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksDe la EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksÎncă nu există evaluări

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksDe la EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksÎncă nu există evaluări

- Environmental Justice: Issues, Policies, and SolutionsDe la EverandEnvironmental Justice: Issues, Policies, and SolutionsÎncă nu există evaluări

- Introduction to Ecology and Environmental Laws in IndiaDe la EverandIntroduction to Ecology and Environmental Laws in IndiaÎncă nu există evaluări

- The Rights of Nature: A Legal Revolution That Could Save the WorldDe la EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldEvaluare: 5 din 5 stele5/5 (1)

- Debunking Creation Myths about America's Public LandsDe la EverandDebunking Creation Myths about America's Public LandsÎncă nu există evaluări

- Busted!: Drug War Survival Skills and True Dope DDe la EverandBusted!: Drug War Survival Skills and True Dope DEvaluare: 3.5 din 5 stele3.5/5 (7)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionDe la Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionÎncă nu există evaluări

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933De la EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Încă nu există evaluări

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontDe la EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontEvaluare: 4.5 din 5 stele4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsDe la EverandEnvironmental Education in Practice: Concepts and ApplicationsÎncă nu există evaluări

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawDe la EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawEvaluare: 4 din 5 stele4/5 (334)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksDe la EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksÎncă nu există evaluări

- Obstacles to Environmental Progress: A U.S. perspectiveDe la EverandObstacles to Environmental Progress: A U.S. perspectiveÎncă nu există evaluări