Documente Academic

Documente Profesional

Documente Cultură

Starter Motor, Disassemble, Inspect and Assemble - Repair

Încărcat de

Wayank Van HellsingDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Starter Motor, Disassemble, Inspect and Assemble - Repair

Încărcat de

Wayank Van HellsingDrepturi de autor:

Formate disponibile

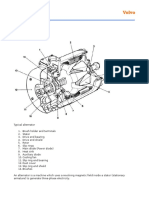

Starting motor and relay _ Repair

Mechanic Development Program

Starter motor, disassemble, inspect and

assemble

Incl. function check

Cau

tion

Follow the instructions carefully in order to avoid personal injury or damage to

products or equipment.

Part number: 1161033, 1161138, 1161246

Special tools: 9990148

Other special equipment: 9510060, 9988460

Disassembly

1

Place a plastic bag over the front bearing housing and the starter pinion and seal it.

Clean the outside of the starter motor before commencing.

Note: Cleaning agent must not be allowed to enter via the starter pinion, as this will

dissolve the lubricant in the overrunning clutch.

Grip the starter motor in a vice with soft jaws. Mark the position of the stator shell in

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 1/22

Starting motor and relay _ Repair

Mechanic Development Program

relation to the front and rear bearing housings. Mark the control relay and the front

bearing housing.

3

Go directly to step 13 if the starter motor is not being disassembled completely and only

the brushes are to be inspected.

The starter pinion must be removed if the starter motor is being disassembled

completely.

Remove all the electrical connections on

the control relay. Remove both bolts holding the control relay to the front bearing

housing.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 2/22

Starting motor and relay _ Repair

Mechanic Development Program

Lift up the control relay and pull it out.

Make sure the sealing ring comes with it.

Pull out the starter pinion and shaft. Place a counterhold 9990148 behind the fork arm.

Special tools: 9990148

Push in the washer and tension the fork arm with the wing nut.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 3/22

Starting motor and relay _ Repair

Mechanic Development Program

Use a 19 mm socket to tap in the stop ring for the lock ring.

Note: The stop ring is then approx. 3.5 mm from the end of the shaft.

Remove the lock ring. Use a narrow screwdriver to prise out the lock ring.

10

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 4/22

Starting motor and relay _ Repair

Mechanic Development Program

Remove the stop ring, starter pinion and spring.

11

Remove the starter relay from the front bearing housing.

12

Unplug the electric connector. Remove the counterhold 9990148.

Special tools: 9990148

13

Grip the front bearing housing in a vice. Remove the two bolts for the brush retainer and

the long through bolts for the bearing housing.

14

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 5/22

Starting motor and relay _ Repair

Mechanic Development Program

Lift up the bearing housing.

15

Bend one end of a piece of piano wire

( 3 mm) 90 degrees.

Hook it onto the brush spring and pull out the spring, secure the brush with the spring.

Note: Do not pull out the spring any farther than the brush can just be pulled out.

Otherwise, there is a risk that the spring will break.

16

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 6/22

Starting motor and relay _ Repair

Mechanic Development Program

Pull out all the brushes from the brush retainer. Release the springs into the brush

retainer to relieve them.

17

Remove the O-ring located on one end of the stator shell. Lift up the seal for the thermal

protection.

18

Lift off the brush retainer.

19

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 7/22

Starting motor and relay _ Repair

Mechanic Development Program

Lift up the rotor and remove the ball if it is still on the rotor.

20

Lift off the stator and remove the O-ring on the end.

21

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 8/22

Starting motor and relay _ Repair

Mechanic Development Program

Remove the metal cover and seal.

22

Pull up the seal and washer for the fork arm.

23

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 9/22

Starting motor and relay _ Repair

Mechanic Development Program

Lift up the planetary gear with the overrunning clutch and fork arm. Remove the fork

arm.

Note: Make a note of the direction of the fork arm.

24

Pull apart the planetary gear including the shaft from the overrunning clutch.

Check and note the location of both E-circlips. Lay a cloth or piece of paper over the E-

circlips and remove them.

Cau

tion

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 10/22

Starting motor and relay _ Repair

Mechanic Development Program

The E-circlips can shoot off during removal.

Note: The raised part of the E-circlip must be facing the planetary gear.

25

Pull apart the clutch and the shaft as follows:

Press the planetary gear against the overrunning clutch. Hold the gear with one finger

and turn the shaft to change the position of the splines in the overrunning clutch.

Note: If the splines are in the wrong position, it will not be possible to pull apart the

clutch and the shaft.

26

Pull out the shaft from the planetary gear ring gear. Then remove the planet gear and

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 11/22

Starting motor and relay _ Repair

Mechanic Development Program

the wear washer from the bottom of the ring gear and the ball for the rotor shaft under

the needle bearing in the planetary gear if not removed earlier.

Clean and check

General

Change the rotor if it is worn or the test values are incorrect.

Check the gears, ball race and bearing with O-ring for wear.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 12/22

Starting motor and relay _ Repair

Mechanic Development Program

Check for a ground fault in the windings with multimeter 9510060 or a so-called

Growler and a suitable piece of metal, e.g. a hacksaw blade. If the windings are short-

circuited, the piece of metal will make a fluttering sound when it is held over the rotor.

Other special equipment: 9510060

Measure the diameter of the commutator.

Min 38.1 mm.

Specifications:

38.1 mm

Measure the distance down to the commutator insulation and compare with the

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 13/22

Starting motor and relay _ Repair

Mechanic Development Program

diameter measured on the commutator.

Min depth 0.2 mm.

If the surface of the commutator is rough, burnt or oval, it can be machined down.

Note: Remove as little material as possible. The diameter of the commutator must not

be below 38.1 mm.

After machining down the commutator, cut the commutator insulation to a depth of

approx. 0.4 mm. Use a milling machine or specially ground hacksaw blade.

A = Incorrect machining

B = Correct machining

Field winding

General

Check the field winding cable for short circuit or open circuit. Use multimeter 9510060.

Change the stator shell if the test values are incorrect.

Check the ground:

Connect the multimeter to the field winding and the stator shell.

Turn the multimeter knob to buzzer mode. The buzzer should not sound at this

stage.

Check for open circuit:

Connect the multimeter to the field winding cable and the brush.

Turn the multimeter knob to buzzer mode. The buzzer should sound.

Brush retainer

General

Inspect the brush retainer for wear, short circuit and open circuit. Use multimeter

9510060.

Change the brush retainer and stator shell if the test values are incorrect.

1. Thermal protection

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 14/22

Starting motor and relay _ Repair

Mechanic Development Program

2. Insulation

3. Insulation

Measure the length of the brush, min 11.0 mm. If the brush is shorter than 11.0 mm,

change the brush retainer and stator shell.

Check that the brush does not stick in the retainer and that the springs are not fatigued

or cracked.

Specifications:

min 11.0 mm

Check for open circuit:

Connect the multimeter to the metal on the brush retainer and to the cable for

the thermoswitch.

Turn the multimeter knob to buzzer mode. The buzzer should sound.

Check the ground:

Connect the multimeter to the metal on the brush retainer and to the brush

sleeve that is insulated to the brush retainer.

Turn the multimeter knob to buzzer mode. The buzzer should not sound.

Overrunning clutch, planetary gear

General

The overrunning clutch is filled with lubricating grease and must not be washed with

liquid.

Change the overrunning clutch together with the planetary gear if any of the

components are defective.

Grip the overrunning clutch shaft in a vice.

2

Rotate the shaft. It should rotate easily in one direction.

Note: It should not be possible to rotate the shaft in the opposite direction.

3

Inspect the splines on the shaft.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 15/22

Starting motor and relay _ Repair

Mechanic Development Program

Check the planetary gear for wear on the gears, ring gear, needle bearing and journals.

Check also the bearing in the ring gear.

In case of any defects, the whole planetary gear with overrunning clutch must be

changed.

Starter pinion

1

Check the starter pinion for wear, cracks and other damage. In case of any defects,

change the starter pinion.

Front bearing housing

1

Check the seal and bearing condition. Change the bearing housing if it is defective.

Fork arm

1

Check the fork arm for cracks and other defects.

Measure the fork arm pins, min 6.0 mm.

Specifications:

min 6.0 mm

Control relay

General

Inspect the control relay for short circuit and open circuit. Use multimeter 9510060.

Change the control relay if the values are incorrect.

A = Starter key

B = Thermal protection

Check for open circuit:

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 16/22

Starting motor and relay _ Repair

Mechanic Development Program

Connect the multimeter across connections M and S.

Set the multimeter knob to buzzer mode. The buzzer should sound.

Check the resistance of the H-coil ():

Connect across S and ground.

Value 1.2 -1.4 at +20C.

Check the resistance of the P-coil ():

Connect across M and ground.

Value 1.3 -1.6 at +20C

Connect across M and B.

Turn the multimeter knob to buzzer mode. The buzzer should not sound, i.e.

there should not be any contact between these points.

Then press the control piston all the way down. The buzzer should sound, i.e.

full contact should be obtained.

Starter relay

General

Inspect the starter relay for short circuit and open circuit. Use multimeter 9510060.

Change the starter relay if the values are incorrect.

Connect across SW and ground.

Turn the multimeter knob to buzzer mode. The buzzer should not sound, i.e.

there should not be any contact between these points.

Check the resistance ():

Connect between SW and L.

Value 10.32 10% at +20C.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 17/22

Starting motor and relay _ Repair

Mechanic Development Program

Specifications:

10.32 10%

Connect across SW and B

Turn the multimeter knob to buzzer mode. The buzzer should not sound, i.e.

there should not be any contact between these points.

Connect the multimeter across connections B and S.

Turn the multimeter knob to buzzer mode. The buzzer should not sound, i.e.

there should not be any contact between these points.

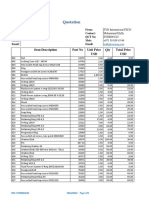

Assembly

1

Fill the space between the teeth on the ring gear with synthetic grease part no.:

1161033.

Part number: 1161033

2

Apply synthetic grease part no.: 1161033 on both sides of the wear washer and on the

bearing surface in the ring gear.

Part number: 1161033

3

Place the wear washer and planet gear shaft into the ring gear.

4

Apply grease part no.: 1161138 to the splines on the planet gear shaft and the splines

in the overrunning clutch.

Part number: 1161138

Assemble both shafts. Turn the shaft so that the splines are in such a position that they

cannot be separated.

Press down both E-circlips with the stamped boss facing the planetary gear.

Note: Make sure the stamped bosses on the E-circlips fit into each other and are facing

the planetary gear.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 18/22

Starting motor and relay _ Repair

Mechanic Development Program

6

Coat the journals and needle bearing in the shaft as well as the gears with synthetic

grease part no.: 1161033.

Part number: 1161033

7

Fit the gears to the journals.

8

Coat the overrunning clutch shaft with grease part no.: 1161246.

Part number: 1161246

9

Apply a thin layer of grease (part no.: 1161246) to the surfaces in the ball bearing and

on the sealing ring in the front bearing housing as well as the surfaces on the fork arm

for the overrunning clutch.

Part number: 1161246

10

Grip the front bearing housing in a vice.

11

Assemble the fork arm as marked.

Note: Movement will be limited if the plastic yoke on the fork arm is mounted in the

wrong direction.

12

Coat the fork arm pins and control relay mounting with grease part no.: 1161246.

Part number: 1161246

13

Place the fork into the overrunning clutch and drop it into the bearing housing.

Position the ring gear lugs in the bearing housing.

14

Fit the washer for the fork arm plastic yoke. The flat side should be facing the planetary

gear.

Press down the seal.

15

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 19/22

Starting motor and relay _ Repair

Mechanic Development Program

Coat the side of the metal cover towards the planetary gear with synthetic grease part

no.: 1161033.

Fit the seal and the metal cover.

Part number: 1161033

16

Coat the rotor gear teeth and the ball seat in the end of the shaft with synthetic grease

part no.: 1161033.

Part number: 1161033

17

Fit the ball into the end of the shaft and drop the rotor into the planetary gear.

Note: Make sure the ball does not fall out.

18

Place a new O-ring in the groove on the end of the stator.

Place the stator over the rotor as marked.

19

Pull out the brush spring in the brush retainer and secure both the brush and the

springs.

Place the brush retainer and a new O-ring in the groove on the end of the stator.

20

Pull out the brush springs and push all the brushes into the retainer.

Note: Do not pull out the spring any farther than the brush can just be fitted.

Note: Make sure the cables on the brush are outside the outer diameter of the brush

retainer.

21

Cut off the head of an M5x30 mm bolt and screw it into one of the threaded brush

retainer holes as a guide.

Coat the bearing seat in the rear cover with grease part no.: 1161246.

Lubricate the threads on both the long through bolts.

Part number: 1161246

22

Fit the O-ring on the bearing if it was removed.

23

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 20/22

Starting motor and relay _ Repair

Mechanic Development Program

Fit the bearing housing as marked and tighten the screws to 10.2 2.4 Nm.

Specifications:

10.2 2.4 Nm

24

Screw in one of the bolts for the brush holder through the bearing housing.

Remove the guide bolt and fit the other bolt. Tighten the bolts to 3.4 1.0 Nm.

Specifications:

3.4 1.0 Nm

25

Fit counterhold 9990148 under the fork arm. Tighten with the wing nut.

Special tools: 9990148

26

Fasten the starter motor to the stator. Fit the spring, starter pinion and a new stop ring.

27

Fit a new lock ring on the shaft. Press out the stop ring with a screwdriver and press the

lock ring into the stop ring groove.

Note: Make sure the stop ring is located approx. 1.5-2.0 mm under the end of the shaft.

The stop ring should be easy to turn.

28

Remove the counterhold tool.

29

Fit the seal in the end of the control relay if it was removed.

Lubricate the fork arm groove on the control relay with grease part no.: 1161246.

Fit the control relay as marked and hook it onto the fork arm.

Apply locking fluid part no.: 1161053 to the bolts holding the control relay to the front

bearing housing. Fit and tighten the bolts to 6.8 1.9 Nm.

Part number: 1161246 1161053

Specifications:

6.8 1.9 Nm

30

Screw on the starter relay. Tighten the bolts to 6.8 1.9 Nm.

Specifications:

6.8 1.9 Nm

31

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 21/22

Starting motor and relay _ Repair

Mechanic Development Program

Plug in the thermal protection connector to the control relay. Connect all cables to the

control relay. Tighten the nut (M10) for the cable between the stator and the control

relay to 18 2 Nm.

Tighten the bolt (M5) on the control relay to 3.4 1 Nm.

Specifications:

18 2 Nm 3.4 1 Nm

Function check

Test of starter motor without load

Wiring diagram

1. Ammeter

2. Battery (24V)

3. Voltmeter

4. Starter key

5. Starter motor

1

Connect the starter motor according to the wiring diagram.

Note: Use cables 35 - 50 mm for the power supply to the control relay. 2.5 mm for

other cables.

Tighten all connections.

2

Apply current to the starter relay and check the speed with a tachometer 9988460 and

the current (A) and voltage (V). Compare test values with the specifications. Starter

motor.

Warning

Cut the current within 10 sec. Continued current supply can cause overheating and

damage the starter motor.Other special equipment: 9988460

3

Repeat the test after about 1 min.

4

Perform a new check of the starter motor components if incorrect values are obtained.

Create by Plant Instructor Pasar panas 159_Print date 07/04/2017 22/22

S-ar putea să vă placă și

- Component of Lubrication SystemDocument12 paginiComponent of Lubrication SystemJohn Jhay CanlasÎncă nu există evaluări

- ElectropneumaticsDocument11 paginiElectropneumaticsSandeep MandaliÎncă nu există evaluări

- Disassembly and Reassembly (Alternator)Document16 paginiDisassembly and Reassembly (Alternator)arstjunkÎncă nu există evaluări

- Parts and Functions of The Ignition SystemDocument3 paginiParts and Functions of The Ignition SystemJestoni100% (2)

- Chapter 1 - Introduction To Automotive Electrical and Electronic SystemDocument26 paginiChapter 1 - Introduction To Automotive Electrical and Electronic SystemThao HuynhÎncă nu există evaluări

- Ohm's Law Practice ProblemsDocument1 paginăOhm's Law Practice ProblemsLouis Solis100% (1)

- Two Station Motor ControlDocument3 paginiTwo Station Motor ControlJames Adrian Abalde SaboÎncă nu există evaluări

- HMWK5 SolutionsDocument4 paginiHMWK5 SolutionsWana BilaÎncă nu există evaluări

- CBLM Service Ignition System For TraineeDocument75 paginiCBLM Service Ignition System For TraineeCedric Vlog & GamesÎncă nu există evaluări

- NR-Diesel Engine Tune UpDocument4 paginiNR-Diesel Engine Tune UpKhate ÜüÎncă nu există evaluări

- CHAPTER 10 Position and Warning Systems PDFDocument14 paginiCHAPTER 10 Position and Warning Systems PDFxrashexÎncă nu există evaluări

- FDC Misamis Power CorporationDocument18 paginiFDC Misamis Power CorporationRemar Joseph CarpinaÎncă nu există evaluări

- Grade 9 AutoDocument10 paginiGrade 9 AutoKariza PugalÎncă nu există evaluări

- Engine Types and ClassificationsDocument16 paginiEngine Types and ClassificationsVõ Thanh Liêm100% (1)

- Module 4 - Lesson 2 - MEEC 101ADocument35 paginiModule 4 - Lesson 2 - MEEC 101ADomingo NoverasÎncă nu există evaluări

- Automotive Servicing NCI: Written TestDocument27 paginiAutomotive Servicing NCI: Written Testjayson platinoÎncă nu există evaluări

- Em2 Quiz With AnswerDocument13 paginiEm2 Quiz With Answerkarthi100% (1)

- Lamp Holder and Its TypeDocument20 paginiLamp Holder and Its TypeKeempee ArconadaÎncă nu există evaluări

- Module - 1 - Only MachinesDocument20 paginiModule - 1 - Only MachinessdanharoldÎncă nu există evaluări

- Electropneumatics ExamDocument4 paginiElectropneumatics ExamEarl FloresÎncă nu există evaluări

- Mechanical Engineering Department: Lab ReportDocument17 paginiMechanical Engineering Department: Lab ReportLukman Hadi0% (2)

- Besta 1994-2003 2.2 PDFDocument10 paginiBesta 1994-2003 2.2 PDFMaritza CandiaÎncă nu există evaluări

- Hydraulic Cylinder Liner PullerDocument4 paginiHydraulic Cylinder Liner PullerLogeshMech100% (5)

- IgnitionDocument79 paginiIgnitionJM Llaban RamosÎncă nu există evaluări

- Small Engine Disassembly: A Visual GuideDocument30 paginiSmall Engine Disassembly: A Visual GuideHada NanuÎncă nu există evaluări

- Enhanced Module On Applying Appropriate Sealant or AdhesiveDocument53 paginiEnhanced Module On Applying Appropriate Sealant or AdhesiveClayton Mark CadampogÎncă nu există evaluări

- ECEN 20093 - Lesson 4 Unit 1-4 - Salamat, Andre Agassi DDocument1 paginăECEN 20093 - Lesson 4 Unit 1-4 - Salamat, Andre Agassi DandreagassiÎncă nu există evaluări

- Seatwork No.3Document1 paginăSeatwork No.3Earl Stanley Baliwag Leonardo100% (1)

- Topics For Thesis M E CEM Mail 1Document8 paginiTopics For Thesis M E CEM Mail 1vishwasÎncă nu există evaluări

- Execution and Business PlanDocument8 paginiExecution and Business PlanKrisleen Elyzel GullasÎncă nu există evaluări

- Starting SystemDocument21 paginiStarting SystemNikunj Yagnik100% (1)

- Development of Electrical JackDocument8 paginiDevelopment of Electrical JackTom Dulin BitangaÎncă nu există evaluări

- Engine DisassemblyDocument30 paginiEngine Disassemblybertoy100% (1)

- Monthly Report - OJTDocument7 paginiMonthly Report - OJTResshille Ann T. SalleyÎncă nu există evaluări

- DifferentialDocument12 paginiDifferentialprashant86% (7)

- Charging of RefrigerantDocument14 paginiCharging of RefrigerantMARIO BULANADIÎncă nu există evaluări

- Check Conditions of Tools and EquipmentDocument26 paginiCheck Conditions of Tools and EquipmentJustine VergaraÎncă nu există evaluări

- Unit-2 Velocity and Acceleration Analysis - Graphical MethodDocument41 paginiUnit-2 Velocity and Acceleration Analysis - Graphical MethodSumit Kumar0% (1)

- Engine Tune Up Procedure PDFDocument23 paginiEngine Tune Up Procedure PDFmirna sari100% (2)

- TLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Document23 paginiTLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Lorde FloresÎncă nu există evaluări

- Literature ReportDocument14 paginiLiterature ReportKashif KhanÎncă nu există evaluări

- Problems of Pneumatic Circuit DesignDocument13 paginiProblems of Pneumatic Circuit Designvijay75% (4)

- Engine Intake & Exhaust SystemDocument27 paginiEngine Intake & Exhaust Systemmahmudul adil60% (5)

- Circuit ApplicationsDocument65 paginiCircuit ApplicationsAman Baviskar100% (1)

- Servicing Ignition SytemDocument55 paginiServicing Ignition SytemYvan LopezÎncă nu există evaluări

- Automotive-Pecs Lo1-Activity-SheetsDocument6 paginiAutomotive-Pecs Lo1-Activity-SheetsJumar BaldrezÎncă nu există evaluări

- 11 Parts of Car Starter Motor and FunctionDocument8 pagini11 Parts of Car Starter Motor and FunctionJayson B. Cadelina100% (2)

- RRLDocument3 paginiRRLHarvey Jones BahalaÎncă nu există evaluări

- 2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsDocument14 pagini2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsJheng Delos Reyes Pantoja100% (4)

- Multi Spray NozzleDocument20 paginiMulti Spray NozzleRahul Dhadbanjan100% (1)

- Handling Precaution For Optical Disk Drive & MediaDocument2 paginiHandling Precaution For Optical Disk Drive & MediaVichi Arvind SharmaÎncă nu există evaluări

- Servicing Brake SystemDocument31 paginiServicing Brake SystemFrancis Martinez100% (1)

- Exercises On The Development of Electro-Pneumatic Circuits: Problem1Document7 paginiExercises On The Development of Electro-Pneumatic Circuits: Problem1Julius Chavez100% (1)

- Quiz Steering (Answer Key)Document2 paginiQuiz Steering (Answer Key)earlesparciaÎncă nu există evaluări

- Purpose and Function of A ClutchDocument12 paginiPurpose and Function of A ClutchabasÎncă nu există evaluări

- Carburetor Parts and Their Function (With Diagram)Document6 paginiCarburetor Parts and Their Function (With Diagram)Celso Amoto50% (2)

- Disassembly and Reassembly: Manual Transmission AssemblyDocument31 paginiDisassembly and Reassembly: Manual Transmission AssemblyMohd raziffÎncă nu există evaluări

- Seatwork6 Withanswer Final PDFDocument2 paginiSeatwork6 Withanswer Final PDFLester John PrecillasÎncă nu există evaluări

- Leiten - Manual - Escarificador Masalta MC8Document11 paginiLeiten - Manual - Escarificador Masalta MC8bqbovercon2Încă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Rubber Tyred Gantry Cranes: Equipment Units CapacityDocument1 paginăRubber Tyred Gantry Cranes: Equipment Units CapacityWayank Van HellsingÎncă nu există evaluări

- 2 Bab Buku PCMDocument9 pagini2 Bab Buku PCMWayank Van HellsingÎncă nu există evaluări

- 2BabBukuPCM PDFDocument59 pagini2BabBukuPCM PDFWayank Van HellsingÎncă nu există evaluări

- Iwsuardana: Berita Biologi 9 (6) - Desember 2009Document8 paginiIwsuardana: Berita Biologi 9 (6) - Desember 2009Wayank Van HellsingÎncă nu există evaluări

- Tabel StatistikDocument13 paginiTabel StatistikWayank Van HellsingÎncă nu există evaluări

- TT - Color Code CableDocument3 paginiTT - Color Code CableWayank Van HellsingÎncă nu există evaluări

- Tacho Grop HDocument7 paginiTacho Grop HWayank Van HellsingÎncă nu există evaluări

- Alternator Volvo - KnowledgeDocument19 paginiAlternator Volvo - KnowledgeWayank Van Hellsing100% (1)

- Metraflex MightySphereDocument2 paginiMetraflex MightySphereWilliam Ronald Ochoa PaucarÎncă nu există evaluări

- P&Id Area 47 - Sulphidiser Plant Dehumidifier and Co2 SystemDocument1 paginăP&Id Area 47 - Sulphidiser Plant Dehumidifier and Co2 SystemGoulet KostÎncă nu există evaluări

- Air-Conditioning System DesignDocument95 paginiAir-Conditioning System DesignZaid Tariq AlabiryÎncă nu există evaluări

- MD Wf9ZcV3EOIm6.JpgDocument35 paginiMD Wf9ZcV3EOIm6.JpgSpulber AlexandruÎncă nu există evaluări

- Jis and Fixture NotesDocument60 paginiJis and Fixture NotesMohammed KhatibÎncă nu există evaluări

- RKS50E2V1B, RKS60E2V1B Wiring DiagramDocument51 paginiRKS50E2V1B, RKS60E2V1B Wiring DiagramAbdulSattarÎncă nu există evaluări

- Manual TV Samsung LN26B350Document61 paginiManual TV Samsung LN26B350Vitor ZagoÎncă nu există evaluări

- Harman Kardon Dvd47Document40 paginiHarman Kardon Dvd47videosonÎncă nu există evaluări

- Asko Dryer Spare Parts Catalog 2003 EditionDocument12 paginiAsko Dryer Spare Parts Catalog 2003 EditionTom SenbergÎncă nu există evaluări

- SPG 400 Amp Mig Gun Packages: P.O. Box 898 - Pearland, TX 77588-0898Document2 paginiSPG 400 Amp Mig Gun Packages: P.O. Box 898 - Pearland, TX 77588-0898kadid de jesus reyes solanaÎncă nu există evaluări

- FDPS Bom PRDocument35 paginiFDPS Bom PRAnonymous m65TTcfOTÎncă nu există evaluări

- Transmission Diagnostic Trouble Codes F343-F348Document2 paginiTransmission Diagnostic Trouble Codes F343-F348Lupin GonzalezÎncă nu există evaluări

- Distribution BoardDocument7 paginiDistribution BoardsvirkomartinkoÎncă nu există evaluări

- Technical Data: Gagging Bush See NoteDocument1 paginăTechnical Data: Gagging Bush See NoteTrần HiếuÎncă nu există evaluări

- Happy HCG-B Parts ListDocument108 paginiHappy HCG-B Parts ListPhilip TadrousÎncă nu există evaluări

- Pt. Langgeng Daya Agrindo Plant Departement Jobsite: BGG: 5 UnitDocument4 paginiPt. Langgeng Daya Agrindo Plant Departement Jobsite: BGG: 5 UnitHenny Komala Sari SibaraniÎncă nu există evaluări

- Pines Ecu Codigos y Pruebas Control Electronico Del Motor Chery Orinoco m11 Service Manual-122-288.PDF Versión 1Document167 paginiPines Ecu Codigos y Pruebas Control Electronico Del Motor Chery Orinoco m11 Service Manual-122-288.PDF Versión 1oscar vergara100% (2)

- Phillips Home TheatreDocument16 paginiPhillips Home TheatreSuresh ChandraÎncă nu există evaluări

- Elements of Jigs and FixturesDocument9 paginiElements of Jigs and FixtureskhuljascribdÎncă nu există evaluări

- KAfo DCMC AdvantagesDocument14 paginiKAfo DCMC AdvantagesRajiv GandhiÎncă nu există evaluări

- SB Pka-A30ka7 Puy-A30nha7 (-BS) 201908Document3 paginiSB Pka-A30ka7 Puy-A30nha7 (-BS) 201908Adrian ConfortiÎncă nu există evaluări

- Scroll Saw 40-100 16 1246Document8 paginiScroll Saw 40-100 16 1246Theodor EikeÎncă nu există evaluări

- MUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Document4 paginiMUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Mani RichardÎncă nu există evaluări

- Panasonic Gp2 Chassis Tx29f150m TV SMDocument20 paginiPanasonic Gp2 Chassis Tx29f150m TV SMRider AlexandreÎncă nu există evaluări

- Zydb004 22Document5 paginiZydb004 22Sherief MagdyÎncă nu există evaluări

- Antrees ManualDocument7 paginiAntrees ManualHidayat MirabdulbaghiÎncă nu există evaluări

- Massey Ferguson 2012Document220 paginiMassey Ferguson 2012Jukiuz100% (1)

- Duplex Thrust BearingsDocument4 paginiDuplex Thrust Bearingspetronila66Încă nu există evaluări

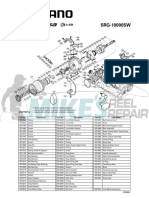

- Shimano Saragosa SRG10000SW SchematicDocument1 paginăShimano Saragosa SRG10000SW SchematicDani Indra GunawanÎncă nu există evaluări

- XX15 Disc Lock Alarm User ManualDocument1 paginăXX15 Disc Lock Alarm User Manualmanovi06Încă nu există evaluări