Documente Academic

Documente Profesional

Documente Cultură

FA Fineness - Comparing Residue On 45 and Blaine PDF

Încărcat de

Tran Huynh NamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FA Fineness - Comparing Residue On 45 and Blaine PDF

Încărcat de

Tran Huynh NamDrepturi de autor:

Formate disponibile

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/294623979

Fly ash fineness - Comparing residue on 45

micron sieve with Blaine's surface area

Article August 2012

CITATIONS READS

0 318

3 authors, including:

Surjyoti Bagchi

Reliance Power Ltd.

20 PUBLICATIONS 5 CITATIONS

SEE PROFILE

All content following this page was uploaded by Surjyoti Bagchi on 03 March 2016.

The user has requested enhancement of the downloaded file.

Point of View

Fly ash fineness Comparing residue on 45 micron sieve with

Blaine's surface area

S.S. Bagchi, S.V. Ghule and R.T. Jadhav

This paper compares the residue on 45 micron test sieve to use, less prone to variations and does not require

with Blaines air permeability results and shows that specialised instrument and laboratory conditions.

the latter is sensitive to loss on ignition (LOI). The 45

micron sieve test for ascertaining the fineness of fly is Material and method

an optional test in the Indian Code IS 3812:2003 part

Fly ash samples were collected from unit 7 of Koradi

I and II.1,2 With the help of laboratory data the paper

thermal power station (210 MW) and unit 1 and 2 of

proposes to make the test a mandatory quality control

Dahanu thermal power station (250 MW) from the

tool for using fly ash as a pozzolona.

electrostatic precipitators (ESP) hoppers. The ESPs

at Koradi and Dahanu thermal power stations were

The quality of fly ash generated by coal fired Thermal

commissioned in 1983-84 and 1993-94 respectively.

Power Station shows a wide range of variation in both

chemical and physical properties because both the

Six Samples from Koradi thermal power station Unit 7

quality of coal and the combustion condition of boilers

and 4 composite samples from Dahanu thermal power

vary. While supplying fly ash quantities, matching users

station Unit 1 and Unit 2 collected on different dates,

specification is important; past investigations show that

made a set of 10 samples for analysis.

the pozzolanic properties of fly ash are not so much

governed by the chemistry as by the mineralogy and

The specimens fineness was determined by wet sieving

particle size. Regardless of the fly ash type, particles

through a 45 micron sieve following IS 460:1962. In

under 10 micron are the ones that contribute to the 7 and

addition, their Blaines air permeability was measured

28 days strengths. Particles between 10 and 45 micron

following IS 1727:1967.4 Tables 1 and 2 shows the

contribute to strength from 28 days and up to about one

results.

year. Particle above 45 microns are considered inert.

They behave like sand particles. It has been reported To find out if a relationship existed between Loss on

that the particles below 10 microns govern the fly ash ignition, Residue on sieve (ROS) and Blaines value

reactivity.3 Therefore fineness of fly ash correlates with additional samples were prepared in the laboratory.

concrete strength. This paper focuses on the importance Addition of coal dust of fineness below 75 micron (200

of 45 micron wet sieve test analysis over Blaines test. mesh sieve) to fly ash samples of known LOI gave

Like the former, the latter also gives measurement of specimens with different LOI.

the particle size of fly ash. However, the former is simple

AUGUST 2012 The Indian Concrete Journal 39

Point of View

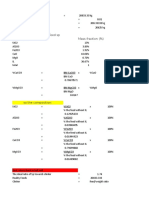

Table 1. Residue on 45 (m) sieve and corresponding specific surface area by Blaines permeability method

2

(m /kg) of Unit-7 Koradi ESP rows

EPS 1 2 3 4 5

field#

Specimen Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45

number value, (m) value, (m) value, (m) value, (m) value, (m)

m2/Kg % m2/kg % m2/Kg % m2/Kg % m2/Kg %

1 202 50.7 294 24.2 325 17.5 389 11.6 430 4.2

2 210 51.2 296 24.1 320 18 390 11.5 440 4.8

3 203 50.8 290 24.2 289 18 395 11 440 5.3

4 215 50.1 298 24.1 302 17.8 400 10.5 425 5.2

5 214 50.5 299 24.5 330 17.3 390 11.2 430 4.7

6 195 50.3 293 25.1 319 17.2 410 10.3 422 5.8

Mean 206.5 50.6 295 24.36 314.16 17.63 395.66 11.01 431.16 5.0

Standard 7.82 0.38 3.34 0.38 15.53 0.35 8.16 0.52 7.49 0.55

deviation

()

320 m2/kg Blaine's value is mandatory as per Indian standard IS 3812 part I guidelines and 200 m2/kg as per Indian standard IS 3812 part II

guidelines.

Table 2. Residue on 45 (m) sieve and corresponding specific surface area by Blaines permeability method

2

(m /kg) of Unit 1 and 2 of Dahanu ESP rows

EPS 1 2 3 4 5 6

field#

Specimen Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45 Blaine's ROS 45

number value (m) value (m) value (m) value (m) value (m) value (m)

m2/kg % m2/kg % m2/kg % m2/kg % m2/kg % m2/kg %

1 230.2 48.66 395.3 13.19 462.21 4.75 520.79 0.5 570.29 0.12 550.95 0.46

2 195.32 61.15 444.83 6.78 487.32 2.12 545.32 0.3 580.32 0.16 590.12 0.02

3 207.36 53.83 368.52 14.6 501.25 2.2 580.45 0.1 590.25 0.25 575.3 0.2

4 189.94 62.6 408.36 10.49 503.21 2.38 582.6 0.5 540.2 0.6 589.69 0.01

Mean 205.70 56.56 404.25 11.27 488.49 2.86 557.29 0.35 570.26 0.28 576.51 0.17

Standard 17.88 6.51 31.73 3.44 18.89 1.26 29.70 0.19 21.64 0.21 18.38 0.21

deviation

()

Loss on ignition was determined at 1000 25oC following Result and discussion

IS 1727:1967.4 The samples analysis took place at 60%

Indian code IS 3812:2003 part-I specifies that fly ash

2% relative humidity and 35oC 1oC. A standard cement

fineness by Blaines permeability method should be

sample calibrated the Blaines apparatus. The known

more than 320 m2/kg, which corresponds to a maximum

LOI of Koradi and Dahanu samples were 1% and 0.5%

of 34% residue on 45 micron sieve and IS 3812:2003

respectively. The Dahanu thermal power station being

part II specifies 200 m2/kg fineness corresponding to

a new plant had better coal quality and combustion

the residue on 45 micron sieve of maximum 50%. Table

efficiency than Koradi thermal power station. Table 3

4 summarises the Indian standards. Koradi specimen

shows the variation in Blaines with LOI.

40 The Indian Concrete Journal AUGUST 2012

Point of View

Table 3. Variation in Blaine's value with Loss on Table 4. Indian code for the siliceous pulverised fuel

ignition percentage ash

Sample with different % Residue on 45 Blaine's No. Component / characteristics Unit IS 3812 S 3812

loss on ignition (LOI) micron sieve value m2/kg (part I) (part II)

2003 2003

1.00% 18% 324

1.25% 18% 316

Koradi

1.85% 18% 357 Chemical requirement

TPS

2.08% 18% 370

2.50% 18% 378 1. SiO2 + Al2O3 + Fe2O3, min % 70 70

3.10% 18% 382 2. SiO2, min % 35 35

3.57% 18% 390 3. MgO, max % 5.0 5.0

4. Total sulphur as SO3, max. % 3.0 5.0

5. Alkali as Na2O, max. % 1.5 1.5

0.49% 10% 390

6. Loss on Ignition % 5.0 5.0

Dahanu 0.75% 10% 390

7. Moisture content, max. % - -

TPS 0.85% 10% 410

1.00% 10% 410 Physical requirement

1.50% 10% 419

1.75% 10% 422 1. Specific surface (Blaine's), min. m2/kg 320* 200

2.50% 10% 445

3.07% 10% 450 2. Sieve residue on 45 micron % 34 50

3.52% 10% 458 sieve, max (optional (optional

test) test)

from field# 3 and Dahanu specimen from field#2 While every effort was made to achieve precision,

onwards satisfy IS 3812:2003 part-I in terms of Blaine's performing Blaines measurement was prone to error

fineness. From Table1, it is observed that Blaine fineness due to failure to sufficiently compress the sample and

value of 320 m2/kg corresponds to about 18% residue control the humidity. Indian standard recommends that

on 45 micron sieve and not 34 % as specified in the IS the apparatus shall be calibrated periodically to check

3812:2003 part-I; however Blaine fineness value of 200 for possible wear on plunger or permeability cell, loss

m2/kg corresponds to 50% residue on 45 micron sieve, in manometer fluid and the quality of filter paper used

which matches with the Indian code, IS 3812:2003 part-II for the test.4 The most important precaution is that

(Tables 1&2). the apparatus calibration should be made by the same

operator who does the fineness determination. Blaines

Brink and Halstead postulated that the particles of value is based on air permeability; hence porosity is

unburnt carbon being highly porous, influence the directly related to the uniformity of the sample.

results of air permeability method because of both

external and internal surface of particles of carbon.5 Conclusion

An increase in carbon content is accompanied by an Blaines value apparatus operation needs utmost care

increase in total surface area even though the external because with this equipment the probability of variation

surface area and actual fineness decrease, introducing is high even when the same operator uses the equipment.

an error in the fineness as determined by Blaines Therefore for fly ash samples, the Blaines surface area

method. is at best a supplementary measurement. The most

significant physical performance characteristic is the

To verify this, an exercise was undertaken by blending particle size. This determination with wet sieve method

fine coal of known LOI with fly ash and wet sieving the is robust and low cost giving a good reproducibility.

specimen through a 45 micron sieve and comparing Therefore the relevant Indian code should give more

the results with Blaines surface area (Table3). This importance to the sieve analysis by making it mandatory

table shows that by increasing LOI, the Blaines surface rather than keeping it an optional test.

increased even though the residue on 45 micron had not

changed. Indeed the LOI increase introduces an error in

the fineness measurement in the surface area.

AUGUST 2012 The Indian Concrete Journal 41

Point of View

Acknowledgement Mr. Surjyoti S. Bagchi, MSc (Analytical

The authors are thankful to the management of Koradi Chemistry), MSc (Environment) Nagpur

University, has worked in several thermal power

thermal Power station, MSPGCL and Dahanu thermal plants of Maharashtra State Power Generation

power station, Reliance Infrastructure Ltd for providing Company. He has also worked in Reliance

necessary help for sample collection and analysis. The Infrastructure Ltd as a Senior Manager and is

authors are also grateful to the management of these currently working with Avantha Power and

Infrastructure Ltd in the same capacity. He has

organisations for giving permission to publish this co-authored several technical papers and his field of interest

paper. lies in utililisation of fly ash and water chemistry.

References Mr. Sanjay V. Ghule, MSc (Organic Chemistry),

1. ______ Pulverized fuel ash specification part-I for use as pozzolana in cement, is the Deputy General Manager at Reliance

cement mortar and concrete, IS 3812 Part-(I): 2003, Bureau of Indian Standards, Infrastructure Ltd, Dahanu Thermal Power

New Delhi.

Station, Maharashtra.

2. ______Pulverized fuel ash specification part-II for use as admixture in cement

mortar and concrete, IS 3812 Part (II): 2003, Bureau of Indian Standards,

New Delhi.

3. Mehta, P.K., Role of fly ash in sustainable Development concrete, Proceedings

of forum on fly ash and environment, December 8, 1998.

Late Dr. R.T. Jadhav was Vice Principal, SRKN Engineering

4. ______Method of test for pozzolanic materials, IS 1727:1967, Bureau of Indian College, Nagpur. He had 30 years of teaching experience and

Standards, New Delhi published more than 100 research papers; guided four PhD

5. Brink R.H. and Halstead W.J Studies relating to the testing of fly ash for scholars and acquired one patent to his credit.

use in concrete Public Roads, Vol. 29(6), February 1967.

42 The Indian Concrete Journal AUGUST 2012

View publication stats

S-ar putea să vă placă și

- Random FactsDocument353 paginiRandom FactsSergio Rivas100% (1)

- 6th Grade Spelling ListsDocument10 pagini6th Grade Spelling Listsapi-326416336Încă nu există evaluări

- Prevention of Reflective Cracking in Pavements - Vanelstraete PDFDocument136 paginiPrevention of Reflective Cracking in Pavements - Vanelstraete PDFTran Huynh Nam100% (3)

- (PDF) Books Toxic Parents Epub Popular Download - by Susan ForwardDocument1 pagină(PDF) Books Toxic Parents Epub Popular Download - by Susan Forwardmartagonzalezbordonaba0% (3)

- Structral DatasheetDocument254 paginiStructral DatasheetdeepakÎncă nu există evaluări

- Free LimeDocument10 paginiFree LimeHazem DiabÎncă nu există evaluări

- Determination of Feo Content in ClinkeDocument17 paginiDetermination of Feo Content in Clinkemahendra senÎncă nu există evaluări

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Document14 paginiCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamÎncă nu există evaluări

- Test For Properties of Cement: Physical & ChemicalDocument4 paginiTest For Properties of Cement: Physical & ChemicalmuqeetÎncă nu există evaluări

- Fundamental Unit of Life 1-25Document25 paginiFundamental Unit of Life 1-25Anisha PanditÎncă nu există evaluări

- Calculation of The C3A Percentage in High Sulfur ClinkerDocument6 paginiCalculation of The C3A Percentage in High Sulfur Clinkeranon_802179908100% (1)

- Additives For A Challenging Cement Market PDFDocument8 paginiAdditives For A Challenging Cement Market PDFTran Huynh NamÎncă nu există evaluări

- Formulas of Chemical Analysis of CementDocument1 paginăFormulas of Chemical Analysis of CementFahadullah Khan AfridiÎncă nu există evaluări

- Concrete TechnologyDocument23 paginiConcrete TechnologyM NANDITHA CIVIL STAFF100% (1)

- It's A Product of An Intimate Mixture of Correctly ProportionedDocument28 paginiIt's A Product of An Intimate Mixture of Correctly ProportionedshahriarÎncă nu există evaluări

- 2.02.burning Zone CoatingDocument2 pagini2.02.burning Zone CoatingJCSÎncă nu există evaluări

- Coal and Its AnalysisDocument8 paginiCoal and Its AnalysisPratik AgajÎncă nu există evaluări

- The Effect of Coal Ash On Synthesis and Properties of C3SDocument6 paginiThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhÎncă nu există evaluări

- Ball Mills - Guidelines For Sample Amount and Ball ChargeDocument4 paginiBall Mills - Guidelines For Sample Amount and Ball ChargeAndrejs AndrejsÎncă nu există evaluări

- Influence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsDocument11 paginiInfluence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsJohn GiannakopoulosÎncă nu există evaluări

- PDAJChallenge KitDocument15 paginiPDAJChallenge KitElango Minnoor100% (1)

- Chemical Technology Subject Code: CH2001Document13 paginiChemical Technology Subject Code: CH2001U SANKAR TEJOÎncă nu există evaluări

- Cement PDFDocument70 paginiCement PDFhamza2k19Încă nu există evaluări

- SOK Clinker OPCDocument2 paginiSOK Clinker OPCAmr A. NaderÎncă nu există evaluări

- Measurements of The Quality of Cement Produced From Looped LimestoneDocument30 paginiMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- Affect of LSF, SM and Iron On Free LimeDocument1 paginăAffect of LSF, SM and Iron On Free Limeoscop2009100% (1)

- 3 Strategies For Reducing Cement KilnDocument14 pagini3 Strategies For Reducing Cement Kilnorientanjali7066100% (1)

- Dry Feed: Feed Entered SP H2O Content in SP H2O Content in SPDocument20 paginiDry Feed: Feed Entered SP H2O Content in SP H2O Content in SPIrfan Ahmed100% (1)

- Umali v. Estanislao (1992, 209 SCRA 446)Document12 paginiUmali v. Estanislao (1992, 209 SCRA 446)KTÎncă nu există evaluări

- Slide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid TuliDocument33 paginiSlide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid Tulishivam aggarwalÎncă nu există evaluări

- 07 Post Task Theory Matrix Table RevisedDocument8 pagini07 Post Task Theory Matrix Table RevisedHemalyn Bereber100% (1)

- Raw Mix DesignDocument8 paginiRaw Mix DesignkazamÎncă nu există evaluări

- Rapid Techniques For Determination of Free CaO and Free MgO and Portlandite in Hydrate Cement PDFDocument10 paginiRapid Techniques For Determination of Free CaO and Free MgO and Portlandite in Hydrate Cement PDFTran Huynh NamÎncă nu există evaluări

- Sulphate ModulusDocument2 paginiSulphate ModulusM. Ali ParvezÎncă nu există evaluări

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 paginiCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiÎncă nu există evaluări

- Mombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanDocument22 paginiMombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanmustafÎncă nu există evaluări

- 7-Mineral Phases of Portland CementDocument28 pagini7-Mineral Phases of Portland CementzamriseramikÎncă nu există evaluări

- Ring-Formation-in-Kiln - 2 ReportDocument12 paginiRing-Formation-in-Kiln - 2 ReportIrfan AhmedÎncă nu există evaluări

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pagini1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiÎncă nu există evaluări

- Department of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesDocument26 paginiDepartment of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesVijaya GosuÎncă nu există evaluări

- Chemical AnalysisDocument8 paginiChemical Analysisصفاء رجبÎncă nu există evaluări

- Variation of Feed Chemical Composition and Its Effect On Clinker Formation PDFDocument7 paginiVariation of Feed Chemical Composition and Its Effect On Clinker Formation PDFs_prasy6540Încă nu există evaluări

- Solid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversityDocument36 paginiSolid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversitysreeÎncă nu există evaluări

- Unit 2 - CementDocument55 paginiUnit 2 - CementSaharsha GadariÎncă nu există evaluări

- Cement Manufacturing ProcessDocument26 paginiCement Manufacturing ProcessZubair KhanÎncă nu există evaluări

- Insurance CodeDocument18 paginiInsurance CodeKenneth Holasca100% (1)

- Cement Chemistry Notation and Mineral NamesDocument2 paginiCement Chemistry Notation and Mineral NamesAfqan B-vÎncă nu există evaluări

- Calculation of The Formation Process of Clinker inDocument7 paginiCalculation of The Formation Process of Clinker inYounas BugtiÎncă nu există evaluări

- SOx Emmissions Absortion FLSDocument14 paginiSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezÎncă nu există evaluări

- Alkali Bypass WHRPP Nov - 11 PDFDocument18 paginiAlkali Bypass WHRPP Nov - 11 PDFNinad Bhave100% (1)

- Grinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent GuillotDocument15 paginiGrinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent Guillotnathaniel villanuevaÎncă nu există evaluări

- The Cement Grinding Office: Home About Us Services Mining Area Links and ContactDocument2 paginiThe Cement Grinding Office: Home About Us Services Mining Area Links and ContactVisnu SankarÎncă nu există evaluări

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDocument12 paginiStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationÎncă nu există evaluări

- Modeling of Cement Clinker ChemistryDocument24 paginiModeling of Cement Clinker ChemistryBitbitter100% (1)

- Blast Furnace Slag Weathering StudyDocument8 paginiBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- Raw Meal Grinding Aids: Improving BurnabilityDocument3 paginiRaw Meal Grinding Aids: Improving BurnabilityfaheemqcÎncă nu există evaluări

- ABC Cooler Inlet PDFDocument4 paginiABC Cooler Inlet PDFSushant GuptaÎncă nu există evaluări

- Burning The Mix 1Document11 paginiBurning The Mix 1John GiannakopoulosÎncă nu există evaluări

- Energy ManagementDocument9 paginiEnergy Managementhasan_jafri_2Încă nu există evaluări

- Kiln OptimizationDocument7 paginiKiln Optimizationneo 87Încă nu există evaluări

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 paginiBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyÎncă nu există evaluări

- 03mill SlidesDocument21 pagini03mill SlidesNael El SayyadÎncă nu există evaluări

- Cement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionDocument2 paginiCement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionalbertbunguriÎncă nu există evaluări

- Cement Chapter 6Document17 paginiCement Chapter 6shani5573Încă nu există evaluări

- Department of Chemical EngineeringDocument19 paginiDepartment of Chemical EngineeringPandia RajanÎncă nu există evaluări

- LSF CaculationDocument5 paginiLSF CaculationhamedÎncă nu există evaluări

- Sulfates Topic: Synthesis of The Setting Kinetics ProjectDocument10 paginiSulfates Topic: Synthesis of The Setting Kinetics ProjectcemsavantÎncă nu există evaluări

- United States Patent: (45) Date of Patent: Mar - 19, 2019Document17 paginiUnited States Patent: (45) Date of Patent: Mar - 19, 2019Kristína100% (1)

- NCV CalculationDocument4 paginiNCV CalculationNaveed Ul Qamar Mughal100% (1)

- The Use of Coal As Fuel For Cement Rotary KilnDocument23 paginiThe Use of Coal As Fuel For Cement Rotary KilnDheo Ebhee LouVeÎncă nu există evaluări

- 1Document5 pagini1Dee HsÎncă nu există evaluări

- Use of RHA in Concrete PDFDocument8 paginiUse of RHA in Concrete PDFTran Huynh NamÎncă nu există evaluări

- Study Mechanical Behaviours RHA and Carrot Powders As Mortar For Cement Replacement PDFDocument6 paginiStudy Mechanical Behaviours RHA and Carrot Powders As Mortar For Cement Replacement PDFTran Huynh NamÎncă nu există evaluări

- Role of Cement Content in Specification For Concrete Durability - Aggregate Type Influence PDFDocument14 paginiRole of Cement Content in Specification For Concrete Durability - Aggregate Type Influence PDFTran Huynh NamÎncă nu există evaluări

- Role of Cement Content in Specification For Concrete Durability - Cement Type Influence PDFDocument15 paginiRole of Cement Content in Specification For Concrete Durability - Cement Type Influence PDFTran Huynh NamÎncă nu există evaluări

- Fresh Concrete - Workability PDFDocument31 paginiFresh Concrete - Workability PDFTran Huynh Nam100% (1)

- Influence of Cement Ageing and Addition Time On The Performance of Superplastics PDFDocument10 paginiInfluence of Cement Ageing and Addition Time On The Performance of Superplastics PDFTran Huynh NamÎncă nu există evaluări

- Amniotic Fluid DisordersDocument16 paginiAmniotic Fluid DisordersLytiana Williams100% (2)

- SCL NotesDocument4 paginiSCL NotesmayaÎncă nu există evaluări

- 8582d Soldering Station English User GuideDocument9 pagini8582d Soldering Station English User Guide1valdasÎncă nu există evaluări

- Gulayan Sa Barangay OrdinanceDocument2 paginiGulayan Sa Barangay OrdinancekonsinoyeÎncă nu există evaluări

- Zemoso - PM AssignmentDocument3 paginiZemoso - PM AssignmentTushar Basakhtre (HBK)Încă nu există evaluări

- Sathyamangalam Chennai MR Sivakumar N: Rolsun TravelsDocument2 paginiSathyamangalam Chennai MR Sivakumar N: Rolsun TravelsGayu carita catoÎncă nu există evaluări

- Chapter 23Document9 paginiChapter 23Trixie Myr AndoyÎncă nu există evaluări

- Midyear Budget ReportDocument402 paginiMidyear Budget Reportcbs6albanyÎncă nu există evaluări

- CHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosDocument26 paginiCHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosHARSHVARDHAN KHATRIÎncă nu există evaluări

- CV Ilham AP 2022 CniDocument1 paginăCV Ilham AP 2022 CniAzuan SyahrilÎncă nu există evaluări

- Heating System Design (Student)Document25 paginiHeating System Design (Student)markbrennan1Încă nu există evaluări

- Amp. 100 Watt ExtractedDocument6 paginiAmp. 100 Watt ExtractedJosue CórdovaÎncă nu există evaluări

- ProjectxDocument8 paginiProjectxAvinash KumarÎncă nu există evaluări

- Labor Case DigestDocument2 paginiLabor Case DigestJhollinaÎncă nu există evaluări

- 08 163 4 JPL ScheickDocument50 pagini08 163 4 JPL ScheickSaqib Ali KhanÎncă nu există evaluări

- GASESDocument55 paginiGASESja_QuinineÎncă nu există evaluări

- Apport D Un Fonds de Commerce en SocieteDocument28 paginiApport D Un Fonds de Commerce en SocieteJezebethÎncă nu există evaluări

- Business-Plan (John Lloyd A Perido Grade 12-Arc)Document4 paginiBusiness-Plan (John Lloyd A Perido Grade 12-Arc)Jaypher PeridoÎncă nu există evaluări

- Water Security STD 9th Textbook by Techy BagDocument86 paginiWater Security STD 9th Textbook by Techy Bagpooja TiwariÎncă nu există evaluări

- CSF LeaksDocument3 paginiCSF LeaksDrTarek Mahmoud Abo KammerÎncă nu există evaluări

- SCI Fayette Greene..2007-2009 ViolationsDocument10 paginiSCI Fayette Greene..2007-2009 ViolationsHRCFedUpÎncă nu există evaluări