Documente Academic

Documente Profesional

Documente Cultură

Aalco Metals LTD Copper and Copper Alloys CW624N Bar and Profiles 116

Încărcat de

Rafi UdeenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aalco Metals LTD Copper and Copper Alloys CW624N Bar and Profiles 116

Încărcat de

Rafi UdeenDrepturi de autor:

Formate disponibile

Copper and Copper Alloys

CW624N Bar and Profiles

SPECIFICATIONS GENERIC PHYSICAL PROPERTIES

Commercial CZ130 Property Value

Density 8.44 g/cm

Brasses are alloys of Copper and Zinc. They may also Melting Point 890 C

contain small amounts of other alloying elements to Thermal Conductivity 109 W/m.K

impart advantageous properties. Brasses have high

corrosion resistance and high tensile strength. They

are also suited to fabrication by hot forging. Free

machining grades of brass set the standard for MECHANICAL PROPERTIES

machining, by which other metals are compared.

Brasses are divided into two classes. The alpha alloys, Property Value

with less than 37% Zinc, and the alpha/beta alloys Proof Stress 150-220 MPa

with 37-45% Zinc. Alpha alloys are ductile and can be

Tensile Strength 350-420 MPa

cold worked. Alpha/beta or duplex alloys have limited

cold ductility and are harder and stronger. Elongation A50 mm 20-30 %

CZ130/CW624N is a duplex or alpha/beta alloy.

Hardness Vickers 90 to 120 HV

Brass alloy CZ130/CW624N is a machinable brass with

an attractive yellow lustre that is typically used in Mechanical properties vary widely according to condition (soft/half

sections such as angle. hard/etc)

Applications

CORROSION RESISTANCE

CZ130 is typically used in decorative applications such

as: CZ130/CW624N has good corrosion resistance in most

Shopfittings environments.

Machine parts

Instruments

COLD WORKING

Electrical appliances

Hinges CZ130/CW624N has a poor to fair rating for cold

working.

CHEMICAL COMPOSITION

HOT WORKING

EN 12167:2011

CW624N Brass

Hot working of CZ130/CW624N is excellent. It is

normally formed into complex profiles using hot

Element % Present extrusion.

Copper (Cu) 55.00 - 57.00 The hot forgeability rating of CZ130 is good to

excellent.

Aluminium (Al) 0.05 - 5.00

Lead (Pb) 1.60 - 3.00

MACHINABILITY

Zinc (Zn) Balance

CZ130/CW624N has a very good machinability rating

of 90 compared to CZ121/CW614N Brass which is

rated as 100.

ALLOY DESIGNATIONS

CZ130/CW624N corresponds to the following WELDABILITY

designations:

ISO CuZn43Pb2Al / CuZn43Pb2 Soldering of CZ130/CW624N is rated as excellent.

CW623N Oxyacetylene welding and gas shielded arc welding are

not recommended.

Resistance welding is rated as fair.

SUPPLIED FORMS Friction welding is rated as good.

CZ130/CW624N is typically supplied as Angle

Bar

Angle

[1 OF 2] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Copper and Copper Alloys

CW624N Bar and Profiles

CONTACT

Address: Please make contact directly with your local

service centre, which can be found via the

Locations page of our web site

Web: www.aalco.co.uk

REVISION HISTORY

Datasheet Updated 11 January 2016

DISCLAIMER

This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

widely with temper, product and product dimensions. All information is

based on our present knowledge and is given in good faith. No liability will

be accepted by the Company in respect of any action taken by any third

party in reliance thereon.

Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

The information provided in this datasheet has been drawn from various

recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers data. No guarantee is given that the

information is from the latest issue of those sources or about the accuracy of

those sources.

Material supplied by the Company may vary significantly from this data, but

will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

purpose, whether expressed or implied.

Advice given by the Company to any third party is given for that partys

assistance only and without liability on the part of the Company. All

transactions are subject to the Companys current Conditions of Sale. The

extent of the Companys liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[2 OF 2]

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

S-ar putea să vă placă și

- Moralitydefinitionofrevised12 15 2018mssversionDocument8 paginiMoralitydefinitionofrevised12 15 2018mssversionBryan AguilarÎncă nu există evaluări

- Moralitydefinitionofrevised12 15 2018mssversionDocument8 paginiMoralitydefinitionofrevised12 15 2018mssversionBryan AguilarÎncă nu există evaluări

- Mold Work Order Request FormDocument1 paginăMold Work Order Request FormRafi UdeenÎncă nu există evaluări

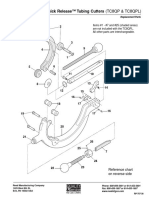

- Quick Release™ Tubing Cutters: Operating InstructionsDocument2 paginiQuick Release™ Tubing Cutters: Operating InstructionsRafi UdeenÎncă nu există evaluări

- Customer Support Programs BrochureDocument2 paginiCustomer Support Programs BrochureRafi UdeenÎncă nu există evaluări

- Din 8078 2008Document17 paginiDin 8078 2008Abdel Nasser AdamÎncă nu există evaluări

- Hardness and Torsion LabDocument20 paginiHardness and Torsion LabRafi UdeenÎncă nu există evaluări

- Soil Physical Characteristics of Peat SoilDocument9 paginiSoil Physical Characteristics of Peat SoilArthur SanÎncă nu există evaluări

- Fall 2020 PSAT Practice 2Document64 paginiFall 2020 PSAT Practice 2Muriel100% (1)

- PDF 2331765822Document2 paginiPDF 2331765822Rafi UdeenÎncă nu există evaluări

- Quick Release™ Tubing Cutters: Operating InstructionsDocument2 paginiQuick Release™ Tubing Cutters: Operating InstructionsRafi UdeenÎncă nu există evaluări

- K.T.P. Thermopipe ﺔﯾراﺮﺤﻟا ﻲﺑ ﻲﺗ ﻲﻛ ﺐﯿﺑﺎﻧ Sample Test RequestDocument2 paginiK.T.P. Thermopipe ﺔﯾراﺮﺤﻟا ﻲﺑ ﻲﺗ ﻲﻛ ﺐﯿﺑﺎﻧ Sample Test RequestRafi UdeenÎncă nu există evaluări

- Module I Materials and MetallurgyDocument33 paginiModule I Materials and MetallurgyRafi UdeenÎncă nu există evaluări

- Clariant SDS AddWorks IBC 760 Australia EnglishDocument10 paginiClariant SDS AddWorks IBC 760 Australia EnglishRafi UdeenÎncă nu există evaluări

- CW614N Chemical Composition: Thanking You ForDocument2 paginiCW614N Chemical Composition: Thanking You ForRafi UdeenÎncă nu există evaluări

- Bs En1504 1Document22 paginiBs En1504 1Hsaam HsaamÎncă nu există evaluări

- PP 760 CoaDocument2 paginiPP 760 CoaRafi UdeenÎncă nu există evaluări

- Metals 05 01440Document14 paginiMetals 05 01440Bolboacă AndreiÎncă nu există evaluări

- TDS+XPURGE+EX20T+ (Apr+19) Rev+3Document1 paginăTDS+XPURGE+EX20T+ (Apr+19) Rev+3Rafi UdeenÎncă nu există evaluări

- Melt Flow Rate (MFR) - ASTM D 1238Document10 paginiMelt Flow Rate (MFR) - ASTM D 1238khuelvÎncă nu există evaluări

- Tubing Cutters (TC1Q & TC2Q) : Parts ListDocument1 paginăTubing Cutters (TC1Q & TC2Q) : Parts ListRafi UdeenÎncă nu există evaluări

- Laboratory Quality Control Based On Risk ManagementDocument6 paginiLaboratory Quality Control Based On Risk ManagementRafi UdeenÎncă nu există evaluări

- 1-2 Hex Male InsertDocument1 pagină1-2 Hex Male InsertRafi UdeenÎncă nu există evaluări

- The at Risk RegisterDocument2 paginiThe at Risk RegisterRafi UdeenÎncă nu există evaluări

- 38 Tc8qp Tc8qpl CutterDocument2 pagini38 Tc8qp Tc8qpl CutterRafi UdeenÎncă nu există evaluări

- 101 Random Acts of KindnessDocument32 pagini101 Random Acts of KindnessRafi UdeenÎncă nu există evaluări

- Module I Materials and MetallurgyDocument33 paginiModule I Materials and MetallurgyRafi UdeenÎncă nu există evaluări

- Tubing Cutters (TC1Q & TC2Q) : Parts ListDocument1 paginăTubing Cutters (TC1Q & TC2Q) : Parts ListRafi UdeenÎncă nu există evaluări

- Histamine Intolerance and Probiotics: Managing Excess HistamineDocument13 paginiHistamine Intolerance and Probiotics: Managing Excess HistamineRafi UdeenÎncă nu există evaluări

- Potassium Food List PDFDocument4 paginiPotassium Food List PDFRafi UdeenÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Test Bank For Nutrition For Health and Healthcare 5th Edition DebruyneDocument11 paginiTest Bank For Nutrition For Health and Healthcare 5th Edition DebruyneClintonCarterownza100% (36)

- Astm A 153 - A 153M-09Document5 paginiAstm A 153 - A 153M-09Amr FathallaÎncă nu există evaluări

- Metals and Non Metals Notes Class 10Document19 paginiMetals and Non Metals Notes Class 10Deepayan PaikÎncă nu există evaluări

- Desulfurization by Hot Zinc OxideDocument2 paginiDesulfurization by Hot Zinc OxideFaris HamidiÎncă nu există evaluări

- LWT - Food Science and Technology: A A B CDocument9 paginiLWT - Food Science and Technology: A A B CThuÎncă nu există evaluări

- A Potent Cytotoxicity and Antimicrobial Activity of Zinc Oxide Nanoparticles Synthesized by Leaf of Ipomoea Pes-Caprae (L.) R. BRDocument7 paginiA Potent Cytotoxicity and Antimicrobial Activity of Zinc Oxide Nanoparticles Synthesized by Leaf of Ipomoea Pes-Caprae (L.) R. BRSrinivasulu KÎncă nu există evaluări

- 10 - Chapter 2Document38 pagini10 - Chapter 2Divya BajpaiÎncă nu există evaluări

- Survey of Cattle Feed Channel and An Including Dealer District Network and Dairies and To Part 1Document41 paginiSurvey of Cattle Feed Channel and An Including Dealer District Network and Dairies and To Part 1kundankumarsharmaÎncă nu există evaluări

- Drilling Fluids Manual HandbookDocument578 paginiDrilling Fluids Manual HandbookYuthia Aulia Riani100% (13)

- CELINDocument9 paginiCELINaikoestrellaÎncă nu există evaluări

- Study Material Class 10 Chapter 3 2017 PDFDocument10 paginiStudy Material Class 10 Chapter 3 2017 PDFKaran Pratap67% (3)

- Method of Analysis of Hydrochloric Acid Caustic SodaDocument5 paginiMethod of Analysis of Hydrochloric Acid Caustic SodaSreedhar Patnaik.MÎncă nu există evaluări

- Role of Chelated Mineral in Animal Production PerformanceDocument38 paginiRole of Chelated Mineral in Animal Production PerformanceBharathidhasan Selvarasu100% (1)

- USP Monographs - Zinc Sulfate Usp29-Nf24Document1 paginăUSP Monographs - Zinc Sulfate Usp29-Nf24CharltondialÎncă nu există evaluări

- Removal of Heavy Metal From Industrial Wastewater Using Hydrogen PeroxideDocument5 paginiRemoval of Heavy Metal From Industrial Wastewater Using Hydrogen PeroxideLaliethaÎncă nu există evaluări

- Group 4 CATHODIC INHIBITORDocument9 paginiGroup 4 CATHODIC INHIBITORfadelomar28_gmail_coÎncă nu există evaluări

- Comparative Analysis of Mineral Constituents of Ethanol Leaf and SeedDocument9 paginiComparative Analysis of Mineral Constituents of Ethanol Leaf and SeedKIU PUBLICATION AND EXTENSIONÎncă nu există evaluări

- Balanced Equations & Associated Calc's 05 QPDocument8 paginiBalanced Equations & Associated Calc's 05 QPlmao lmaoÎncă nu există evaluări

- IGCSE Chem PDFDocument14 paginiIGCSE Chem PDFLara HawreÎncă nu există evaluări

- Liu Et Al, 2015Document26 paginiLiu Et Al, 2015AbeiasaÎncă nu există evaluări

- Liquid TreteDocument2 paginiLiquid TreteErick CruzÎncă nu există evaluări

- How To Teach The Periodic TableDocument18 paginiHow To Teach The Periodic Tablejbsckothari100% (2)

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument16 paginiUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Încă nu există evaluări

- 03 Specification PDFDocument8 pagini03 Specification PDFSihamaSihamÎncă nu există evaluări

- 04 12-03-18 7 E4 Jee Adv Olympiad ChemistryDocument4 pagini04 12-03-18 7 E4 Jee Adv Olympiad Chemistrynaga divya100% (1)

- An 10.1 The Importance of Zinc For Human HealthDocument4 paginiAn 10.1 The Importance of Zinc For Human HealthnarmathaÎncă nu există evaluări

- Science Checkpoint Revision Y8Document16 paginiScience Checkpoint Revision Y8Mark ZuckerburgÎncă nu există evaluări

- Recent Saple 2 - Final Biology IA - 2018-19Document15 paginiRecent Saple 2 - Final Biology IA - 2018-19RahilÎncă nu există evaluări

- 1b) - 14 Environment (Protection) Fourth Amendment Rules, 2018Document6 pagini1b) - 14 Environment (Protection) Fourth Amendment Rules, 2018Tarun KathpaliaÎncă nu există evaluări

- A153 PDFDocument4 paginiA153 PDFfernandoraiasaÎncă nu există evaluări