Documente Academic

Documente Profesional

Documente Cultură

OSG - Charts

Încărcat de

CTN2010Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

OSG - Charts

Încărcat de

CTN2010Drepturi de autor:

Formate disponibile

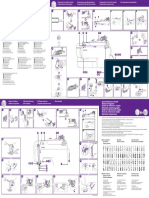

DRILLING APPLICATION GUIDE

VOL. 9

Carbide Powdered Metal HSS-Va & HSS-Co

2017/18 Cutting Tool Solutions Page Number 48- 56- 60- 63- 71- 76- 90- 103- 113- 136- 128- 173- 180- 182- 185- 187- 194- 197- 202- 208-

112

55 59 62 70 73 89 102 111 127 147 135 179 181 184 186 193 196 201 207 238

EXOCARB WDO 10D-30D

EXOCARB WDO 3D-8D

EXOPRO Mega Muscle

EXOCARB MAX-OIL AL

EXOCARB MAX-MINI*

EXOCARB WDO-SUS

EXOPRO WHO-Ni

Hardness

EXOCARB WH70

Work Material Material

EXOCARB ADF

HY-PRO CARB

HY-PRO CARB

EXOCARB WD

EX-SUS-GOLD

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

Material Designation Condition

EX-GOLD

V-HO GDR

VPH GDR

VPH GDS

VP GDR

HELIOS

V-Select

NEXUS

BHN HRC

Low Carbon Steel 1010, 1018 Normalized ~190 ~10 l l l l l l l l l l l l l l

Medium Carbon Steel 1035, 1045 Normalized ~208 ~15 l l l l l l l l l l l l l l l

High Carbon Steel 1065, 1095 Normalized ~253 ~25 l l l l l l l l l l l l l

P

Alloy Steel

4140, 4340, 8620 Normalized 253~301 25~32 l l l l l l l l l l l l l l l

4140, 4340, 8620 Hardened 327~390 35~42 l l l l l l l l l

300 Series / 400 Series Annealed ~253 ~25 l l l l l l

Stainless Steel

300 Series / 400 Series Hardened 327~390 35~42 l l l l l

M

17-4, 15-5, A286 Annealed ~253 ~25 l l l l l

17-4, 15-5, A286 Hardened 327~390 35~42 l l l

Cast Iron Nodular, Grey As Cast ~208 ~15 l l l l l l l l l l l l

K

Aluminum Alloy 6061, 7075, 2011 Normalized ~150 l l l l

N

Die Cast Aluminum 356AL, 390AL As Cast ~150 l l l l

Inconel 718, 625 Annealed 253~301 25~32 l l l l

Nickel Based Alloy

Inconel 718 Hardened 327~390 35~42 l l l l

Hastelloy, Waspaloy Normalized 25~40 l l l

S

Kovar Normalized 25~40 l

Titanium Alloy

6Al4V Annealed 253~301 25~32 l l

6Al4V, 6AL6V Hardened 327~390 35~42 l l

D2, H13, P20, S7 Annealed 190~253 10~25 l l l l l l l l l l l l l

Tool Steel

H13 Hardened 327~450 35~48 l l l l l

H

D2, A2 Hardened 48~55 l l

D2, A2 Hardened 55~70 l l

Magnesium ~100 l l l l

Brass, Bronze ~150 l l l l

Other

Copper ~150 l l l l

Beryllium Copper ~253 ~25 l l l l

Cobalt-Chrome Stellite l

*EXOCARB MAX-MINI covers different materials for each list number.

Verify recommended materials on each product page. l = 1st Choice = 2nd Choice

OSG USA, INC.

800.837.2223 www.osgtool.com

TAPPING SPEED/APPLICATION GUIDE

VOL. 9

Form Taps Cut Taps Pipe Taps

See See 364-369 416-417 See

2017/18 Cutting Tool Solutions Page Number 325-345 313-324 308-312 347-349

Index Index 372-374

370-371

420-421

418-419 392 484-485

Index

518-526

EXOTAP A-TAP POT

EXOTAP A-TAP POT

EXOTAP A-TAP SFT

EXOTAP A-TAP SFT

HY-PRO Synchro AL

EXOPRO XPF-OIL

Hardness

EXOTAP NRT &

Work Material Material

EXOCARB VX

EXOPRO XPF

Coolant-Through

Coolant-Through

Coolant-Through

Coolant-Through

HY-PRO NRT

Material Designation Condition

Pipe Taps

General

General

Carbide

Carbide

BHN HRC

Low Carbon Steel 1010, 1018 Normalized ~190 ~10 35-130 50-115 75-130 40-145 25-80 50-120 80-120 100-200 80-120 100-200 85-105 - 35-100 15-40

Medium Carbon Steel 1035, 1045 Normalized ~208 ~15 20-50 50-115 75-130 25-60 20-50 45-110 80-120 100-200 80-120 100-200 85-105 - 30-70 10-25

High Carbon Steel 1065, 1095 Normalized ~253 ~25 15-30 50-85 65-100 20-35 20-45 40-100 80-120 100-200 80-120 100-200 70-85 - 30-60 10-20

P

4140, 4340, 8620 Normalized 253~301 25~32 15-30 50-85 65-100 20-35 20-50 45-110 35-50 50-100 40-65 50-120 70-85 - 30-70 10-25

Alloy Steel

4140, 4340, 8620 Hardened 327~390 35~42 - 10-40 20-50 - 15-20 20-60 20-40 40-80 35-55 45-110 - - 20-35 10-15

300 Series / 400 Series Annealed ~253 ~25 15-40 15-40 20-50 20-60 20-45 30-70 15-35 25-70 25-75 40-120 - - 25-55 10-25

300 Series / 400 Series Hardened 327~390 35~42 15-35 15-35 20-45 20-50 12-20 20-50 15-35 25-70 25-75 40-120 - - 15-30 8-12

Stainless Steel

M

17-4, 15-5, A286 Annealed ~253 ~25 15-25 15-30 20-40 20-40 15-20 20-50 15-25 25-50 25-60 40-100 - - 20-35 8-12

17-4, 15-5, A286 Hardened 327~390 35~42 - 10-25 15-30 - 8-20 15-40 15-25 25-50 25-60 40-100 - - 10-25 8-12

Cast Iron Nodular, Grey As Cast ~208 ~15 - - - - 25-75 40-100 50-80 60-150 60-100 80-160 - - 40-90 15-50

K

Aluminum Alloy 6061, 7075, 2011 Normalized ~150 50-150 65-115 80-130 60-160 40-80 50-125 70-120 90-220 70-120 90-220 300-800 - 50-100 15-40

N

Die Cast Aluminum 356AL, 390AL As Cast ~150 45-130 65-90 75-110 55-120 40-65 50-110 70-120 90-220 70-120 90-220 200-700 - 50-80 20-35

Inconel 718, 625 Annealed 253~301 25~32 - 8-12 8-10 - 8-15 - - - - - - - 10-20 -

Inconel 718 Hardened 327~390 35~42 - 8-10 - - 8-15 - - - - - - - 10-20 -

Nickel Based Alloy

Hastelloy, Waspaloy Normalized 25~40 - - - - 8-15 - - - - - - - 10-20 -

S

Kovar Normalized 25~40 - - - - 8-15 - - - - - - - 10-20 -

6Al4V Annealed 253~301 25~32 - 8-15 8-10 - 15-20 - - - - - - - 20-30 -

Titanium Alloy

6Al4V, 6AL6V Hardened 327~390 35~42 - 8-12 - - 3-10 - - - - - - - 5-12 -

D2, H13, P20, S7 Annealed 190~253 10~25 20-45 15-50 20-65 25-60 15-35 20-60 30-55 50-110 40-65 60-120 - - 20-50 10-20

H13 Hardened 327~450 35~48 10-15 12-25 20-35 15-30 8-15 15-50 - - 20-50 30-80 - - 10-20 8-12

Tool Steel

H

D2, A2 Hardened 48~55 - - - - 3-10 - - - 15-40 25-75 - 5-12 5-12 -

D2, A2 Hardened 55~70 - - - - 3-8 - - - - - - 3-10 3-10 -

MMC 30-60

Copper Alloys 40-330

Other

Fiberglass 30-60

Cobalt-Chrome 15-60

In the above chart, if a product shows a recommended speed range then it is recommended for that material.

More detailed application recommendations are available on pages 282-299 in the 2017/18 Cutting Tool Solutions catalog.

For EXOCARB Thread Mill speeds please refer to page 565-567 in the 2017/18 Cutting Tool Solutions catalog.

For conversions to RPM please refer to page 536 in the 2017/18 Cutting Tool Solutions catalog.

OSG USA, INC.

Copyright 2017 OSG USA, INC. All rights reserved. Printed in USA. EDP# 800100CA-V9 800.837.2223 www.osgtool.com

S-ar putea să vă placă și

- 2021 02 24 Liste Traitements Electropoli-MinDocument1 pagină2021 02 24 Liste Traitements Electropoli-Minpedro66Încă nu există evaluări

- M303 FSPDocument12 paginiM303 FSPFabián Caicedo TorresÎncă nu există evaluări

- EGLO Interior Lighting 2015 16Document772 paginiEGLO Interior Lighting 2015 16Enrique IbarraÎncă nu există evaluări

- TP2 Roches Magmatiques G211Document37 paginiTP2 Roches Magmatiques G211Najib BonnÎncă nu există evaluări

- Catalogue PERMADocument20 paginiCatalogue PERMAHugues TEMATEÎncă nu există evaluări

- Projet Oral MGC AluminiumDocument28 paginiProjet Oral MGC Aluminiumcle904Încă nu există evaluări

- Pem Chapitre 2Document22 paginiPem Chapitre 2anderson57.kaÎncă nu există evaluări

- Du Minerai À L'acier, Histoire D'un Processus de Fabrication, Par Gilles Durvaux PDFDocument9 paginiDu Minerai À L'acier, Histoire D'un Processus de Fabrication, Par Gilles Durvaux PDFStéphane LannoyÎncă nu există evaluări

- Chapitre 4 - Partie 1Document18 paginiChapitre 4 - Partie 1oussama bensassiÎncă nu există evaluări

- Chapitre 02: Procédés D'obtention Des Pièces Sans Enlèvement de MatièreDocument11 paginiChapitre 02: Procédés D'obtention Des Pièces Sans Enlèvement de Matièreheythem boukedjaniÎncă nu există evaluări

- Introduction Au Traitement Des MineraisDocument6 paginiIntroduction Au Traitement Des Mineraissicke lunkomoÎncă nu există evaluări

- Etude Microstructurale Et Mécanique Sur L'effet de La Boruration Sur La Nouvelle Phases Max Cr2AlC PDFDocument120 paginiEtude Microstructurale Et Mécanique Sur L'effet de La Boruration Sur La Nouvelle Phases Max Cr2AlC PDFIslem SoukeurÎncă nu există evaluări

- 000 Memoire FinaleDocument155 pagini000 Memoire Finalesamir harounÎncă nu există evaluări

- THERMPROCESS 2019 Silicon RAS BV Product GMTN2019.2577667 db22nOrnSVSeSl6ezcKpHgDocument2 paginiTHERMPROCESS 2019 Silicon RAS BV Product GMTN2019.2577667 db22nOrnSVSeSl6ezcKpHgAbdo BejaadiÎncă nu există evaluări

- Rapport Procédé de FabricationDocument35 paginiRapport Procédé de Fabricationamine tabichÎncă nu există evaluări

- 002-CTM Maintenance 2015 SommaireDocument16 pagini002-CTM Maintenance 2015 SommaireImane KhammouriÎncă nu există evaluări

- Aide Mémoire STS Construction MétalliqueDocument23 paginiAide Mémoire STS Construction Métalliquedjfeghali100% (1)

- Rapport de Metallurgie La Corrosion SecheDocument27 paginiRapport de Metallurgie La Corrosion SecheHoreb Ago100% (1)

- Rapport de Stage Ocp Soukaina Raki (Enregistré Automatiquement) (Enregistré Automatiquement)Document26 paginiRapport de Stage Ocp Soukaina Raki (Enregistré Automatiquement) (Enregistré Automatiquement)Ihsan AfriadÎncă nu există evaluări

- TP GéochimieDocument12 paginiTP GéochimieRabab TamouhÎncă nu există evaluări

- Correction Travaux Diriges N2Document3 paginiCorrection Travaux Diriges N2Talel Missaoui100% (2)

- Description Du Procédé de La Fabrication de Faïence: Spécialité: Génie Des ProcédésDocument19 paginiDescription Du Procédé de La Fabrication de Faïence: Spécialité: Génie Des ProcédésNouhaila RadadiÎncă nu există evaluări

- Analyse Qualitative5Document15 paginiAnalyse Qualitative5yayaÎncă nu există evaluări

- Oxydation-Des-métaux Prof - Katif (WWW - Pc1.ma)Document10 paginiOxydation-Des-métaux Prof - Katif (WWW - Pc1.ma)gtÎncă nu există evaluări

- Soudure Et Procédés Courants: Cours TechnologieDocument9 paginiSoudure Et Procédés Courants: Cours TechnologiesaisÎncă nu există evaluări

- Ce 8080 QG 01 EndefrnlitesruDocument2 paginiCe 8080 QG 01 EndefrnlitesruSemper FileÎncă nu există evaluări

- Phenomenes de Corrosion Humide TPDocument4 paginiPhenomenes de Corrosion Humide TPLou BalonÎncă nu există evaluări

- LesceramiquesDocument5 paginiLesceramiquesCHAIMA GAALOULÎncă nu există evaluări

- Rappel CristallographieDocument7 paginiRappel CristallographieHamza ZitouniÎncă nu există evaluări

- Imzi-Naouel Laminoir AnnabaDocument82 paginiImzi-Naouel Laminoir AnnabaYoussef DHAIMINIÎncă nu există evaluări