Documente Academic

Documente Profesional

Documente Cultură

Fish Processing Industry

Încărcat de

raja0 evaluări0% au considerat acest document util (0 voturi)

1 vizualizări22 paginiprocess

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentprocess

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

1 vizualizări22 paginiFish Processing Industry

Încărcat de

rajaprocess

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 22

s4n017 Planing a engineering data 2 Fish caning 4 Processing

GQ *ocrrPoraepocunerrserosonr Produced by: Fisheries and Aquaculture

‘Department

Title: Planning and engineering dat. 2. Fish Canning.

More detail

4. PROCESSING

4.1 Technological Processes

442 Processing Operations:

4.1 Technological Processes

‘The main objective of canning is to obtain a shell-stable product that can be stored in sultable containers for a

considerable lenath of time (atleast two years) without undergoing food spolage, while retaining desirable nutrional

‘and sensory quales.

‘To achieve satisfactory sheltife the folowing conditions must be observed:

|. The contents ofthe cans must be commercially sterlized

{i The inside ofthe can must be resistant to and damaging effects from the contents and the outside must be

resistant to corrosion under reasonable storage conditions.

li, The can ends must be Sealed to prevent ingress of water andior air or any form of contamination.

4.2 Processing Operations

4.2.1 General

Fish should be chil stored at a temperature between 0° and 2 *C, or sorted frozen in freezers at temperatures below

28°C.

When frozen fish is used, it must be thawed before grading andlor dressing.

In the following descriptions ofthe pracessing stages for various products, operations which are simfar are described

in Chapter 4.2.2 “Description of canning tuna in brine’, and subsequently only mentioned.

4.2.2 Description of canning tuna in brine

‘The description is related to canning plant with a capacity of 20 tons whole raw fish (bluefin or yellowfin tuna) per 8

hours, The overall yield is approximately 50-55% which gives approximately 10 000 450 g (1 pound) cans or 20 000

225 g (1/2 pound) cans per 8 hours. See Figure 4 "Layout for tuna cannery"

Simplified flow sheets for canning tuna in brine, tuna flakes with vegetables and tuna. pet food are shown in Figures 8,

‘and 7 respectively.

‘Sequential processing operations for canning tuna are described as folows:

a. Frozen tuna is thawed, preferably, by means of running water at a temperature of 10-15 °C. Loss during

thawing is 0.5-1.0%,

Holding of rozen tuna for long periods before thawing may lead to oxidation of fatresuting in a yellow to orange:

lscolouration on the surface of the cooked loins, Usually this surface discolouration can be removed when the

fish i cleaned.

». Longitudinal cuts are common with large sized tuna and the viscera are removed from the fish on board fishing

vessels prior to freezing. Bonito and skip jack are frozen with viscera. Once thawed, the tuna is washed and

inspected for spoilage. Iftuna isnot eviscerated on board vessels tis must be done inthe plant, The spliting

{and evisceration procedure isthe aaly butchering operation performed on the tuna while i fs nthe raw

Condition. All other cleaning Is performed after the tuna has been cooked. Loss of weight is approximately 24-

2%,

Iiip ww fo or gdoerop00QREB1BEIRESTEEOS Hm see

s4n017 Planing ad engineering data 2 Fish caning 4 Processing

crtnarons, wennert 5

‘BND COUPON +

"Hawn CONTANERS.

Seung PREPARATION

Convever

Sahn

Conveyor

TUNA code paskers

Wash PACHNE FoR

Sass

5, TONn PRE-cooreR

‘2. FECDNG CONVEYOR FoR

“Una BASKETS

sn. ean TABLE

12. ROLLER COnVEYOR

1 Patki TABLE

1S. YDRAULE PRESS.

. BeTY CAIs

Th AUTORAmC FLUNG HACHNE

Fon Tk

‘specTON

owas

Arora samme nao me

asin

cowevor

eroats

WASHING £ ORYIG MACINE

conveyor

Chee

caareane

PaLLenanG

oth

———— ed

a

os

a

brim

5

§

Figure 4 Layout fortuna cannery

Iiip ww fo or gdoerop00QREB1BEIRESTEEOS Hm

s4n017

FROZEN TUNA FROM STORAGE

{THAWING

sing

FILLING IN” TRAYS ANO RACKS:

PRECOOKING IW STEAM,

[ERPATON OF BONES SKIN AIT OneR|_/BONES STE]

TONTROL OF QUALITY & WEIGHT

SEAR

WATER

[STEAMWATER, JWASTE WATER,

| armed ome EE

TABELLING,

PACKING CARTONS

CLOSINGS COONG_CARTONS:

PALLET

STORAGE,

Figure 5 Flow sheet for canning tuna in brine

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm

Planing a engineering data 2 Fish caning 4 Processing

s4n017 Planing a engineering data 2 Fish caning 4 Processing

‘SEPARATIONS,

‘SEAMING

v

FURTHER OPERATIONS SAME AS. FLOW SHEET FOR CANNING TUNA

Figure 6 Flow sheet for tuna flakes with vegetables

wana}

Eee]

y me]

:

3

Deane

Ed

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TNA,

Figure 7 Flow sheet for tuna pet food

«, The tuna is given a pre-cook by heating at a temperature in range of 102 to 104 °C, This operation is necessary

to make it possible to hand pick the light meat from the carcass and also to remove some of the ol rom oly fish

The fish is placed in baskets which are placed on racks. The racks of butchered fish are rolled into the cookers

which are usually of rectangular eross section and made of reinforced steel plate wih a doar, of doors, at ane or

both ends. The pre-cooking isa batch type operation,

‘Steam is admitted through a steam spreader on the floor ofthe cooker. Steam vent and drain valves are

provided to permit removal of air and condensate, Pre-cooking may also De carried out in boing brine.

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm

s4n017

Planing a engineering data 2 Fish caning 4 Processing

‘The pre-cooking time fr individual batches varies widely according tothe sizeof tuna. For example, the cooking

time may vary from 1 1/2 hours for small tuna to & to 10 hoUrs, or more, for larger tuna, Loss of we}BRINING / WASHING }_ paste a]

paxoag} {none Td

SAR FEC] ER]

z

{FOROENSED |

ot abe oF TE

Senn oS

Sune L RO

SEATON

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TUNA

Figure 11 Flow sheet for canning sardines in ol

3. After nobbing the sardines pass through a washing process to remove blood and surface slime. Washing

‘machines of many types may be used, Washing should be with potable waler or sea water of similar quality. (For

certain species with hard and inedible scales, such as pllchard, special washing machines sutable for removing

scales are used)

The sardines are then transported, usually by a conveyor, to a brining machine. The brining can elther be a

batch or a continuous operation. The speed of the process and the concentration of the brine can be controled.

‘The fish are loaded ito the brining unit in one end where they are immersed in concentrated salt soluton, and

then serewed through the unit and simultaneously brined, The fish are then discharged atthe opposite end of

the unt,

‘Salts absorbed by the flesh; a salt content of about 1-2% of fish weight, when in boxes is acceptable. The

brining machine is equipped with fitr to sereen particles from the Brine

In addition to giving the product the desired salt content, brining has other beneficial effects. The process

brightens the appearance of the fish by remaving remaining slime and also toughens the skin; when unorined

fish are canned much of the skin adheres to the can.

Alter brining, the fish are allowed to dean before being transported tothe packing table.

The brine must be prepared from salt which does not contain large quantites of magnesium chloride, a common

contaminant in unrefined salt. The brine should be replaced regularly as otherwise it becomes a source of

contamination

5. After the brining process the sardines are packed (manually or automaticaly) into pre-ashed cans,

‘A manually operated packing line is equipped with conveyor belts, the speed of which can be altered in order to

ensure a smooth supply of sardines and cans tothe packers. The filed cans and waste are removed by the

conveyor after packing

In commen sardine lines the filed cans pass over a weight control unt to a can algner and then to a can pusher,

which automatically feeds the conveyor transferring them to the pre-cooker.

CChange of yiels during the packing process depends on the quality of raw material, but on average 5% loss of

‘weights expected.

6. A typical flash cooker for sardines consists of 2 sections, one for cooking (in steam at about 96 °C) and one for

{tying (in hot air at about 120 °C). The cans wth the open end upwards are automatically transferred to crates,

hier are hanging on crossbars mounted on a continuous chain conveyor ring in slings up awards ino the

‘ooking section, and into sings downwards in the drying section.

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm s1n2

s4n017

8.

Planing a engineering data 2 Fish caning 4 Processing

Between the two sections water is drained from cans as the erates are tured through 360° around a tumbler.

‘The heat inthe cooking section is obtained from supply of direct steam while the heat in the drying section is

indirectly supplied from a heat exchanger. A fan located onthe top of the section circulates the heated ai

Weightloss during this operation is approximately 25 %.

From the cooker the cans are automaticaly transferred onto a conveyor which takes then to the ol dispenser

and onto the seaming machine where they are sealed.

Before the retoring process the cans are washed to remove fish residues and oll from the outside of the

containers,

Further operations as for canning tuna in brine, See chapter 4.2.2. .

‘Table 9 Examples of retorting temperatures and time for canning sardines

Gan type | Temp. (6) | Retortng time (min)

eu | et %

Wa angley |_ 115-116 &

4.2.5 Description of canning pre-smoked sardines in tomato sauce or oil

Most ofthe operations in this process are similar to those described for canning sardines in ol

“Tho description is related toa plant capacity of § tons of raw fish per 8 hours.

The yield from canning of sardines and other pre-smoked smal fishes approximate the yields obtained when canning

sardines in ol

See Figure 12 "Flow sheot for canning pro-smoked small sh in tomato sauce and ol, and Figure 13 “Layout for oro»

‘smoked small fish cannery" which shows a plant ofthe capacty mentoned above.

‘The various operations are described below,

1

2

3

7

- Grading is similar to the operation described for canine sardines in ol,

Brining is similar to the operation described for canning sardines in oll

The fish are rodded, I, hung an rods thraugh the eyes. This operation can be done automaticaly or manually.

The automatic rodding being a complicated pracess is only practised in large plants. The rodded fish are placed

Into frames which are fited to tre smoking racks.

‘The frames have usually accommodate for 30 rods, each with 30 ish

The fish are smoked for approximately 1 hour at temperatures up to [30 °C. The main purposes of the smoking

Isto enhance flavour and to lower the water content ofthe fish,

Usualy tunnel type smoking kins are used in which there is @ controlled temperature gradient between 30° and

125-130°C,

‘The air passes through a heat exchanger while smoke added, The smoke is produced by a smoke generator

Using sawdust from hard woods (oak or similar) Loss during smoking is approximately 25%.

‘After smoking the bodies ofthe fish are separated from the heads with an automatic cuting machine. The heads

are then removed from the rods with an automatic rod striping machine. Loss of weight during the deneading

‘operation is approximately 10-12%,

‘The packing, the fling of sauce or il and the double seaming operations are similar to those described for

canning sardines in ol

\When preparing tomato sauce, puree of good qualiy must be used and to ths is addad ove ol or fish oll, ote

‘Typical mixtures comprise one part ol and two parts tomato puree (20% concentration).

{Al subsequent operations are similar to those described for canning sardines inal

4.2.6 Description of canning fish paste products

‘The description is related toa fish paste canning plant with a capacty of 10 tons whole raw fish per 8 hours. The

production is based on ether deheaded, gutted fsh with an average weight of 1.5 kg of smaller industial fish, Seo

Figure 14 "Layout for fish paste products cannery" which shows a plant of the capacity mentioned above,

‘Overall yield when manufacturing canned fish paste products depends on species involved, however, approximately

45-65% of raw fish weight could be used for planning purposes.

itp dew fo. gfdoerep09RR6818EIRETBEDS Nm sor

s4n017 Planing a engineering data 2 Fish caning 4 Processing

‘The output from a plant producing meatballs is approximately 25 000/850 mi cans per 8 hours; alternatively 8 000/850

mi cans of fsh cakes or 15 000/850 ml cans of meat balls could be produced.

FRESH FISH FROZEN FISH

Trans} fase ie]

car Tan {as om

ami OPAED

Re] ODOING

ESE OAL

— FSH Ou, COM

ans} SHORING ese ware

Pega On )

x

TERCED

cas PACING Teen

| EO

: SEAMING

bos, coins

STERIUZATION

T

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TUNA,

Figure 12 Flow sheet for canning pre-smoked small sh in tomato sauce and ol

“The flow sheet fr canning fish paste produc is shown in Figure 16

“The various processing operations are summarised as flows.

‘Tho raw material has to go through @ grincingchopping and mincing process.

4. Tho fsh are washed, doscalod when necossary,evscorated and deheadod

2. According to skin thickness and size, the fish will have to be split into halves from head to tall along the

backbone,

3. The splt and opened fish are washed and cleaned.

4. The washed splt fish is separated in a meat-bone separator. According tothe type of ish one will get an

acceptable minced product, and offal, Bones and skin.

5. Ifthe minge is unacceptable, (|. ciscaloured because of blaod ete. jit may be necessary to have t washed

ang then dewatered by means of a screwpress

6. The minced fish's mixed ina bowl chopper or mincer with the other ingredients. itis important to add the salt

first and to allow the minoor to work for afew minutes Oetore adding the remaining ingredients to the mixture.

‘This will improve the binding properties of the fish, See Figure 16 "Processing line for fish meat’

itp dew fo. gfdoerep09RR6818EIRETBEDS Nm a2

s4no17 Planing a engineering data 2 Fish caning 4 Processing

OPERATIONS, MACHINERY

AND EQUIPHENT |

1 RNG

2. BRNING TANK

3 ROOONG TABLE

1. breesmoneR

}---—-------+ 5. CONTANER FOR HEADS

1

roo STRIPPER

CUTTING MACHINE FOR

heads

(AN CONTAINER.

PACKING UNE

TOMATO FLING MACHINE

Te GAN SEAMING MACHNE

vata CuNCHER

a. fevoar easker

1B RETORT

1. CAN WASHING & DRYING

ache

15, CARTON

8 PALLETS

fon

cn

mae ® ®

x 1

I

Figure 13 Layout for pre-smoked small fish cannery

itp ww fo orgdoerop00QREBIBEIRESTEEOS Hm

s4n017 Planing ad engineering data 2 Fish caning 4 Processing

‘TORNGT

Fama CPL Root eau

ir

catons

ra 7 HANK) <

‘OSES [WaaPPING

i

— figous}o[ vases

| er

= pg By

a a zg] lel 18

bees

iid .

J Er :

3 —, jTROLe|

page E

a

| ie

MINCER | Ma

7

a

Fafa] coon ron visu suis (Aetne

cal oom

ee eee

ht

SCALE IN METRES

Figure 14 Layout for fish paste products cannery

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm

18122

s4n017 Planing a engineering data 2 Fish caning 4 Processing

waren

WATER

var} {hems | — es]

—E

iNCED FISH

L.

Say |} ——————faurmaciarincnc

AER HN

Ea cae

UIA

TSAO CoOME Fare

fH

| —_a

A

a

(ger seen]

T

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TUNA,

Figure 15 Flow sheet for canning fish paste product

7. Starch, spices and, f necessary, onions, fat, etc, are added.

8. Liquid mik is added and according tothe type of mincer, it will take 10-12 min forthe materials to reach a soft

and fermable conditions.

9. The fish balls can be formed in machines, by hand with spaon, or by hands only, and dropped into a1 112%

solutions of salt water at approximately 90 °C.

10. After cooking in the salt solution for approximately §-8 min the fish balls are filed into cans.

11, Hot brine or fish boullon is added,

12, After seaming the product goes immediately to retoting.

(hae =.

a

Fish CONVEY SCREW PRESS.

Boo f

i

Ye

Figure 16 Processing ine for fish meat

itp dew fo. gfdoerep09RR6818EIRETBEDS Nm 622

s4n017 Planing a engineering data 2 Fish caning 4 Processing

aay, Kanne -- —frrorns

: Seaver

3

Sorat

faces

core

s

5 5

fe cenne

TaeLuns

cao

contre

firape |

sana

T

Na

SCALE IN METRES

Figure 17 Layout for salmon cannery

Several ateratives fr retorting temperatures and times are shown in Table 10.

‘Table 10 Examples of rtorting temperatures and times for canned fish paste products

‘Alternative Initial product temp. (C) Heating

Temp. (C)] time

(in)

Fish meat ballin bnelboailon|

AGO m/ G9 112mm cane

nip shew fo ogfdoerepO09R6818EIRESTEEDS Nm

sree

s4no17 Planing a engineering data 2 Fish caning 4 Processing

1! 20 tos | 20 | 0 | 15

w 2 7 || as |

425 ml (99x 63m) ears

T 2 wm [a] m@ 13

7 20 we [| as | %

Fish cakes in bonefboulion

aS0 m1 9x 119mm) cans

T 3 wm [0] mo |S

450,19 69 mm)_cans

T 2 wo [| im | @

Further descriptions are as fer canning tuna in brine

4.27 Description of canning salmon

“The description is related toa processing plant with a capacity of 8 tons of raw fish per 8 hours; this capacity has been

based on using whole ish weighing 4 kg each. See Figure 17 “layout for salmon cannery’

“The overall yield when canning salmon is between 55 to 60 %, depending on the size of the fish, With a yield of 55%, 1

ton of raw salmon wil give 3 400,

(8437) 228 g (1/2 pound) cans.

‘The processing operations are described below. See Figure 18 "Flow sheet for canning salmon™

1. The fsh are transported to sorting table and sorted by species.

2. The salmon are eviscerated with an iron chink machine which remaves the head, fins and viscera from the

salman (s00 Figure 1) The loss of woight is approximately 35-40 %

3. The eviscerated, deheaded fish is next conveyed tothe siming table. Sliming consists of removing fins, viscera

{and blood, ec. not removed by the buchering machine. During the sling operation the fish's throughly

‘washed. The loss of weight is approximately 3-5 %.

a

i

=

joeneclcoern

x

Cai 7AND KIDNEY,

(eae

en FASS OF)

1 a

nd ue

L

CANS

FILLING

‘sar

WEIGHING

z

ios “CLINCHING

war

SEAMING

WASHING STE WATER]

L

STERILIZATION

T

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TUNA

Figure 18. Flow sheet for canning salmon.

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm

s4n017

Plareing and enginexing data 2. Fish caning 4 Processing

4. From the siming table the leaned fish i conveyed toa sh cuter ites with revolving skies which cut the fish

Ifo ies. The see are hen fede an automate ing mactino, Te ss cf wig eperxiataly 05-10

5. The filing machine fils the cans with the salmon after which salts added

6. The filed cans pass through an automate scale which sors for under Welght cans.

7. Fram the scale the cans pass ino a vacuum seaming machine

8. The filed and sealed cans are then discharged from the seaming machine through a can washer.

8. After seaming the product goos immediately to retorting. Retorting conditons of approximately 115 °C for 100,

min are used for 450 ml cans

10. Further descriptions are as for canning tuna in brine

4.2.8 Description of canning shrimps

Headless, peeled sirimps are graded according to number of shrimps per 100 g of drained product. See Table 11

(Codex Stan 37-1981),

2. FISHIN POSITION FOR HEADING

5. BULL RING WHICH CARRIES FISH THROUGH THE MACHINE:

4 BACK PINCERS

5. TAIL PINCERS ADVANCED AND GRASPING FISH

8. TAIL CUA OFF SAW

7. BELLY FINNING KNIFE

15, BACK PINCERS ADVANCED AND GRASPING FISH

9. BACK FINNING KNIFE

40. BELLY SLITTING SAW

11, GUIDE TO OPEN BELLY FLAPS FOR GUTTING REEL

12, GUTTING REEL TO REMOVE VICERA.

19. KNIFE AND REEL TO SLIT KIDNEY MEMBRANE AND TO REMOVE KIDNEY

‘4, BRUSH TO REMOVE BLOOD AND MEMBRANES

45, ROLLER TO SUPPORT ULL RING

418. FISH RELEASED AS BACK AND TAIL PINCERS RETRACT

$7, CONVEYOR TO REMOVE BUTCHERED FISH

Figure 19 ron chink for dressing salmon

Table 14 Number of shrimp per 100 g of drained product

Size Designation ‘Conventional Cleaned

Ex lage or jumbo | Tess than 12.3 Tess than 13.4

Lage Ste TFT weave Bato TO.t nehane

Medium | more than 18.1 bral more than 91.8 [more than 191 ul nt more than 36.6

Smal ‘more than S18 bu not more than 60 | more than 246 but not more than 65.3

“Tiey or inuscular more than 60.0 more than 652

itp dew fo. gfdoerep09RR6818EIRETBEDS Nm

a2

s4n017 Planing a engineering data 2 Fish caning 4 Processing

omrne |] [cooana

2 fase

z 8 z

5 a 3

fe g

$2] =

Eo z

. 3

iC

eeunc

z

ra

PALLETIZING 5 g i

rm @ # |

| 8g

a é

2 =

5 frasHinGeORr ING

row

ort

St

SLE wera

Figure 20 Layout for shrimp cannery

It is usual to can only those shrimp which fallin the medium to very smal size range.

‘The description is based on a processing plant capacty of 3.6 tons raw shrimp per 8 hours. This corresponds to

production of 12 000-14 000 cans, each containing 75 9 shrimp, in & hours,

“The overall yield ‘rom canning shrimp is between 25 ta 30% of raw weight. See Figure 20 "Layout for shrimp cannery”

\which shows a plant ofthe capacity mentioned above. The description is based on using iced raw shrimp asthe raw

material, The shrimps are usually graded before delivery tothe cannery. See Figure 21 "Flow sheet for canning

shrimps!

The operations in the canning process are summarized below:

2. On artval atthe cannery, ce is removed before washing the stimps.

». The shrimps are throughly washed while being conveyed into the plant

itp shew fo. gfdoerep 0968 18EIRESTEEDS Nm

s4n017 Planing a engineering data 2 Fish caning 4 Processing

«After washing the shrimps are inspected and foreign debris removed,

4. The shrimps are then conveyed to a peeling machine, which separates the shells and heads from the body. This

‘operation can also be done manually, Aproximately 46% ofthe total weigh is lost during this process.

«2. Alter peeling, the shrimps pass through to a waste separator, which removes fragments left after peeling.

{The cleaned shrimps are loaded into baskets and placed into a bong sal solution for cooking, Average salt

concentration inthe solution is 11-13%. The cooking time varies from 6-10 minutes depending on the size ofthe

shrimps.

{9. After cooking the shrimps are inspected and any broken ones andlor pieces are removed. The shrimps are then

cried by fans.

1. The shrimps are weighed and hand-filed into cans. The weight ofthe shrimps . should be 64% ofthe content of,

the can, Aluminium cans are preferably used ‘or shrimp canning, however if tin plate cans are used, layers of

parchment paper should be placed between the shrimps and the can to prevent corrasion. Hat or cold brine is.

filed into the cans.

Table 12 Example of mixture for brine

Sat (ae

Suara

Giine acid [091

water | 7001

1. The cans are automaticaly closed and transferred to retorts for processing,

FRESH SHRIMP

Ie

ware} wasn

as

maine} [ase]

£ c

we Tsine (ast aR

INSPECTION

Toa

aot |} _—fasttaren

wa Et A

ine oe a

5 ane} cag

il

Wiha of STERILIZATION STE WATER]

[SOLUTION

FURTHER OPERATIONS SAME AS FLOW SHEET FOR CANNING TUNA.

Figure 21 Flow sheet for canning shrimp

‘Table 13 Examples of retorting temperatures and times for canning shrimp

[Alternatives [Preheating Conditions | Processing Conditions|

‘emp. [time | temp. | dime

ce) | tiny | cc) | min)

T 104 a +6 2

0 108 0

j. Further operations are as for canning tuna in brine

nip hww fo. gfdoeropO09RR6818EIRESTBEDS Nm ame

s4no17 Planing ad engineering data 2 Fish caning 4 Processing

Iiip ww fo or gdoerop00QREB1BEIRESTEEOS Hm

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Microsoft Office Project - Mobilization PlanDocument1 paginăMicrosoft Office Project - Mobilization PlanrajaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Weekly Safety ReportDocument5 paginiWeekly Safety ReportrajaÎncă nu există evaluări

- Construction Progress PaymentDocument4 paginiConstruction Progress PaymentrajaÎncă nu există evaluări

- Fishing Problem: 10 August 2016 Advance Problem Arun MahajanDocument6 paginiFishing Problem: 10 August 2016 Advance Problem Arun MahajanSoumalya BhanjaÎncă nu există evaluări

- Lines of Credit - Financial Products - Exim Bank 2Document2 paginiLines of Credit - Financial Products - Exim Bank 2rajaÎncă nu există evaluări

- JTC 01 Foundations and Pile CapsDocument10 paginiJTC 01 Foundations and Pile CapsrajaÎncă nu există evaluări

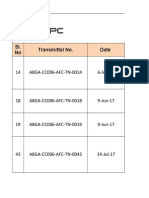

- Bauxite Export Project, Guinea - CC - 006 Port Development and Infrastructure Inward Register For Transmittal From Afcons Sl. NoDocument10 paginiBauxite Export Project, Guinea - CC - 006 Port Development and Infrastructure Inward Register For Transmittal From Afcons Sl. NorajaÎncă nu există evaluări

- Bauxite Export Project, Guinea - CC - 006 Port Development and Infrastructure Inward Register For Transmittal From Afcons Sl. NoDocument10 paginiBauxite Export Project, Guinea - CC - 006 Port Development and Infrastructure Inward Register For Transmittal From Afcons Sl. NorajaÎncă nu există evaluări

- Bauxite Export Project, Guinea - CC - 006 Method Statement For Lateral Load Test SP-A8GA-006-FLR-CS-PL-5010 RCDocument10 paginiBauxite Export Project, Guinea - CC - 006 Method Statement For Lateral Load Test SP-A8GA-006-FLR-CS-PL-5010 RCrajaÎncă nu există evaluări

- 501 - Concrete - PlantsDocument4 pagini501 - Concrete - PlantsrajaÎncă nu există evaluări

- Bored-Piling Mar2016 PDFDocument4 paginiBored-Piling Mar2016 PDFrajaÎncă nu există evaluări

- Aira Condominium - OriginalDocument21 paginiAira Condominium - OriginalrajaÎncă nu există evaluări

- 024Document2 pagini024rajaÎncă nu există evaluări

- NCR ResponseDocument2 paginiNCR ResponserajaÎncă nu există evaluări

- 501 - Concrete - PlantsDocument4 pagini501 - Concrete - PlantsrajaÎncă nu există evaluări

- Recovery Plan: SL - No. Area Description Start End ResourceDocument4 paginiRecovery Plan: SL - No. Area Description Start End ResourcerajaÎncă nu există evaluări

- 501 - Concrete - PlantsDocument4 pagini501 - Concrete - PlantsrajaÎncă nu există evaluări

- 4 Phases Involved in Bored Cast In-Situ Pile Construction Work - CivilblogDocument9 pagini4 Phases Involved in Bored Cast In-Situ Pile Construction Work - CivilblograjaÎncă nu există evaluări

- Bored Piling Mar2016Document4 paginiBored Piling Mar2016rajaÎncă nu există evaluări

- Quality Control Lab EquipmentsDocument1 paginăQuality Control Lab EquipmentsrajaÎncă nu există evaluări

- Project OverviewDocument1 paginăProject OverviewrajaÎncă nu există evaluări

- 01 10 00arcDocument2 pagini01 10 00arcrajaÎncă nu există evaluări

- Staad CommandsDocument6 paginiStaad CommandsrajaÎncă nu există evaluări

- Architectue PlansDocument25 paginiArchitectue PlansrajaÎncă nu există evaluări

- Project OverviewDocument1 paginăProject OverviewrajaÎncă nu există evaluări

- Minimum Standard For High Rise BuildingDocument6 paginiMinimum Standard For High Rise BuildingDedy KristiantoÎncă nu există evaluări

- Design of Plumbing Systems For Multi-Storey Buildings PDFDocument14 paginiDesign of Plumbing Systems For Multi-Storey Buildings PDFpequenita34100% (4)

- Table of ContentsDocument2 paginiTable of ContentsrajaÎncă nu există evaluări

- 1457E1 Civil Enquiry C002B Rev 01 NN CommentsDocument44 pagini1457E1 Civil Enquiry C002B Rev 01 NN CommentsrajaÎncă nu există evaluări

- 2006 Status of Coho Salmon in CaliforniaDocument213 pagini2006 Status of Coho Salmon in CaliforniaMartha LetchingerÎncă nu există evaluări

- ITC HS ClassificationDocument144 paginiITC HS Classificationwijido9671Încă nu există evaluări

- Lisa Nurpatimah: Nama: LISA Kelas: 8CDocument4 paginiLisa Nurpatimah: Nama: LISA Kelas: 8CLezard El-EzharÎncă nu există evaluări

- IEM - Harvesting Equipment (Fishing Gears)Document49 paginiIEM - Harvesting Equipment (Fishing Gears)Eddy Edlin Bin MervinÎncă nu există evaluări

- WI DNR Trout Stock 2018Document17 paginiWI DNR Trout Stock 2018Fredrick smothsÎncă nu există evaluări

- The Lunker PDFDocument23 paginiThe Lunker PDFFechete LaviniaÎncă nu există evaluări

- Western - angler.truePDF April - May.2017Document100 paginiWestern - angler.truePDF April - May.2017Ciprian CociubaÎncă nu există evaluări

- Mola Mola Fish - Google SearchDocument1 paginăMola Mola Fish - Google SearchRuth Rasalhaque LubisÎncă nu există evaluări

- Body Shape: Fusiform DepressedDocument2 paginiBody Shape: Fusiform DepressedZaky MfaÎncă nu există evaluări

- Fishing Knots, Swivels, SinkersDocument41 paginiFishing Knots, Swivels, SinkersRyan RodeÎncă nu există evaluări

- Dok Engl TisDocument24 paginiDok Engl TisSaleemÎncă nu există evaluări

- Tenkara Fishing: Richard AdeneyDocument16 paginiTenkara Fishing: Richard AdeneyMarceloÎncă nu există evaluări

- Major Species of Tuna in The PhilippinesDocument7 paginiMajor Species of Tuna in The PhilippinesKent Malig-onÎncă nu există evaluări

- Unit - 10 Exercises (Answers) : English Grammar in Use - 5 EditionDocument2 paginiUnit - 10 Exercises (Answers) : English Grammar in Use - 5 EditionMahdiÎncă nu există evaluări

- 6 - Poster Jenis Ikan Dominan Dengan API Longline FinalDocument1 pagină6 - Poster Jenis Ikan Dominan Dengan API Longline Finalgirindri sugestiÎncă nu există evaluări

- Mustad - Americas Catalog - 2016Document158 paginiMustad - Americas Catalog - 2016champ97Încă nu există evaluări

- Wa0004Document15 paginiWa0004Daniel OscarÎncă nu există evaluări

- Fishing LineDocument80 paginiFishing LineStart AmazonÎncă nu există evaluări

- Fishing Lure Lipless Crank BaitDocument23 paginiFishing Lure Lipless Crank BaitDESTROERs cRaZyes100% (1)

- Muntinlupa MuseumDocument1 paginăMuntinlupa MuseumPaula Mae NogalesÎncă nu există evaluări

- 000 - DMC FormattingDocument261 pagini000 - DMC FormattingTemp EmailÎncă nu există evaluări

- Floating Buck Creek: Bluewater Trails Bluewater TrailsDocument4 paginiFloating Buck Creek: Bluewater Trails Bluewater TrailsJames WentworthÎncă nu există evaluări

- Adapted FishingDocument2 paginiAdapted Fishingapi-541744798Încă nu există evaluări

- A Basic Guide For The Beginning AnglerDocument52 paginiA Basic Guide For The Beginning AnglerMirkoÎncă nu există evaluări

- Product Catalogue: Sales@frenzee - Co.uk WWW - Frenzee.co - Uk FrenzeeDocument48 paginiProduct Catalogue: Sales@frenzee - Co.uk WWW - Frenzee.co - Uk FrenzeedaveagriffÎncă nu există evaluări

- Beachfishing SCDocument2 paginiBeachfishing SClolichansilva84Încă nu există evaluări

- SJK (C) Pei Hwa Year 3 English Language Assessment 3Document6 paginiSJK (C) Pei Hwa Year 3 English Language Assessment 3hanujaÎncă nu există evaluări

- List of Indonesia Approved Establishments For The Export of Fish Products (Wild Catch) To The Kingdom of Saudi ArabiaDocument22 paginiList of Indonesia Approved Establishments For The Export of Fish Products (Wild Catch) To The Kingdom of Saudi ArabiaMuhammad DirhamÎncă nu există evaluări

- Barangay HistoryDocument1 paginăBarangay HistoryDianka Glory Cenabre EdrozoÎncă nu există evaluări