Documente Academic

Documente Profesional

Documente Cultură

Elastomeric Composition For Tire Treads. Us5362793

Încărcat de

renagoncTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Elastomeric Composition For Tire Treads. Us5362793

Încărcat de

renagoncDrepturi de autor:

Formate disponibile

US005362793A

United States Patent [191 [11] Patent Number: 5,362,793

Garro et a1. [45] Date of Patent: Nov. 8, 1994

[54] ELASTOMERIC COMPOSITION FOR TIRE 4,431,755 2/ 1984 Weber et a1. ...................... .. 524/575

TREADS 4,436,847 3/ 1984 Wagner .. . .. .. . .... .. . . . . .. 524/575

4,485,205 11/1984 Fujimaki et a1. .... .. 524/526

[75] Inventors: Luciano Garro; Mario Martin, both 4,640,952 2/ 1987 Takiguchi et a1. . . . . . . . . . .. 524/296

of Milan, Italy 4,748,168 5/1988 Kawakami et a1. . . . . . . . . .. 524/474

4,786,680 11/1988 Suzuki et al. . .. .. . . . . .. 524/495

[73] Assignee: Pirelli Coordinamento Pneumatici 4,820,751 4/ 1989 Takeshita et a1. .. .... .. 524/495

S.p.A., Milan, Italy 5,007,471 4/1991 Maiocchi ........................... .. 245/ 1.5

[21] Appl. No.: 58,808 FOREIGN PATENT DOCUMENTS

[22] Filed: May 10, 1993 0288986 11/ 1988 European Pat. Off. .

63-240405 10/1988 Japan .

Related US. Application Data 01197540 8/1989 Japan .

[63] Continuation of Ser. No. 673,320, Mar. 22, 1991, aban Primary ExaminerEdward J. Cain

doned. Attorney, Agent, or FirmStevens, Davis, Miller &

[30] Foreign Application Priority Data Mosher

Mar. 23, 1990 [IT] Italy ................................ .. 19781A90 [57] ABSTRACT

[51] , Int. Cl.5 .............................................. .. C08K 3/04 An elasomeric mix for pneumatic tire treads to enhance

[52] US. Cl. . . . . . . . . . . .. 524/495; 524/496; driving behavior including road holding ability on wet

524/296 surfaces, abrasion resistance and low rolling resistance.

[58] Field of Search ...................... .. 524/495, 496, 296 The inventive elastomeric mix on E"/E' ratio dynamic

[56] References Cited moduli value equal to or greater than 0.3 at 0 C. and

equal to or less than 0.16 at 70 C. The mix is based upon

U.S. PATENT DOCUMENTS natural rubber and lampblack comprising, for 100 parts

3,664,403 5/ 1972 Doran et a1. ................... .. 524/575.5 of elastomer, from 5 to 20 parts by weight of a synthetic

3,768,537 10/1973 Hess et a1. . . . .. .. .. . . . . .. 524/571 polymer selected from the group consisting polychloro

3,873,489 3/1975 Thurn et a1. . . .. .. . . . . .. 524/552 prene, chlorinated butyl rubber and brominated butyl

3,881,536 5/1975 Doran Jr. et a1. . .. 524/575.5

rubber.

3,949,800 4/ 1976 Lejeune . . . .. . .. ... .. . . . . . .. 152/547

4,143,027 3/ 1979 Sollman et- a1. . . . . . . . ._ 524/ 571

4,420,025 12/1983 Ghilardi et a1. ................... .. 152/531 11 Claims, No Drawings

5,362,793

1 2 .

In this way the expert is obliged to look for the best

ELASTOMERIC COR/{POSITION FOR TlRE possible compromise between the different characteris

TREADS tics in view of all the possible features of performance

required of a speci?c type of tire.

This application is a continuation of application Ser. In order indeed to reach the best compromise in rela

No. 07/673,320, ?led Mar. 22, 1991 now abandoned. tion to that particular type of use, the current state of

the art utilizes for the uses speci?ed above different

BACKGROUND OF THE INVENTION

types of tread mix.

The present invention relates to the elastomer mixes These types of mix use natural rubber as an elasto

used in the manufacture of tires for motor vehicles and 10 meric material, in combination with appropriate

in particular it relates to elastomer mixes selected for charges of other speci?c materials (lampblack, vulcani

the preparation of a tire tread strip. The invention re zation regulators, anti-aging products, etc.) and can also

lates more speci?cally to tires having enhanced perfor contain other reinforcing charges in siliceous materials

mance resulting from the use of the above mixes in the for the purpose of suitably changing certain of their

tire strip and the method for obtaining such tires. characteristics.

It is known that motor vehicle tires comprise a toroi Two characteristics of the tire that are very impor

dal-shaped carcass, to be mounted on a wheel rim, inter tant for the safety of road and motorway transport are

nally hollow and in?ated with air under pressure to behavior on a dry surface and road-holding on a wet

allow the operation of the tire. In the tire crown, that is, surface.

in a radially external position, the tire has a thick strip These two characteristics determine the possibility of

(tread strip or more simply tread) of an appropriate controlling the direction of the motor vehicle, prevent

elastomeric composition, hereinafter called a mix, ing dangerous swerves, even under emergency condi

onto which a tread design is impressed. tions due, say, to a sudden obstacle to be avoided.

It is also known that different characteristics of the These characteristics are measured by means of the

tires behavior and performance depend to a not negligi assessment of the behavior of the tire mounted on the

ble extent on the characteristics of the above tread mix: vehicle, driven along a speci?c type of route.

as an example, it is sufficient to mention resistance to The assessment can be carried out on the basis of a

abrasion, which determines length of the life of the tire, feeling on the part of the test driver or by means of the

road-holding features on dry as well as wet surfaces, measurement of time and speed.

resistance to rolling, properties of energy dissipation On the basis of tests carried out by the Applicant with

and drivability. radial tubeless truck vehicle tires, size 315/80 R 22.5,

A speci?c type of use to which tires used for heavy provided with different types of tread mixes, the behav

truck vehicles are subjected is that, distinguishable into ior on dry surfaces and road-holding features on wet

two variants, commonly known to the experts as ON surfaces have been shown to be mathematically corre

and SUPER-ON, which substantially indicate the use latable with the dynamic properties of the tread mixes,

of the tire on vehicles with a high loading capacity, expressed by the parameters: E=elastic modulus

which run prevalently (ON) or almost exclusively (SU (which measures the energy conserved and recovered

PER-ON) at high operating speeds, on substantially during a cyclic deformation); E"=viscous modulus

rectilinear and ?at roads, in good or better surface con (which measures the energy dissipated as heat during a

ditions, such as interstate highways. cyclic deformation); tang 8=E"/E.

These tires ape generally distinguished by a tread Another characteristic of fundamental importance in

design of the so-called ruled type, that is comprising truck vehicle tires is the rolling resistance, that is the

a plurality of continuous circumferential ribs, axially energy dissipated during rolling. This property, as is

separated one from the other by longitudinal grooves, 45 known to experts in the ?eld, affects not only fuel con

circumferentially continuous, with a zig-zag pattern, or sumption but also the useful life of the tire.

of the type having small blocks with a high tractability. In fact the higher the Polling resistance the higher the

With this type of operation the qualities of good road tires operating temperature and the quicker are those

holding under all surface conditions, of response to processes of chemical and physical decay of the materi

driving conditions, of low tearability, of low Polling 50 als which lead to the tire having to be discarded.

resistance, and of resistance to wear under low severity The Applicant, carrying out tests still with the above

conditions, such as those indeed presented by the mentioned tires size 315/80 R 22.5 and using different

above-mentioned types of roads, acquire particular im tread mixes has found a correlation between the dy

portance. namic properties of the tread mixes and the rolling

Unfortunately several of these characteristics one 55 resistance, which can both be expressed in relation to

substantially incompatible with one another, in the tang 8.

sense that mixes outstanding as regards some of them

are generally poor as regards the others, such as, for THE PRIOR ART

example, mixes based on natural rubber which ape According to the current state of the art, in order to

highly resistant to tear and have a low Polling resistance enhance the behavior on a dry surface as well as fea

but frequently have an insuf?cient road-holding fea tures of road-holding on a wet surface it is possible to

tures and high abradability. use appropriate mixes (blends) of natural rubber (NR)

The addition in the recipe of these mixes of given with the two synthetic rubbers commonly used in tread

quantities of speci?c elastomeric materials (for example, mixes for motor cars or light truck tires, that is the

styrene-butadiene rubbers) on the one hand raises road 65 styrene-butadiene copolymer (SBR) and polybutadiene

holding ability and resistance to abrasion but, at the (BR). More in particular, it is possible to use NR/SBR

same time, worsens rolling resistance and tearability blends or NR/BR blends or also NR/SBR/BR blends

under certain operating conditions. containing at least 50 parts by weight of natural rubber.

5,362,793

3 4

It must be clear that all abreviations adopted for the Preferably in the above mix the value of the elastic

mixes in the present description have the exclusive pur modulus E is 58 MPa at a temperature of 0 C. and 5

pose of facilitating the reading of the text and of the MPa at a temperature of 70 C.

tables comparing the different mixes without any limit

ing intent, especially with reference to their features of 5 DETAILED DESCRIPTION OF THE

any kind. INVENTION

As shall be shown later, these formulations attain the More speci?cally such mix, especially in the use with

objective but; to the detriment of a worsening (increase) the above tires, is characterized in that, for 100 parts by

in rolling resistance, with the negative consequences weight of elastomeric material, it comprises from 80 to

described earlier. 10 95 parts by weight of natural rubber or of a mix of it

with styrene-butadiene and/or with polybutadiene (in

SUMMARY OF THE INVENTION

the NR/SBR, NR/SBR/BR, NR/BR blends), the natu

The Applicant has now discovered that it is possible ral rubber being present in said mix with at least 50 parts

to appreciably enhance the qualitative level of current by weight of 100 parts of said mix, so that the sum of the

tires, in particular those for heavy truck vehicles pro concentrations remains in the range of from 80 to 95

vided with a tread strip in natural rubber, adopted in parts per 100 parts by weight of the overall elastomeric

ON type and SUPER-ON type operations, using a material, and correspondingly from 20 to 5 parts by

speci?c type of blend for natural rubber, that is a mix weight of a synthetic polymer selected from the family

ture of the base elastomer with speci?c synthetic poly comprising polychloroprenic rubbers and halogenated

mers, so that the object of the present invention is the butyl rubbers.

de?nition of an elastomeric composition, speci?cally Preferably the quantity of the above synthetic poly

for treads strips, which allows the enhancement in tires mer ranges from 8 to 15 parts by weight per 100 parts of

of road-holding features in particular, both on dry and elastomer, while the quantity of lampblack ranges pref

on wet surfaces, without increasing rolling resistance to erably from 45 to 55 parts by weight per 100 parts of

any signi?cant extent and without compromising the 25 elastomeric material.

current qualitative level of the other characteristics of In one of its further embodiments, the present inven

the mix and of the tire, both as regards the product tion also relates to a method for enhancing the perfor

obtained and the production process followed. mance of tires for motor vehicles, especially those used

Thus, in a ?rst embodiment the present invention in heavy goods transport, in operations distinguished by

relates in a general manner to a tire for vehicle wheels 30 high running speeds over long and smooth routes, char

comprising a carcass, a tread strip placed as a crown to acterized in that it comprises the step of accomplishing

such carcass, as well as sides and beads for anchoring said tread mix with a mixture of elastomers comprising,

said tire to a corresponding assembly rim, characterized per 100 parts by weight of elastomeric material:

in that said tread strip is made with a mix based on from 80 to 95 parts by weight of natural rubber or of

natural rubber and lampblack having a value of the 35 a mixture of it with styrene-butadiene and/or with

E/E ratio, that is, a value of tang 520.3 at a tempera polybutadiene, the natural rubber being present in

ture of 0 C. and 50.16 at a temperature of 70 C. said mixture with at least 50 parts by weight of 100

In a second more speci?c embodiment the present parts of said mix, and correspondingly

invention relates to a tire of the type with no inner tube, from 20 to 5 parts by weight of a synthetic polymer

usually better known and hereinafter indicated as tube 40 selected from the family comprising polychloro

less, for wheels of heavy truck vehicles, which com prenic rubbers and halogenated butyl rubbers, spe

prises a carcass provided with sides and beads for an ci?cally polycholoroprene, chlorinated butyl rub

choring said tire to a corresponding assembly rim, a ber and brominated butyl rubber.

tread strip with a relief design and placed as a crown to Polycholoroprenic rubbers are intended as the homo

said carcass and an annular reinforcing structure, cir 45 polymers of 2-chloro-1,3-butadiene and the copolymers

cumferentially inextensible, placed between said carcass of 2-chloro-l,33-butadiene with dienic monomers such

and said tread strip, said carcass being of a metal single as butadiene and isoprene, having an average molecular

ply radial type with the ends thereof turned up axially weight ranging from 2X 104 to 106, whose molecular

from the inside to the outside around a metal annular weight is regulated with the use of molecules containing

bead core reinforcing said beads. The core is of the 50 sulphur or alkylmercaptans and whose Mooney viscos

so-called packet described in the allowed U.S. appli ity, measured according to the ASTM speci?cation D

cation Ser. No. 07/183,639, the desclosure of which is 1646, ranges from 20 to 100 ML(1 +4), measured at 100

hereby incorporated by reference type, comprising a C.

plurality of turns of bare metal wire, placed in recipro Halogenated butyl rubbers are intended as isobuty

cal contact in both the axial and the radial directions lene-isoprene copolymers, with an isoprene content of

and having, in a plane containing the tires axis of rota up to 5% in mols, having an average molecular weight

tion, a straight cross-section of a polygonal shape whose ranging from 104 to 106, modi?ed by the action of

radially innermost internal side is arranged at an angle substances containing chlorine or bromine. Chlorobutyl

of about 15 to said axis of rotation, said tire being char rubbers have a maximum chlorine content of 3% by

acterized in that said tread strip is prepared with a mix weight.

based on natural rubber and lampblack having a E"/E Bromobutyl rubbers have a maximum bromine con

ratio (value of tang (3)203 at a temperature of 0 C. tent of 3% by weight.

and 20.16 at a temperature of 70 C. The Mooney viscosity of chlorobutyl and bromobu

In a third embodiment the invention also relates to an tyl rubbers, measured according to the ASTM speci?

elastomeric composition (mix) based on natural rubber cation D 1646, ranges from 20 to 60 ML(1 +8), at 125

and lampblack having a E/E ratio (value of tang C.

8) 50.3 at a temperature of 0 C. and 50.16 at a temper Preferably in the tires and in the mixes according to

ature of 70 C. the invention the quantity of said synthetic polymers

5,362,793

5 6

included in the above-mentioned elastomeric composi illustration in US. Pat. No. 3,949,800 or in European

tion is limited to a range from 8 to 15 parts by weight patent application EP 288,986 published 2.11.88, in the

per 100 parts by weight of elastomeric material. name of the same Assignee; both disclosures of which

According to a further preferred method of the in are hereby incorporated by reference.

vention, in said elastomeric composition the quantity of 5 A straight cross-section of the above-mentioned

lampblack contained ranges from 45 to 55 parts by wires, in the plane containing the tires axis of rotation,

weight per 100 parts by weight of elastomeric material. is a polygonal ?gure (say, a rhomboid or a hexagon)

These and other objects of the present invention shall with the more radially internal side at an angle in a

now be more easily understood with the help of the direction parallel to the corresponding surface of the

following description and of the enclosed tables, pro rim, that is, at about 15 to the above-mentioned axis of

vided merely as a non-limiting example, wherein: rotation.

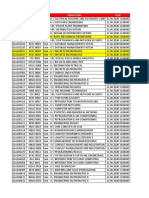

Table 1 illustrates the composition of the mix accord In these tires the tread strip is provided with a tread

ing to the invention compared with the compositions of pattern specially suitable for continuous service at high

other mixes known of the state of the art; speed, say, of the grooved type, that is, comprising a

Table 2 illustrates, by means of a series of values 15 plurality of continuous circumferential ribs separated

referring to some dynamic parameters, some features of one from the other by longitudinal grooves, also contin~

the mixes of table 1; uous, generally with a zig-zag pattern, or, remaining

Table 3 illustrates the result by comparison of tests of within this scope, of the type having small blocks with

the behavior on the road carried out on samples of a high tractability.

radial tubeless goods vehicle tires, size 315/80 R 22.5, 20 Lastly, between the carcass and the tread there is

provided with treads made with the mix of the inven positioned a belt, of any convenient known type, prefer

tion and with the usual state of the art mixes, respec ably that described in US. Pat. No. 4.420.025 issued

tively, as per Table 1; 13.12.83, (the disclosure of which is hereby incorpo

Table 4 illustrates, again with a series of values refer rated by reference) in the name of the same Assignee,

ring to the above dynamic parameters, the effect of 25 comprising two radially superimposed layers of rubber

different synthetic rubbers in the blend, in increasing coated textile material reinforced with thin metal

quantities, with natural rubbers in a formulation typical twisted together strands parallel to one another in each

of a mix for truck vehicle treads. layer, arranged at an angle to the tires circumferential

The present invention thus relates ?rst of all to tires direction and at right angles to those of the adjacent

for motor vehicles and in particular to those tires used layer, and on the extremities of said layers, in a radially

for heavy truck vehicles which travel over long routes external position, two radially superimposed strips of

at high running speed on roads having limited abrasion. rubber-coated material reinforced with thin metal

It is known that in its more general form the tire twisted together strands of the type having high elonga

comprises a carcass having a toroidal shape whose side tion, oriented in the circumferential direction.

walls terminate radially on the inside with two high With the object of enhancing its performance in the.

rigidity areas, known as beads, which have the speci?c uses mentioned above, tires in general but especially

task of ?rmly anchoring the tire to a corresponding those for heavy truck vehicles, according to the inven

assembly rim. tion have a tread strip made of an elastomeric composi

The carcass may be constituted by one or more rein tion, also the object of the present invention, whose

forcing plies, provided with textile or metal twisted 40 dynamic parameters E and E" have values such that

together strands, arranged radially, that is lying in their ratio E"/E, better known as tang 8, is 50.3 at a

planes containing the tires axis of rotation, or at an temperature of 0 C. and 20.16 at a temperature of 70

angle to the above-mentioned planes. C.

The ends of one or more of the carcass plies are This result is conveniently attained with an elasto

turned up axially from the inside to the outside each 45 meric composition based on natural rubber blended

around a metal annular bead core, known as a bead with a suitable polymer, that is comprising per 100 parts

wire, reinforcing the bead, constituted by a plurality of by weight of elastomeric material, a quantity ranging

bare or rubber-coated metal wire turns, according to from 80 to 95 parts by weight of natural rubber and a

the type of tire. corresponding quantity ranging from 20 to 5 parts by

The carcass is again completed by a tread strip, 50 weight of a synthetic polymer selected from the family

placed on the crown and having a tread pattern for including:

contact with the ground, and possibly by a reinforcing chloroprenic rubbers,

annular structure, circumferentially inextensible, better chlorinated butyl rubbers,

known as a belt, placed between carcass and tread strip, brominated butyl rubbers. ,

whose presence is essential in the case of radial car As an alternative, in place of the natural rubber itself

casses for the correct behaviour of the tire on the road. (NR) it is also possible to use two of its mixtures

If we now examine tires speci?cally designed for use (blends) with other polymers and more precisely with

on heavy truck vehicles in operations of the type 0N styrene-butadiene (SBR) and polybutadiene (ER) in the

and SUPER-ON these are preferably tubeless tires NR/BR, NR/SBR, NR/SBR/BR combinations,

mounted on charmel-type rims with a keying diameter 60 wherein, however, natural rubber constitutes at least

measuring 22.5 and bead seats at an angle of 15 to the 50% by weight.

rims axis of rotation. The polymers indicated above are elastomers in

Such tires comprise a metal single-ply radial carcass themselves by now well known to the technicians, so

whose ends are turned up around the reinforcement that it does not appear necessary here to provide a more

wires of the packet type; such bead wires, as is well 65 detailed description of their chemical constitution; a

known, comprise a plurality of turns of bare metal wire brief description of the rubbers mentioned in this inven

which touch one another both in the radial direction tion is given, for example, in the book The Rubber

and in the transverse direction, say according to the Manual by Khaizi Nagdi, edited by Tecniche Nuove,

5,362,793

7 8

the disclosure of which is hereby incorporated by refer increasing quantities of synthetic polymer (PS) accord

ence. On the basis of the correlations between the char ing to the invention, wherein the quantity of polymer

acteristics of the tires and the dynamic properties of the used for the blend has been made to range from 5 to 20

tread mixes, as indicated earlier, a mix which enhances parts by weight of polymer for 100 parts by weight of

road-holding features on wet surfaces and on dry roads 5 elastomer, with the object of assessing the correspond

and which, at the same time, keeps rolling resistance at ing variation of the value of the related parameters,

levels acceptable for a tire used on heavy truck vehicles indicated with the same numeric reference already used

in operations of the ON and SUPER-ON type must in Table 2.

simultaneously have the following properties: The formulation used is the same for all mixes in the

tang s at 0 0.20.3 (1)

Table and it is identical with that of mix A, given in

tang a at 70" C.-_<-0.l6 (2) Table l; the difference between the different mixes is

only in the type of synthetic polymer used in the blend

and preferably also; with the natural rubber.

In addition to the synthetic rubbers of the invention

E at 0 C28 MPa (3) 15

(POLYCHLOROPRENE, CHLOROBUTYL and

BROMOBUTYL, respectively) table 4 also gives the

E" at 70 C25 MPa. (4)

results related to natural rubber only (NR) and to blends

The above values have been observed after subject of natural rubber with other synthetic rubbers (STY

ing a cylindrical specimen of vulcanized mix, having a 20 RENE-BUTADIENE copolymer. ACRYLONI

diameter equal to 18 mm and a height of 25 mm, pre TRILE copolymer, NATURAL EPOXIED RUB

loaded to compression up to a longitudinal deformation BER) commonly used in the tread mixes of tires for

of 20% of its original height and kept at the preset tem motor cars and heavy truck vehicles, to demonstrate

perature, to a dynamic sinusoidal deformation having a that only with the rubbers according to the invention it

maximum amplitude equal to more or less 7.5% of the 25 is possible to obtain the required properties.

height under pre-load, at a frequency of 100 cycles per The results have not, however, been given relating to

second (100 Hz). mixes which, instead of natural rubber, have mixtures of

Table 1 illustrates the formulations of some mixes it with other polymers, as indicated, for example, the

produced in a plant, on industrial installations, which NR/SBR blend with the addition of polychloroprene in

have been used for the manufacture of the radial tube 30 the proportions according to the present invention.

less heavy truck vehicle tires mentioned earlier, size Such data would have weighted down the descrip

315/80 R 22.5, as indicated in Table 3. Mixes A, C and tion to an unnecessary extent without offering greater

D, being NR, NR/SBR, NR/BR, respectively, repre information since the absolute values of tang 8 and of

sent the state of the art before the invention, the mix B E, though different from those related to the mixes

(NR/Polychloroprene) is typical of the present inven 35 shown. maintains the same type of reciprocal ratio,

t1on. expressed by the limit conditions (1), (2), (3), (4) given

Table 2 gives the values of the dynamic properties, above.

mentioned above, of the mixes of table 1. It is obvious The mixes of Table 4 have been prepared in the labo

from this table that only the mix according to the inven ratory.

tion satis?es the four conditions (1), (2), (3), (4), de?ned 40 It is obvious from Table 4 that only the mixes of the

above. invention, containing polychloroprene or chlorobutyl

Table 3 shows the test results on road behavior car rubber of bromobutyl rubber, exhibit the required prop

ried out with the mentioned heavy truck vehicle tires erties.

size 315/80 R 22.5, provided with treads constituted by In fact the dynamic properties of mix (A) in natural

the mixes A, B, C, D, respectively, as shown in the 45 rubber only are such as to give it a good rolling resis

previous Table l. tance [see (2), that is tang 8 at 70 C.0.16] but road

The results are expressed as percentages of those holding features on dry and wet surfaces and tractabil

given by the tires having a tread of mix A, in natural ity on wet surfaces are insufficient [because conditions

rubber only. (1) and (3) are not satis?ed tang 8 at 0 C.0.3 and E

It can be seen that mixes C, D, prepared according to

the prior art, exhibit a behavior on dry roads, road-hold

at 0 C28 MPa]. And neither do the mixes containing

ing features on wet surfaces, and a tractability on a

epoxidated natural rubber (H) or the styrene-butadiene

smooth and wet surface that are far better that those of copolymer (C) or the butadiene-acrylonitrile copoly

mix A but at the same time also have higher Polling mer (G) have dynamic properties which satisfy the set

resistance. 55 of conditions imposed.

Thus mixes C and D do not thus constitute a real Only the mixes according to the invention, containing

improvement but only a displacement of the point of polychloroprene or chlorinated or brominated butyl

equilibrium of the different properties. Mix B, on the rubbers fully satisfy such conditions when the synthetic

other hand, manufactured with a blend of natural rub polymers are present in a concentration equal to or

ber and synthetic polymer, as described according to higher than 5 parts by weight.

the present invention, attains the objective of having at More speci?cally it is possible to see that the above

the same time, with respect to reference A, enhanced interval is certainly valid in the case of use of chlorobu

properties of driveability while keeping rolling resis tyl (E), while as far as polychloroprene (B) and

tance unchanged. bromobutyl (F) are concerned, condition (2) is satis?ed

Lastly, Table 4 gives the results of an experiment 65 for a content of synthetic polymer ranging from 5 to 10

executed on a group of mixes (M) with a formulation parts by weight.

typical for treads of heavy truck vehicles, based on On the other hand, when the concentration of syn

natural rubber (NR) blended with different types and thetic polymer is 20 parts by weight it is possible to see

5,362,793

10

from the results given that tearing resistance decreases TABLE 3

appreciably. Road tests with radial tubeless tires size 315/80 R 22.5

According to the above observations, the preferred NATURAL

concentration of said polymers thus ranges from 8 to 15 RUBBER INVEN- M

parts by weight per 100 parts of elastomer. MIXES A TION B C D

The mix according to the invention has demonstrated ROLLING 100 100 110 120

that it has achieved the proposed objects. RESISTANCE

BEHAVIOR ON 100 115 105 108

As regards its workability, the quantity of mix neces DRY SURFACES

sary for laboratory tests, for all experimental tests and ROAD-HOLDING 100 1 I5 110 1 10

for the manufacture of the tires used in the mentioned ON WET SURFACES

TRACTABILITY ON 100 120 120 110

tests has been made with an identical process and on the SMOOTH/WET

same machines used for the manufacture of the usual SURFACES

known mixes, used as comparison mixes in order to

assess the rheometric, static and dynamic characteristics

of the mixes according to the invention. TABLE 2

More accurately, the mixes of the invention, prepared PARAMETERS

AND MIXES A B C D

according to the known methods of the art, have dem

I-IYSTERESIS

onstrated that they have characteristics of processabil

(1) tg 8 100 Hz 0 C. 0.282 0.343 0.340 0.330

ity that are altogether equivalent to the mixes normally (2) tg 8 100 Hz 70 C. 0.152 0.150 0.169 0.186

used: in other words the processing of such mixes exe MODULES

cuted on Banbury units, mixers, extruders and calen (3) E 100 Hz 0 C. 7.56 8.80 8.21 8.49

(4) E 100 Hz 70 C. 4.60 5.32 4.90 5.01

ders, both in the elastomer mixing stage and in the stage (5) E" 100 Hz 0 C. 2.13 3.02 2.79 2.80

wherein the various charges of different materials are 25 (6) E" 100 Hz 70 C. 0.70 0.80 0.83 0.93

absorbed into the elastomer, as well as in the prepara TEARING RESISTANCE

tion of semi-?nished products in the plant, does not (7) ASTM/B kN/m 388 358 352 280

(8) peeling kg/S mm 107 83 82 70

cause dif?culty of any kind leading to the manufacture ABRASION RESISTANCE

of semi-finished products having a quality equal to that (9) ABRASION DIN m3 122 117 110 100

of the usual ones, in particular as regards the surface

appearance and the degree of porosity.

In addition to that, the tires according to the inven TABLE 4

tion, accomplished with the above mixes, have attained M NR PS (1) (2) (3) (4) (7) (8)

several advantages of usage among which the main ones 35 NATURAL RUBBER

to be highlighted are better behavior under driving A 100 0 .266 .145 7.02 4.90 384 116

STYRENE-BUTADIENE

conditions and better road-holding features both on dry

C1 95 5 .275 .154 7.08 4.77 370 110

and wet surfaces, in particular due to the high hysteresis C2 90 10 .286 .162 7.60 5.82 352 108

of the tread mix at low temperatures only, and thus with C3 80 20 .320 .166 8.01 5.17 312 95

equal rolling resistance, and a better abrasion resistance POLYCHLOROPRENE

especially under conditions of low severity, with the B1 95 5 .279 .150 8.12 5.55 370 110

B2 90 10 .302 .152 8.57 5.75 356 104

consequent increase in the length of the life of the tire B3 80 20 .320 .157 10.86 6.38 282 90

under conditions of the ON and SUPER-ON type. w

On the basis of the above it can then be pointed out E1 95 5 .304 .141 7.57 4.95 355 104

that the Applicant has also accomplished a new method 45 E2

E3

90

80

10

20

.360

.405

.147

.155

8.47

9.15

5.12

5.26

325

305

92

83

for enhancing the performance of tires, which thus falls w

within the scope of the present invention and which is F1 95 5 .285 .140 7.30 4.96 353 105

completely described here. F2 90 10 .335 .155 8.10 5.04 320 102

ACRYLONITRILE

The present description is purely illustrative and not

G1 95 5 .299 .164 8.15 4.90 384 114

limiting, thus, the expert in the ?eld can make changes G2 90 10 .331 .175 9.75 5.43 393 129

and variants, not described here but easily deducible NATURAL EPOXIED RUBBER

from the present inventive idea, and thus fall within the H1 95 5 .281 .165 9.66 5.44 370 112

H2 90 10 .327 .183 12.63 5.87 350 108

scope of the present invention.

TABLE 1 55

We claim:

INGREDIENTS AND MIXES A B C D 1. A tire for a vehicle wheel comprising a carcass, a

Natural rubber 100.00 90.00 80.00 50.00 tread strip on the crown of said carcass, sidewalls and

Sulphur polychloroprene 10.00 beads for anchoring said tire to corresponding wheel

SBR - 20.00 20.00

60 rim, which comprises using in the tread thereof an elas

BR - 30.00

N110 Lampblack 50.00 48.00 48.00 48.00

tomeric composition of natural rubber and carbon

Stearic acid 2 2 2 2 black, containing 100 parts by weight of an elastomeric

Zinc oxide 3.5 3.5 3.5 3.5 material of:

Sulphur 1.2 1.4 1.2 1.2 a) from 80 to 95 parts by weight of natural rubber or

Oxybenzothiazylsulphenamide 1.5 1.6 1.6 1.6 of a mixture of natural rubber with styrene-butadi

Anti-oxidant 1.5 1.5 1.5 1.5 ene and/or with polybutadiene, the amount of

Anti-ozonizer 1.5 1.5 1.5 1.5

natural rubber being at least 50 parts by weight on

100 parts of said elastomeric composition, and

5,362,793

11 12

b) from 20 to 5 parts by weight of a synthetic rubber 6. A tubeless tire as claimed in claim 5, wherein the

consisting essentially either or homopolymers of amount of said synthetic polymer is between 8 and 15

2-chloro-l,3-butadiene or copolymers of the for parts by weight, per 100 parts of said elastomeric mate

mer with dienic monomers, selected from the rial.

group consisting of butadiene and isoprene, said 7. An elastomeric composition containing natural

synthetic rubber having a molecular weight from rubber and carbon black for use in the tread band of a

2x104 to 106, and a Mooney viscosity from 20 to vehicle tire containing for 100 parts by weight of a

100 ML(1+4), as measured at 100 C. according to mixture of:

ASTM speci?cation D 1646, whereby said elasto from 80 to 95 parts by weight of natural rubber or a

meric composition has a loss tangent (tan 8) at 0 C. mixture of natural rubber with styrene-butadiene

of not less than 0.30 and a loss tangent (tan 8) at 70

and/or with polybutadiene, the amount of natural

rubber being at least 50 parts by weight on 100

C. of not more than 0.16.

2. A tire as claimed in claim 1, wherein said elasto

parts of said mixture, and

from 20 to 5 parts by weight of a synthetic rubber

meric composition has a dynamic storage modulus (E) consisting essentially either of homopolymers of

of not not less than 8 MPa at 0 C. and of not less than

2-chloro-1,3-butadiene or copolymers of the for

5 MPa at 70 C. mer with dienic monomers, selected from the

3. A tire as claimed in claim 2, wherein the amount of group consisting of butadiene and isoprene, said

said synthetic polymer is between 8 and 15 parts by synthetic rubber having a molecular weight from

weight per 100 parts of said elastomeric material. 20 2X 104 to 106, and a Mooney viscosity from 20 to

4. A tubeless tire for wheels of heavy vehicles, com 100 ML(1 +4), as measured at 100 C. according to

prising a carcass having sidewalls and beads for anchor ASTM speci?cation D 1646, whereby said elasto

ing said tire to a corresponding wheel rim, a treat band meric composition has a loss tangent (tan 8) at 0 C.

with a tread design on the crown of said carcass and an of not less than 0.30 and a loss tangent (tan 8) at 70

annular reinforcing structure, circumferentially inexten C. of not more than 0.16.

sible, positioned between said carcass and said tread 8. An elastomeric composition as claimed in claim 7

band, said carcass being a metal single-ply radial with having a dynamic storage modulus (E') of not less than

the ply ends turned up axially from the inside to the 8 MPa at-0 C. and of not less than 5 MPa at 70 C.

outside around a metal annular bead core reinforcing 9. An elastomeric composition as claimed in claim 8,

said beads, said bead core comprising a plurality of 30 wherein the amount of said synthetic polymer is be

turns of bare metal wire in contact with each other both tween 8 and 15 parts by weight per 100 parts of said

along the axial and the radial directions, and having, in elastomeric material.

a plane containing the tire axis of rotation, a straight 10. An elastomeric composition as claimed in claim 9

cross-section of a polygonal shape whose radially inner wherein the amount of carbon black is between 45 and

side is arranged at an angle of about 15 to said axis of 35 55 parts by weight for 100 parts by weight of the elasto

rotation, which comprises using in the tread thereof an meric material.

elastomeric composition of natural rubber and carbon 11. A method for enhancing the performance of

black, containing for 100 parts by weight of elastomeric motor vehicle tires in operation at high running speed

material of: over long and smooth routes, comprising the steps of:

from 80 to 95 parts by weight of natural rubber or a 40 providing said tires with a tread band made of an

mixture of natural rubber _with styrene-butadiene elastomeric composition of natural rubber and car

and/or with polybutadiene, the amount of natural bon black, and containing 100 parts by weight of

rubber being at least 50 parts by weight on 100

said elastomeric composition of:

from 80 to 95 parts by weight natural rubber or of

parts of said elastomeric composition, and a mixture of natural rubber with styrene-butadi

from 20 to 5 parts by weight of a synthetic rubber ene and/or with polybutadiene, the amount of

consisting essentially either of homopolymers of natural rubber being at least 50 parts by weight

2-chloro-l,3-butadiene or copolymers of the for on 100 parts of said mixture, and

mer with dienic monomers, selected from the form 20 to 5 parts by weight of a synthetic rubber

group consisting of butadiene and isoprene, said consisting essentially either of homopolymers of

synthetic rubber having a molecular weight from 2-chloro-1,3-butadiene or copolymers of the for

2X 104 to 106, and a Mooney viscosity from 20 to mer with dienic monomers, selected from the

100 ML(1+4), as measured at 100 C. according to group consisting of butadiene and isoprene, said

ASTM speci?cation D 1646, whereby said elasto synthetic rubber having a molecular weight from

meric composition has a loss tangent (tan 6) at 0 C. 2 X 104to 106, and a Mooney viscosity from 20 to

of not less than 0.30 and a loss tangent (tan 8) at 70 100 ML(1+4), as measured at 100 C. according

C. of not more than 0.16. to ASTM speci?cation D 1646, and

5. A tubeless tire as claimed in claim 4, wherein said impressing upon said tread band a tread design

elastomeric composition has a dynamic storage modu adapted to affect the driving characteristics of said

lus (E') of not less than 8 MPa at 0 C. and of not less 60 tire during operation.

than 5 MPa at 70 C. * * * * *

65

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Stratfor - WorldView Evaluating Iranian Terrorism CapabilitiesDocument5 paginiStratfor - WorldView Evaluating Iranian Terrorism CapabilitiesrenagoncÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Defining EPDM For The Past and The Next 50 Years - Kgk-Rubberpoint - deDocument14 paginiDefining EPDM For The Past and The Next 50 Years - Kgk-Rubberpoint - derenagoncÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Peter Thiel Says Google's AI Work in China Is 'Bad For America' - CNETDocument1 paginăPeter Thiel Says Google's AI Work in China Is 'Bad For America' - CNETrenagoncÎncă nu există evaluări

- Corporate Tax Rates Table - KPMG GlobalDocument1 paginăCorporate Tax Rates Table - KPMG GlobalrenagoncÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Insights Digital CurrencyDocument30 paginiInsights Digital CurrencyrenagoncÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Rosary Killed My Porn Addiction - Catholic in RecoveryDocument1 paginăThe Rosary Killed My Porn Addiction - Catholic in RecoveryrenagoncÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Proof of Stake White PaperDocument33 paginiProof of Stake White PaperrenagoncÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Bulletin of Household Energy Survey 2019 en 1 PDFDocument253 paginiBulletin of Household Energy Survey 2019 en 1 PDFrenagoncÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Sweden's Coronavirus Strategy Will Soon Be The World's - Foreign AffairsDocument1 paginăSweden's Coronavirus Strategy Will Soon Be The World's - Foreign AffairsrenagoncÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- NoteTech 29 EN-2 PDFDocument16 paginiNoteTech 29 EN-2 PDFrenagoncÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Com TradeDocument6 paginiCom TraderenagoncÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- SPM Chemistry Form 5 - Redox Part 1Document4 paginiSPM Chemistry Form 5 - Redox Part 1ysheng98Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- DLP MonsoonDocument2 paginiDLP MonsoonjennifertariaoÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- RestrictedDocument51 paginiRestrictedsridharpalledaÎncă nu există evaluări

- Manual For Noncommissioned Officers and Privates of Infantry of The Army of The United StatesDocument250 paginiManual For Noncommissioned Officers and Privates of Infantry of The Army of The United StatesGutenberg.org100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Method Statement For Painting WorksDocument2 paginiMethod Statement For Painting Worksmustafa100% (3)

- (Js-Umum) Daftar Harga 01 Maret '23Document1 pagină(Js-Umum) Daftar Harga 01 Maret '23Kristin NataliaÎncă nu există evaluări

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 paginiAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- X Glo LED Strip Lighting For Tunnelling BrochureDocument6 paginiX Glo LED Strip Lighting For Tunnelling BrochureJOSE HUAMANIÎncă nu există evaluări

- Project Report of Dhanashree Goat FarmDocument56 paginiProject Report of Dhanashree Goat FarmNandan GowdaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- O221771s - Mil Pipe Pro 450 RFC PDFDocument84 paginiO221771s - Mil Pipe Pro 450 RFC PDFJavier Isaac Berrocal Torres100% (1)

- MHT-CET 2021 Question Paper: 25 September 2021Document3 paginiMHT-CET 2021 Question Paper: 25 September 2021Sank DamÎncă nu există evaluări

- Dyson - Environmental AssesmentDocument16 paginiDyson - Environmental AssesmentShaneWilson100% (5)

- Science BiologyDocument76 paginiScience BiologynaninanyeshÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Annual Syllabus Class 7 1Document3 paginiAnnual Syllabus Class 7 1Ni shÎncă nu există evaluări

- Staff Code Subject Code Subject Data FromDocument36 paginiStaff Code Subject Code Subject Data FromPooja PathakÎncă nu există evaluări

- Stahl - PUDSDocument29 paginiStahl - PUDSsusanasusana_Încă nu există evaluări

- BFE II ScenariosDocument25 paginiBFE II Scenarioselmitxel100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- 9 Quw 9 CjuDocument188 pagini9 Quw 9 CjuJavier MorenoÎncă nu există evaluări

- Reservoir Rock PropertiesDocument148 paginiReservoir Rock Propertiesiscribdusername100% (7)

- Acc05 SCG116Document42 paginiAcc05 SCG116Hilal HazaaÎncă nu există evaluări

- Pottery Making May06 Poi0506dDocument52 paginiPottery Making May06 Poi0506dMadeleineÎncă nu există evaluări

- 16950Document16 pagini16950uddinnadeemÎncă nu există evaluări

- Ingles y Español Unidad 7Document9 paginiIngles y Español Unidad 7Pier Jhoani Ñañez LlanosÎncă nu există evaluări

- Guide To Storage Tanks and EquipmentDocument15 paginiGuide To Storage Tanks and EquipmentbadelitamariusÎncă nu există evaluări

- The Church of Kapnikarea in Athens - N. GkiolesDocument13 paginiThe Church of Kapnikarea in Athens - N. GkiolesMaronasÎncă nu există evaluări

- MC 1Document109 paginiMC 1ricogamingÎncă nu există evaluări

- Journal Homepage: - : IntroductionDocument9 paginiJournal Homepage: - : IntroductionIJAR JOURNALÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- BHS Inggris 2021Document6 paginiBHS Inggris 2021Muhammad FirmanÎncă nu există evaluări

- Core12 Mod 1Document1 paginăCore12 Mod 1Michael SaberonÎncă nu există evaluări

- PPP-B-676 e PDFDocument34 paginiPPP-B-676 e PDFffincher4203Încă nu există evaluări