Documente Academic

Documente Profesional

Documente Cultură

93 LC 46 B

Încărcat de

wabp_23Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

93 LC 46 B

Încărcat de

wabp_23Drepturi de autor:

Formate disponibile

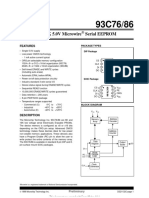

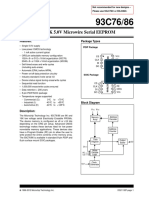

M 93LC46A/B

1K 2.5V Microwire Serial EEPROM

FEATURES BLOCK DIAGRAM

Single supply with operation down to 2.5V

MEMORY ADDRESS

Low power CMOS technology ARRAY DECODER

- 1 mA active current (typical)

- 1 A standby current (maximum)

128 x 8 bit organization (93LC46A)

ADDRESS

64 x 16 bit organization (93LC46B) COUNTER

Self-timed ERASE and WRITE cycles

(including auto-erase) DATA OUTPUT

REGISTER DO

Automatic ERAL before WRAL BUFFER

Power on/off data protection circuitry DI

Industry standard 3-wire serial interface MODE

Device status signal during ERASE/WRITE DECODE

CS LOGIC

cycles

Sequential READ function CLOCK

Vcc

CLK Vss

1,000,000 E/W cycles guaranteed GENERATOR

Data retention > 200 years

8-pin PDIP/SOIC and 8-pin TSSOP packages

Available for the following temperature ranges: DESCRIPTION

- Commercial (C): 0C to +70C The Microchip Technology Inc. 93LC46AX/BX are 1K-

- Industrial (I): -40C to +85C bit, low voltage serial Electrically Erasable PROMs.

The device memory is configured as x8 (93LC46A) or

x16 bits (93LC46B). Advanced CMOS technology

makes these devices ideal for low power nonvolatile

memory applications. The 93LC46AX/BX is available in

standard 8-pin DIP, 8-pin surface mount SOIC, and

TSSOP packages. The 93LC46AX/BX are offered only

in a 150-mil SOIC package.

PACKAGE TYPE

DIP SOIC SOIC TSSOP

93LC46A/B

CS 1 8 Vcc CS 1 8 Vcc

93LC46AX/BX

1 8 VCC NC 1 8 NC 2 7

93LC46A/B

CS CLK NC

93LC46A/B

CLK 2 7 NC DI 3 6 NC

2 7 NC Vcc 2 7 Vss DO 4 5 Vss

CLK

DI 3 6 NC

DI 3 6 NC CS 3 6 DO

DO 4 5 Vss

DO 4 5 Vss CLK 4 5 DI

Microwire is a registered trademark of National Semiconductor Incorporated.

1998 Microchip Technology Inc. DS21173E-page 1

93LC46A/B

1.0 ELECTRICAL TABLE 1-1 PIN FUNCTION TABLE

CHARACTERISTICS Name Function

1.1 Maximum Ratings* CS Chip Select

CLK Serial Data Clock

Vcc ...................................................................................7.0V

All inputs and outputs w.r.t. Vss ................ -0.6V to Vcc +1.0V DI Serial Data Input

Storage temperature .....................................-65C to +150C DO Serial Data Output

Ambient temp. with power applied.................-65C to +125C

VSS Ground

Soldering temperature of leads (10 seconds) ............. +300C

ESD protection on all pins................................................4 kV NC No Connect

*Notice: Stresses above those listed under Maximum ratings may VCC Power Supply

cause permanent damage to the device. This is a stress rating only and

functional operation of the device at those or any other conditions

above those indicated in the operational listings of this specification is

not implied. Exposure to maximum rating conditions for extended peri-

ods may affect device reliability.

TABLE 1-2 DC AND AC ELECTRICAL CHARACTERISTICS

All parameters apply over the specified Commercial (C): VCC = +2.5V to +6.0V Tamb = 0C to +70C

operating ranges unless otherwise Industrial (I): VCC = +2.5V to +6.0V Tamb = -40C to +85C

noted

Parameter Symbol Min. Max. Units Conditions

VIH1 2.0 Vcc +1 V 2.7V < VCC 6.0V (Note 2)

High level input voltage

VIH2 0.7 VCC Vcc +1 V VCC < 2.7V

VIL1 -0.3 0.8 V VCC > 2.7V (Note 2)

Low level input voltage

VIL2 -0.3 0.2 Vcc V VCC < 2.7V

VOL1 0.4 V IOL = 2.1 mA; Vcc = 4.5V

Low level output voltage

VOL2 0.2 V IOL =100 A; Vcc = Vcc Min.

VOH1 2.4 V IOH = -400 A; Vcc = 4.5V

High level output voltage

VOH2 VCC-0.2 V IOH = -100 A; Vcc = Vcc Min.

Input leakage current ILI -10 10 A VIN = VSS to Vcc

Output leakage current ILO -10 10 A VOUT = VSS to Vcc

Pin capacitance VIN/VOUT = 0 V (Notes 1 & 2)

CIN, COUT 7 pF

(all inputs/outputs) Tamb = +25C, FCLK = 1 MHz

ICC write 1.5 mA

Operating current 1 mA FCLK = 2 MHz; Vcc = 6.0V

ICC read

500 A FCLK = 1 MHz; Vcc = 3.0V

Standby current ICCS 1 A CS = Vss; DI = VSS

2 MHz VCC > 4.5V

Clock frequency FCLK

1 MHz VCC < 4.5V

Clock high time TCKH 250 ns

Clock low time TCKL 250 ns

Chip select setup time TCSS 50 ns Relative to CLK

Chip select hold time TCSH 0 ns Relative to CLK

Chip select low time TCSL 250 ns

Data input setup time TDIS 100 ns Relative to CLK

Data input hold time TDIH 100 ns Relative to CLK

Data output delay time TPD 400 ns CL = 100 pF

Data output disable time TCZ 100 ns CL = 100 pF (Note 2)

Status valid time TSV 500 ns CL = 100 pF

TWC 6 ms ERASE/WRITE mode

Program cycle time TEC 6 ms ERAL mode

TWL 15 ms WRAL mode

Endurance 1M cycles 25C, VCC = 5.0V, Block Mode (Note 3)

Note 1: This parameter is tested at Tamb = 25C and Fclk = 1 MHz.

2: This parameter is periodically sampled and not 100% tested.

3: This application is not tested but guaranteed by characterization. For endurance estimates in a specific application, please consult the Total

Endurance Model which may be obtained on our website.

DS21173E-page 2 1998 Microchip Technology Inc.

93LC46A/B

2.0 PIN DESCRIPTION CLK cycles are not required during the self-timed

WRITE (i.e., auto ERASE/WRITE) cycle.

2.1 Chip Select (CS) After detection of a START condition the specified num-

ber of clock cycles (respectively low to high transitions

A high level selects the device; a low level deselects the

of CLK) must be provided. These clock cycles are

device and forces it into standby mode. However, a pro-

required to clock in all required opcode, address, and

gramming cycle which is already in progress will be

data bits before an instruction is executed (Table 2-1

completed, regardless of the Chip Select (CS) input

and Table 2-2). CLK and DI then become don't care

signal. If CS is brought low during a program cycle, the

inputs waiting for a new START condition to be

device will go into standby mode as soon as the pro-

detected.

gramming cycle is completed.

CS must be low for 250 ns minimum (TCSL) between 2.3 Data In (DI)

consecutive instructions. If CS is low, the internal con-

trol logic is held in a RESET status. Data In (DI) is used to clock in a START bit, opcode,

address, and data synchronously with the CLK input.

2.2 Serial Clock (CLK)

2.4 Data Out (DO)

The Serial Clock is used to synchronize the communi-

cation between a master device and the 93LC46AX/ Data Out (DO) is used in the READ mode to output

BX. Opcodes, address, and data bits are clocked in on data synchronously with the CLK input (TPD after the

the positive edge of CLK. Data bits are also clocked out positive edge of CLK).

on the positive edge of CLK. This pin also provides READY/BUSY status informa-

CLK can be stopped anywhere in the transmission tion during ERASE and WRITE cycles. READY/BUSY

sequence (at high or low level) and can be continued status information is available on the DO pin if CS is

anytime with respect to clock high time (TCKH) and brought high after being low for minimum chip select

clock low time (TCKL). This gives the controlling master low time (TCSL) and an ERASE or WRITE operation

freedom in preparing opcode, address, and data. has been initiated.

CLK is a Don't Care if CS is low (device deselected). The status signal is not available on DO, if CS is held

If CS is high, but the START condition has not been low during the entire ERASE or WRITE cycle. In this

detected, any number of clock cycles can be received case, DO is in the HIGH-Z mode. If status is checked

by the device without changing its status (i.e., waiting after the ERASE/WRITE cycle, the data line will be high

for a START condition). to indicate the device is ready.

TABLE 2-1 INSTRUCTION SET FOR 93LC46A

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE 1 11 A6 A5 A4 A3 A2 A1 A0 (RDY/BSY) 10

ERAL 1 00 1 0 X X X X X (RDY/BSY) 10

EWDS 1 00 0 0 X X X X X HIGH-Z 10

EWEN 1 00 1 1 X X X X X HIGH-Z 10

READ 1 10 A6 A5 A4 A3 A2 A1 A0 D7 - D0 18

WRITE 1 01 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY) 18

WRAL 1 00 0 1 X X X X X D7 - D0 (RDY/BSY) 18

TABLE 2-2 INSTRUCTION SET FOR 93LC46B

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE 1 11 A5 A4 A3 A2 A1 A0 (RDY/BSY) 9

ERAL 1 00 1 0 X X X X (RDY/BSY) 9

EWDS 1 00 0 0 X X X X HIGH-Z 9

EWEN 1 00 1 1 X X X X HIGH-Z 9

READ 1 10 A5 A4 A3 A2 A1 A0 D15 - D0 25

WRITE 1 01 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY) 25

WRAL 1 00 0 1 X X X X D15 - D0 (RDY/BSY) 25

1998 Microchip Technology Inc. DS21173E-page 3

93LC46A/B

3.0 FUNCTIONAL DESCRIPTION 3.2 Data In (DI) and Data Out (DO)

Instructions, addresses, and write data are clocked into It is possible to connect the Data In (DI) and Data Out

the DI pin on the rising edge of the clock (CLK). The DO (DO) pins together. However, with this configuration, if

pin is normally held in a HIGH-Z state except when A0 is a logic-high level, it is possible for a bus conflict

reading data from the device, or when checking the to occur during the dummy zero that precedes the

READY/BUSY status during a programming operation. READ operation. Under such a condition the voltage

The READY/BUSY status can be verified during an level seen at DO is undefined and will depend upon the

ERASE/WRITE operation by polling the DO pin; DO relative impedances of DO and the signal source driv-

low indicates that programming is still in progress, while ing A0. The higher the current sourcing capability of A0,

DO high indicates the device is ready. The DO will enter the higher the voltage at the DO pin.

the HIGH-Z state on the falling edge of the CS.

3.3 Data Protection

3.1 START Condition

During power-up, all programming modes of operation

The START bit is detected by the device if CS and DI are inhibited until Vcc has reached a level greater than

are both high with respect to the positive edge of CLK 2.2V. During power-down, the source data protection

for the first time. circuitry acts to inhibit all programming modes when

Before a START condition is detected, CS, CLK, and DI Vcc has fallen below 2.2V at nominal conditions.

may change in any combination (except to that of a The ERASE/WRITE Disable (EWDS) and ERASE/

START condition), without resulting in any device oper- WRITE Enable (EWDS) commands give additional pro-

ation (ERASE, ERAL, EWDS, EWEN, READ, WRITE, tection against accidentally programming during nor-

and WRAL). As soon as CS is high, the device is no mal operation.

longer in the standby mode.

After power-up, the device is automatically in the

An instruction following a START condition will only be EWDS mode. Therefore, an EWEN instruction must be

executed if the required amount of opcodes, performed before any ERASE or WRITE instruction

addresses, and data bits for any particular instruction is can be executed.

clocked in.

After execution of an instruction (i.e., clock in or out of

the last required address or data bit) CLK and DI

become don't care bits until a new START condition is

detected.

FIGURE 3-1: SYNCHRONOUS DATA TIMING

VIH

CS

VIL TCSS TCKH TCKL

TCSH

VIH

CLK

VIL

TDIS TDIH

VIH

DI

VIL

TPD TCZ

TPD

DO VOH

(READ) VOL TCZ

TSV

DO VOH

(PROGRAM) STATUS VALID

VOL

Note: AC Test Conditions: VIL = 0.4V, VIH = 2.4V

DS21173E-page 4 1998 Microchip Technology Inc.

93LC46A/B

3.4 ERASE 3.5 Erase All (ERAL)

The ERASE instruction forces all data bits of the spec- The Erase All (ERAL) instruction will erase the entire

ified address to the logical 1 state. CS is brought low memory array to the logical 1 state. The ERAL cycle

following the loading of the last address bit. This falling is identical to the ERASE cycle, except for the different

edge of the CS pin initiates the self-timed programming opcode. The ERAL cycle is completely self-timed and

cycle. commences at the falling edge of the CS. Clocking of

The DO pin indicates the READY/BUSY status of the the CLK pin is not necessary after the device has

device if CS is brought high after a minimum of 250 ns entered the ERAL cycle.

low (TCSL). DO at logical 0 indicates that program- The DO pin indicates the READY/BUSY status of the

ming is still in progress. DO at logical 1 indicates that device, if CS is brought high after a minimum of 250 ns

the register at the specified address has been erased low (TCSL) and before the entire ERAL cycle is com-

and the device is ready for another instruction. plete.

FIGURE 3-2: ERASE TIMING

TCSL

CS

CHECK STATUS

CLK

DI 1 1 1 AN AN-1 AN-2 A0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TWC

FIGURE 3-3: ERAL TIMING

TCSL

CS

CHECK STATUS

CLK

DI 1 0 0 1 0 X X

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TEC

Guaranteed at Vcc = 4.5V to +6.0V.

1998 Microchip Technology Inc. DS21173E-page 5

93LC46A/B

3.6 ERASE/WRITE Disable and Enable 3.7 READ

(EWDS/EWEN)

The READ instruction outputs the serial data of the

The 93LC46A/B powers up in the ERASE/WRITE Dis- addressed memory location on the DO pin. A dummy

able (EWDS) state. All programming modes must be zero bit precedes the 8-bit (93LC46A) or 16-bit

preceded by an ERASE/WRITE Enable (EWEN) (93LC46B) output string. The output data bits will tog-

instruction. Once the EWEN instruction is executed, gle on the rising edge of the CLK and are stable after

programming remains enabled until an EWDS instruc- the specified time delay (TPD). Sequential read is pos-

tion is executed or Vcc is removed from the device. To sible when CS is held high. The memory data will auto-

protect against accidental data disturbance, the EWDS matically cycle to the next register and output

instruction can be used to disable all ERASE/WRITE sequentially.

functions and should follow all programming opera-

tions. Execution of a READ instruction is independent

of both the EWEN and EWDS instructions.

FIGURE 3-4: EWDS TIMING

TCSL

CS

CLK

DI 1 0 0 0 0 X X

FIGURE 3-5: EWEN TIMING

TCSL

CS

CLK

1 0 0 1 1 X X

DI

FIGURE 3-6: READ TIMING

CS

CLK

DI 1 1 0 An A0

HIGH-Z

DO 0 Dx D0 Dx D0 Dx D0

DS21173E-page 6 1998 Microchip Technology Inc.

93LC46A/B

3.8 WRITE 3.9 Write All (WRAL)

The WRITE instruction is followed by 8 bits (93LC46A) The Write All (WRAL) instruction will write the entire

or 16 bits (93LC46B) of data which are written into the memory array with the data specified in the command.

specified address. After the last data bit is put on the DI The WRAL cycle is completely self-timed and com-

pin, the falling edge of CS initiates the self-timed auto- mences at the falling edge of the CS. Clocking of the

erase and programming cycle. CLK pin is not necessary after the device has entered

The DO pin indicates the READY/BUSY status of the the WRAL cycle. The WRAL command does include an

device, if CS is brought high after a minimum of 250 ns automatic ERAL cycle for the device. Therefore, the

low (TCSL) and before the entire write cycle is complete. WRAL instruction does not require an ERAL instruction

DO at logical 0 indicates that programming is still in but the chip must be in the EWEN status.

progress. DO at logical 1 indicates that the register at The DO pin indicates the READY/BUSY status of the

the specified address has been written with the data device if CS is brought high after a minimum of 250 ns

specified and the device is ready for another instruc- low (TCSL).

tion.

FIGURE 3-7: WRITE TIMING

TCSL

CS

CLK

DI 1 0 1 An A0 Dx D0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

Twc

FIGURE 3-8: WRAL TIMING

TCSL

CS

CLK

DI 1 0 0 0 1 X X Dx D0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TWL

Guaranteed at Vcc = 4.5V to +6.0V.

1998 Microchip Technology Inc. DS21173E-page 7

93LC46A/B

NOTES:

DS21173E-page 8 1998 Microchip Technology Inc.

93LC46A/B

NOTES:

1998 Microchip Technology Inc. DS21173E-page 9

93LC46A/B

NOTES:

DS21173E-page 10 1998 Microchip Technology Inc.

93LC46A/B

93LC46A/B PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

93LC46A/B /P P = Plastic DIP (300 mil Body), 8-lead

SN = Plastic SOIC (150 mil Body), 8-lead

Package:

SM = Plastic SOIC (208 mil Body), 8-lead

ST = TSSOP, 8-lead

Temperature Blank = 0 C to +70C

Range: I = -40C to +85C

93LC46A 1K Microwire Serial EEPROM (x8)

93LC46AT 1K Microwire Serial EEPROM (x8)

Tape and Reel

93LC46AX 1K Microwire Serial EEPROM (x8)

in alternate pinout (SN only)

93LC46AXT 1K Microwire Serial EEPROM (x8)

in alternate pinout, Tape and Reel (SN only)

Device:

93LC46B 1K Microwire Serial EEPROM (x16)

93LC46BT 1K Microwire Serial EEPROM (x16)

Tape and Reel

93LC46BX 1K Microwire Serial EEPROM (x16)

in alternate pinout (SN only)

93LC46BXT 1K Microwire Serial EEPROM (x16)

in alternate pinout, Tape and Reel (SN only)

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recom-

mended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (602) 786-7277

3. The Microchip Worldwide Web Site (www.microchip.com)

1998 Microchip Technology Inc. DS21173E-page 11

M

WORLDWIDE SALES AND SERVICE

AMERICAS AMERICAS (continued) ASIA/PACIFIC (continued)

Corporate Office Toronto Singapore

Microchip Technology Inc. Microchip Technology Inc. Microchip Technology Singapore Pte Ltd.

2355 West Chandler Blvd. 5925 Airport Road, Suite 200 200 Middle Road

Chandler, AZ 85224-6199 Mississauga, Ontario L4V 1W1, Canada #07-02 Prime Centre

Tel: 602-786-7200 Fax: 602-786-7277 Tel: 905-405-6279 Fax: 905-405-6253 Singapore 188980

Technical Support: 602 786-7627 Tel: 65-334-8870 Fax: 65-334-8850

Web: http://www.microchip.com ASIA/PACIFIC Taiwan, R.O.C

Atlanta Hong Kong Microchip Technology Taiwan

Microchip Technology Inc. Microchip Asia Pacific 10F-1C 207

500 Sugar Mill Road, Suite 200B RM 3801B, Tower Two Tung Hua North Road

Atlanta, GA 30350 Metroplaza Taipei, Taiwan, ROC

Tel: 770-640-0034 Fax: 770-640-0307 223 Hing Fong Road Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Boston Kwai Fong, N.T., Hong Kong

Microchip Technology Inc. Tel: 852-2-401-1200 Fax: 852-2-401-3431 EUROPE

5 Mount Royal Avenue India United Kingdom

Marlborough, MA 01752 Microchip Technology Inc. Arizona Microchip Technology Ltd.

Tel: 508-480-9990 Fax: 508-480-8575 India Liaison Office 505 Eskdale Road

Chicago No. 6, Legacy, Convent Road Winnersh Triangle

Microchip Technology Inc. Bangalore 560 025, India Wokingham

333 Pierce Road, Suite 180 Tel: 91-80-229-0061 Fax: 91-80-229-0062 Berkshire, England RG41 5TU

Itasca, IL 60143 Japan Tel: 44-1189-21-5858 Fax: 44-1189-21-5835

Tel: 630-285-0071 Fax: 630-285-0075 Microchip Technology Intl. Inc. France

Dallas Benex S-1 6F Arizona Microchip Technology SARL

Microchip Technology Inc. 3-18-20, Shinyokohama Zone Industrielle de la Bonde

14651 Dallas Parkway, Suite 816 Kohoku-Ku, Yokohama-shi 2 Rue du Buisson aux Fraises

Dallas, TX 75240-8809 Kanagawa 222-0033 Japan 91300 Massy, France

Tel: 972-991-7177 Fax: 972-991-8588 Tel: 81-45-471- 6166 Fax: 81-45-471-6122 Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Dayton Korea Germany

Microchip Technology Korea Arizona Microchip Technology GmbH

Microchip Technology Inc.

168-1, Youngbo Bldg. 3 Floor Gustav-Heinemann-Ring 125

Two Prestige Place, Suite 150

Samsung-Dong, Kangnam-Ku D-81739 Mchen, Germany

Miamisburg, OH 45342

Seoul, Korea Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Tel: 937-291-1654 Fax: 937-291-9175

Tel: 82-2-554-7200 Fax: 82-2-558-5934 Italy

Detroit

Shanghai Arizona Microchip Technology SRL

Microchip Technology Inc.

Microchip Technology Centro Direzionale Colleoni

42705 Grand River, Suite 201

RM 406 Shanghai Golden Bridge Bldg. Palazzo Taurus 1 V. Le Colleoni 1

Novi, MI 48375-1727

2077 Yanan Road West, Hong Qiao District 20041 Agrate Brianza

Tel: 248-374-1888 Fax: 248-374-2878

Shanghai, PRC 200335 Milan, Italy

Los Angeles Tel: 86-21-6275-5700 Fax: 86 21-6275-5060 Tel: 39-39-6899939 Fax: 39-39-6899883

Microchip Technology Inc.

18201 Von Karman, Suite 1090 6/11/98

Irvine, CA 92612

Tel: 714-263-1888 Fax: 714-263-1338

Microchip received ISO 9001 Quality

New York

System certification for its worldwide

Microchip Technology Inc.

headquarters, design, and wafer

150 Motor Parkway, Suite 202

Hauppauge, NY 11788 fabrication facilities in January, 1997.

Tel: 516-273-5305 Fax: 516-273-5335 Our field-programmable PICmicro

8-bit MCUs, Serial EEPROMs,

San Jose

related specialty memory products

Microchip Technology Inc.

2107 North First Street, Suite 590

and development systems conform

San Jose, CA 95131 to the stringent quality standards of

Tel: 408-436-7950 Fax: 408-436-7955 the International Standard

Organization (ISO).

All rights reserved. 1998, Microchip Technology Incorporated, USA. 7/98 Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or warranty is given and no

liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual property rights arising from such use

or otherwise. Use of Microchips products as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or

otherwise, under any intellectual property rights. The Microchip logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other

trademarks mentioned herein are the property of their respective companies.

DS21173E-page 12 1998 Microchip Technology Inc.

S-ar putea să vă placă și

- Fiat - 55 66 70 66 LP DT LP - Workshop - Sec - Wat PDFDocument43 paginiFiat - 55 66 70 66 LP DT LP - Workshop - Sec - Wat PDFKemal Lisnik Arnautovic100% (3)

- DSP2 Manual PDFDocument147 paginiDSP2 Manual PDFEcaterina Irimia100% (2)

- Car Engine PartsDocument20 paginiCar Engine PartsHealth Club100% (2)

- Mac Puarsa MRL OthyssoneDocument254 paginiMac Puarsa MRL OthyssoneVilla Robert Ramoa100% (1)

- F-Series Training 795F AC Participants Copy 810Document96 paginiF-Series Training 795F AC Participants Copy 810Karen Margarita Muñoz Contreras100% (7)

- V0lvo &scaniaDocument41 paginiV0lvo &scaniairawan budi santosaÎncă nu există evaluări

- Method Statement 14728983812691479973057231Document6 paginiMethod Statement 14728983812691479973057231Abhinav SinhaÎncă nu există evaluări

- Data SheetDocument12 paginiData SheetPrasetyo Muhammad SaktiÎncă nu există evaluări

- 93LC66A/B: 4K 2.5V Microwire Serial EEPROMDocument12 pagini93LC66A/B: 4K 2.5V Microwire Serial EEPROMinsomnium86Încă nu există evaluări

- 1K 5.0V Microwire Serial EEPROM: Features Block DiagramDocument12 pagini1K 5.0V Microwire Serial EEPROM: Features Block Diagraminsomnium86Încă nu există evaluări

- 2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDocument12 pagini2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDanielÎncă nu există evaluări

- 1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package TypesDocument20 pagini1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package TypesJoão PauloÎncă nu există evaluări

- 8K/16K 5.0V Microwire Serial EEPROM: FeaturesDocument12 pagini8K/16K 5.0V Microwire Serial EEPROM: FeaturesStephensonÎncă nu există evaluări

- 93C66Document12 pagini93C66Alex AlvarezÎncă nu există evaluări

- 256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeDocument8 pagini256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeAgustin AndrokaitesÎncă nu există evaluări

- 1K-16K Microwire Compatible Serial Eeproms: Features: DescriptionDocument38 pagini1K-16K Microwire Compatible Serial Eeproms: Features: DescriptionStuxnetÎncă nu există evaluări

- Bus Serial EEPROMDocument12 paginiBus Serial EEPROMMatiasÎncă nu există evaluări

- 8K/16K 5.0V Microwire Serial EEPROM: Features: Package TypesDocument20 pagini8K/16K 5.0V Microwire Serial EEPROM: Features: Package Typesfarhood ranjbarkhanghahÎncă nu există evaluări

- 2K Microwire Compatible Serial EEPROM: 93AA56A/B/C, 93LC56A/B/C, 93C56A/B/CDocument30 pagini2K Microwire Compatible Serial EEPROM: 93AA56A/B/C, 93LC56A/B/C, 93C56A/B/CAndrea MartinezÎncă nu există evaluări

- Ic PDFDocument36 paginiIc PDFdharamÎncă nu există evaluări

- 93LC46ADocument34 pagini93LC46AmordiscoverdeÎncă nu există evaluări

- 93C66 PDFDocument22 pagini93C66 PDFCristian Esteban TamashiroÎncă nu există evaluări

- AK93C45A / 55A / 65A / 75A: 1K / 2K / 4K / 8kbit Serial CMOS EEPROMDocument14 paginiAK93C45A / 55A / 65A / 75A: 1K / 2K / 4K / 8kbit Serial CMOS EEPROMmansoorhayatÎncă nu există evaluări

- 24Lc04B/08B: 4K/8K 2.5V I C Serial EepromsDocument12 pagini24Lc04B/08B: 4K/8K 2.5V I C Serial Eepromsjiaxin zhangÎncă nu există evaluări

- 93C86Document20 pagini93C86cgmannerheimÎncă nu există evaluări

- I2c EEPROM 24xx256 DsDocument28 paginiI2c EEPROM 24xx256 DsRizwan AmirÎncă nu există evaluări

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDocument45 pagini24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoÎncă nu există evaluări

- EEPROM 24LC256 - Microchip PDFDocument28 paginiEEPROM 24LC256 - Microchip PDFValdir DerlannÎncă nu există evaluări

- 42 45S32200LDocument59 pagini42 45S32200LNelson Pimiento SerranoÎncă nu există evaluări

- 24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMDocument12 pagini24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMmacepaÎncă nu există evaluări

- 24 LC 256Document38 pagini24 LC 256johnÎncă nu există evaluări

- Datasheet PDFDocument26 paginiDatasheet PDFNicoli LourençoÎncă nu există evaluări

- En25qa64a EonDocument68 paginiEn25qa64a Eongbjhasd344Încă nu există evaluări

- MX25L8005 MxicDocument41 paginiMX25L8005 Mxicdanehcan graÎncă nu există evaluări

- 93LC46Document30 pagini93LC46DCTRONICSÎncă nu există evaluări

- 24C320-EP MicrochipTechnologyDocument12 pagini24C320-EP MicrochipTechnologyMateus CorrêaÎncă nu există evaluări

- 24LC04B PDFDocument22 pagini24LC04B PDFEddy RosarioÎncă nu există evaluări

- 24LC08 PDFDocument30 pagini24LC08 PDFJaime BarrancoÎncă nu există evaluări

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pagini24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaÎncă nu există evaluări

- Xmc-Xm25qh64ahig C328461Document75 paginiXmc-Xm25qh64ahig C328461c4rl0slinuxÎncă nu există evaluări

- 24aa08 - 24lc08 Eeprom PDFDocument40 pagini24aa08 - 24lc08 Eeprom PDFEdgar DauzonÎncă nu există evaluări

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pagini24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezÎncă nu există evaluări

- M24256-BW M24256-BR M24256-BF M24256-DR M24256-DF: 256-Kbit Serial I C Bus EEPROMDocument47 paginiM24256-BW M24256-BR M24256-BF M24256-DR M24256-DF: 256-Kbit Serial I C Bus EEPROMNguyễn Thế MạnhÎncă nu există evaluări

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pagini24AA08/24LC08B: 8KI C Serial EEPROMjoseÎncă nu există evaluări

- Datasheet EN29LV800BDocument41 paginiDatasheet EN29LV800BJackson de Oliveira SilvaÎncă nu există evaluări

- MCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDocument38 paginiMCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDaniel CortelettiÎncă nu există evaluări

- 24AA16/24LC16B: 16K I C Serial EEPROMDocument25 pagini24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezÎncă nu există evaluări

- Datasheet 25c040Document22 paginiDatasheet 25c040Perona PabloÎncă nu există evaluări

- En25qh64a EonDocument75 paginiEn25qh64a EonMarcelituz RojasÎncă nu există evaluări

- Features Description: 2K X 8 Asynchronous CMOS Static RAMDocument8 paginiFeatures Description: 2K X 8 Asynchronous CMOS Static RAMKontak SynthetizadorÎncă nu există evaluări

- Datashet Etron TechDocument54 paginiDatashet Etron TechAndres OrjuelaÎncă nu există evaluări

- Doc0172 PDFDocument20 paginiDoc0172 PDFnarayanÎncă nu există evaluări

- 25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMDocument11 pagini25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMAndrey OliveiraÎncă nu există evaluări

- Macronix Nbit Memory Family: 64M-Bit (X 1) Cmos Serial Elite Flash MemoryDocument24 paginiMacronix Nbit Memory Family: 64M-Bit (X 1) Cmos Serial Elite Flash MemoryJavierÎncă nu există evaluări

- 25AA640/25LC640: 64K Spi Bus Serial EEPROMDocument12 pagini25AA640/25LC640: 64K Spi Bus Serial EEPROMinsomnium86Încă nu există evaluări

- EN25Q32C 32 Megabit Serial Flash Memory With 4kbyte Uniform SectorDocument62 paginiEN25Q32C 32 Megabit Serial Flash Memory With 4kbyte Uniform Sectoramir baroughÎncă nu există evaluări

- Data Sheet EN25QDocument50 paginiData Sheet EN25Qsvetislav_vuksanovicÎncă nu există evaluări

- Spi Eeprom PDFDocument44 paginiSpi Eeprom PDFEma HarmaÎncă nu există evaluări

- IS42S32800D IS45S32800D: 8Mx32 256Mb Synchronous DramDocument60 paginiIS42S32800D IS45S32800D: 8Mx32 256Mb Synchronous Dramcruz yorisÎncă nu există evaluări

- 4M (512K 8/256K 16) BIT: Flash MemoryDocument55 pagini4M (512K 8/256K 16) BIT: Flash MemorytecrgoÎncă nu există evaluări

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pagini25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийÎncă nu există evaluări

- Em63a165ts v1Document51 paginiEm63a165ts v1api-432313169Încă nu există evaluări

- 24lc512 DatasheetDocument27 pagini24lc512 DatasheetLeonardo QuevedoÎncă nu există evaluări

- Consulta Placa de MotoDocument2 paginiConsulta Placa de Motowabp_23Încă nu există evaluări

- Torrent: Sentinel StrengthDocument8 paginiTorrent: Sentinel Strengthwabp_23Încă nu există evaluări

- 24c64 PDFDocument12 pagini24c64 PDFwabp_23Încă nu există evaluări

- Nuevo Documento de Microsoft WordDocument1 paginăNuevo Documento de Microsoft Wordwabp_23Încă nu există evaluări

- 24 LC 64Document12 pagini24 LC 64wabp_23Încă nu există evaluări

- Nuevo Documento de TextoDocument1 paginăNuevo Documento de Textowabp_23Încă nu există evaluări

- Datasheet 2 N 3906Document8 paginiDatasheet 2 N 3906Julian Alberto Chacon CaperaÎncă nu există evaluări

- 2N3906Document8 pagini2N3906wabp_23Încă nu există evaluări

- 1 N 4148Document4 pagini1 N 4148arunan55Încă nu există evaluări

- 1 N N4007Document3 pagini1 N N4007Trương Quốc HưngÎncă nu există evaluări

- 2N3904Document7 pagini2N3904api-3697683Încă nu există evaluări

- Data Sheet: PNP Switching TransistorsDocument8 paginiData Sheet: PNP Switching TransistorsvdăduicăÎncă nu există evaluări

- SeniorReliabilityEngineer PDFDocument1 paginăSeniorReliabilityEngineer PDFwabp_23Încă nu există evaluări

- 1N4001 DDocument4 pagini1N4001 DJohn SharpÎncă nu există evaluări

- TutorialDocument1 paginăTutorialwabp_23Încă nu există evaluări

- Senior Project Engineer Rio TintoDocument3 paginiSenior Project Engineer Rio TintoluceroÎncă nu există evaluări

- TutorialDocument1 paginăTutorialwabp_23Încă nu există evaluări

- Mac VendorDocument382 paginiMac Vendorleo_2896outlookcomÎncă nu există evaluări

- AfricaDocument3 paginiAfricawabp_23Încă nu există evaluări

- Torrent: Sentinel StrengthDocument8 paginiTorrent: Sentinel Strengthwabp_23Încă nu există evaluări

- MashedDocument1 paginăMashedwabp_23Încă nu există evaluări

- AfricaDocument3 paginiAfricawabp_23Încă nu există evaluări

- AfricaDocument3 paginiAfricawabp_23Încă nu există evaluări

- AfricaDocument3 paginiAfricawabp_23Încă nu există evaluări

- Matrix Series GX2000 and GX2150 Owner's Manual: 25 Watt VHF/FM Marine TransceiversDocument144 paginiMatrix Series GX2000 and GX2150 Owner's Manual: 25 Watt VHF/FM Marine TransceiversManuel Diaz GomezÎncă nu există evaluări

- User ManualDocument1 paginăUser ManualAnil ChowdaryÎncă nu există evaluări

- Candy cdpn-2d522px Safety InstructionsDocument38 paginiCandy cdpn-2d522px Safety Instructionsjdv1234Încă nu există evaluări

- 2009 Audi A3: Quick Reference GuideDocument16 pagini2009 Audi A3: Quick Reference GuideFotokopirnicaSonyPSÎncă nu există evaluări

- Cm200dy-24nf eDocument4 paginiCm200dy-24nf eWesamÎncă nu există evaluări

- Fresadora B40pte B40e 2 PDFDocument70 paginiFresadora B40pte B40e 2 PDFRaul Alanoca ColqueÎncă nu există evaluări

- A3377module1+2 NumericalDocument11 paginiA3377module1+2 NumericalSomil GuptaÎncă nu există evaluări

- DTB113ZKT146 PDFDocument6 paginiDTB113ZKT146 PDFshezad shezadÎncă nu există evaluări

- G. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Document87 paginiG. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Sreenath SreenathÎncă nu există evaluări

- Crossvent-3+: Operation & Service ManualDocument102 paginiCrossvent-3+: Operation & Service ManualIngenieria NemoconÎncă nu există evaluări

- 8RY 800 001-SF6密度继电器说明书 (ABB)Document8 pagini8RY 800 001-SF6密度继电器说明书 (ABB)Trần Văn HiếuÎncă nu există evaluări

- Myferrari - Purosangue - 41ADp4dDocument11 paginiMyferrari - Purosangue - 41ADp4dSoom SoomÎncă nu există evaluări

- Sony DCR Hc40Document68 paginiSony DCR Hc40Fabi PXÎncă nu există evaluări

- Unor3smbus 2.inoDocument6 paginiUnor3smbus 2.inoM. Randy AswinÎncă nu există evaluări

- The Pipe Crawler: Eiki Martinson Mark Miller Sheraz WasiDocument39 paginiThe Pipe Crawler: Eiki Martinson Mark Miller Sheraz WasiMuhammed Abo-FandoodÎncă nu există evaluări

- Hytera tc610 User GuideDocument41 paginiHytera tc610 User GuideAriel BecerraÎncă nu există evaluări

- Volvo 850 EngineDocument15 paginiVolvo 850 Enginevanapeer100% (3)

- Capacitor CatalogueDocument44 paginiCapacitor CatalogueSabrina Adystia SÎncă nu există evaluări

- H BridgeDocument41 paginiH BridgeSheikh IsmailÎncă nu există evaluări

- Danfoss FCM300 Quick SetupDocument5 paginiDanfoss FCM300 Quick SetupLuis MorenoÎncă nu există evaluări

- VAJ ManualDocument6 paginiVAJ Manualshailesh28467% (3)

- LA450AXD2Document10 paginiLA450AXD2Libro AzulÎncă nu există evaluări

- T7411A / LF20 / LF10 / C7068: Duct Temperature SensorsDocument4 paginiT7411A / LF20 / LF10 / C7068: Duct Temperature SensorsAudi eko susatyoÎncă nu există evaluări