Documente Academic

Documente Profesional

Documente Cultură

Belt Conveyor

Încărcat de

Valium MorphineDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Belt Conveyor

Încărcat de

Valium MorphineDrepturi de autor:

Formate disponibile

Belt Weight

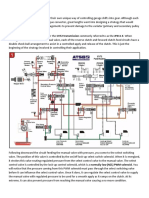

The following steps can be taken to calculate the required take up weight for a conveyor:

- calculate total resistance for the conveyor, this includes the lift of material, acceleration, skirt

friction, idler friction, belt indentation over the idlers and any other secondary resistance. When

you add all these up you get the Te - effective force to be produced by the conveyor drive at the

driven pulley shaft

- Now you calculate the required T2, the force at the slack side of the drive pulley. This force is

calculated as a function of Te, belt wrap angle over the pulley and the friction between the belt

and the driven pulley. This is the Euler formula that can b found in the CEMA book. The main

purpose of T2 is to ensure that the force can be transferred over from the drive pulley to the belt

- The tension force in the tight side of the belt at the pulley is T1=T2+Te

- You need to check if this T1 force is sufficient to ensure against excessive sag of the belt

between the idlers. If the drive is not at the head end you should check the belt tension force at

the head end of the conveyor

- If your gravity take up is close to the drive pulley then the required gravity take up weight is

twice the T2 tension.

- Things get a bit more complicated with double drives, tandem drives etc. the above is the

procedure for a single drive conveyor

- Gravity take up is used for bigger conveyors and have main advantage of keeping T2 constant

regardless of the belt stretch etc.

- Screw take up is used for smaller conveyors that utilize fabric belt. The tension is lost over time

due to belt stretch so they need to be adjusted periodically

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- CVT ValvesDocument3 paginiCVT ValvesHussein Mohamed100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 6F35 GearspdfDocument6 pagini6F35 GearspdfNuman283% (12)

- 4L60 4l60-E 4l65-E 4l70-E QR PDFDocument10 pagini4L60 4l60-E 4l65-E 4l70-E QR PDFHumberto100% (7)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Guide to updating Ford Focus Mk2/Mk2.5 using ELM327 cable and FF2 programDocument14 paginiGuide to updating Ford Focus Mk2/Mk2.5 using ELM327 cable and FF2 programValium Morphine100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- TM PDFDocument441 paginiTM PDFBrian MorenoÎncă nu există evaluări

- Gear Trains ProblemsDocument9 paginiGear Trains Problemsa c s Kumar100% (1)

- VW 6 Speed DQ250 Dual Clutch Transmission 02E Repair Manual Edition 09.2015Document160 paginiVW 6 Speed DQ250 Dual Clutch Transmission 02E Repair Manual Edition 09.2015adao100% (1)

- Transmission System Service Manual for G9180 GraderDocument44 paginiTransmission System Service Manual for G9180 GraderGeorge Jhonson100% (6)

- 8287 9084 ActDocument9 pagini8287 9084 ActossoskiÎncă nu există evaluări

- FinallDocument175 paginiFinallremeceldo dagamac100% (1)

- Belt Tension CalculatorDocument1 paginăBelt Tension CalculatorValium MorphineÎncă nu există evaluări

- New Generation Gearbox PDFDocument141 paginiNew Generation Gearbox PDFyousef ALadwanÎncă nu există evaluări

- Power Train SOTA RENR5124 PDFDocument132 paginiPower Train SOTA RENR5124 PDFHerrera Salazar VisnuÎncă nu există evaluări

- Automatic Transmission 4at PDFDocument148 paginiAutomatic Transmission 4at PDFDaniel CaminatiÎncă nu există evaluări

- Shell and Tube Heat Exchanger DesignDocument19 paginiShell and Tube Heat Exchanger DesignValium MorphineÎncă nu există evaluări

- Air Cooled Heat ExhangerDocument2 paginiAir Cooled Heat ExhangerValium MorphineÎncă nu există evaluări

- Belt PM SheetDocument2 paginiBelt PM SheetValium MorphineÎncă nu există evaluări

- BeltingDocument2 paginiBeltingValium MorphineÎncă nu există evaluări

- Belt PM SheetDocument2 paginiBelt PM SheetValium MorphineÎncă nu există evaluări

- Belt Conveyor CounterDocument1 paginăBelt Conveyor CounterValium MorphineÎncă nu există evaluări

- Water Demand CalculationDocument6 paginiWater Demand CalculationValium MorphineÎncă nu există evaluări

- Air Cooled Heat ExhangerDocument2 paginiAir Cooled Heat ExhangerValium MorphineÎncă nu există evaluări

- Air Cooled Heat ExhangerDocument2 paginiAir Cooled Heat ExhangerValium MorphineÎncă nu există evaluări

- Belt Conveyor Counter WeightDocument1 paginăBelt Conveyor Counter WeightValium MorphineÎncă nu există evaluări

- Calcul BandeDocument1 paginăCalcul BandeValium MorphineÎncă nu există evaluări

- BeltingDocument2 paginiBeltingValium MorphineÎncă nu există evaluări

- Belt Conveyor Counter WeightDocument1 paginăBelt Conveyor Counter WeightValium MorphineÎncă nu există evaluări

- Belt PM SheetDocument2 paginiBelt PM SheetValium MorphineÎncă nu există evaluări

- Calculation WorksheetDocument1 paginăCalculation WorksheetValium MorphineÎncă nu există evaluări

- Mixed Convection Within A Porous Heat Generating Horizontal AnnulusDocument11 paginiMixed Convection Within A Porous Heat Generating Horizontal AnnulusValium MorphineÎncă nu există evaluări

- BeltonveyorsCalculationsDIN22101 EngDocument9 paginiBeltonveyorsCalculationsDIN22101 EngOscar EduardoÎncă nu există evaluări

- BeltonveyorsCalculationsDIN22101 EngDocument9 paginiBeltonveyorsCalculationsDIN22101 EngOscar EduardoÎncă nu există evaluări

- 2011 9Document10 pagini2011 9Valium MorphineÎncă nu există evaluări

- Evaporation: T - v - sat °C h - v - sat kJ/kg η %Document3 paginiEvaporation: T - v - sat °C h - v - sat kJ/kg η %Valium MorphineÎncă nu există evaluări

- BeltonveyorsCalculationsDIN22101 EngDocument9 paginiBeltonveyorsCalculationsDIN22101 EngOscar EduardoÎncă nu există evaluări

- Non Uniform Grids For PDE in FinanceDocument23 paginiNon Uniform Grids For PDE in FinanceValium MorphineÎncă nu există evaluări

- 235 11254 0 Hin202Document18 pagini235 11254 0 Hin202Valium MorphineÎncă nu există evaluări

- Notes Week8Document4 paginiNotes Week8Valium MorphineÎncă nu există evaluări

- PET524 1d PorosityDocument8 paginiPET524 1d PorosityValium MorphineÎncă nu există evaluări

- Differential Functions Parts Woking Advantages Disadvantages and Applications PDFDocument6 paginiDifferential Functions Parts Woking Advantages Disadvantages and Applications PDFRohan ModhÎncă nu există evaluări

- History of GearsDocument12 paginiHistory of GearsmorolosusÎncă nu există evaluări

- Coupling - Wheel Loaders Volvo L50D - Power Transmission Transmission, Hydraulic Control Transmission, Hydraulic Control - 777partsDocument2 paginiCoupling - Wheel Loaders Volvo L50D - Power Transmission Transmission, Hydraulic Control Transmission, Hydraulic Control - 777partsElisa PlacintaÎncă nu există evaluări

- GearsjohannesDocument7 paginiGearsjohannesapi-238276665Încă nu există evaluări

- ME6601-Design of Transmission Systems PDFDocument27 paginiME6601-Design of Transmission Systems PDFJeevitha RÎncă nu există evaluări

- Belt Drive Handout - 05Document3 paginiBelt Drive Handout - 05NkoshiEpaphrasShoopalaÎncă nu există evaluări

- Howto FindDocument8 paginiHowto FindSebastian Ruiz PeraltaÎncă nu există evaluări

- Mill House IjazDocument24 paginiMill House IjazZulal AliÎncă nu există evaluări

- Lista de Precios Lubricantes ROSHFRANS 2018.12Document2 paginiLista de Precios Lubricantes ROSHFRANS 2018.12Anonymous eJwbx9WnÎncă nu există evaluări

- FIG FIG F4350W32.071 F4350W32.071 FIG Fig No. NO. F4350-71A0 F4350-71A0 TORQUE Torque Converter ConverterDocument2 paginiFIG FIG F4350W32.071 F4350W32.071 FIG Fig No. NO. F4350-71A0 F4350-71A0 TORQUE Torque Converter ConverterIvan PalominoÎncă nu există evaluări

- Heavy-Duty Clutch SelectorDocument2 paginiHeavy-Duty Clutch SelectorDavid LeónÎncă nu există evaluări

- Course Title Course Level: UG Credit Units: Course Code: MAE301Document3 paginiCourse Title Course Level: UG Credit Units: Course Code: MAE301Himanshu JangidÎncă nu există evaluări

- (2010 AND AFTER) : Mercedes-Benz (Eu) Atego Euro 5 375/950/970/972/974/975/976 ATEGO 1226 F Euro 5Document4 pagini(2010 AND AFTER) : Mercedes-Benz (Eu) Atego Euro 5 375/950/970/972/974/975/976 ATEGO 1226 F Euro 5MoussaÎncă nu există evaluări

- Module 1 - Activity No. 1 (Prelim)Document2 paginiModule 1 - Activity No. 1 (Prelim)Leyzer MalumayÎncă nu există evaluări

- Case Construction Front Axle Housing Assembly Replacement PartsDocument3 paginiCase Construction Front Axle Housing Assembly Replacement PartsAntonio MejicanosÎncă nu există evaluări

- Motor list-ENDocument1 paginăMotor list-ENAndrija MaticÎncă nu există evaluări

- 18MRH-X242A Axle Service ManualDocument60 pagini18MRH-X242A Axle Service Manualheiner duran100% (1)

- 3314 Ijmech 11Document8 pagini3314 Ijmech 11Burak KoyuncuogluÎncă nu există evaluări