Documente Academic

Documente Profesional

Documente Cultură

Changeover Loader PDF

Încărcat de

cpkakopeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Changeover Loader PDF

Încărcat de

cpkakopeDrepturi de autor:

Formate disponibile

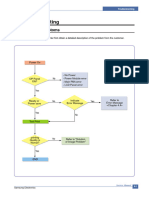

Changeover-Loader System PPM-s0701

Reminders Overview Instructions & Explanations Target 22 min

1 Prepare for 1.1 Complete & notify 1,2 1 2.1, 2.2 Swing to Release Bar

applies Changeover 1.2 Sanitize hands OR wear sterile gloves

1.3 Shutdown & Tag Loader

Checks on 1.4 Check changeover requirements against

back page

current setup 1 :

handle

1 Co-ordinate

with: Warehouse brush

& Packer Operator aligner

2

1. Loosen nut

2.1 If handle adjustment required

2 Notify: 2 Setup Component 2. Swing out bar

Supervisor - when Positions

changeover starts release valve lock 1

set vertical position 1,2 2 2.3 Aligner Assembly

PPM-LOTO-001 lock valve in place (tighten lock nut)

1. Loosen

2.2 If brush adjustment required clamps

Tag-Out

Loader release valve lock 1

set vertical position 1,2

Picture/info in lock valve in place (tighten lock nut)

following tables 2. Locate pin

2.3 If aligner adjustment required

loosen both knobs & remove pin 2 3. Slide plate so pin drops

Picture/info on 4. Tighten clamps

right place pin in position 1

slide plate until pin drops

Repeat Sub- tighten knobs 3 3 - 5 Touch Screen Control

Steps for each bay 3

``````````

Critical Step:

3 Select Recipe 3.1 Identify product recipe 1

incorrect action = 3.2 Navigate to Operation Screen 3

downtime 3.3 Press: Tool Screen > Recipe

3.4 Scroll to required product recipe

3.5 Press: Select Table Entry > enter password

3.6 Press: Enter Recipe to confirm

4

Start Button

4 Remove LOTO & 4.1 Ensure Loader is clear of materials/tools

Reset Robots 4.2 Remove Locks & Tags

4.3 On touch screen, press: Home Robots 3

4.4 Ensure robots move to home positions

4.5 Clear faults

5

5 Start Loader 5.1 Press Start 3

Author: Talsico Sample Effective: 2010-03-03

Version: 2

Doc owner: Talsico Sample Review by: 2099-01-01 Approv

vals:

als:

Talsico Process Picture Maps & all associated intellectual property are owned by Talsico International, ABN 20 419 167 619, & subject to licensing Agreement Page 1 of 2

Changeover-Loader System PPM-s0701

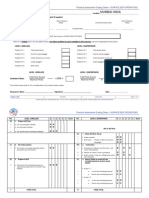

Pre-Checks (before starting this procedure) 2 2.1, 2.2 Vacuum Valve Positions - (refer: 1 for settings)

Remove product & material from line & area Vac. valve

Line clearance documentation completed in Inside Vertical Position (groove):

Position T = Top

Former & Sealer ready M = Middle

Raw materials available B = Bottom

Product in filled trays available & ready to load

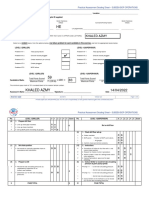

1 1 - 3 Settings for Loader Changeover

Brush Type Handle Brush Aligner Recipe

Vertical Horizontal Pin

Adult Single Compact T L 5 5

Adult Single Full T L 4 6

Adult Dual Compact T L 5 7

Adult Dual Full T L 4 8

Adult Pro Compact T L 5 9

Horizontal Position (hole):

Adult Pro Full T L 4 10 Left = Outside

Child BigGrip 2 M L 4 2 Right = Inside

Child BigGrip M R 4 1

Dirt Digger M R 1 12

Dirt Digger Compact T R 3 13

Teen T R 6 11

Simple Full T R 2 14

Simple Compact T R 2 15

Curve Compact T R 4 16

Curve Full T R 3 17

Talsico Process Picture Maps & all associated intellectual property are owned by Talsico International, ABN 20 419 167 619, & subject to licensing Agreement Page 2 of 2

S-ar putea să vă placă și

- DT-900 Inline Tabber Operation Manual: With DF915/920Document15 paginiDT-900 Inline Tabber Operation Manual: With DF915/920nidalkerdiyaÎncă nu există evaluări

- Check 4WDDocument13 paginiCheck 4WDCM MudjiotoÎncă nu există evaluări

- Service Manual For Computerized Sewing MachineDocument14 paginiService Manual For Computerized Sewing MachineИгорь ДобролюбовÎncă nu există evaluări

- Stat Fax - 2200: Service ManualDocument18 paginiStat Fax - 2200: Service ManualNguyễn Văn DuyÎncă nu există evaluări

- Main Drive Gear Alignment Service DocumentDocument2 paginiMain Drive Gear Alignment Service DocumentMaximiliano AndrésÎncă nu există evaluări

- Providing Optimized Alignment & Automatic Interchange Design Software TutorialDocument11 paginiProviding Optimized Alignment & Automatic Interchange Design Software Tutorialadera1Încă nu există evaluări

- Novation Dicer Eng 1Document11 paginiNovation Dicer Eng 1Hugo Esteban Arroyo FallasÎncă nu există evaluări

- Tup900 Series: Thermal PrinterDocument53 paginiTup900 Series: Thermal PrinterWilliam CorreaÎncă nu există evaluări

- Bree Zaire X H Installation enDocument16 paginiBree Zaire X H Installation en123GinodemÎncă nu există evaluări

- RXII Series User ManualDocument220 paginiRXII Series User ManualDavid DuarteÎncă nu există evaluări

- Series: Operation ManualDocument26 paginiSeries: Operation ManualMoon JaehyunÎncă nu există evaluări

- Fermator Door Operator VF7 Can Quick Start Guide SW V7.01.04 - 05 - 2018Document8 paginiFermator Door Operator VF7 Can Quick Start Guide SW V7.01.04 - 05 - 2018alfreliaÎncă nu există evaluări

- B2000 - Proper Assist PDFDocument9 paginiB2000 - Proper Assist PDFOmar Ramirez SarmientoÎncă nu există evaluări

- JT708PB 1 Instruction Manual ENDocument21 paginiJT708PB 1 Instruction Manual ENsanjith bugwandeenÎncă nu există evaluări

- TempTale® - GEO Eagle - Instructions - For - UseDocument7 paginiTempTale® - GEO Eagle - Instructions - For - UseDenis Sousa MartinsÎncă nu există evaluări

- Power On & PrestartDocument7 paginiPower On & PrestartbharatÎncă nu există evaluări

- CBM820 Service ManualDocument41 paginiCBM820 Service Manualhaithembs2017Încă nu există evaluări

- Exgo SeriesDocument24 paginiExgo SeriesThein TunÎncă nu există evaluări

- NBC ELETTRONICA SRL Load Cell ManualDocument36 paginiNBC ELETTRONICA SRL Load Cell ManualРуслан НелюбінÎncă nu există evaluări

- Manual For PD48LM46SP - 1Document148 paginiManual For PD48LM46SP - 1s3ms0Încă nu există evaluări

- F. Error Codes: Nh-1800 7. AppendixDocument19 paginiF. Error Codes: Nh-1800 7. AppendixShashi K KumarÎncă nu există evaluări

- Eccentricity Measurements: Operation and Maintenance ManualDocument32 paginiEccentricity Measurements: Operation and Maintenance ManualRabah AmidiÎncă nu există evaluări

- Ch.0-1 Contents Rev.1Document7 paginiCh.0-1 Contents Rev.1Nguyễn PhúÎncă nu există evaluări

- Humaclot ProDocument28 paginiHumaclot ProHuy Trung GiápÎncă nu există evaluări

- Leica Ts15: Athletics Measurements Manual For Smartworx Viva Onboard ApplicationDocument28 paginiLeica Ts15: Athletics Measurements Manual For Smartworx Viva Onboard ApplicationhetenÎncă nu există evaluări

- UM JL-GE enDocument28 paginiUM JL-GE enadjay xxxÎncă nu există evaluări

- Owner's Manual: 4820 Currency CounterDocument16 paginiOwner's Manual: 4820 Currency CounterBushara MahmoudÎncă nu există evaluări

- Supplement To The Instruction Manual and Parts List For The Series 1180, 3701, 5483Document32 paginiSupplement To The Instruction Manual and Parts List For The Series 1180, 3701, 5483Іван ПриймакÎncă nu există evaluări

- Maxxum 6 Bin and 10 Bin Vertical Collators: "When You Need More Than Staples."Document10 paginiMaxxum 6 Bin and 10 Bin Vertical Collators: "When You Need More Than Staples."LaurentEuniceÎncă nu există evaluări

- Centrifuge DSC-203,303SD (Manual) - 2021Document3 paginiCentrifuge DSC-203,303SD (Manual) - 2021Leah DarinoÎncă nu există evaluări

- Sd0001e0 2.0 Con Taratura 957Document37 paginiSd0001e0 2.0 Con Taratura 957JayRellvic Guy-ab0% (1)

- iTrite Electronic Titrator User Manual: Setup, Operation & Maintenance GuideDocument45 paginiiTrite Electronic Titrator User Manual: Setup, Operation & Maintenance GuideEdgardo BonillaÎncă nu există evaluări

- AC-0019 Practical Assessment Grading Sheet - Subsea BOP OperationsDocument6 paginiAC-0019 Practical Assessment Grading Sheet - Subsea BOP OperationsAlam AlsaharaÎncă nu există evaluări

- Moza Air-2-User-Manual-V3Document23 paginiMoza Air-2-User-Manual-V3Alejandro GiraldoÎncă nu există evaluări

- Subsea BOP Operations Grading SheetDocument6 paginiSubsea BOP Operations Grading Sheetairlinemembership100% (1)

- 2 Troubleshooting: 2.1 2.2 Troubleshooting With Error Messages.......................... 15Document46 pagini2 Troubleshooting: 2.1 2.2 Troubleshooting With Error Messages.......................... 15Tuan DinhÎncă nu există evaluări

- UM JE enDocument40 paginiUM JE enmd-ariful.islamÎncă nu există evaluări

- Ohaus SPX2201Document20 paginiOhaus SPX2201Ronald BarciaÎncă nu există evaluări

- Operation Taiyo Draft R2Document32 paginiOperation Taiyo Draft R2Saivul ChazisÎncă nu există evaluări

- Operating Instructions Mettler Toledo BD BalancesDocument16 paginiOperating Instructions Mettler Toledo BD BalancesLEDOMGÎncă nu există evaluări

- Presentation Slide showQJ341 QJ241..ppsxDocument120 paginiPresentation Slide showQJ341 QJ241..ppsxdaniel100% (1)

- Vehicle Electrical Components: Console BoxDocument15 paginiVehicle Electrical Components: Console BoxIvaylo PetkovÎncă nu există evaluări

- TofwatchDocument82 paginiTofwatchST HospitalÎncă nu există evaluări

- AC-0020 Practical Assessment Grading Sheet - Surface BOP OperationsDocument7 paginiAC-0020 Practical Assessment Grading Sheet - Surface BOP OperationsManash Hazarika100% (2)

- Bureta Digital - ManualDocument42 paginiBureta Digital - ManualIvt RomeroÎncă nu există evaluări

- Epson Stylus 400ch4Document11 paginiEpson Stylus 400ch4SerwisÎncă nu există evaluări

- Operation Manual-EN - DosificadoresDocument6 paginiOperation Manual-EN - Dosificadoresgiacomo pedicinoÎncă nu există evaluări

- SCX 4521FDocument37 paginiSCX 4521FadycrsÎncă nu există evaluări

- StandAssemblyGuide PDFDocument10 paginiStandAssemblyGuide PDFkdsÎncă nu există evaluări

- Refrigerator Truck Data Logger RMS-010 User GuideDocument16 paginiRefrigerator Truck Data Logger RMS-010 User GuideCristianÎncă nu există evaluări

- MOD 30ML Operation Lab 2: 2.1 ForewordDocument10 paginiMOD 30ML Operation Lab 2: 2.1 ForewordMario BozicevicÎncă nu există evaluări

- DISH+20 1-21 1+Remote+User+Guide PDFDocument64 paginiDISH+20 1-21 1+Remote+User+Guide PDFKaren CarterÎncă nu există evaluări

- L2X (M3) Service Manual-04Document14 paginiL2X (M3) Service Manual-04Akaki SkhirtladzeÎncă nu există evaluări

- NOT3072 December 2014 B - FALCON BALANCER Quickstart ENDocument12 paginiNOT3072 December 2014 B - FALCON BALANCER Quickstart ENRicardo NeryÎncă nu există evaluări

- VFD Control Operations ProcedureDocument14 paginiVFD Control Operations ProcedureDon CauilaneÎncă nu există evaluări

- 13.7.5 DSC Bus Check: 13.8 Memory/Storage StatusDocument2 pagini13.7.5 DSC Bus Check: 13.8 Memory/Storage Statushans villanuevaÎncă nu există evaluări

- Configure J-1175 Crusher Speed SensorDocument63 paginiConfigure J-1175 Crusher Speed SensorKilton Biswas100% (2)

- Mi Curved Gaming Monitor 34 User ManualDocument14 paginiMi Curved Gaming Monitor 34 User ManualAnak SolehÎncă nu există evaluări

- Ater Chillers: Operating and Maintenance ManualDocument68 paginiAter Chillers: Operating and Maintenance ManualDelmiro MartinÎncă nu există evaluări

- Motion Control ReportDe la EverandMotion Control ReportEvaluare: 4 din 5 stele4/5 (1)

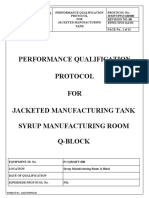

- Pure & Cure Healthcare Pvt. LTD: HaridwarDocument3 paginiPure & Cure Healthcare Pvt. LTD: HaridwarcpkakopeÎncă nu există evaluări

- 13 e Customer ServiceDocument33 pagini13 e Customer ServicecpkakopeÎncă nu există evaluări

- Step Up Card Certification Diploma Gustavo HenriqueDocument1 paginăStep Up Card Certification Diploma Gustavo HenriquecpkakopeÎncă nu există evaluări

- Performance Qualification Protocol FOR Induction Sealing Machine (Cephalosporin Block)Document17 paginiPerformance Qualification Protocol FOR Induction Sealing Machine (Cephalosporin Block)cpkakope100% (3)

- Analisis de Riesgo Eng-CoaterDocument44 paginiAnalisis de Riesgo Eng-CoatercpkakopeÎncă nu există evaluări

- Alarm Verification FOR Incubators (Microbiology, Q-Block)Document13 paginiAlarm Verification FOR Incubators (Microbiology, Q-Block)cpkakopeÎncă nu există evaluări

- Alarm Verification Protocol FOR Incubators (Microbiology, Q-Block)Document10 paginiAlarm Verification Protocol FOR Incubators (Microbiology, Q-Block)cpkakope100% (1)

- PQ-Sample fIVEDocument13 paginiPQ-Sample fIVEcpkakopeÎncă nu există evaluări

- PQ and Monitoring Water SystemsDocument18 paginiPQ and Monitoring Water SystemsRama KrishnaÎncă nu există evaluări

- Audit Checklist 9001 13485 21 CFR 820Document66 paginiAudit Checklist 9001 13485 21 CFR 820Zoli0984100% (5)

- PQ-Sample One PharmaDocument10 paginiPQ-Sample One Pharmacpkakope100% (5)

- 2015 GMP Validation Forum D2.T4.1.1 Ashley Isbel Writing An Effective FSE URS 2Document29 pagini2015 GMP Validation Forum D2.T4.1.1 Ashley Isbel Writing An Effective FSE URS 2zombiecorpÎncă nu există evaluări

- PQ-Sample TwoDocument11 paginiPQ-Sample Twocpkakope100% (4)

- PQ-Sample FOURDocument9 paginiPQ-Sample FOURcpkakopeÎncă nu există evaluări

- COMPUTER SYSTEM VALIDATION MASTER PLAN - Pharmaceutical Guidance - RecognizedDocument57 paginiCOMPUTER SYSTEM VALIDATION MASTER PLAN - Pharmaceutical Guidance - Recognizedcpkakope67% (3)

- Documents - Pub - Compressed Air Quality Audit Iso 8573Document8 paginiDocuments - Pub - Compressed Air Quality Audit Iso 8573cpkakopeÎncă nu există evaluări

- Automation Gamp5Document4 paginiAutomation Gamp5kolokithia100% (1)

- Computer System Validation Master PlanDocument54 paginiComputer System Validation Master Plancpkakope86% (7)

- Reimagining Enterprise Innovation Through Crowdsourcing: ManufacturingDocument19 paginiReimagining Enterprise Innovation Through Crowdsourcing: ManufacturingcpkakopeÎncă nu există evaluări

- Six Sigma Orientation: © All Rights Reserved Treqna 2005Document37 paginiSix Sigma Orientation: © All Rights Reserved Treqna 2005cpkakopeÎncă nu există evaluări

- Computer System Validation Risk Assessment ToolDocument3 paginiComputer System Validation Risk Assessment Toolcpkakope100% (1)

- Six Sigma Infrastructure and Cultural DevelopmentDocument30 paginiSix Sigma Infrastructure and Cultural DevelopmentcpkakopeÎncă nu există evaluări

- QMS-Six Sigma Introduction PDFDocument15 paginiQMS-Six Sigma Introduction PDFcpkakopeÎncă nu există evaluări

- Documents - Pub - Compressed Air Quality Audit Iso 8573Document8 paginiDocuments - Pub - Compressed Air Quality Audit Iso 8573cpkakopeÎncă nu există evaluări

- Capturing Customer Voice for Continuous ImprovementDocument30 paginiCapturing Customer Voice for Continuous ImprovementcpkakopeÎncă nu există evaluări

- Automation Gamp5Document4 paginiAutomation Gamp5kolokithia100% (1)

- HVAC Installation Qualification Protocol SummaryDocument36 paginiHVAC Installation Qualification Protocol SummarycpkakopeÎncă nu există evaluări

- Validation Master Plan (VMP) For Plasmapheresis. Plasmapheresis in 54 StepsDocument21 paginiValidation Master Plan (VMP) For Plasmapheresis. Plasmapheresis in 54 StepscpkakopeÎncă nu există evaluări

- Monitoring Temperature and HumidityDocument27 paginiMonitoring Temperature and HumidityCyprian Cypu100% (1)

- Praxis Spreadsheet-ValidationDocument67 paginiPraxis Spreadsheet-ValidationcpkakopeÎncă nu există evaluări

- Dosificadora EVODocument4 paginiDosificadora EVOCentury_1962Încă nu există evaluări

- InfiniSolar Plus 5KW Manual 201501203Document54 paginiInfiniSolar Plus 5KW Manual 201501203phanvanhtÎncă nu există evaluări

- MB4 CNC Conversion: Parts List Description Product NameDocument4 paginiMB4 CNC Conversion: Parts List Description Product NameRichard RichardÎncă nu există evaluări

- Autopilot Rotaryswitch - Maintenance PracticesDocument2 paginiAutopilot Rotaryswitch - Maintenance PracticesEleazarÎncă nu există evaluări

- Adafruit Mics5524 Gas Sensor BreakoutDocument12 paginiAdafruit Mics5524 Gas Sensor BreakoutWerliock MorlorumÎncă nu există evaluări

- Operation and Service Manual For Hermetic Sampler GT-STRD: Portable Closed Sampling DeviceDocument40 paginiOperation and Service Manual For Hermetic Sampler GT-STRD: Portable Closed Sampling DeviceGMÎncă nu există evaluări

- ZPA PogonDocument57 paginiZPA PogonMacakafkaÎncă nu există evaluări

- Microchip MCP6006 6R 6U 7 9 Data Sheet 20006411BDocument46 paginiMicrochip MCP6006 6R 6U 7 9 Data Sheet 20006411BMiguel BaixauliÎncă nu există evaluări

- 11 KV Ring Main Units and AccessoriesDocument35 pagini11 KV Ring Main Units and AccessoriesAbdus Salam0% (1)

- Simplex TrueAlert ES Design GuideDocument14 paginiSimplex TrueAlert ES Design GuidecboueidÎncă nu există evaluări

- PHL Series Diaphragm Pump Instruction ManualDocument46 paginiPHL Series Diaphragm Pump Instruction ManualnadipallsrirajÎncă nu există evaluări

- Electrical Water Heater Calore Control User Manual 30L-40L - 50L - 60L - 80LDocument7 paginiElectrical Water Heater Calore Control User Manual 30L-40L - 50L - 60L - 80LSameera LakmalÎncă nu există evaluări

- Adi Final Icepower 50asx2 Rumble 150 2010 Schematic Rev-BDocument2 paginiAdi Final Icepower 50asx2 Rumble 150 2010 Schematic Rev-Bbioteky85% (13)

- Cylinder Head - Install: Desarmado y ArmadoDocument4 paginiCylinder Head - Install: Desarmado y ArmadoJulio MezaÎncă nu există evaluări

- Basic Circuits, Laws, and Measurements: Chapter ObjectivesDocument20 paginiBasic Circuits, Laws, and Measurements: Chapter ObjectivesSneha PavithranÎncă nu există evaluări

- Schematic - 131675901 3512 Electronico PDFDocument2 paginiSchematic - 131675901 3512 Electronico PDFkhanghanh2017 a0% (1)

- AKAI GX Reel To Reel RecorderDocument11 paginiAKAI GX Reel To Reel RecorderRoger CalvertÎncă nu există evaluări

- Database-Mm2100 Company Name ListDocument15 paginiDatabase-Mm2100 Company Name ListRina RachmanÎncă nu există evaluări

- Daihatsu DK 20 Injection Timing MeasurementDocument5 paginiDaihatsu DK 20 Injection Timing MeasurementStathis Moumousis100% (3)

- 12d Step 1 Computer Purchase AssignmentDocument3 pagini12d Step 1 Computer Purchase Assignmentapi-245212314Încă nu există evaluări

- NJQS Product and Service Code GuidanceDocument40 paginiNJQS Product and Service Code GuidanceAF Dowell MirinÎncă nu există evaluări

- Book Parts E-WE 1204-55 INGDocument138 paginiBook Parts E-WE 1204-55 INGricardo assaf marchetiÎncă nu există evaluări

- A320mh 220712 (En+ru+cn)Document82 paginiA320mh 220712 (En+ru+cn)apolakan65Încă nu există evaluări

- Emcp 42 Getset WirringDocument1 paginăEmcp 42 Getset WirringPhanNamÎncă nu există evaluări

- Emergency and Standby Power Systems Design and Code RequirementsDocument14 paginiEmergency and Standby Power Systems Design and Code RequirementsSteffanie Jorj EspirituÎncă nu există evaluări

- DTC B2799 (Engine Immobilizer System) - Lexux IS 250 - 2007Document4 paginiDTC B2799 (Engine Immobilizer System) - Lexux IS 250 - 2007YusleiviÎncă nu există evaluări

- Monitoring and protecting 3-phase motors with the LR97D solid state overload relayDocument2 paginiMonitoring and protecting 3-phase motors with the LR97D solid state overload relayandreÎncă nu există evaluări

- AWIC Product InformationDocument55 paginiAWIC Product InformationWarren VingnoÎncă nu există evaluări

- Spare Parts Catalogue CR 253 4WDocument94 paginiSpare Parts Catalogue CR 253 4WАлексей100% (1)

- SDM-N50R Service ManualDocument76 paginiSDM-N50R Service ManualFöldi BélaÎncă nu există evaluări