Documente Academic

Documente Profesional

Documente Cultură

Bitumastic 300 M PDS

Încărcat de

rekstromDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bitumastic 300 M PDS

Încărcat de

rekstromDrepturi de autor:

Formate disponibile

Bitumastic 300 M

Selection & Specification Data Substrates & Surface Preparation

Generic Type Coal Tar Epoxy Concrete or CMU Concrete must be cured 28 days at 75F (24C) and

Description Renowned high build coal tar epoxy for protection of 50% relative humidity or equivalent. Prepare surfaces

steel and concrete in single or two-coat applications in in accordance with ASTM D4258 Surface Cleaning of

a broad variety of aggressive industrial applications. Concrete and ASTM D4259 Abrading Concrete. Voids

in concrete may require surfacing.

Features Excellent chemical, corrosion and abrasion

resistance

High-build, 16-24 mils (400-610 microns) in a single Performance Data

coat (up to 35 mils with force curing)

Test Method System Results

Compatible with controlled cathodic protection

ASTM B117 Salt Fog Blasted Steel No blistering, rusting

Suitable for use in exposures as referenced in the

2 cts. 300M or delamination.

following specifications:

No measurable

Corp of Engineers C-200, C200a

undercutting at scribe

AWWA C-210 for exterior

after 2000 hours

SSPC-Paint 16

Steel Tank Institute Corrosion Control System STI- ASTM D2794 Impact Blasted Steel Impact site diameter,

P3 2 cts. 300M Inches: 3/8,3/8, 1/2

100 in/lbs Gardner

Color Black (0900) Impactor at 1/2 in. diam.

Primer Self-priming, or use suitable prime as recommended ASTM D4060 Abrasion Blasted Steel 130 mg. loss after

by Carboline. 2 cts. 300M 1000 cycles, CS17

Dry Film Thickness 16.0 mils (406 microns) in one or two coats wheel, 1000 gm load

ASTM D4541 Adhesion Blasted Steel 1443 psi (Pneumatic)

2 cts. 300M

Total dry film thickness less than 8 mils (200microns) or in excess of 35

mils (875 microns) is not recommended. Wet-on-wet spray techniques Test reports and additional data available upon written request. *Disclaimer: Bitumastic 300M is a

should be used for high thicknesses allowing time for solvents to flash proprietary formula that is not necessarily formulated to the exact compositional guidelines set forth

between passes. in some of these standards. Minor deviations that control and improve application characteristics

may be present, but does not have a detrimental effect on the suitability for use outlined therein.

Solids Content By Volume 74% +/- 2%

Theoretical 2 2

Coverage Rate

1187 ft at 1.0 mils (29.1 m /l at 25 microns) Mixing & Thinning

2 2

74 ft at 16.0 mils (1.8 m /l at 400 microns)

Mixing Power mix separately, then combine and power mix

for a minimum of two minutes. DO NOT MIX PARTIAL

Allow for loss in mixing and application.

KITS.

VOC Values Thinner 10 10 oz/gal: 2.2 lbs/gal 269 g/l

Thinning Up to 10 oz/gal (8%) w/ #10

As Supplied 1.85 lbs/gal 222 g/l

Up to 25 oz/gal (20%) w/ #10 for the first coat

These are nominal values.

Thinner 10: 25 oz/gal: 2.7 lbs/gal 327 g/l

application to concrete.

*Maximum thinning for 250 g/l restricted areas is 6 oz/gal. Use of thinners other than those supplied or

recommended by Carboline may adversely affect

Dry Temp. Continuous: 350 F (177 C) product performance and void product warranty,

Resistance Non-Continuous: 370 F (188 C) whether expressed or implied.

Limitations Do not use for potable water requirements. Ratio 4:1 Ratio (A to B)

Topcoats Not recommended Pot Life 75F (24C) 2 Hours

Wet Temp. Immersion temperature should not exceed 120F 90F (32C) 1 Hour

Resistance (49C) Pot life ends when coating loses body and begins to

sag.

Substrates & Surface Preparation

Application Equipment Guidelines

General Surfaces must be clean and dry. Employ adequate

Listed below are general equipment guidelines for the application of this product. Job site conditions

methods to remove dirt, dust, oil and all other may require modifications to these guidelines to achieve the desired results.

contaminants that could interfere with adhesion of the

coating. Spray Application This is a high solids coating and may require

Steel Immersion: SSPC-SP10 (General) adjustments in spray techniques. Wet film thickness

Non-Immersion: SSPC-SP6 is easily and quickly achieved. The following spray

SSPC-SP2 or SP3 as minimum requirement. equipment has been found suitable and is available

Surface Profile: 2.0-3.0 mils (50-75 micron) from manufacturers such as Binks, DeVilbiss and

Graco.

Conventional Pressure pot equipped with dual regulators, 3/8 I.D.

Spray minimum material hose, with 50' maximum material

hose .086 I.D. fluid tip and appropriate air cap.

November 2016 0165

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 1 of 2

Bitumastic 300 M

Application Equipment Guidelines Packaging, Handling & Storage

Listed below are general equipment guidelines for the application of this product. Job site conditions Shelf Life Part A: Min. 24 months at 75F (24C)

may require modifications to these guidelines to achieve the desired results.

Part B: Min. 36 months at 75F (24C)

Airless Spray Pump Ratio: 30:1* *Shelf Life: (actual stated shelf life) when kept at recommended storage

conditions and in original unopened containers.

GPM Output: 3.0 (min.)

Material Hose: I.D. (min.) Shipping Weight 1.25 Gallon Kit - 12 lbs (6 kg)

Tip Size: .023-.035 (Approximate) 5 Gallon Kit - 50 lbs (26 kg)

Output PSI: 2100-2500

Filter Size: 30 mesh Storage 40 -110F (4-43C)

*Teflon packings are recommended and available from Temperature & 0-100% Relative Humidity

the pump manufacturer. Humidity

Brush & Roller Recommended for touch up, striping of weld seams Flash Point Part A: 75F (24C)

(General) and hard-to-coat areas only. Avoid excessive re- (Setaflash) Part B: >200F (93C)

brushing or re-rolling. Storage Store indoors

Brush Use a medium bristle brush.

Roller Use a short-nap synthetic roller cover with phenolic

core.

Application Conditions

Condition Material Surface Ambient Humidity

Minimum 50 F (10 C) 50 F (10 C) 50 F (10 C) 0%

Maximum 90 F (32 C) 125 F (52 C) 110 F (43 C) 90%

Condensation due to substrate temperatures below the dew point can cause flash rusting on

prepared steel and interfere with proper adhesion to the substrate. Special application techniques

may be required above or below normal application conditions.

Curing Schedule

Surface Dry to Touch Final Cure Maximum Minimum

* Immersion Recoat Time Recoat Time

Temp.

50 F (10 C) 8 Hours 14 Days 24 Hours 10 Hours

75 F (24 C) 4 Hours 7 Days 24 Hours 6 Hours

90 F (32 C) 2 Hours 5 Days 24 Hours 3 Hours

These times are based on a 16.0 mil (400 micron) dry film thickness. Higher film thickness,

insufficient ventilation, high humidity or cooler temperatures will require longer cure times. Excessive

humidity or condensation on the surface during curing can interfere with the cure, can cause

discoloration and may result in a surface haze. Any haze or blush must be removed by water

washing before recoating. If the maximum recoat time is exceeded, the surface must be abraded

by sweep blasting prior to the application of additional coats. Holiday Detection (if required): Wet

sponge types may be used if the dry film thickness is below 20 mils (500 microns). High voltage

spark testing should be used when the dry film thickness exceeds 20 mils (500 microns). Refer to

the latest version of NACE SP0188 for specific procedures.

FORCE CURING recommended for thicknesses above 24 mils

Hold substrate at 150 F for 8 hours and material will be ready to handle for immersion service.

Cleanup & Safety

Cleanup Use #2 Thinner or Acetone. In case of spillage, absorb

and dispose of in accordance with local applicable

regulations.

Safety Read and follow all caution statements on this

product data sheet and on the MSDS for this product.

Employ normal workmanlike safety precautions.

Hypersensitive persons should wear protective

clothing, gloves and use protective cream on face,

hands and all exposed areas.

Caution This product contains flammable solvents. Keep away

from sparks and open flames. All electrical equipment

and installations should be made and grounded in

accordance with the National Electric Code. In areas

where explosion hazards exist, workers should be

required to use non-ferrous tools and wear conductive

and non-sparking shoes.

November 2016 0165

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 2 of 2

S-ar putea să vă placă și

- Bitumastic 300 M PDSDocument2 paginiBitumastic 300 M PDSMuhammad RizwanÎncă nu există evaluări

- Bitumastic 300M: Selection & Specification DataDocument4 paginiBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINÎncă nu există evaluări

- Carboguard 893 PDSDocument2 paginiCarboguard 893 PDSNguyễn Thị Châu TâyÎncă nu există evaluări

- Phenoline 187 Primer and FinishDocument2 paginiPhenoline 187 Primer and Finish이선엽Încă nu există evaluări

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pagini3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanÎncă nu există evaluări

- Interline 984+td+eng PDFDocument1 paginăInterline 984+td+eng PDFMohamed Nouzer100% (2)

- Carboguard 890 PDSDocument5 paginiCarboguard 890 PDScrisÎncă nu există evaluări

- Urethane Coating 165 PWDocument3 paginiUrethane Coating 165 PWANIBALLOPEZVEGAÎncă nu există evaluări

- Plascoat Ppa 571: Performance Polymer Alloy CoatingDocument2 paginiPlascoat Ppa 571: Performance Polymer Alloy CoatingEidrish ShaikhÎncă nu există evaluări

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 paginiDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CJhune UrabaÎncă nu există evaluări

- Sikawrap 300 CDocument5 paginiSikawrap 300 CAkram ShakirÎncă nu există evaluări

- F13 - Carboguard 893-Zn PDS 10-09Document2 paginiF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989Încă nu există evaluări

- Carboguard 890 PDSDocument5 paginiCarboguard 890 PDSAchraf BoudayaÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CAlexis KarampasÎncă nu există evaluări

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 paginiSABIC® HDPE - M200056 - Global - Technical - Data - SheetRishiÎncă nu există evaluări

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 paginăGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviÎncă nu există evaluări

- 612 en Sureseal Epdm TdsDocument1 pagină612 en Sureseal Epdm TdsMohamed Ismail ShehabÎncă nu există evaluări

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 paginiSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiÎncă nu există evaluări

- Sikawrap 301 C Pds enDocument4 paginiSikawrap 301 C Pds enjohanes b muda100% (1)

- Iocl PPCP 8 Mfi 4080maDocument1 paginăIocl PPCP 8 Mfi 4080mayaonik himmatramkaÎncă nu există evaluări

- 3M Scotchkote Epoxy Primer GP 120+Document2 pagini3M Scotchkote Epoxy Primer GP 120+satya ranjanÎncă nu există evaluări

- Iocl PPCP Injection Molding 11 Mfi 4100mhDocument1 paginăIocl PPCP Injection Molding 11 Mfi 4100mhAparesh GantaitÎncă nu există evaluări

- Sabic - Sabic® Hdpe CC453 PDFDocument4 paginiSabic - Sabic® Hdpe CC453 PDFquangga10091986Încă nu există evaluări

- Iocl-3030mg (U)Document1 paginăIocl-3030mg (U)Vignesh SubramanianÎncă nu există evaluări

- 002DP48 PDFDocument2 pagini002DP48 PDFDiadam SharmaÎncă nu există evaluări

- Vetotop DOC TECHNICAL MAP en 3589Document2 paginiVetotop DOC TECHNICAL MAP en 3589Demac SaudÎncă nu există evaluări

- 1110mg Iocl PP Injection Moulding GranulesDocument1 pagină1110mg Iocl PP Injection Moulding Granulessantosh.bhattÎncă nu există evaluări

- Hdpe 080M60Document1 paginăHdpe 080M60pbÎncă nu există evaluări

- 05 Vetocrete FC803 - 020521Document2 pagini05 Vetocrete FC803 - 020521Herminio Lagran CarinoÎncă nu există evaluări

- Sikawrap - 230 CDocument4 paginiSikawrap - 230 CNyein ZawÎncă nu există evaluări

- Twisted Wire Gabion BasketsDocument3 paginiTwisted Wire Gabion Basketsthink padÎncă nu există evaluări

- Resicoat V - F R4 ESDocument3 paginiResicoat V - F R4 ESABHISHEK SINGHÎncă nu există evaluări

- Carbomastic 15 PDSDocument4 paginiCarbomastic 15 PDSRiyaz Basheer100% (1)

- Carboguard 893: Selection & Specification DataDocument5 paginiCarboguard 893: Selection & Specification DataQuy RomÎncă nu există evaluări

- Product Datasheet: BU Powder CoatingsDocument1 paginăProduct Datasheet: BU Powder CoatingsAndras StegerÎncă nu există evaluări

- PPA 571 EsDocument4 paginiPPA 571 EsRohit Sangwan0% (1)

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 paginiDTM Bonding Primer: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- GRI-GM30: Weld Easier. Install Faster. Contain BetterDocument2 paginiGRI-GM30: Weld Easier. Install Faster. Contain BetterAndreas Erdian WijayaÎncă nu există evaluări

- PP PP9074MED DatasheetDocument1 paginăPP PP9074MED DatasheetDiogo SouzaÎncă nu există evaluări

- Pro Mastic Ste 87Document4 paginiPro Mastic Ste 87ahmedyahea181Încă nu există evaluări

- LL7410D1Document1 paginăLL7410D1Nitin MaheshwariÎncă nu există evaluări

- Polyken 930: Product Data SheetDocument2 paginiPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Sabic BM 1052Document2 paginiSabic BM 1052ifahÎncă nu există evaluări

- Sikalastic®-632: Product Data SheetDocument5 paginiSikalastic®-632: Product Data SheetShanaei MiskinÎncă nu există evaluări

- TDS Conbextra EP160 Saudi ArabiaDocument4 paginiTDS Conbextra EP160 Saudi ArabiajasonÎncă nu există evaluări

- 88 Imi ImiplastDocument2 pagini88 Imi ImiplastEngr KamalÎncă nu există evaluări

- Polyken 930: Product Data SheetDocument2 paginiPolyken 930: Product Data SheetAgustina De Winne100% (1)

- New 1000 CSDocument2 paginiNew 1000 CSSantiago MonteroÎncă nu există evaluări

- ENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD PolyesterDocument1 paginăENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD Polyesterlong chanÎncă nu există evaluări

- Certene™ Llbf-218aDocument1 paginăCertene™ Llbf-218aJose FernandezÎncă nu există evaluări

- 718 Stangard Egf (NV)Document5 pagini718 Stangard Egf (NV)Sandeep gangulyÎncă nu există evaluări

- TDS Nitoflor SL3000 UT IndiaDocument4 paginiTDS Nitoflor SL3000 UT IndiaqmsudhirÎncă nu există evaluări

- MacMat Technical Data SheetDocument1 paginăMacMat Technical Data SheetinfoÎncă nu există evaluări

- Estowrap 300H - Estop Japan - Carbon FRP-1Document3 paginiEstowrap 300H - Estop Japan - Carbon FRP-1nugraha pierreÎncă nu există evaluări

- Iocl 1030rDocument1 paginăIocl 1030rLaxman AhirÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- Self-healing Ceramic Matrix Composites: A MonographDe la EverandSelf-healing Ceramic Matrix Composites: A MonographÎncă nu există evaluări

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDe la EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingÎncă nu există evaluări

- 80 - 40 - H2 - Displacement PDFDocument1 pagină80 - 40 - H2 - Displacement PDFrekstromÎncă nu există evaluări

- 80 - 40 - H1 - Volume InfoDocument1 pagină80 - 40 - H1 - Volume InforekstromÎncă nu există evaluări

- 4/7/2020 80 - 40 - H1 - Test 26: Maximum Value 0.9987 Minimum Value 0.5034Document1 pagină4/7/2020 80 - 40 - H1 - Test 26: Maximum Value 0.9987 Minimum Value 0.5034rekstromÎncă nu există evaluări

- Index: Ments For Masonry Structures), 11Document11 paginiIndex: Ments For Masonry Structures), 11rekstromÎncă nu există evaluări

- 80 - 40 - H1 - General InfoDocument1 pagină80 - 40 - H1 - General InforekstromÎncă nu există evaluări

- 80 - 40 - H3 - DisplacementDocument1 pagină80 - 40 - H3 - DisplacementrekstromÎncă nu există evaluări

- 80 - 40 - H1 - Shear StressDocument1 pagină80 - 40 - H1 - Shear StressrekstromÎncă nu există evaluări

- 4/7/2020 80 - 40 - H1 - Test: Connectivity PlotDocument1 pagină4/7/2020 80 - 40 - H1 - Test: Connectivity PlotrekstromÎncă nu există evaluări

- 80 - 40 - H4 - DisplacementDocument1 pagină80 - 40 - H4 - DisplacementrekstromÎncă nu există evaluări

- APA Diaphragm ConnectionsDocument20 paginiAPA Diaphragm ConnectionsrekstromÎncă nu există evaluări

- 4/7/2020 80 - 40 - H1 - Test: Connectivity PlotDocument1 pagină4/7/2020 80 - 40 - H1 - Test: Connectivity PlotrekstromÎncă nu există evaluări

- EqnsDocument1 paginăEqnsrekstromÎncă nu există evaluări

- 4/7/2020 80 - 40 - H1 - Test: Connectivity PlotDocument1 pagină4/7/2020 80 - 40 - H1 - Test: Connectivity PlotrekstromÎncă nu există evaluări

- Great Smoky Mountains National ParkDocument2 paginiGreat Smoky Mountains National ParkrekstromÎncă nu există evaluări

- Polyethylene-Acrylic Acid Copolymer: Mechanical FasteningDocument1 paginăPolyethylene-Acrylic Acid Copolymer: Mechanical FasteningrekstromÎncă nu există evaluări

- Ethylene-Propylene-Diene Copolymer: Hot Gas WeldingDocument1 paginăEthylene-Propylene-Diene Copolymer: Hot Gas WeldingrekstromÎncă nu există evaluări

- Enerpac StudyDocument260 paginiEnerpac StudyrekstromÎncă nu există evaluări

- Generic Thermoplastic Elastomer: WeldingDocument1 paginăGeneric Thermoplastic Elastomer: WeldingrekstromÎncă nu există evaluări

- Umwd 06516 XD PDFDocument3 paginiUmwd 06516 XD PDFceca89Încă nu există evaluări

- Prevention of Waterborne DiseasesDocument2 paginiPrevention of Waterborne DiseasesRixin JamtshoÎncă nu există evaluări

- Hướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangDocument4 paginiHướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangHưng Quân VõÎncă nu există evaluări

- Health Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyDocument3 paginiHealth Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyihealthmailboxÎncă nu există evaluări

- Progressive Muscle RelaxationDocument4 paginiProgressive Muscle RelaxationEstéphany Rodrigues ZanonatoÎncă nu există evaluări

- Sveba Dahlen - SRP240Document16 paginiSveba Dahlen - SRP240Paola MendozaÎncă nu există evaluări

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Document22 paginiMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCÎncă nu există evaluări

- Recitation Math 001 - Term 221 (26166)Document36 paginiRecitation Math 001 - Term 221 (26166)Ma NaÎncă nu există evaluări

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 paginăNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدÎncă nu există evaluări

- 50114a Isolemfi 50114a MonoDocument2 pagini50114a Isolemfi 50114a MonoUsama AwadÎncă nu există evaluări

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDocument11 paginiGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaÎncă nu există evaluări

- Student Exploration: Inclined Plane - Simple MachineDocument9 paginiStudent Exploration: Inclined Plane - Simple MachineLuka MkrtichyanÎncă nu există evaluări

- Configuring BGP On Cisco Routers Lab Guide 3.2Document106 paginiConfiguring BGP On Cisco Routers Lab Guide 3.2skuzurov67% (3)

- Cisco BGP ASPATH FilterDocument115 paginiCisco BGP ASPATH FilterHalison SantosÎncă nu există evaluări

- Lecture 2 Effects of Operating Conditions in VCCDocument9 paginiLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezÎncă nu există evaluări

- Continue Practice Exam Test Questions Part 1 of The SeriesDocument7 paginiContinue Practice Exam Test Questions Part 1 of The SeriesKenn Earl Bringino VillanuevaÎncă nu există evaluări

- Skills Checklist - Gastrostomy Tube FeedingDocument2 paginiSkills Checklist - Gastrostomy Tube Feedingpunam todkar100% (1)

- Model 255 Aerosol Generator (Metone)Document20 paginiModel 255 Aerosol Generator (Metone)Ali RizviÎncă nu există evaluări

- HatfieldDocument33 paginiHatfieldAlex ForrestÎncă nu există evaluări

- Clockwork Dragon's Expanded ArmoryDocument13 paginiClockwork Dragon's Expanded Armoryabel chabanÎncă nu există evaluări

- Building Services Planning Manual-2007Document122 paginiBuilding Services Planning Manual-2007razanmrm90% (10)

- Quarter 1 - Module 1Document31 paginiQuarter 1 - Module 1Roger Santos Peña75% (4)

- Quiz 140322224412 Phpapp02Document26 paginiQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriÎncă nu există evaluări

- Aluminum PorterDocument2 paginiAluminum PorterAmir ShameemÎncă nu există evaluări

- Chapter - I Introduction and Design of The StudyDocument72 paginiChapter - I Introduction and Design of The StudyramÎncă nu există evaluări

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Document1 paginăWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedÎncă nu există evaluări

- YIC Chapter 1 (2) MKTDocument63 paginiYIC Chapter 1 (2) MKTMebre WelduÎncă nu există evaluări

- LP For EarthquakeDocument6 paginiLP For Earthquakejelena jorgeoÎncă nu există evaluări

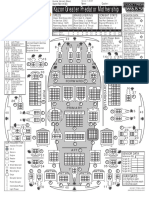

- Kazon Greater Predator MothershipDocument1 paginăKazon Greater Predator MothershipknavealphaÎncă nu există evaluări

- Safety Procedures in Using Hand Tools and EquipmentDocument12 paginiSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezÎncă nu există evaluări