Documente Academic

Documente Profesional

Documente Cultură

Kta38 G5

Încărcat de

Patricio Andres Ibañez ConchaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kta38 G5

Încărcat de

Patricio Andres Ibañez ConchaDrepturi de autor:

Formate disponibile

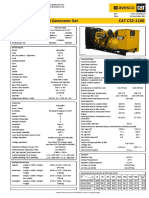

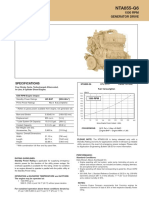

KTA38-G5

GENERATOR DRIVE

1500 RPM

SPECIFICATIONS

4-Stroke Cycle, Turbocharged/Aftercooled,

V-12 Cylinder Diesel Engine.

1500 RPM Engine Output

Standby Power Rating 1300 BHP [970 kWm*] Litre/hour

250.0

Prime Power Rating 1180 BHP [880 kWm*]

Continuous Power Rating 880 BHP [656 kWm*] 200.0

*Refers to gross power available from engine, not generator set.

150.0

Bore and Stroke 6.25x6.25 in. [159x159 mm]

Displacement 2300 cu. in. [38 L] 100.0

**Lube System Oil Capacity 34.0 U.S. gal. [129 L]

50.0

Coolant Capacity 31.25 U.S. gal. [118 L]

Net Weight with Standard

0.0

Accessories, Dry 9,482 lb. [4300 kg] 0 100 200 300 400 500 600 700 800 900 1000

Approx. Overall Dimensions: Gross Engine Power Output - kWm

Width 52.9 in. [1343 mm] (U.S. Gal = Litres x 0.2642) (BHP = kWm x 1.34)

Length 89.1 in. [2263 mm]

Height 65.3 in. [1659 mm]

** Spin-on bypass filters are included in total.

PERFORMANCE:

RATING GUIDELINES:

Standard Conditions:

Standby Power Rating is applicable for supplying emergency

Data Shown Above Are Based On:

electric power for the duration of the utility power outage. No

Engine operating with fuel system, water pump, lubricating oil pump, air

overload capability is available for this rating. Under no condition cleaner and exhaust silencer; not included are battery charging alternator, fan

is an engine allowed to operate in parallel with the public utility at and optional driven components.

the Standby Power rating. Engine operating with diesel fuel corresponding to grade No. 2D per ASTM

Prime Power Rating is applicable for supplying electric power in D975.

lieu of commercially purchased power. Prime Power is the ISO-3046, Part 1, Standard Reference Conditions of: 29.53 in. Hg. [100 kPa]

maximum power available at variable load for an unlimited barometric pressure (361 ft. [110 m] altitude), 77 F [25 C] air temperature

number of hours. A 10% overload capability is available. and a relative humidity of 30%.

OPERATION at ELEVATED TEMPERATURE and ALTITUDE: NOTES:

The engine may be operated at: For Continuous Power or Base Power, Interruptible Power (Utility Power

1500 RPM up to: Curtailment) and Peak Shaving, contact the local Cummins representative.

5000 ft. [1525 m] and 104 F [40 C] without power deration. Cummins Engine Company recommends that Cummins engines be operated

For sustained operation above these conditions derate by: at a minimum load of 30% of their respective Standby Power rating.

4% per 1,000 ft. [300 m] and 1% per 10 F [2% per 11 C].

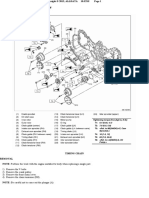

KTA38-G5

GENERATOR DRIVE

1500 RPM

DESIGN FEATURES AVAILABLE EQUIPMENT

Aftercooler: Large capacity aftercooler results in cooler, denser Cooling System

intake air for more efficient combustion and reduced internal 1. Fan drive for radiator (0.5:1 drive ratio, 24.0 in. [610 mm] center).

stresses for longer life. Aftercooler is located in engine coolant 2. Heat exchanger tube type, copper nickel.

system, eliminating need for special plumbing. 3. Remote cooling (engine water pump only).

Bearings: Replaceable, precision type, steel backed inserts. Nine Exhaust System:

main bearings, 6.5 in. [165 mm] diameter. Connecting rod 1. Dry exhaust manifold.

bearings 4.25 in. [108 mm] diameter.

2. Flexible exhaust connection.

Camshaft: Dual camshafts precisely control valve and injector

Filters: Fleetguard.

timing. Lobes are induction hardened for long life. Eighteen

replaceable precision type bushings 3.0 in. [76 mm] diameter. 1. Lubricating oil: Spin-on paper element full flow and bypass type.

Camshaft Followers: Induction hardened, roller type for long cam 2. Fuel: Dual spin-on paper element type.

and follower life. Flywheel: To fit SAE-518 (22.500 in. [571.5 mm] diameter) or

Connecting Rods: Drop forged, I-beam section 11.4 in. [290 mm] SAE-521 (26.500 in. [673 mm] diameter), generator flexible drive

center-to-center length. Rifle drilled for pressure lubrication of disk - reference SAE standard J162a.

piston pin. Rod is tapered on piston pin end to reduce unit Flywheel Housing: SAE No. 0 or SAE No. 00, dry type.

pressures. Governors: Electric or hydraulic; for droop or isochronous operation.

Cooling System: Gear driven centrifugal water pump. Large Cummins EFC (electric fuel control) or others.

volume water passages provide even flow of coolant around Starting System:

cylinder liners, valves, and injectors. Four modulating bypass 1. Electric starter (24 volt positive engagement).

thermostats regulate coolant temperature. Spin-on corrosion 2. Compressed air starter.

resistors check rust and corrosion, control acidity and remove

3. Battery charging alternator (24 volt, 35 ampere).

impurities.

For other available equipment consult your local Cummins

Crankshaft: High tensile strength steel forging with induction

representative.

hardened fillets and journals. Fully counterweighted and

dynamically balanced.

Cylinder Block: Alloy cast iron with removable wet liners. Cross

bolt support to main bearing cap provides extra strength and

AGENCY APPROVAL

stability. Certification: Consult your local Cummins representative.

Cylinder Heads: Alloy cast iron. Each head serves one cylinder.

Valve seats are replaceable corrosion resistant inserts. Valve

guides and cross head guides are replaceable inserts.

Cylinder Liners: Replaceable wet liners dissipate heat faster than

dry liners and are easily replaced without reboring the block.

Fuel System: Cummins exclusive low pressure PT system

with wear compensating pump and integral dual flyweight

governor. Camshaft actuated fuel injectors give accurate

metering and timing. Fuel lines are internal drilled passages in

cylinder heads. Spin-on fuel filter.

Gear Train: Timing gears and accessory drive gears are induction

hardened helical gears driven from crankshaft and located at

front of block.

Lubrication: Large capacity gear pump provides pressure

lubrication to all bearings and oil supply for piston cooling. All

pressure lines are internal drilled passages in block and heads.

Oil cooler, full flow filters, and bypass filters maintain oil condition

and maximize oil and engine life.

Pistons: Aluminum alloy, cam ground and barrel shaped to

compensate for thermal expansion assures precise fit at

operating temperatures. Grooved skirt finish provides superior

lubrication. Oil cooled for rapid heat dissipation. Two

compression and one oil ring.

Piston Pins: Full floating, tubular steel retained by snap rings

2.4 in. [61 mm] diameter.

Turbocharger: Holset exhaust gas driven turbocharger mounted

Cummins has always been a pioneer in product improvement. Thus,

at top of engine. Turbocharging provides more power, improved specifications may change without notice. Illustrations may include optional

fuel economy, altitude compensation, and lower smoke and equipment.

noise levels.

Valves: Dual 2.22 in. [56 mm] diameter poppet type intake and

exhaust valves. Wear resistant face on exhaust valves.

Cummins Engine Company, Inc.

Box 3005

Columbus, IN 47202-3005

U.S.A.

1997 Bulletin 3885275 Printed in U.S.A. 06/97

S-ar putea să vă placă și

- Kta38 G5Document2 paginiKta38 G5Camilo Sanchez Vanegas50% (2)

- Specifications KTA38 G DRIVEDocument2 paginiSpecifications KTA38 G DRIVEMehdi ChakrouneÎncă nu există evaluări

- Water PumpsDocument119 paginiWater PumpsLesly LeslyÎncă nu există evaluări

- Cummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingDocument2 paginiCummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingMuhammad rizkiÎncă nu există evaluări

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 paginiDoosan Infracore Generator Engine: Ratings (KWM/PS)moisesÎncă nu există evaluări

- V222TIDocument2 paginiV222TIcmendezÎncă nu există evaluări

- Cummins n855 Engine Specs PDF FreeDocument6 paginiCummins n855 Engine Specs PDF Freema.powersourceÎncă nu există evaluări

- M2000Document7 paginiM2000kylegazeÎncă nu există evaluări

- C15 Acert Spec SheetDocument4 paginiC15 Acert Spec SheetMalasquez Leon XavierÎncă nu există evaluări

- KTA19 G4 Generator Specsheet PDFDocument2 paginiKTA19 G4 Generator Specsheet PDFstrato1977Încă nu există evaluări

- 6ey17w PDFDocument1 pagină6ey17w PDFfajee_faridÎncă nu există evaluări

- 03 Mechanical AdjustmentDocument25 pagini03 Mechanical AdjustmentHải Lưu MinhÎncă nu există evaluări

- Tad 722 GeDocument2 paginiTad 722 GePaulo César Managó100% (1)

- 6HYM ETE BrochureDocument2 pagini6HYM ETE BrochureRudy PriatnaÎncă nu există evaluări

- Oil ValveDocument4 paginiOil ValveGolbert GolbiÎncă nu există evaluări

- Caution: Counterclockwise, As Viewed From TheDocument19 paginiCaution: Counterclockwise, As Viewed From TheanilÎncă nu există evaluări

- 6BT5 9-G1Document5 pagini6BT5 9-G1Jorge Martinez G.Încă nu există evaluări

- CW6200Document3 paginiCW6200cgÎncă nu există evaluări

- Daihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)Document114 paginiDaihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)andriy.b1979Încă nu există evaluări

- Technical Data TAD1030GE: GeneralDocument7 paginiTechnical Data TAD1030GE: GeneralbaljeetjatÎncă nu există evaluări

- Lubricating Oil System - QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualDocument2 paginiLubricating Oil System - QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service Manualbagus hutomo100% (1)

- New Dme Catalog PDFDocument72 paginiNew Dme Catalog PDFBrandon TrocÎncă nu există evaluări

- QSK19 DM PDFDocument2 paginiQSK19 DM PDFSoumya Ranjan Nayak100% (2)

- Optimum ManualDocument17 paginiOptimum ManualJohn IpsilantisÎncă nu există evaluări

- D2842 Heavy DutyDocument4 paginiD2842 Heavy Dutym_najman100% (2)

- Static Injector TimingDocument12 paginiStatic Injector TimingMohamed Mohamed100% (1)

- Eliminator™ FilterDocument35 paginiEliminator™ FiltertstkupdhÎncă nu există evaluări

- Kta38 DM1Document2 paginiKta38 DM1samir badriÎncă nu există evaluări

- Tad730ge 111797s01Document8 paginiTad730ge 111797s01roozbehxoxÎncă nu există evaluări

- Cap KSM72Document6 paginiCap KSM72Jaffer HussainÎncă nu există evaluări

- 6BT5.9-DM Non-Certified Ratings SSDocument2 pagini6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- Man BW Stationary Engines and Small Bore Gensets ProgrammeDocument62 paginiMan BW Stationary Engines and Small Bore Gensets ProgrammeRhaanzahÎncă nu există evaluări

- Valvoline 6Document2 paginiValvoline 6munh100% (1)

- Guascor Siemens SLE Family - F & S (F - SF)Document441 paginiGuascor Siemens SLE Family - F & S (F - SF)Oleg GorlushinÎncă nu există evaluări

- 2506C E15tag2Document2 pagini2506C E15tag2Rafa Pdf100% (1)

- C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDocument5 paginiC18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDenis JimenezÎncă nu există evaluări

- 3512B 1500RPM 1300KW BrochureDocument4 pagini3512B 1500RPM 1300KW BrochuresalembatopÎncă nu există evaluări

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Document2 pagini4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaÎncă nu există evaluări

- Every Ton.: Non-Certified Engines For Mining ApplicationsDocument4 paginiEvery Ton.: Non-Certified Engines For Mining ApplicationsCarlos andres Revelo gomezÎncă nu există evaluări

- Technical Data: @perkinsDocument6 paginiTechnical Data: @perkinsLakshan WeliwattaÎncă nu există evaluări

- 220Document1 pagină220fahmi wibowoÎncă nu există evaluări

- Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Document73 paginiCopia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Gallego CarlosÎncă nu există evaluări

- D2840 - V10 Diesel GeneratorDocument4 paginiD2840 - V10 Diesel GeneratorМария ЗинченкоÎncă nu există evaluări

- Operation and Maintenance Manual Bulletin Nh220Document4 paginiOperation and Maintenance Manual Bulletin Nh220Cordova MarcosÎncă nu există evaluări

- Cat C32-1100 en PDFDocument1 paginăCat C32-1100 en PDFOsanebi Chukwudi LuckyÎncă nu există evaluări

- 628Document4 pagini628sdiamanÎncă nu există evaluări

- Service Drawings: KTA38 Engine PlatformDocument19 paginiService Drawings: KTA38 Engine PlatformMehdi Chakroune100% (1)

- QSK60 G6 PDFDocument2 paginiQSK60 G6 PDFShahzad Ali100% (2)

- Data Sheet 1013ec PumpDocument6 paginiData Sheet 1013ec PumpJulio Alvarado MoralesÎncă nu există evaluări

- Damage Form - en 2210649 DMH GG#2 P145 Crankcase Problem 20-06-14Document4 paginiDamage Form - en 2210649 DMH GG#2 P145 Crankcase Problem 20-06-14aravindhana1a1Încă nu există evaluări

- Pompa Kew Pump Tipe CM, FM, KSDocument5 paginiPompa Kew Pump Tipe CM, FM, KSPurnomo NugrohoÎncă nu există evaluări

- 04 Turbo PDFDocument26 pagini04 Turbo PDFFabioMacielÎncă nu există evaluări

- MAN Diesel L28/32A-VO: Project GuideDocument222 paginiMAN Diesel L28/32A-VO: Project GuideИгорь100% (2)

- MCOT 049tanks FiscalisationDocument18 paginiMCOT 049tanks FiscalisationLembang ApangÎncă nu există evaluări

- McCormick C-L Europa Tier 3 (2008-2015) - RS51 - C80L Tractor Service Repair Manual PDFDocument29 paginiMcCormick C-L Europa Tier 3 (2008-2015) - RS51 - C80L Tractor Service Repair Manual PDFfjkkekmdmÎncă nu există evaluări

- 3885019 (2)Document2 pagini3885019 (2)acere18100% (2)

- Kta19 G3Document2 paginiKta19 G3ryan fernandezÎncă nu există evaluări

- NTA855-G6: 1500 RPM Generator DriveDocument2 paginiNTA855-G6: 1500 RPM Generator DriveUnit Alkal100% (1)

- Caterpillar KTA50-G9 Spec SheetDocument2 paginiCaterpillar KTA50-G9 Spec Sheet배광득100% (1)

- Chevy 350 V 8Document177 paginiChevy 350 V 8Jamey Basham83% (12)

- Screemin EagleDocument97 paginiScreemin EagleSerban DraganÎncă nu există evaluări

- 709 LP BsiiDocument366 pagini709 LP BsiiflytorahulÎncă nu există evaluări

- Dragsted History Booklet 2013 PDFDocument98 paginiDragsted History Booklet 2013 PDFTapas ChaudhuriÎncă nu există evaluări

- Lancer Evolutionviii PDFDocument347 paginiLancer Evolutionviii PDFKavinda MadhusankaÎncă nu există evaluări

- D4GA - EURO4 For MightyDocument41 paginiD4GA - EURO4 For Mightykingtiger.bkÎncă nu există evaluări

- MGPlistDocument2.217 paginiMGPlistSUPRIYA NANDI100% (2)

- Dokumen - Tips - Same Laser 90 100 110 130 150 170 Repair Manual TractorDocument28 paginiDokumen - Tips - Same Laser 90 100 110 130 150 170 Repair Manual TractorDiogo A D AgostinhoÎncă nu există evaluări

- Ignition & ElectronicsDocument16 paginiIgnition & Electronicswordpower777Încă nu există evaluări

- Nissan Tiida C11 2010 Engine Mechanical PDFDocument233 paginiNissan Tiida C11 2010 Engine Mechanical PDFalejandro sanchez100% (1)

- Glosario de Terminos CAT en Ingles PDFDocument92 paginiGlosario de Terminos CAT en Ingles PDFRicardo AndradeÎncă nu există evaluări

- 14 - Manual Motor WeichaiDocument220 pagini14 - Manual Motor WeichaiJoão Paulo Gobbo AugustoÎncă nu există evaluări

- Suspension Assemblies: Service Manual For SAF Axles andDocument55 paginiSuspension Assemblies: Service Manual For SAF Axles andWaldemar JęczewskiÎncă nu există evaluări

- XL 125 v1Document33 paginiXL 125 v1Oscar SolanoÎncă nu există evaluări

- CT100 (1!30!2015) With New DecalsDocument53 paginiCT100 (1!30!2015) With New DecalsGAYLE GO100% (1)

- KORANDO 2 Montagem Do MotorDocument28 paginiKORANDO 2 Montagem Do Motorcrisprusch1gmailcomÎncă nu există evaluări

- John Deere 400 Lawn Garden Tractor Service Manual PDFDocument17 paginiJohn Deere 400 Lawn Garden Tractor Service Manual PDFWalter Lazo33% (3)

- Subaru Cadena Outback 3.0Document10 paginiSubaru Cadena Outback 3.0801400Încă nu există evaluări

- Mack September 2016 New Monthly Releases PV776-K-MP8 EPA2007 Engine TOCDocument7 paginiMack September 2016 New Monthly Releases PV776-K-MP8 EPA2007 Engine TOCGustampa TampaÎncă nu există evaluări

- 11 Engine ComponentsDocument42 pagini11 Engine ComponentsEdwinGeorgeParuvananyÎncă nu există evaluări

- Bajaj Re-205-&-Re-205-D-SpcDocument135 paginiBajaj Re-205-&-Re-205-D-SpcSamseer UÎncă nu există evaluări

- IB-303 - NS 200 NS-Fi RS200 - Modification of Cylinder Head AsslyDocument4 paginiIB-303 - NS 200 NS-Fi RS200 - Modification of Cylinder Head AsslyDeibid RVÎncă nu există evaluări

- 2012 Offroad Pa 4-27 47 enDocument13 pagini2012 Offroad Pa 4-27 47 enJacob Jack YoshaÎncă nu există evaluări

- CH 02Document9 paginiCH 02Niño PerezÎncă nu există evaluări

- 3.0l Engine With Variable TimingDocument150 pagini3.0l Engine With Variable TimingMichael Kosarev100% (3)

- Byt BZB 1 8 Tsfi Eng UnlockedDocument51 paginiByt BZB 1 8 Tsfi Eng Unlockedlugui8188Încă nu există evaluări

- Catalogo de Servicos I Td226b Eng Rev1 2011Document26 paginiCatalogo de Servicos I Td226b Eng Rev1 2011AndreyIvanov100% (1)

- Maximum BoostDocument251 paginiMaximum BoostemomoÎncă nu există evaluări

- Stella-4T Service Station Manual PDFDocument178 paginiStella-4T Service Station Manual PDFVroum Vroumvroum100% (1)

- 1.3 PART III - Engine Construction and Engine Conponenets PDFDocument105 pagini1.3 PART III - Engine Construction and Engine Conponenets PDFSiraye AbirhamÎncă nu există evaluări

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Workbook to Accompany Maintenance & Reliability Best PracticesDe la EverandWorkbook to Accompany Maintenance & Reliability Best PracticesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDe la EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!De la EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Încă nu există evaluări

- Practical Reservoir Engineering and CharacterizationDe la EverandPractical Reservoir Engineering and CharacterizationEvaluare: 4.5 din 5 stele4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsDe la EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsÎncă nu există evaluări

- A Complete Guide to Safety Officer Interview Questions and AnswersDe la EverandA Complete Guide to Safety Officer Interview Questions and AnswersEvaluare: 4 din 5 stele4/5 (1)

- Renewable Energy: A Very Short IntroductionDe la EverandRenewable Energy: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDe la EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successEvaluare: 4.5 din 5 stele4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977De la EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Încă nu există evaluări

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Global Landscape of Renewable Energy FinanceDe la EverandGlobal Landscape of Renewable Energy FinanceÎncă nu există evaluări

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDe la EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerÎncă nu există evaluări

- Guidelines for Auditing Process Safety Management SystemsDe la EverandGuidelines for Auditing Process Safety Management SystemsÎncă nu există evaluări

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsDe la EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDe la EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsEvaluare: 4 din 5 stele4/5 (11)

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări