Documente Academic

Documente Profesional

Documente Cultură

LEACH Hermetically Sealed Relay Relais Hermetique M320

Încărcat de

GIUSEPPEDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LEACH Hermetically Sealed Relay Relais Hermetique M320

Încărcat de

GIUSEPPEDrepturi de autor:

Formate disponibile

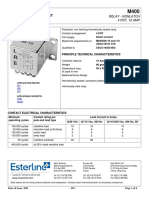

M320

ENGINEERING DATA SHEET RELAY - NONLATCH

1 PDT, 25 AMP

Polarized, non latching hermetically sealed relay

Contact arrangement 1 PDT

Coil supply Direct current

Meets the requirements of MIL-R-6106/19

Qualified to CECC16101-031

CECC16103-809

PRINCIPLE TECHNICAL CHARACTERISTICS

Contacts rated at 28 Vdc; 115 Vac, 400 Hz

Weight 45 grams max

Dimensions max. 26 x 25.7 x 13.3

of case in mm

Balanced-force design

Hermetically sealed, corrosion protected metal can

APPLICATION NOTES:

001

007

023

APPLICABLE SOCKET:

S320

CONTACT ELECTRICAL CHARACTERISTICS

Minimum Contact rating per Load Current in Amps

operating cycles pole and load type

@28 Vdc @115 Vac, 400 Hz

50,000 cycles resistive load 25 25

10,000 cycles inductive load (L/R=5ms) 12 12

50,000 cycles motor load 10 10

50,000 cycles lamp load 5 5

50 cycles resistive overload 50 80

200,000 cycles at 25% rated resistive load

AMERICAS EUROPE ASIA

6900 Orangethorpe Ave. 2 Rue Goethe Units 602-603 6/F Lakeside 1

P.O. Box 5032 57430 Sarralbe No.8 Science Park West Avenue

Buena Park, CA 90622 France Phase Two, Hong Kong Science Park

Featuring LEACH power and control solutions . . Pak Shek Kok, Tai Po, N.T.

www.leachintl.com . . Hong Kong

Tel: (01) 714-736-7599 Tel: (33) 3 87 97 31 01 Tel: (852) 2 191 3830

Fax: (01) 714-670-1145 Fax: (33) 3 87 97 96 86 Fax: (852) 2 389 5803

Data sheets are for initial product selection and comparison. Contact Esterline Power Systems prior to choosing a component.

Date of issue: 9/07 - 157 - Page 1 of 4

COIL CHARACTERISTICS (Vdc) M320

CODE A B C N

Nominal operating voltage 28 12 6 28

Maximum operating voltage 29 14.5 7.3 29

Maximum pick-up voltage at +125 C 18 9 4.5 18

Maximum drop-out voltage at -65 C 1.5 0.7 0.35 1.5

Coil resistance 10% at +25 C 320 80 20 320

Back EMF suppressed to (Vdc) N/A N/A N/A -42

GENERAL CHARACTERISTICS

Temperature range -65C to +125C

Dielectric strength at sea level

- Contacts to ground and between contacts 1250 Vrms / 50 Hz

- Coil to ground 1000 Vrms / 50 Hz

Dielectric strength at altitude 25,000 m (all points) 350 Vrms / 50 Hz

Initial insulation resistance at 500 Vdc 100 M min.

Sinusoidal vibration (except G and O mounting) 30G / 75 to 3000 Hz

Sinusoidal vibration (G and O mounting only) 20G / 75 to 3000 Hz

Shock (except G and O mounting) 200G / 6 ms

Shock (G and O mounting only) 50G / 11 ms

Maximum contact opening time under vibration and shock 10 s

Operate time at nominal voltage 10 ms max

Release time 10 ms max

Bounce time 1 ms max

Contact voltage drop at nominal current

- initial value 150 mV max

- after life 175 mV max

Date of issue: 9/07 - 158 - Page 2 of 4

MOUNTING STYLES M320

2 5

25.7

A B D

MAX 0.1 1

7.5

0.5

4

0.15

4 0.15

M3 4

13.3 12.3

3.8

MAX MAX

CONTRASTING BEAD 0.15 35.5

26 MAX 35.7

36.7

44 MAX 44 MAX

M3.5 OR

6.32 UNC 2A

1.2 9.5

MAX

3.8

G : UNC

J

O : SI M3.5

12.7

12.3

MAX

1

8 MAX

=

35.5 = 15.9 =

36.7

44 MAX

Dimensions in mm

Tolerances, unless otherwise specified, 0.25mm

TERMINAL TYPES

0.05

1.01

5.08 11

5.9

2.360.05 0.05

1.6

+0.03

2.360.05

1.6 -0.05 +0.05

2.36-0.025

16

SILICON GASKET

SHORE A15-30

1 2 4

0.1

1.3

0.5

6.35 7.1 MAX 0.5 7.6

9.5

0.5

15.9

TIN PLATED PINS SOLDER HOOKS GOLD PLATED PINS

Date of issue: 9/07 - 159 - Page 3 of 4

SCHEMATIC DIAGRAM M320

BOTTOM VIEW, DE-ENERGIZED COIL

N COIL

1 -X2 2 3 1 -X2 2 3

C

A + A +

E

+X1 +X1

CE: COIL SUPPRESSION

NUMBERING SYSTEM

M320 A 1 A C ER

Basic series designation__________________________| | | | | |

1-Mounting Style (A,B,C,D,J,K,G,O,R)____________________| | | | |

2-Terminal Types (1,2,4,8)__________________________________| | | |

3-Coil Voltage (A,B,C,N)________________________________________| | |

4-See Note [4] Below________________________________________________| |

5-See Note [5] Below____________________________________________________|

NOTES

1. Relays with mounting styles B,D and terminal type 4 are compatible with socket families S320...

2. Isolation spacer pads for PCB mounting available on request.

3. For other mounting styles or terminal types, please contact the factory.

[4]. Options

- C: Circuit breaker compatibility 30 A / 1 hour; 50 A / 5 sec; 100 A / 1.2 sec 250 A / 0.2 sec;

350 A /0.1 sec

- D: low level: 10 A / 10 mV

[5]. Quality level:

- D005: Model qualified to CECC16101-031

- D006: Model qualified to CECC16103-809

- ER: Please contact factory.

TYPICAL CHARACTERISTICS

Coil resistance/temperature change: See application note no. 001

Date of issue: 9/07 - 160 - Page 4 of 4

Application notes N001

CORRECTION DUE TO COIL COPPER WIRE RESISTANCE

CHANGE IN TEMPERATURE

1.8

1.6

Correction coefficient

1.4

1.2

0.8

0.6

-80 -30 20 70 120 170

Temperature ( C)

Nominal Resistance at 25C Nominal Resistance at 20C

Example: Coil resistance at 25C: 935 ohms. What is it at 125C?

Correction coefficient on diagram is: 1.39 at 125C. R becomes: 935x1.39=1299 Ohms

Correction also applies to operating voltages

Date of issue: 3/06 -1- Page 1 of 1

Application notes N007

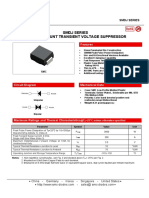

SUPPRESSOR DEVICES FOR RELAY COILS

The inductive nature of relay coils allows them to create magnetic forces which are converted to mechanical movements to

operate contact systems. When voltage is applied to a coil, the resulting current generates a magnetic flux, creating

mechanical work. Upon deenergizing the coil, the collapasing magnetic field induces a reverse voltage (also known as back

EMF) which tends to maintain current flow in the coil. The induced voltage level mainly depends on the duration of the

deenergization. The faster the switch-off, the higher the induced voltage.

All coil suppression networks are based on a reduction of speed of current decay. This reduction may also slow down the

opening of contacts, adversly effecting contact life and reliability. Therefore, it is very important to have a clear understanding

of these phenomena when designing a coil suppression circuitry.

Typical coil characteristics

On the graph below, the upper record shows the contacts state. (High level NO contacts closed, low level NC contacts

closed, intermediate state contact transfer). The lower record shows the voltage across the coil when the current is switched

off by another relay contact.

The surge voltage is limited to -300V by the arc generated across contact poles. Discharge duration is about 200

mircoseconds after which the current change does not generate sufficient voltage. The voltage decreases to the point where

the contacts start to move, at this time, the voltage increases due to the energy contained in the NO contact springs. The

voltage decreases again during transfer, and increases once more when the magnetic circuit is closed on permanent

magnet.

Operating times are as follows:

Time to start the movement 1.5ms

Total motion time 2.3ms

Transfer time 1.4ms

Contact State

Date of issue: 6/00 -8- Page 1 of 4

Types of suppressors:

Passive devices.

The resistor capacitor circuit

It eliminates the power dissipation problem, as well as fast voltage rises. With a proper match between coil and resistor,

approximate capacitance value can be calculated from:

C = 0.02xT/R, where

T = operating time in milliseconds

R = coil resistance in kiloOhms

C = capacitance in microFarads

The series resistor must be between 0.5 and 1 times the coil resistance. Special consideration must be taken for the

capacitor inrush current in the case of a low resistance coil.

The record shown opposite is performed on the same relay as above. The operation time becomes:

- time to start the movement 2.3ms

- transfer time 1.2ms

The major difficulty comes from the capacitor volume. In our example of a relay with a 290 coil and time delay of 8 ms, a

capacitance value of C=0.5 uF is found. This non polarized capacitor, with a voltage of 63V minimum, has a volume of about

1cm3. For 150V, this volume becomes 1.5 cm3.

Date of issue: 6/00 -9- Page 2 of 4

The bifilar coil

The principle is to wind on the magnetic circuit of the main coil a second coil shorted on itself. By a proper adaptation of the

internal resistance of this second coil it is possible to find an acceptable equilibrium between surge voltage and reduction of

the opening speed. To be efficient at fast voltage changes, the coupling of two coils must be perfect. This implies embedded

windings. The volume occupied by the second coil reduces the efficiency of the main coil and results in higher coil power

consumption. This method cannot be applied efficiently to products not specifically designed for this purpose.

The resistor (parallel with the coil)

For efficient action, the resistor must be of the same order of magnitude as the coil resistance. A resistor 1.5 times the coil

resistance will limit the surge to 1.5 times the supply voltage. Release time and opening speed are moderately affected. The

major problem is the extra power dissipated.

Semi-conductor devices

The diode

It is the most simple method to totally suppress the surge voltage. It has the major disadvantage of the higher reduction of

contact opening speed. This is due to the total recycling, through the diode, of the energy contained in the coil itself. The

following measurement is performed once again on the same relay. Operation times are given by the upper curve:

- time to start the movement 14ms

- transfer time 5ms

These times are multiplied by a coefficient from 4 to 8.

The lower curve shows the coil current. The increase prior to NO contact opening indicates that the contact spring dissipates

its energy. At the opening time the current becomes constant as a result of practically zero opening speed.

Due to this kind of behavior, this type of suppression must be avoided for power relays. For small relays which have to switch

low currents of less than 0.2 A, degradation of life is not that significant and the method may be acceptable.

Date of issue: 6/00 - 10 - Page 3 of 4

The diode + resistor network

It eliminates the inconvenience of the resistor alone, explained above, and it limits the action of a single diode. It is now

preferred to used the diode + zener network.

The diode + zener network

Like the resistor, the zener allows a faster decurrent decay. In addition it introduces a threshold level for current conduction

which avoids the recycling of energy released during contact movement.

The lower curve on the opposite record demonstrates those characteristics. Voltage limitation occurs at 42V. The two

voltages spikes generated by internal movement are at lower levels than zener conduction. As a result, no current is recycled

in the coil.

The opening time phases are as follows:

- time to start the movement 2.6ms

- total motion time 2.4ms

- transfer time 1.4ms

The release time is slightly increased. The contacts' opening speed remains unchanged.

Date of issue: 6/00 - 11 - Page 4 of 4

Application notes N023

MOUNTING DISTANCE BETWEEN RELAYS

Applicable to M2XX / M3XX / M4XX / M5XX

Definition and applicability

This application note defines the minimum distance between relays to maintain the whole performances of the

relays as given in our data sheets.

Phenomenon analysis

Each relay generates a magnetic field either when relay is de-energised because of the permanent magnet or in

the energised position because of permanent magnet and coil. The magnetic field generated by one relay could

affect the performance of another relay when the below minimum distance between relay is not respected. If the

relays are mounted adjacent to each other, it is advisable to alternate direction of magnetic path on every other unit

and to keep a 1.6 mm space between relays, figure A. Or when mounted in the same direction, separate each

relay from the other by 3.2 mm, figure B. If two or more rows of relays are installed, allow clearance of 3.2 mm

between rows, figures C and D. Provide 4.8 mm space between relays if used in opposition, figure E. Distance

in millimetre.

Date of issue: 9/07 - 25 - Page 1 of 1

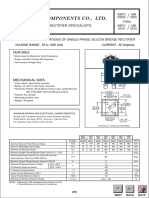

S320

ENGINEERING DATA SHEET RELAY SOCKET

25 AMP

BASIC SOCKET SERIES DESIGNATION FOR:

Series M320

GENERAL CHARACTERISTICS

Crimp tool M 22520/1-01 with turret M 22520/1-02 or MS 3191-1

Insertion and extraction tool NAS 1664-12 / 1664-16.

Weight 25g max.

Temperature range -70 C to +125 C.

This connection is designed to the standards and requirements of MIL-S-12883 Contacts and hardware to be delivered disassembled in

a plastic bag. Tolerances, unless otherwise, specified 0.25mm.

AMERICAS EUROPE ASIA

6900 Orangethorpe Ave. 2 Rue Goethe Units 602-603 6/F Lakeside 1

P.O. Box 5032 57430 Sarralbe No.8 Science Park West Avenue

Buena Park, CA 90622 France Phase Two, Hong Kong Science Park

Featuring LEACH power and control solutions . . Pak Shek Kok, Tai Po, N.T.

www.esterline.com . . Hong Kong

Tel: (01) 714-736-7599 Tel: (33) 3 87 97 31 01 Tel: (852) 2 191 3830

Fax: (01) 714-670-1145 Fax: (33) 3 87 97 96 86 Fax: (852) 2 389 5803

Data sheets are for initial product selection and comparison. Contact Esterline Power Systems prior to choosing a component.

Date of issue: 3/06 - 21 - Page 1 of 3

TERMINAL LAYOUT S320

CODE B S320 MOUNTING HOLE LAYOUT

16.0 35.7 0.1

11.0

0.3

5.9

14.1

3 2 X2

1

5.08

28.2 0.3

X1

FOR HOLE CLEARANCE,

SEE HARDWARE CODE

MOUNTING HARDWARE

CODE 1 : 05-284-12 CODE 2 : 05-284-00 CODE 3 : 05-284-07

LOOSE UNC HARDWARE LOOSE METRIC HARDWARE LOOSE METRIC HARDWARE

BOTTOM MOUNT TOP MOUNT TOP MOUNT

2.4 MAX

4.0 MAX

4.0

MOUNTING TORQUE

NUT 4/40:0,45 0,1 Nm

NUT 10-32:1,2 MAX

:3,6 mm

MOUNTING TORQUE:0,45 0,1 Nm MOUNTING TORQUE:0,45 0,1 Nm

:3,6 mm :3,6 mm

CODE 6 : 05-284-13 CODE 7 : 05-284-15

UNC HARDWARE METRIC HARDWARE

TOP MOUNT

BOTTOM MOUNT TOP MOUNT

1.2

1.2

1.2

MOUNTING TORQUE:0,45 0,1 Nm

FOR RELAYS WITH CODE B TERMINALS

MOUNTING HOLE:3,6 mm

MOUNTING TORQUE:0,45 0,1 Nm

MOUNTING HOLE:3,6 mm MOUNTING HOLE:3,6 mm

CODE 8 : 05-284-20 CODE 9 : 05-284-21

LOOSE UNC STUDS MIL-S-12883/41 - EDIT C FIXED UNC STUDS PER MIL-S-12883/41 - EDIT C

BOTTOM MOUNT TOP MOUNT BOTTOM MOUNT TOP MOUNT

2.4 MAX

2.4

3.2 MAX

3.2

MOUNTIONG TORQUE: NUT 4/40:0,45 0,1 Nm - NUT 10-32: 1,2 MAX MOUNTING TORQUE: NUT 4/40:0,45 0,1 Nm - NUT 10-32: 1,2 MAX

MOUNTING HOLE: 5,3 mm MOUNTING HOLE: 3,6 mm MOUNTING HOLE: 5,3 mm MOUNTING HOLE: 3,6 mm

Date of issue: 3/06 - 22 - Page 2 of 3

GROMMET TO SEAL ON WIRE INSULATION DIA S320

Code A

Diam from 2.8 ......3.4mm

CONTACT SIZE AND STYLE

Code 8 Crimp end to Code 10 Crimp end to

05 910 00 accomodate 05 910 01 accomodate

AWG12-14 AWG16

Contact mating end #12 Contact mating end #12

Coil contacts X1-X2 Crimp end to Coil contacts X1-X2 Crimp end to

05 911 00 accomodate 05 910 01 accomodate

AWG16-18-20 AWG16-18-20

Contact mating end #16 Contact mating end #16

Code 0 Without contacts Code 11 MIL-C-39029/92-535 Code 13 MIL-C-39029/92-536

30 976 00 Bin Code color bands 31 099 00 Bin Code color bands

or Bin Code numbering or Bin Code numbering

on crimpside on crimpside

Crimp end to accomodate Crimp end to accomodate

AWG 12 AWG 16

Contact mating end #12 Contact mating end #12

Coil contacts MIL-C-39029/92-533 Coil contacts MIL-C-39029/92-533

X1-X2 Bin Code color bands X1-X2 Bin Code color bands

30 315 00 or Bin Code numbering 30 315 00 or Bin Code numbering

on crimpside on crimpside

Crimp end to accomodate Crimp end to accomodate

AWG16-18-20 AWG16-18-20

Contact mating end #16 Contact mating end #16

SOCKET NUMBERING SYSTEM

S320 A 1 A 8

1-Basic socket designation________________________| | | | |

2-Terminal Layout_____________________________________| | | |

3-Mounting Hardware_______________________________________| | |

4-Grommet to seal on wire insulation__________________________| |

5-Contact size and style___________________________________________|

Date of issue: 3/06 - 23 - Page 3 of 3

S-ar putea să vă placă și

- HagerDocument209 paginiHagerJack Elhaq100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Technical Info Temperature Sensor 22 (FAE 33160)Document2 paginiTechnical Info Temperature Sensor 22 (FAE 33160)GIUSEPPEÎncă nu există evaluări

- AK Training - Common Rail Diesel Fuel SystemsDocument61 paginiAK Training - Common Rail Diesel Fuel Systemslongtrandang5867100% (20)

- AK Training - Common Rail Diesel Fuel SystemsDocument61 paginiAK Training - Common Rail Diesel Fuel Systemslongtrandang5867100% (20)

- Repair Autocom CDP VCIDocument5 paginiRepair Autocom CDP VCIAdi Catanescu100% (2)

- Cummins ISX-CM570: Electrical Circuit DiagramDocument12 paginiCummins ISX-CM570: Electrical Circuit DiagramEduar Ortega100% (5)

- Hermetically Sealed Relay - Ukm300Document20 paginiHermetically Sealed Relay - Ukm300ATR Assistência Técnica (ATR)Încă nu există evaluări

- M400 D4N 003Document19 paginiM400 D4N 003Mian FahimÎncă nu există evaluări

- User Manual 1374484Document12 paginiUser Manual 1374484gutierkÎncă nu există evaluări

- Eng DS KCS03X 885Document8 paginiEng DS KCS03X 885clipclapÎncă nu există evaluări

- Advanced Switching Solutions: FeaturesDocument4 paginiAdvanced Switching Solutions: Featuresraza239Încă nu există evaluări

- Rectron: SemiconductorDocument2 paginiRectron: SemiconductorFrancisco Fernando SouzaÎncă nu există evaluări

- Automotive Relays PCB Single Relays: F076 - fcw2bDocument4 paginiAutomotive Relays PCB Single Relays: F076 - fcw2bdanythe007Încă nu există evaluări

- Datasheet Moc 4030 PDFDocument4 paginiDatasheet Moc 4030 PDFMarcelituz RojasÎncă nu există evaluări

- Moc3040 EtcDocument4 paginiMoc3040 EtcYasser AbrahantesÎncă nu există evaluări

- Schrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysDocument4 paginiSchrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysWilson Rubiano AlfaroÎncă nu există evaluări

- R404N02000 27 04 17a-2501314-DatasheetDocument3 paginiR404N02000 27 04 17a-2501314-DatasheetsanetÎncă nu există evaluări

- MB352W RectronElectronicEnterpriseDocument2 paginiMB352W RectronElectronicEnterpriseJerzy RistujczinÎncă nu există evaluări

- Optically Coupled Bilateral Switch Non-Zero Crossing TriacDocument3 paginiOptically Coupled Bilateral Switch Non-Zero Crossing TriacElectronicos CaldasÎncă nu există evaluări

- SMDJ Series N1696 Rev.aDocument6 paginiSMDJ Series N1696 Rev.aDaniel NavaÎncă nu există evaluări

- Ev200haana RelayDocument2 paginiEv200haana RelaySJS68Încă nu există evaluări

- FR301 7Document2 paginiFR301 7Leonel MessiÎncă nu există evaluări

- SBL2030PT, SBL2040PT: Vishay General SemiconductorDocument4 paginiSBL2030PT, SBL2040PT: Vishay General SemiconductortallertecuÎncă nu există evaluări

- TE Connectivity AMP 4 1393238 7 DatasheetDocument2 paginiTE Connectivity AMP 4 1393238 7 DatasheetastizeÎncă nu există evaluări

- PCB Relay: NRP - 17 - C - 12DDocument2 paginiPCB Relay: NRP - 17 - C - 12DZaman SahibÎncă nu există evaluări

- 1.0A Schottky Barrier Rectifier: DO-41 Plastic Dim Min Max A B C D All Dimensions in MMDocument2 pagini1.0A Schottky Barrier Rectifier: DO-41 Plastic Dim Min Max A B C D All Dimensions in MMRicardo LimonÎncă nu există evaluări

- GV240 Series: Advanced Switching SolutionsDocument7 paginiGV240 Series: Advanced Switching SolutionsBiagio PadulaÎncă nu există evaluări

- Cheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESDocument2 paginiCheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESThomas ThomasÎncă nu există evaluări

- LM4001 THRU LM4007: FeaturesDocument2 paginiLM4001 THRU LM4007: FeaturesSetyo RiniÎncă nu există evaluări

- Jameco Part Number 95038ISOCOM: Distributed byDocument4 paginiJameco Part Number 95038ISOCOM: Distributed bymejmakÎncă nu există evaluări

- Moc 3030Document4 paginiMoc 3030Chava Hernandez RamírezÎncă nu există evaluări

- Moc3031 PDFDocument3 paginiMoc3031 PDFINGWIRBOÎncă nu există evaluări

- Moc 3031Document3 paginiMoc 3031raveendraÎncă nu există evaluări

- Schrack Force Guided Relay SR2MDocument3 paginiSchrack Force Guided Relay SR2MyandexÎncă nu există evaluări

- Schrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysDocument3 paginiSchrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysJadi PurwonoÎncă nu există evaluări

- 1 C/O Relay Interface ModulesDocument9 pagini1 C/O Relay Interface ModulesHoang Nam NguyenÎncă nu există evaluări

- EV500 Series DC ContactorDocument8 paginiEV500 Series DC ContactorDIEGO VICENTE SANCHEZÎncă nu există evaluări

- IS P627 DatasheetDocument2 paginiIS P627 Datasheetucb51525354Încă nu există evaluări

- MBRD20100TDocument4 paginiMBRD20100TDuta HastaÎncă nu există evaluări

- Moc3030, Moc3031, Moc3032, Moc 3033Document2 paginiMoc3030, Moc3031, Moc3032, Moc 3033lopezgarciajosericardoÎncă nu există evaluări

- Schrack Power PCB Relay RPII/2: General Purpose Relays PCB RelaysDocument2 paginiSchrack Power PCB Relay RPII/2: General Purpose Relays PCB RelaysCor GratÎncă nu există evaluări

- MK21 Series Reed Sensors: M K 2 1 / X - 0 X 0 0 X - 0 0 0 XDocument3 paginiMK21 Series Reed Sensors: M K 2 1 / X - 0 X 0 0 X - 0 0 0 XFajrulIqbalMubarokÎncă nu există evaluări

- Disc Onti Nue D: MB3505 Thru MB3510Document4 paginiDisc Onti Nue D: MB3505 Thru MB3510Rudi AlfadliÎncă nu există evaluări

- Datasheet (Puente de Diodos - MB6S)Document3 paginiDatasheet (Puente de Diodos - MB6S)camilo portelaÎncă nu există evaluări

- Relafy 30 Amps T Typfe RelfayDocument2 paginiRelafy 30 Amps T Typfe RelfayMarudhasalamMarudhaÎncă nu există evaluări

- MJD340 (NPN) MJD350 (PNP) High Voltage Power Transistors: DPAK For Surface Mount ApplicationsDocument5 paginiMJD340 (NPN) MJD350 (PNP) High Voltage Power Transistors: DPAK For Surface Mount ApplicationsBertrand Soppo YokiÎncă nu există evaluări

- 2KBP005M/3N253 - 2KBP10M/3N259: Bridge RectifiersDocument4 pagini2KBP005M/3N253 - 2KBP10M/3N259: Bridge RectifiersDaniel G Zeballos AsconaÎncă nu există evaluări

- Galaxy Electrical: Surface Mount RectifierDocument2 paginiGalaxy Electrical: Surface Mount RectifierVan HuynhÎncă nu există evaluări

- LL103A, LL103B, LL103C: Vishay SemiconductorsDocument4 paginiLL103A, LL103B, LL103C: Vishay SemiconductorsDiego CapezioÎncă nu există evaluări

- S3a Series - L1708-1224229Document7 paginiS3a Series - L1708-1224229Cristián CardonaÎncă nu există evaluări

- DatasheetDocument2 paginiDatasheetSebas EcharteÎncă nu există evaluări

- KG-K111 - Latching Relay - Data Sheet - 052017Document3 paginiKG-K111 - Latching Relay - Data Sheet - 052017pratik gautamÎncă nu există evaluări

- D25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierDocument4 paginiD25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierAlejandro RomeroÎncă nu există evaluări

- ENG DS PCN Series Relay Data Sheet E 0820-728817Document3 paginiENG DS PCN Series Relay Data Sheet E 0820-728817servicoMITÎncă nu există evaluări

- 1N5391G THRU 1N5399G: Chenyi ElectronicsDocument3 pagini1N5391G THRU 1N5399G: Chenyi ElectronicsJoel GOMES ALVESÎncă nu există evaluări

- SBL3030PT, SBL3040PT: Vishay General SemiconductorDocument4 paginiSBL3030PT, SBL3040PT: Vishay General Semiconductorrammstein4445Încă nu există evaluări

- Power Relay F7: Automotive Relays Plug-In Maxi ISO RelaysDocument3 paginiPower Relay F7: Automotive Relays Plug-In Maxi ISO RelaysAHMAD NUR IMAMÎncă nu există evaluări

- Datasheet PDFDocument2 paginiDatasheet PDFnassarkiÎncă nu există evaluări

- KBPC5010Document2 paginiKBPC5010FarhanÎncă nu există evaluări

- DC Components Co., LTD.: Rectifier SpecialistsDocument2 paginiDC Components Co., LTD.: Rectifier Specialistsandree wÎncă nu există evaluări

- Datasheet PDFDocument2 paginiDatasheet PDFnassarkiÎncă nu există evaluări

- KBPC5010Document2 paginiKBPC5010SilvioÎncă nu există evaluări

- SMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFDocument4 paginiSMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFAntoni MonteroÎncă nu există evaluări

- DS9502 ESD Protection Diode: Special Features Symbol and ConventionsDocument3 paginiDS9502 ESD Protection Diode: Special Features Symbol and Conventionsshijith. ppÎncă nu există evaluări

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionDe la EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionEvaluare: 5 din 5 stele5/5 (1)

- 6 Arb ObdDocument43 pagini6 Arb ObdGIUSEPPEÎncă nu există evaluări

- Brochure Reduced FlangeDocument2 paginiBrochure Reduced FlangeGIUSEPPEÎncă nu există evaluări

- Catalogue Backshells PDFDocument24 paginiCatalogue Backshells PDFGIUSEPPEÎncă nu există evaluări

- Cold-Starting Gasoline Engine (ETAS RT - 2007!01!16 - En)Document1 paginăCold-Starting Gasoline Engine (ETAS RT - 2007!01!16 - En)GIUSEPPEÎncă nu există evaluări

- Model Based Control and Efficient Calibration For Crank To Run TransitionDocument173 paginiModel Based Control and Efficient Calibration For Crank To Run TransitionGIUSEPPEÎncă nu există evaluări

- Introduction Into Automotive Electronics DesignDocument39 paginiIntroduction Into Automotive Electronics DesignGIUSEPPE100% (1)

- Power Ground and Signal GroundDocument1 paginăPower Ground and Signal GroundGIUSEPPEÎncă nu există evaluări

- DO160F To G Change SummaryDocument23 paginiDO160F To G Change SummaryGIUSEPPEÎncă nu există evaluări

- Ground PracticesDocument7 paginiGround PracticesGIUSEPPEÎncă nu există evaluări

- Ece R 110 CNGDocument179 paginiEce R 110 CNGGoran KosticÎncă nu există evaluări

- SAE J1939 Messages 2Document6 paginiSAE J1939 Messages 2GIUSEPPE100% (3)

- REF541 Guide EngDocument68 paginiREF541 Guide Eng021804Încă nu există evaluări

- Motor Starter CircuitDocument14 paginiMotor Starter CircuitMyo SeinÎncă nu există evaluări

- DIP ManualDocument386 paginiDIP ManualRajnikant AgrawalÎncă nu există evaluări

- B 1 22 KV 1.2,2.4&3 MVAr Cap Bank Infra Spec 240709Document52 paginiB 1 22 KV 1.2,2.4&3 MVAr Cap Bank Infra Spec 240709balwant singh negiÎncă nu există evaluări

- Chapter Two Literature ReviewDocument18 paginiChapter Two Literature ReviewAhmedÎncă nu există evaluări

- Diagrama Electrico de Camion Volquete-Www - Mineriacapma.blogspotDocument2 paginiDiagrama Electrico de Camion Volquete-Www - Mineriacapma.blogspotJose Luis Tairo Vega - Tave100% (2)

- DSB 240LHDocument96 paginiDSB 240LHGuillermo HernandezÎncă nu există evaluări

- Demand SuppressionDocument20 paginiDemand SuppressionShin QuinnÎncă nu există evaluări

- Mercedes-Benz C-Class (W203 2000-2007) Fuses and RelaysDocument24 paginiMercedes-Benz C-Class (W203 2000-2007) Fuses and RelaysSilvio Madety100% (2)

- TB ShootDocument169 paginiTB Shootashwini100% (1)

- Maintain. TrainingDocument2 paginiMaintain. TrainingNayanÎncă nu există evaluări

- Ax V Manual - EngDocument41 paginiAx V Manual - EngtrutleptÎncă nu există evaluări

- IMS2 Manual EngDocument61 paginiIMS2 Manual EngJhonatan BuenoÎncă nu există evaluări

- Electro Control Equipment:: Relay Circuit UnitDocument14 paginiElectro Control Equipment:: Relay Circuit UnitMarshella Faye CaguranganÎncă nu există evaluări

- M-Line Range Catalogue - MNX (3P), MCX (4P), MX, MX0 ControlDocument22 paginiM-Line Range Catalogue - MNX (3P), MCX (4P), MX, MX0 ControlUlhas Vajre100% (1)

- 7sr17 Rho Catalogue SheetDocument20 pagini7sr17 Rho Catalogue Sheetapi-241473079Încă nu există evaluări

- Nissan Xterra Transfer CaseDocument136 paginiNissan Xterra Transfer CaseJersey Zhang100% (6)

- MCCDocument135 paginiMCCmrwizzard19880% (1)

- Uenr22290001 RBT 1 - 171Document14 paginiUenr22290001 RBT 1 - 171Anderson Oliveira SilvaÎncă nu există evaluări

- TH360B Plano Sistema ElectricoDocument4 paginiTH360B Plano Sistema ElectricoCarlos Irabedra100% (1)

- Guia de Producto Rev615 - AbbDocument60 paginiGuia de Producto Rev615 - Abbper47Încă nu există evaluări

- Resume Sabir MoiduDocument9 paginiResume Sabir MoiduSABIRÎncă nu există evaluări

- Diagnostic Manual (Ems)Document127 paginiDiagnostic Manual (Ems)Mizo QuizÎncă nu există evaluări

- NE Datasheet ManDocument20 paginiNE Datasheet ManszenandreiÎncă nu există evaluări

- Frick 090 020 M QLX 2013 11 Rev 2014 08 PDFDocument172 paginiFrick 090 020 M QLX 2013 11 Rev 2014 08 PDFnachoÎncă nu există evaluări

- 24M EléctricoDocument4 pagini24M EléctricoGabriel ChallapaÎncă nu există evaluări

- Mazda RX-8 Service Highlight 2009Document299 paginiMazda RX-8 Service Highlight 2009frj83Încă nu există evaluări