Documente Academic

Documente Profesional

Documente Cultură

Steel Shield 1200

Încărcat de

Moin AltafDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steel Shield 1200

Încărcat de

Moin AltafDrepturi de autor:

Formate disponibile

STEEL SHIELD 1200

High Build Glass Flake Epoxy

PRODUCT A high solids and high build epoxy coating incorporating glass flakes and inert pigments.

Cures at above and below water/sea level.

DESCRIPTION

Excellent Corrosion resistance.

Excellent resistance against fresh and sea water.

Excellent abrasion resistance.

Good resistance against mild chemicals.

Low VOC hence user and environment friendly.

DESIGNED USE Steel and concrete structures in splash / tidal zone and buried vessels or pipelines.

As a single coat maintenance system.

As a general maintenance coating for on-shore and off-shore installations.

Can also be used in conjunction with CP.

Suitable as topcoat for upto C5 Environment as per ISO12944 Part 2

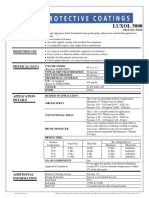

PHYSICAL DATA VOLUME SOLIDS

84 % + 2 %

(Based on ASTM D2697)

TYPICAL DRY FILM THICKNESS 500 microns

WET FILM THICKNESS 595 microns

THEORETICAL COVERAGE 1.7 m2/litre @ 500 microns DFT

VOC As Supplied

160 gms/ltr

(Based on ASTM D3960)

COLOUR Limited Shades

FINISH Low Sheen

APPLICATION METHOD OF APPLICATION :

DETAILS This is the recommended method of application:

Maximum 5% Thinner may be added.

AIRLESS SPRAY

Tip Size: 0.93 - 1.38 mm (0.031 - 0.055 in)

Pressure: 206 - 241 kg/cm2 (3000 3500 psi)

May be used for difficult shapes or touch-up.

BRUSH OR ROLLER However, additional coats may be required to achieve

the recommended film thickness.

DRYING TIME:

Surface Re coating Interval

Touch Dry Hard Dry Pot Life

Temperature Minimum Maximum

15C 9 Hrs 18 Hrs 32 Hrs 21 Days 3 Hrs

25C 6 Hrs 12 Hrs 20 Hrs 14 Days 2 Hrs

35C 4 Hrs 8 Hrs 14 Hrs 7 Days 1 Hr

45C 2 Hrs 6 Hrs 8 Hrs 5 Days 30 mins

NO. OF COMPONENTS Two

Mixing Ratio As per pack size

Do not apply this product if the Relative Humidity

Application Conditions exceeds 85% or if the substrate temperature is within

3C of the dew point

ADDITIONAL Thinner / Cleaning solvent Solvalux 7-45

INFORMATION Storage Instruction Store in a cool shaded dry area

Flash Point Mixed 36C

Packaging 20 liters

Shelf Life 12 months from the date of manufacture.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

STEEL SHIELD 1200

High Build Glass Flake Epoxy

SURFACE This product can be applied either directly to blasted steel or over suitable primer (e.g. EPILUX

610/78 Primers).

PREPARATION Remove all wax, oil and grease by solvent cleaning in accordance with the guidelines given by

SSPC-SPI.

Where necessary remove weld spatter and round off all rough weld seams and sharp edges to a

smooth surface.

Abrasive blast clean to a minimum standard of Sa 2 Swedish Standard SIS 05 59 00 or ISO 8501-

1 : 1988.

For direct application, the surface profile should be in between 75 100 micron.

Any surface defects revealed by blast cleaning should be ground, filled or treated in a suitable

manner.

After blasting, remove dust from the surface.

The surface to be applied must be clean, dry and free from soluble salts. If required, fresh water

wash should follow to remove soluble salts.

CONCRETE

Ensure the surface is sound. Remove laitance by through wire-brushing, acid etching or sweep

blasting. Blowholes and other defects should be filled with EPILUX 829.

SPLASH/ TIDAL ZONE INSTALLATION

Ensure substrate is suitably prepared as described above. Substrate must be dry and above fresh/

sea water level during application of this product. The curing process of the applied coating

continues even if it is completely submerged in Fresh/ Sea water.

PRODUCT USE This product has to be applied over a dry surface

Finish will be matt if cured underwater.

RESTRICTIONS Consult Berger if product is to be applied in non-tropical climate.

Pot life short, hence mix base and hardener only when ready to use.

As common with all Epoxy products, this product also will tend to discolour and chalk on exposure

to direct sunlight.

May also be applied between 250 and 500 microns DFT.

Contact Berger Representative for suggesting suitable paint system

SAFETY Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls, goggles, dust

masks and gloves. Use a barrier cream.

PRECAUTIONS Ensure that there is adequate ventilation in the area where the product is being applied. Do not breathe

vapor or spray.

This product is flammable. Keep away from sources of ignition. Do not smoke. Take precautionary

measures against static discharge. In case of fire blanket flames with foam, carbon dioxide or dry

chemicals

Refer to MSDS for further information.

FIRST AID Eyes: In the event of accidental splashes, flush eyes with water immediately and obtain medical advice

Skin: Wash skin thoroughly with soap and water or approved industrial cleaner.

DO NOT USE solvent or thinners.

Inhalation: Remove to fresh air, loosen collar and keep patient rested.

Ingestion: In case of accidental ingestion, DO NOT INDUCE VOMITING.

Obtain immediate medical attention

The information provided on this data sheet is not intended to be complete and is provided as general advice only. It is the responsibility

DISCLAIMER of the user to ensure that the product is suitable for the purpose for which he wishes to use it. As we have no control over the treatment of

the product, the standard of surface preparation of the substrate, or other factors affecting the use of this product, we are not responsible

for its performance nor would we accept any liability whatsoever or howsoever arising from the use of this product unless specifically

agreed to in writing by us. The information contained in this data sheet may be modified by us from time to time, and without notice, in

the light of our experience and continuous product development.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

S-ar putea să vă placă și

- How To Hack Wifi WPA WPA2 WPS in Windows in 2 Mins Using JumpStart and Dumpper - Hacking DreamDocument14 paginiHow To Hack Wifi WPA WPA2 WPS in Windows in 2 Mins Using JumpStart and Dumpper - Hacking Dreamzonde100% (4)

- 2023-RegisterBook Version 202212Document95 pagini2023-RegisterBook Version 202212Moin AltafÎncă nu există evaluări

- Creative Resin: Easy techniques for contemporary resin artDe la EverandCreative Resin: Easy techniques for contemporary resin artÎncă nu există evaluări

- GB-T 1220-2007Document23 paginiGB-T 1220-2007HieuÎncă nu există evaluări

- Epimastic 4100Document2 paginiEpimastic 4100Moin AltafÎncă nu există evaluări

- Epimastic 4100Document2 paginiEpimastic 4100Moin AltafÎncă nu există evaluări

- Epimastic 4100Document2 paginiEpimastic 4100Moin AltafÎncă nu există evaluări

- IEC 61439-2-2011 - Part01Document25 paginiIEC 61439-2-2011 - Part01hajjar100% (1)

- Contract ManagementDocument20 paginiContract ManagementJohn Fenn100% (1)

- TM 9-2320-338-10Document1.120 paginiTM 9-2320-338-10Advocate100% (2)

- APNIC ROU3IX v1.0Document336 paginiAPNIC ROU3IX v1.0mickysouravÎncă nu există evaluări

- USP-Fume Hood 150428Document63 paginiUSP-Fume Hood 150428Anonymous cZ0Sn4hxF100% (1)

- DEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesDocument30 paginiDEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesMoin AltafÎncă nu există evaluări

- 041957air Transport Pilot License (ATPL) - Multi Pilot License (MPL) - Type Rating-Training Multi Pilot Airplane Skill Test & Proficiency Check ReportDocument4 pagini041957air Transport Pilot License (ATPL) - Multi Pilot License (MPL) - Type Rating-Training Multi Pilot Airplane Skill Test & Proficiency Check ReportA320viatorÎncă nu există evaluări

- Epilux 5: Product DescriptionDocument2 paginiEpilux 5: Product DescriptionShyam ShrishÎncă nu există evaluări

- NEBOSH HSE Certificate in Process Safety Management - NEBOSHDocument8 paginiNEBOSH HSE Certificate in Process Safety Management - NEBOSHamra_41Încă nu există evaluări

- Epilux 82: Product DescriptionDocument2 paginiEpilux 82: Product DescriptionMoin AltafÎncă nu există evaluări

- Apcodur Ehb 500-VocDocument2 paginiApcodur Ehb 500-VocMoin AltafÎncă nu există evaluări

- Zincanode 620 Voc v1 Jan 2018Document2 paginiZincanode 620 Voc v1 Jan 2018Moin AltafÎncă nu există evaluări

- EPIMASTIC 5100-March 2019 Version 2Document2 paginiEPIMASTIC 5100-March 2019 Version 2PraveenÎncă nu există evaluări

- Pds Zincanode 690 VocDocument2 paginiPds Zincanode 690 VocmuthukumarÎncă nu există evaluări

- Epilux 155Document2 paginiEpilux 155Allana100% (1)

- Pds Epilux 218 VocDocument2 paginiPds Epilux 218 VocmuthukumarÎncă nu există evaluări

- Epilux 800Document2 paginiEpilux 800anandÎncă nu există evaluări

- Pds Zincanode 620 VocDocument2 paginiPds Zincanode 620 VocmuthukumarÎncă nu există evaluări

- Apcotherm Epn 200Document2 paginiApcotherm Epn 200Moin AltafÎncă nu există evaluări

- Epilux 218: Product DescriptionDocument2 paginiEpilux 218: Product DescriptionMoin AltafÎncă nu există evaluări

- Epilux 58 M.I.O.: Product DescriptionDocument2 paginiEpilux 58 M.I.O.: Product DescriptionMoin AltafÎncă nu există evaluări

- Epilux 219: Product DescriptionDocument2 paginiEpilux 219: Product DescriptionMoin AltafÎncă nu există evaluări

- EPILUX 850 SF VOC Jan-2017Document2 paginiEPILUX 850 SF VOC Jan-2017PraveenÎncă nu există evaluări

- Epimastic 7200: Product DescriptionDocument2 paginiEpimastic 7200: Product DescriptionSu KaÎncă nu există evaluări

- Apcoline 4100Document2 paginiApcoline 4100Moin AltafÎncă nu există evaluări

- Epilux 8: Product DescriptionDocument2 paginiEpilux 8: Product DescriptionMoin AltafÎncă nu există evaluări

- Epimastic 5200: Product DescriptionDocument2 paginiEpimastic 5200: Product DescriptionsreeÎncă nu există evaluări

- Epimastic 7200 SRDocument2 paginiEpimastic 7200 SRqc_531040655Încă nu există evaluări

- Luxatherm 6200Document2 paginiLuxatherm 6200PraveenÎncă nu există evaluări

- Pds Luxaprime 1400 VocDocument2 paginiPds Luxaprime 1400 VocmuthukumarÎncă nu există evaluări

- Pds Epilux 218 Hs VocDocument2 paginiPds Epilux 218 Hs VocmuthukumarÎncă nu există evaluări

- Rapid Air Dry 10Document2 paginiRapid Air Dry 10Moin AltafÎncă nu există evaluări

- Epilux 155Document2 paginiEpilux 155Tejinder KumarÎncă nu există evaluări

- Steelshield Ve: Product DescriptionDocument2 paginiSteelshield Ve: Product DescriptionMoin AltafÎncă nu există evaluări

- Luxathane 5160Document2 paginiLuxathane 5160shameelÎncă nu există evaluări

- Pds Luxol 1000 VocDocument2 paginiPds Luxol 1000 VocmuthukumarÎncă nu există evaluări

- Steel Shield 1100Document3 paginiSteel Shield 1100Moin AltafÎncă nu există evaluări

- Pds Luxaprime 1000 VocDocument2 paginiPds Luxaprime 1000 VocmuthukumarÎncă nu există evaluări

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 paginiZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakÎncă nu există evaluări

- Pds Luxol 5000 VocDocument2 paginiPds Luxol 5000 VocmuthukumarÎncă nu există evaluări

- Berger: Product SpecificationsDocument2 paginiBerger: Product SpecificationsAabhas UpadhyayaÎncă nu există evaluări

- Microsoft Word - L3 - Epilux82Document2 paginiMicrosoft Word - L3 - Epilux82vitharvanÎncă nu există evaluări

- Epilux 58 - 9702Document2 paginiEpilux 58 - 9702anandÎncă nu există evaluări

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocument2 paginiGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiÎncă nu există evaluări

- Duremax Gpe ZP Aug 2018Document3 paginiDuremax Gpe ZP Aug 2018Biju_PottayilÎncă nu există evaluări

- g9) Berger Apcofine 905 - 8096Document2 paginig9) Berger Apcofine 905 - 8096Wasek SarkerÎncă nu există evaluări

- RobbiathaneDocument2 paginiRobbiathaneAnson FranklinÎncă nu există evaluări

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocument2 paginiLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakÎncă nu există evaluări

- Pds Luxaprime 1500 VocDocument2 paginiPds Luxaprime 1500 VocmuthukumarÎncă nu există evaluări

- b3) Zincanode685 4586Document2 paginib3) Zincanode685 4586Syed FaridÎncă nu există evaluări

- Luxathane 5160-Voc March 2021 V1Document2 paginiLuxathane 5160-Voc March 2021 V1PraveenÎncă nu există evaluări

- l2) Steelshield1200 3041Document2 paginil2) Steelshield1200 3041Syed FaridÎncă nu există evaluări

- b6) Zincanode690 2886Document2 paginib6) Zincanode690 2886Anonymous XVEucVMsEÎncă nu există evaluări

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 paginiLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakÎncă nu există evaluări

- Berger: Product SpecificationsDocument2 paginiBerger: Product SpecificationsAabhas UpadhyayaÎncă nu există evaluări

- Pds Luxathane 5000 VocDocument2 paginiPds Luxathane 5000 Vocmuthukumar100% (1)

- Coaltar Epoxy - Epilux5 - 0474Document2 paginiCoaltar Epoxy - Epilux5 - 0474GautamÎncă nu există evaluări

- pm002 4446Document2 paginipm002 4446Dhanush Kumar RamanÎncă nu există evaluări

- Aquagalv: Water Borne Inorganic Zinc SilicateDocument3 paginiAquagalv: Water Borne Inorganic Zinc SilicatelivefreakÎncă nu există evaluări

- E3) Epimastic5100 4292Document2 paginiE3) Epimastic5100 4292Syed FaridÎncă nu există evaluări

- Duremax GPE: General Purpose Epoxy CoatingDocument4 paginiDuremax GPE: General Purpose Epoxy CoatinglivefreakÎncă nu există evaluări

- Durebild Ste Glass Flake pc239Document3 paginiDurebild Ste Glass Flake pc239livefreakÎncă nu există evaluări

- Epilux 78Document2 paginiEpilux 78MuthuKumar100% (1)

- Revchem HRC 870Document3 paginiRevchem HRC 870marciobispoalmeidaÎncă nu există evaluări

- Zincanode 304: Solvent Borne Inorganic Zinc SilicateDocument3 paginiZincanode 304: Solvent Borne Inorganic Zinc SilicatelivefreakÎncă nu există evaluări

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- Rapid Air Dry 10Document2 paginiRapid Air Dry 10Moin AltafÎncă nu există evaluări

- HilonDeco Cryl 9200-MCDocument2 paginiHilonDeco Cryl 9200-MCMoin AltafÎncă nu există evaluări

- Apcoline 4100Document2 paginiApcoline 4100Moin AltafÎncă nu există evaluări

- PDS-Supreme Eggshell - Silk Version 1Document2 paginiPDS-Supreme Eggshell - Silk Version 1Moin AltafÎncă nu există evaluări

- Epilux 8: Product DescriptionDocument2 paginiEpilux 8: Product DescriptionMoin AltafÎncă nu există evaluări

- Apcotherm Epn 200Document2 paginiApcotherm Epn 200Moin AltafÎncă nu există evaluări

- Epilux 219: Product DescriptionDocument2 paginiEpilux 219: Product DescriptionMoin AltafÎncă nu există evaluări

- Epilux 58 M.I.O.: Product DescriptionDocument2 paginiEpilux 58 M.I.O.: Product DescriptionMoin AltafÎncă nu există evaluări

- Steel Shield 1100Document3 paginiSteel Shield 1100Moin AltafÎncă nu există evaluări

- Epilux 218: Product DescriptionDocument2 paginiEpilux 218: Product DescriptionMoin AltafÎncă nu există evaluări

- Steel Shield 1200Document2 paginiSteel Shield 1200Moin AltafÎncă nu există evaluări

- Steelshield Ve: Product DescriptionDocument2 paginiSteelshield Ve: Product DescriptionMoin AltafÎncă nu există evaluări

- Luxathane 5160Document2 paginiLuxathane 5160shameelÎncă nu există evaluări

- UAE Limited Liability CompanyDocument2 paginiUAE Limited Liability CompanyMoin AltafÎncă nu există evaluări

- Can A SUNNI Man Marry A SHIA GirlDocument2 paginiCan A SUNNI Man Marry A SHIA GirlMoin AltafÎncă nu există evaluări

- FRENIC Mini (C2) CatalogDocument24 paginiFRENIC Mini (C2) CatalogSAYAKÎncă nu există evaluări

- Astm 2019Document2 paginiAstm 2019jamie courneyÎncă nu există evaluări

- Ims Poc Pre Established Push To Talk Session Call Flow PDFDocument4 paginiIms Poc Pre Established Push To Talk Session Call Flow PDFABHINAVÎncă nu există evaluări

- Manual - iGO Primo 2.0Document134 paginiManual - iGO Primo 2.0emersonsfcÎncă nu există evaluări

- 1100 Series: 1104D-E44TADocument5 pagini1100 Series: 1104D-E44TAPiotrek KurkiewiczÎncă nu există evaluări

- AC9 User GuideDocument124 paginiAC9 User GuideDaniel IsailaÎncă nu există evaluări

- SoalDocument3 paginiSoaldekyÎncă nu există evaluări

- OracleBPM PAPIDeveloperGuide 10.3Document36 paginiOracleBPM PAPIDeveloperGuide 10.3Madhukar ReddyÎncă nu există evaluări

- VIO Commands PADMINDocument7 paginiVIO Commands PADMINrajeevkghoshÎncă nu există evaluări

- Design of Machine Members - IDocument8 paginiDesign of Machine Members - IPradeepkumarKatgiÎncă nu există evaluări

- American Wire Gauge Chart and AWG Electrical CurrentDocument1 paginăAmerican Wire Gauge Chart and AWG Electrical CurrentodoalawayeÎncă nu există evaluări

- 514Document8 pagini514hubert_veltenÎncă nu există evaluări

- Tda 3803Document11 paginiTda 3803Alan LópezÎncă nu există evaluări

- Continental IO-550-abcgnpr Overhaul Manual 2000 GGDocument371 paginiContinental IO-550-abcgnpr Overhaul Manual 2000 GGAndi RifkyÎncă nu există evaluări

- Energy Utilization Index and Benchmarking For A Government HospitalDocument7 paginiEnergy Utilization Index and Benchmarking For A Government HospitalAlit PutraÎncă nu există evaluări

- Wireless Headphones PresentationDocument35 paginiWireless Headphones PresentationYu100% (1)

- VidyadhariDocument5 paginiVidyadharividyadhari12Încă nu există evaluări

- DatabaseDocument61 paginiDatabaseNavneet GulatiÎncă nu există evaluări

- LTE PP SlidesDocument13 paginiLTE PP SlidesAnonymous VHXJw23L2l50% (2)

- ASPNET 4 SecurityExtensibilityDocument23 paginiASPNET 4 SecurityExtensibilityzohebdhuka_libraÎncă nu există evaluări

- Treadmill BicycleDocument4 paginiTreadmill BicycleAnonymous kw8Yrp0R5rÎncă nu există evaluări