Documente Academic

Documente Profesional

Documente Cultură

Bituthene 3000-3000 HC With Green Logo

Încărcat de

Domie Neil Bucag SalasDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bituthene 3000-3000 HC With Green Logo

Încărcat de

Domie Neil Bucag SalasDrepturi de autor:

Formate disponibile

P R O D U C T D ATA S H E E T

Bituthene 3000/3000 HC

High performance waterproofing membrane for

sub-structures and flat deck applications

Product Description

Bituthene 3000/3000 HC is a high performance, cold-applied, flexible, preformed waterproof

membrane combining a special high performance, cross-laminated, HDPE carrier film with a unique

self-adhesive rubber bitumen compound.

Elevated or grade level podiums

Product Advantages Plaza decks / Roof gardens / Terraces

Waterproof high hydrostatic head resistance

Installation 040-013-1254

High density cross-laminated polyethylene film

Provides dimensional stability Sub-structure Assembly

Provides puncture resistance

Single layer simple, reliable, low labour cost with Hydroduct

the benefit of site programmed installation 220

Bituthene

Gas Resistant methane, carbon dioxide and 3000/3000 HC Bituthene

radon gas protection in excess of the standard Protection

membrane requirements in BRE Reports 211 Bituthene Primer Board

(radon) and 212 (methane and carbon dioxide) Hydroduct

Adcor 500S /

Coil

Cold-applied Swellseal 3V

No flame hazard

Bituthene

No heating required Liquid

Self-adhesive rubberised asphalt Membrane

Continuity ensured at overlaps Bituthene

Unique rubber/bitumen formulation allows healing 3000/3000

of small punctures HC

Factory controlled thickness no variation by site Bituthene

practices Protection Board

Measures should be taken to ensure that all surfaces are free from

Chemically-resistant provides effective external

protection against aggressive environments and ice, frost or condensation. Roof slab surfaces must be dry, and

ozone attack free from sharp protrusions, and any hollows to be filled with high

strength mortar.

Flexible accommodates minor settlement and

shrinkage movement Horizontal and vertical faces must be smooth, regular, dry and free

from nails. Prime the horizontal and vertical surfaces with one coat

Tanking security combined flexible membrane of Bituthene Primer applied by brush or roller at a rate of 6-8sq m

and waterstop system for security

per litre depending on the porosity of the surface, and allow to dry

completely before the application of Bituthene 3000/3000 HC.

Bituthene 3000/3000 HC should be laid by peeling back the

protective silicone release paper and applying the self-adhesive

Applications face on to the surface to ensure good initial bond.

Basement Adjacent rolls are aligned and overlapped 50mm minimum at

Sub-structures side and 50mm*** at ends, and the overlaps well rolled with a

firm pressure using a lap roller to ensure complete adhesion and

Flat decks

continuity between the layers.

Roof assemblies

*** For usage in China mainland, please follow China GB code requirement for lapping. For

more details, please contact your local GCP representative.

Physical Properties

Property Typical Values Test Method

Colour Dark Grey NA

Nominal Thickness* 1.5mm NA

Tensile Strength Of Membrane 4N / mm ASTM D412 modified **

Elongation Of Membrane (To Ultimate

200% ASTM D412 modified **

Failure Of Rubberised Asphalt)

Lap Adhesion @23C 683 N/ m ASTM D1876

Cycling over crack @-32C No effect 100 cycles ASTM C836

Puncture Resistance Of Membrane >220N ASTM E154

Resistance To Hydrostatic Head 60m ASTM D5385

Tear Resistance 23N / mm ASTM D624

Permeance 1.9na Pa. m2. S ASTM E96 [12]

Typical test values represent average values from samples tested. Test methods noted may be modified.

* Nominal thickness refers to the thickness of the membrane without release liner.

** The test is run at a rate of 100 mm per minute.

Please consult your local GCP representative on recommended installation temperature.

Supply The junction between the slab and parapet shall have a fillet of

Bituthene Liquid Membrane or other acceptable methods placed

Pack Size 1m x 20m roll (20sqm) firmly into position before using 300mm wide reinforcing corner

strips of Bituthene 3000/3000 HC placed centrally over the axis

Gross Weight 39kg

of the change of direction.

Storage Dry conditions below +35C

Always apply Bituthene membrane directly to primed or conditioned

structural substrates. Insulation, if used, must be applied over the

Following the application and inspection, care should be taken to

membrane. Do not apply Bituthene membranes over lightweight

prevent damage by following trades. As soon as practicable after

insulating concrete.

the application, Bituthene 3000/3000 HC should be protected

from exposure to the weather and physical damage using

Bituthene protection boards, insulation or Hydroduct drainage Health and Safety

composites laid dry. Refer to relevant Material Safety Data Sheet.

Any punctured or damaged areas should be cleaned and patched using

Bituthene 3000/3000 HC with minimum 50mm laps all around. Quality Assurance

Following the application, care should be taken to prevent GCP Applied Technologies is certified to ISO 9001 : 2008 by TUV

damage by following trades by using Bituthene protection boards SUD PSB Pte Ltd.

spot bonded with Pak Adhesive or a 25mm screed as horizontal

protection. Vertical faces to be protected against damage from Technical Services

backfilling and reinforcement by using Bituthene protection

boards spot bonded with Pak Adhesive. For assistance with working drawings for projects and additional

technical advice, please contact GCP Applied Technologies.

gcpat.com | For technical information: asia.enq@gcpat.com

Australia 1800 855 525 New Zealand +64 9 448 1146 China Mainland +86 21 3158 2888 Hong Kong +852 2675 7898

India +91 124 488 5900 Indonesia +62 21 893 4260 Japan +81 3 5226 0231 Korea +82 32 820 0800 Malaysia +60 3 9074 6133

Philippines +63 49 549 7373 Singapore +65 6265 3033 Thailand +66 2 709 4470 Vietnam +84 8 3710 6168

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration,

investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and

suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is

intended for any use that would infringe any patent, copyright, or other third party right.

Bituthene, Adcor, Swellseal and Hydroduct are trademarks, which may be registered in the

United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list

has been compiled using available published information as of the publication date and may

not accurately reflect current trademark ownership or status.

Copyright 2016 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140, USA

Printed in Singapore | 03/16 | 300-Bituthene-1

S-ar putea să vă placă și

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- Bituthene 3000-3000 HCDocument2 paginiBituthene 3000-3000 HCRm1262Încă nu există evaluări

- Pre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDocument2 paginiPre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDaniel PratamaÎncă nu există evaluări

- Bituthene Liquid MembraneDocument3 paginiBituthene Liquid MembranenamÎncă nu există evaluări

- Bituthene 8000HCDocument4 paginiBituthene 8000HCa73806780Încă nu există evaluări

- Bitustick XL 1.6mmDocument123 paginiBitustick XL 1.6mmThiva karÎncă nu există evaluări

- Bitu-Impervi LM Waterproofing MembraneDocument2 paginiBitu-Impervi LM Waterproofing MembraneJoeÎncă nu există evaluări

- Mea Polybit Tds Polybit Bitustick XL en MeaDocument2 paginiMea Polybit Tds Polybit Bitustick XL en MeaSabeer HafizÎncă nu există evaluări

- 6 2 1 2 3 Bitustick XLDocument2 pagini6 2 1 2 3 Bitustick XLglen cristian riveraÎncă nu există evaluări

- Bituthene 3000Document10 paginiBituthene 3000vertigoÎncă nu există evaluări

- Bituthene - 8000HC - Me (2016-04-25)Document4 paginiBituthene - 8000HC - Me (2016-04-25)Sankar CdmÎncă nu există evaluări

- Bituthene 3000/3000 HC: Self-Adhesive Rubber/bitumen Polyethylene Waterproof Membrane For Basements and Sub-StructuresDocument2 paginiBituthene 3000/3000 HC: Self-Adhesive Rubber/bitumen Polyethylene Waterproof Membrane For Basements and Sub-StructuresSankar CdmÎncă nu există evaluări

- Bitugum: SmoothDocument2 paginiBitugum: Smoothsr2011glassÎncă nu există evaluări

- BrederoShaw PDS YJ2KDocument2 paginiBrederoShaw PDS YJ2KJayÎncă nu există evaluări

- Bituseal E cold applied flexible protective coatingDocument2 paginiBituseal E cold applied flexible protective coatingYoussef ElgendyÎncă nu există evaluări

- Sika Damp Proofing Slurry Pds CeDocument4 paginiSika Damp Proofing Slurry Pds Cejuli_radÎncă nu există evaluări

- Advanced, Self-Adhesive Water and Vapour Proof Membrane For Sub-StructuresDocument2 paginiAdvanced, Self-Adhesive Water and Vapour Proof Membrane For Sub-StructuresSanjay Singh100% (1)

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDocument2 paginiMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanÎncă nu există evaluări

- BITUTEX FBR fibre reinforced solvented bitumen paintDocument2 paginiBITUTEX FBR fibre reinforced solvented bitumen paintRupesh GenesisÎncă nu există evaluări

- Densolen - System AS39P / R20HT: Product InformationDocument2 paginiDensolen - System AS39P / R20HT: Product InformationCarlos PazÎncă nu există evaluări

- Sikatop 109 SealingDocument4 paginiSikatop 109 SealingRajdeep ShitÎncă nu există evaluări

- Bostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Document4 paginiBostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Arturo Jr. TorresÎncă nu există evaluări

- Tds Consol Top 133 HBDocument3 paginiTds Consol Top 133 HBPEP GUDANGÎncă nu există evaluări

- Mea Polybit Tds Polybit Bitustick en MeaDocument2 paginiMea Polybit Tds Polybit Bitustick en MeaVengatesh HariÎncă nu există evaluări

- Abe Construction Chemicals Duraflex DatasheetDocument2 paginiAbe Construction Chemicals Duraflex DatasheetEthanÎncă nu există evaluări

- BM SELF HD 1 51 waterproofing membraneDocument4 paginiBM SELF HD 1 51 waterproofing membranevinoth kumar SanthanamÎncă nu există evaluări

- Conbextra BB80Document4 paginiConbextra BB80m.elsanee.cubicÎncă nu există evaluări

- Bituthene 6000Document4 paginiBituthene 6000Dileepa DissanayakeÎncă nu există evaluări

- Technical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutDocument2 paginiTechnical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutKhaerul SidikÎncă nu există evaluări

- Sikatop Seal 107Document4 paginiSikatop Seal 107Solomon AbiyeÎncă nu există evaluări

- Vetonit Base WR: Weather Resistant Premix Cement Coating For Internal UseDocument2 paginiVetonit Base WR: Weather Resistant Premix Cement Coating For Internal UseDeyab Mohammed EldesoukyÎncă nu există evaluări

- Sikatop 107 Seal Pds enDocument3 paginiSikatop 107 Seal Pds ensahal_akÎncă nu există evaluări

- 1.5mm Thick, Self-Adhesive Membrane: Bituthene® CPDocument2 pagini1.5mm Thick, Self-Adhesive Membrane: Bituthene® CPSteve AokiÎncă nu există evaluări

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 paginiFosroc Conbextra BB80: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Bostik h985 Sealnflex Weather Shield - enDocument2 paginiBostik h985 Sealnflex Weather Shield - enAngelo Carlo MalabananÎncă nu există evaluări

- Duraflex DSDocument2 paginiDuraflex DSFeyiÎncă nu există evaluări

- Isocrete K Screed Technical Data SheetDocument2 paginiIsocrete K Screed Technical Data SheetIoan PiuÎncă nu există evaluări

- Bituthene® 4000Document2 paginiBituthene® 4000hajisotoudehÎncă nu există evaluări

- Bostik Screed WP Prepacked Drymix Waterproof Floor ScreedDocument2 paginiBostik Screed WP Prepacked Drymix Waterproof Floor Screedraviteja036Încă nu există evaluări

- Bitustick P: Polyester Reinforced Waterproofing MembraneDocument2 paginiBitustick P: Polyester Reinforced Waterproofing MembraneHafnazSabeerÎncă nu există evaluări

- DR Fixit Piditop 444 106 1Document3 paginiDR Fixit Piditop 444 106 1Mohammed Abdul BaseerÎncă nu există evaluări

- MasterEmaco SBR 2 improves strength and reduces crackingDocument3 paginiMasterEmaco SBR 2 improves strength and reduces crackingRadja NurÎncă nu există evaluări

- DR - Fixit Flexi PU 270IDocument4 paginiDR - Fixit Flexi PU 270IKiran KumarÎncă nu există evaluări

- Water Proofing System: For Foundations, Basements, Terraces, Roofs, Underground or Multi Storey CarparksDocument4 paginiWater Proofing System: For Foundations, Basements, Terraces, Roofs, Underground or Multi Storey CarparksdipinnediyaparambathÎncă nu există evaluări

- Bituthene 6000 EIMDocument2 paginiBituthene 6000 EIMSenthilkumar NarayananÎncă nu există evaluări

- Sika Multiseal PdsDocument3 paginiSika Multiseal PdskonstruksiÎncă nu există evaluări

- Stucco Systems FacadesThree System - System BulletinDocument2 paginiStucco Systems FacadesThree System - System BulletinFacadesxiÎncă nu există evaluări

- Bitustick ALDocument45 paginiBitustick ALBavishÎncă nu există evaluări

- Sikatop Seal 109 Hi: Elastic, Liquid Applied Crack Bridging, 2 Pack Acrylic Cementitious Waterproofing Coating SystemDocument4 paginiSikatop Seal 109 Hi: Elastic, Liquid Applied Crack Bridging, 2 Pack Acrylic Cementitious Waterproofing Coating SystemGirish DeshmukhÎncă nu există evaluări

- Concrete Coating Technical Data SheetDocument2 paginiConcrete Coating Technical Data SheetCiput MardiantoÎncă nu există evaluări

- Konsol PDFDocument2 paginiKonsol PDFCiput MardiantoÎncă nu există evaluări

- TDS Consol Grout 600 MFDocument2 paginiTDS Consol Grout 600 MFPEP GUDANGÎncă nu există evaluări

- Conbextra GP4Document4 paginiConbextra GP4Chukwuma OgbonnaÎncă nu există evaluări

- Bituthene 3000 - Page-01Document1 paginăBituthene 3000 - Page-01Md. NazmulÎncă nu există evaluări

- NG NP Sikatop Seal 107Document3 paginiNG NP Sikatop Seal 107NourhoudaÎncă nu există evaluări

- Dr. Fixit Piditop 333 Concrete Floor HardenerDocument3 paginiDr. Fixit Piditop 333 Concrete Floor Hardenerhunky11Încă nu există evaluări

- Vetonit Doc Technical Map en 3193Document2 paginiVetonit Doc Technical Map en 3193Tejinder KumarÎncă nu există evaluări

- TDS Contite FCW 010 Jul11Document4 paginiTDS Contite FCW 010 Jul11พศิน จันทะสิมÎncă nu există evaluări

- Sikatop - 122Document3 paginiSikatop - 122YOSAFAT YUDHA GUNTOROÎncă nu există evaluări

- Consol CosmeticDocument2 paginiConsol Cosmeticotong geyongÎncă nu există evaluări

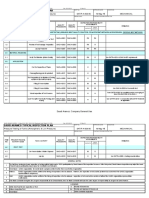

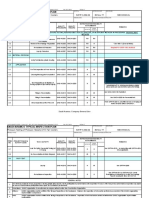

- 10-603159-4200000030-SAC-SRV-WIR-000109_01Document7 pagini10-603159-4200000030-SAC-SRV-WIR-000109_01Domie Neil Bucag SalasÎncă nu există evaluări

- Saudi Arabian Oil Company: Detail of Ladder-5 Detail of Ladder-6Document1 paginăSaudi Arabian Oil Company: Detail of Ladder-5 Detail of Ladder-6Domie Neil Bucag SalasÎncă nu există evaluări

- WO4_As Built Qty Form (13-01-2023)Document1 paginăWO4_As Built Qty Form (13-01-2023)Domie Neil Bucag SalasÎncă nu există evaluări

- Framework Agreement NEOM 128Document1 paginăFramework Agreement NEOM 128Domie Neil Bucag SalasÎncă nu există evaluări

- SaudiAramco ladder designDocument1 paginăSaudiAramco ladder designDomie Neil Bucag SalasÎncă nu există evaluări

- WO-05 (S7) - Remaining Qty Slope OUTSIDE HSR SOUTH SIDE - (ASB-11-01-2024)Document1 paginăWO-05 (S7) - Remaining Qty Slope OUTSIDE HSR SOUTH SIDE - (ASB-11-01-2024)Domie Neil Bucag SalasÎncă nu există evaluări

- DR - WO2 - VN - 02AUG2023.pdf - SpineDocument2 paginiDR - WO2 - VN - 02AUG2023.pdf - SpineDomie Neil Bucag SalasÎncă nu există evaluări

- Abdul Rauf - QS-CVDocument12 paginiAbdul Rauf - QS-CVDomie Neil Bucag SalasÎncă nu există evaluări

- Production Tracker - S8 (Spine) - 02AUG 2023Document3 paginiProduction Tracker - S8 (Spine) - 02AUG 2023Domie Neil Bucag SalasÎncă nu există evaluări

- Elevation: Saudi Arabian Oil CompanyDocument1 paginăElevation: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- WO-05 (S7) - Remaining Qty Slope OUTSIDE HSR NORTH SIDE - (ASB-11-01-2024)Document2 paginiWO-05 (S7) - Remaining Qty Slope OUTSIDE HSR NORTH SIDE - (ASB-11-01-2024)Domie Neil Bucag SalasÎncă nu există evaluări

- Detail: Saudi Arabian Oil CompanyDocument1 paginăDetail: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- WO-05 (S7) - Remaining Qty Slope OUTSIDE HSR SOUTH SIDE - (ASB-11-01-2024)Document1 paginăWO-05 (S7) - Remaining Qty Slope OUTSIDE HSR SOUTH SIDE - (ASB-11-01-2024)Domie Neil Bucag SalasÎncă nu există evaluări

- WO-05 (S7) - Remaining Qty Slope OUTSIDE HSR NORTH SIDE - (ASB-11-01-2024)Document2 paginiWO-05 (S7) - Remaining Qty Slope OUTSIDE HSR NORTH SIDE - (ASB-11-01-2024)Domie Neil Bucag SalasÎncă nu există evaluări

- Hoop Connection: Saudi Arabian Oil CompanyDocument1 paginăHoop Connection: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- Section: Saudi Arabian Oil CompanyDocument1 paginăSection: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- Satip A 104 03eeDocument10 paginiSatip A 104 03eeRijwan MohammadÎncă nu există evaluări

- Reinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDocument1 paginăReinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- Saep 16 PDFDocument20 paginiSaep 16 PDFnadeem shaikhÎncă nu există evaluări

- Saudi Aramco Typical Inspection Plan: Geotechnical Investigation SATIP-A-113-01 14-May-18 CivilDocument10 paginiSaudi Aramco Typical Inspection Plan: Geotechnical Investigation SATIP-A-113-01 14-May-18 CivilDomie Neil Bucag SalasÎncă nu există evaluări

- Saudi Aramco Typical Inspection PlanDocument10 paginiSaudi Aramco Typical Inspection PlanDomie Neil Bucag SalasÎncă nu există evaluări

- Satip A 004 04JJDocument10 paginiSatip A 004 04JJRijwan MohammadÎncă nu există evaluări

- Saudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 14-May-18Document10 paginiSaudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 14-May-18Domie Neil Bucag SalasÎncă nu există evaluări

- Saep 15 PDFDocument16 paginiSaep 15 PDFBIPIN BALANÎncă nu există evaluări

- Best Business Ideas in The PhilippinesDocument61 paginiBest Business Ideas in The PhilippinesDomie Neil Bucag SalasÎncă nu există evaluări

- Saep 14 PDFDocument45 paginiSaep 14 PDFBIPIN BALANÎncă nu există evaluări

- Key Partners Key Activities Value Propositions Customer Relationships Customer SegmentsDocument1 paginăKey Partners Key Activities Value Propositions Customer Relationships Customer SegmentsDomie Neil Bucag SalasÎncă nu există evaluări

- 45582-P0!77!019-V0003 (Earthing and Lightning Materials)Document10 pagini45582-P0!77!019-V0003 (Earthing and Lightning Materials)Domie Neil Bucag SalasÎncă nu există evaluări

- 45582-000!17!0013-P0 (KNPC Earthing Installation Standard)Document37 pagini45582-000!17!0013-P0 (KNPC Earthing Installation Standard)Domie Neil Bucag SalasÎncă nu există evaluări

- Concrete Works Method StatementDocument41 paginiConcrete Works Method StatementDomie Neil Bucag SalasÎncă nu există evaluări

- Principles of Boiler OperationsDocument35 paginiPrinciples of Boiler Operationseblees100Încă nu există evaluări

- A Review On Grease Lubrication in Rolling BearingsDocument12 paginiA Review On Grease Lubrication in Rolling BearingsRepositorio MantenimientoÎncă nu există evaluări

- Superabsorbent PolymerDocument21 paginiSuperabsorbent PolymerIsha MeshramÎncă nu există evaluări

- SQA-Hess's Law QuestionsDocument4 paginiSQA-Hess's Law QuestionsWidya GrantinaÎncă nu există evaluări

- Heterogeneous CatalystDocument24 paginiHeterogeneous Catalystlalukalu420Încă nu există evaluări

- To Do List (Msa)Document17 paginiTo Do List (Msa)Muhammad Umer RanaÎncă nu există evaluări

- Donald L Smith Gamma PatentDocument34 paginiDonald L Smith Gamma PatentjradÎncă nu există evaluări

- Soil Science 1Document17 paginiSoil Science 1Rohit Kumar ChoudhuryÎncă nu există evaluări

- Dumas Method LabDocument5 paginiDumas Method LabJohn JosephÎncă nu există evaluări

- AMMONIA PROCESS SIMULATIONDocument8 paginiAMMONIA PROCESS SIMULATIONChecoCastilloÎncă nu există evaluări

- Environmental EngineeringDocument5 paginiEnvironmental EngineeringOktrian SinathryaÎncă nu există evaluări

- Pour Point TestingDocument10 paginiPour Point TestingAAKASHÎncă nu există evaluări

- Item Bank Grade 9 SciencDocument12 paginiItem Bank Grade 9 SciencMarjorie BrondoÎncă nu există evaluări

- Eat 356/4 - Wastewater Engineering: Sludge Removal ManagementDocument33 paginiEat 356/4 - Wastewater Engineering: Sludge Removal Managementabas ibrahimÎncă nu există evaluări

- Sweeper & Vacuum TruckDocument8 paginiSweeper & Vacuum TruckAfryanto BuliÎncă nu există evaluări

- Part 2 - Materials and Manufacturing ElementsDocument101 paginiPart 2 - Materials and Manufacturing ElementsREYNALD MILOÎncă nu există evaluări

- New Microsoft Word DocumentDocument10 paginiNew Microsoft Word DocumentNawnit KumarÎncă nu există evaluări

- Kinetic Molecular Theory WorksheetDocument2 paginiKinetic Molecular Theory WorksheetnanaÎncă nu există evaluări

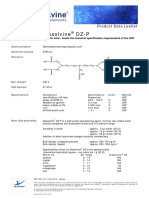

- Dissolvine DZ P PDLDocument2 paginiDissolvine DZ P PDLizzybjÎncă nu există evaluări

- Measuring Active Ingredients in Aspirin with TitrationDocument14 paginiMeasuring Active Ingredients in Aspirin with TitrationAnonno DipÎncă nu există evaluări

- Phenyl AcetoneDocument2 paginiPhenyl Acetoneunderworldinc100% (1)

- Embedding Media and TechniquesDocument8 paginiEmbedding Media and TechniquesAnnur HussainÎncă nu există evaluări

- Practice Problem Sets on Voltaic CellsDocument3 paginiPractice Problem Sets on Voltaic CellsChristian Angelo NECESITOÎncă nu există evaluări

- 5 Separatopn of Substances: MixtureDocument7 pagini5 Separatopn of Substances: MixtureCris CÎncă nu există evaluări

- Effect of Plasticizers On The Properties of Polyvinyl Alcohol FilmsDocument14 paginiEffect of Plasticizers On The Properties of Polyvinyl Alcohol FilmsJuanÎncă nu există evaluări

- Experiment 1: Reactions of Aliphatic HydrocarbonsDocument8 paginiExperiment 1: Reactions of Aliphatic HydrocarbonsTHASVIN OFFICIAL NETWORKÎncă nu există evaluări

- Dokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexDocument40 paginiDokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexRuan MouraÎncă nu există evaluări

- Drug Testing in The PhilippinesDocument51 paginiDrug Testing in The PhilippinesDhanimie Faye74% (23)

- Natural Hydrating Milk CleanserDocument1 paginăNatural Hydrating Milk CleanserNadaNursetiyantiÎncă nu există evaluări

- Excimer Lasers: Edited by Ch. K. RhodesDocument275 paginiExcimer Lasers: Edited by Ch. K. RhodesSujay SwainÎncă nu există evaluări

- An Architect's Guide to Construction: Tales from the Trenches Book 1De la EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Încă nu există evaluări

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (241)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe la EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsEvaluare: 4.5 din 5 stele4.5/5 (6)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItDe la EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItEvaluare: 4 din 5 stele4/5 (16)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe la EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationEvaluare: 4 din 5 stele4/5 (18)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDe la EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsÎncă nu există evaluări

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDe la EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsEvaluare: 1 din 5 stele1/5 (4)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Building Construction Technology: A Useful Guide - Part 2De la EverandBuilding Construction Technology: A Useful Guide - Part 2Evaluare: 5 din 5 stele5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- Real Life: Construction Management Guide from A-ZDe la EverandReal Life: Construction Management Guide from A-ZEvaluare: 4.5 din 5 stele4.5/5 (4)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDe la EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyEvaluare: 4 din 5 stele4/5 (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDe la EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingEvaluare: 5 din 5 stele5/5 (2)

- Residential Construction Performance Guidelines, Contractor ReferenceDe la EverandResidential Construction Performance Guidelines, Contractor ReferenceÎncă nu există evaluări