Documente Academic

Documente Profesional

Documente Cultură

TU-045 - AS-RBP - 9-5.8 in

Încărcat de

Atom InsideDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TU-045 - AS-RBP - 9-5.8 in

Încărcat de

Atom InsideDrepturi de autor:

Formate disponibile

DOWNHOLE

COMPLETIONS

SAPEX OIL TOOLS LTD. DIVISION

PACKERS & COMPLETION EQUIPMENT

WORKOVER & COMPLETION SERVICE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

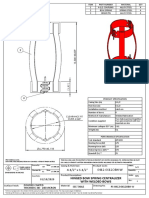

TECH UNIT - 045 : MODEL AS-RBP RETRIEVABLE BRIDGE PLUG, 9-5/8 (P/N: SDL-72496)

The SAPEX-DL Model AS-RBP Retrievable Bridge Plug is a high pressure packer type plug used for multiple

selective zone treating and testing operations. The plug is designed with a large internal bypass to prevent swabbing

when running and retrieving. The bypass closes during the setting of the plug and opens prior to releasing the upper

slips to equalize pressure when unsetting. The AS-RBP plug has the added feature of being able to set and packoff

the element in tension, making it ideal for setting shallow to test well head equipment and also deep, high pressure

wells.

SPECIFICATION GUIDE

CASING MAXIMUM OD OF

SIZE WEIGHT RECOMMENDED TOOL PRODUCT

(IN) (LBS/FT) HOLE SIZE (IN) NUMBER

9-5/8 43.5-53.5 8.535-8.755 8.250 72496-G6

* Tools listed are left hand set/ right hand release.

CAUTION: If the AS-RBP Packer is run with a Model HD Service Packer, make sure the bridge plug J-slot

is compatible with the J-slot on the packer. Whichever direction you set the plug, the packer

should set in the opposite direction.

SETTING PROCEDURE

Tension Set

Run to setting depth while latched to its spring loaded retrieving tool. Pick up, rotate 1/4 turn to the left at the plug,

and lower tubing to set lower slips. Pull tension to pack-off elements, slackoff, then pick up again to assure plug

setting. (See setting force guide.) After setting plug, slack off tubing weight, hold left hand torque and pick up to free

tubing from plug.

Compression Set

Run to setting depth while latched to its spring loaded retrieving tool. Pick up, rotate 1/4 turn to the left at the plug,

and lower tubing to set lower slips. Slack off sufficient weight to pack-off elements, then pick up to firmly set upper

slips and slackoff again. (See setting forces guide.) After setting plug, slack off tubing weight, hold left hand torque

and pick up the free tubing from plug.

RELEASING PROCEDURE

Lower tubing until the retrieving tool automatically latches to the AS-RBP Bridge Plug. Sand may be washed from the

upper slip by circulating through the upper portion of the plug. Slack off weight, hold right hand torque pick up to

open the bypass valve, and wait until differential pressure has equalized. Continue upward movement to release

upper slips, relax packing elements and re-latch. The plug may now be removed or re-located. If the plug will not

release conventionally, slack off re-set then pick straight up to shear J-pins and release the plug (shear value of the

J-pins is variable, see J-pin chart for options.) Once the J-pins are sheared the tool cannot be moved down hole.

TOMORROWS TECHNOLOGY FOR TODAYS ENERGY

DOWNHOLE

COMPLETIONS

SAPEX OIL TOOLS LTD. DIVISION

PACKERS & COMPLETION EQUIPMENT

WORKOVER & COMPLETION SERVICE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 045 : MODEL AS-RBP RETRIEVABLE BRIDGE PLUG, 9-5/8 (P/N: SDL-72496)

SHEAR VALUE FOR J-PIN SETTING FORCE GUIDE

SHEAR VALUE PIN DIAMETER SIZE MINIMUM FORCE (LBS)

50,000 0.909* (IN) REQUIRED AT PACKER

9-5/8 20,000

* Other shear values available on request.

NOTE: Most of the component parts are manufactured from heat treated alloy steel. Therefore,

extended exposure to corrosives can be detrimental to the metallurgy. Care in cleaning the

tool soon after removal from the well can help extend the life of component parts. Close

inspection of the parts is necessary, after removal, to identify any parts which require

replacement.

CAUTION: When running this tool with a packer, make sure the J-slots in the plug, running/ retrieving

tool, and packer are all compatible.

DISASSEMBLY

1.) Place center coupling (23) in vise.

2.) Remove bottom sub (45) from J-slot mandrel (6).

3.) Remove extension body set screws (3).

4.) Remove J-pin body (13) from body extension (14) and remove J-pin (12). LEFT HAND THREADS

5.) Remove extension body (14) from control body (16). LEFT HAND THREADS

6.) Slide control body toward the lower cone and remove rubber mandrel cap (17).

7.) Remove control body assembly and remove slips (33) and slip springs (43).

8.) Clamp on DRAG BLOCK ASSEMBLY/ DISASSEMBLY TOOL P/N: 080-55-900 and remove drag block retainer

(21).

9.) Remove drag blocks (34) and drag block springs (44) from control body (16).

10.) Remove pulling head (1) from upper mandrel (2). Remove spring retaining ring.

11.) Remove follower spring (8) from upper mandrel (2).

12.) Remove upper slip body (7) and remove upper slips (11), slip springs (42), and releasing slip (10).

13.) Remove upper mandrel set screws (3) and remove upper mandrel (2) from sealing mandrel (5).

14.) Remove plug (4) and remove o-ring (40).

15.) Remove J-slot mandrel (6) and sealing mandrel (5) from lower end of rubber mandrel (18).

16.) Remove J-slot mandrel set screws (46).

17.) Remove J-slot mandrel (6) from sealing mandrel (5).

DO NOT CLAMP OR WRENCH ON SEAL SURFACE

18.) Remove set screws (36) from upper cone (25).

19.) Remove upper cone (25) from center coupling (23). Remove o-ring (38).

20.) Remove one seal (24), retaining ring (26) and remaining seal (24) from center coupling (23).

21.) Remove seal o-rings (38).

22.) Remove rubber mandrel assembly from center coupling (23).

23.) Remove elements (29), rubber spacers (30), and lower cone (32) from rubber mandrel (19).

24.) Remove gage ring (28) from center coupling (23). Remove set screws (46) from lower slip sleeve (18) and

remove lower slip sleeve (18) from rubber mandrel (19).

25.) Remove center coupling (23) from vise and remove o-ring (37).

ASSEMBLY NOTE: When installing seal assembly (14) the end of the seal with the o-ring should point

toward the top of the tool.

TOMORROWS TECHNOLOGY FOR TODAYS ENERGY

DOWNHOLE

COMPLETIONS

SAPEX OIL TOOLS LTD. DIVISION

PACKERS & COMPLETION EQUIPMENT

WORKOVER & COMPLETION SERVICE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 045 : MODEL AS-RBP RETRIEVABLE BRIDGE PLUG, 9-5/8 (P/N: SDL-72496)

ITEM QTY PART NUMBER DESCRIPTION MATERIAL

1 1 72485715 PULLING HEAD P-110

2 1 72485210 UPPER MANDREL P-110

3 6 SSS037C050 SET SCREW STEEL

4 1 72485216 PLUG 1018

5 1 72485214 SEALING MANDREL P-110

6 1 72485340 J-SLOT MANDREL P-110

7 1 72495348 UPPER SLIP SUPPORT P-110

8 1 60373920CV FOLLOWER SPRING CHROME

VANADIUM

9 1 93811 UPPER SLIP CAGE P-110

10 2 93809 RELEASING SLIP 1018

11 3 93808 UPPER SLIP P-110

12 2 72485870 J-PIN P-110

13 1 72485875 J-PIN SUB P-110

14 1 72495370 BODY EXTENSION P-110

15 1 60095911 RETAINING RING 1018

16 1 60395335 DRAG BLOCK BODY P-110

17 1 72485230 RUBBER MANDREL CAP 1018

18 1 72485221 LOWER RUBBER MANDREL P-110

19 1 72485220 RUBBER MANDREL P-110

20 1 60395912 SLIP SUPPORT SLEEVE 1018

21 1 60395910 DRAG BLOCK RETAINER 1018

22 1 60095221 SECONDARY RUBBER RUBBER

MANDREL

23 1 72485620 CENTER COUPLING P-110

24 2 60070520 SEAL

25 1 72495410 UPPER CONE P-110

26 1 72485225 SEAL RETAINING RING 1018

27 3 SSS037C050 SET SCREW STEEL

28 1 60295830 GAGE RING 1018

29 3 6029551XS ELEMENT RUBBER

30 2 60295840S RUBBER SPACER 1018

31 1 60295850S RUBBER RETAINER 1018

32 1 60395420S LOWER CONE P-110

33 4 60095135 LOWER SLIP P-110

34 6 9080900 DRAG BLOCK 8620

35 1 SCS050C050 CAP SCREW STEEL

TOMORROWS TECHNOLOGY FOR TODAYS ENERGY

DOWNHOLE

COMPLETIONS

SAPEX OIL TOOLS LTD. DIVISION

PACKERS & COMPLETION EQUIPMENT

WORKOVER & COMPLETION SERVICE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 045 : MODEL AS-RBP RETRIEVABLE BRIDGE PLUG, 9-5/8 (P/N: SDL-72496)

TOMORROWS TECHNOLOGY FOR TODAYS ENERGY

S-ar putea să vă placă și

- Packer 7in Crest-II Sapex SpecDocument3 paginiPacker 7in Crest-II Sapex SpecbayuÎncă nu există evaluări

- GR - WRDSP - Tech LiteratureDocument7 paginiGR - WRDSP - Tech LiteratureDigger Downhole ToolsÎncă nu există evaluări

- Ah Hydraulic Setting ToolDocument12 paginiAh Hydraulic Setting ToolCarlos HolguinÎncă nu există evaluări

- ELDER IX 5 5 X 2 375Document8 paginiELDER IX 5 5 X 2 375crni rokoÎncă nu există evaluări

- BJ S C, USA: Doug LehrDocument12 paginiBJ S C, USA: Doug LehrBalkis FatihaÎncă nu există evaluări

- Arrow-Pak Retrievingtool: Specification GuideDocument7 paginiArrow-Pak Retrievingtool: Specification GuideTech AlfaÎncă nu există evaluări

- FO Cementer Manual SectionDocument44 paginiFO Cementer Manual SectionpaimanÎncă nu există evaluări

- MANDRILDocument2 paginiMANDRILFernando CastelblancoÎncă nu există evaluări

- Ps 0412 0600obh WDocument1 paginăPs 0412 0600obh WHunterÎncă nu există evaluări

- Ps 0412 0612obh WDocument1 paginăPs 0412 0612obh WHunterÎncă nu există evaluări

- BJ Services 9.6 TST-3 Service Packer ManualDocument26 paginiBJ Services 9.6 TST-3 Service Packer ManualBalkis FatihaÎncă nu există evaluări

- Polar RB Seal Bore Packer Technical Manual SummaryDocument3 paginiPolar RB Seal Bore Packer Technical Manual SummaryAlexander KlmÎncă nu există evaluări

- Sect 08 Plug CatchersDocument14 paginiSect 08 Plug CatcherspaimanÎncă nu există evaluări

- Arrow-Pak RT 266-45Document3 paginiArrow-Pak RT 266-45Tech AlfaÎncă nu există evaluări

- Parveen PRHP Packer: Downhole Completion EquipmentDocument5 paginiParveen PRHP Packer: Downhole Completion EquipmentsambhajiÎncă nu există evaluări

- 8023Document10 pagini8023Tamer Hesham AhmedÎncă nu există evaluări

- Basic Design and Maintenance Instructions: No: Sap: 41RO38101 101012267 2-6-04Document13 paginiBasic Design and Maintenance Instructions: No: Sap: 41RO38101 101012267 2-6-04azze bouzÎncă nu există evaluări

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Document4 paginiPacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezÎncă nu există evaluări

- 2023 10.75 TST-2 Service PackerDocument15 pagini2023 10.75 TST-2 Service PackerDhenny FarialÎncă nu există evaluări

- Completion Components: Oil and Gas Well CompletionsDocument28 paginiCompletion Components: Oil and Gas Well CompletionsJuan SueÎncă nu există evaluări

- Landing Nipple Technical SpecificationsDocument11 paginiLanding Nipple Technical SpecificationsscignoniÎncă nu există evaluări

- Locking Systems PDFDocument6 paginiLocking Systems PDFTamer Hesham AhmedÎncă nu există evaluări

- 7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Document5 pagini7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Roberto Andres Sizas ReyÎncă nu există evaluări

- BakerDocument4 paginiBakerWilliam EvansÎncă nu există evaluări

- Lock-Set, J-LokDocument3 paginiLock-Set, J-LokYaqoob IbrahimÎncă nu există evaluări

- 4.000 LOCATOR SEAL ASSEMBLY PARTS LISTDocument1 pagină4.000 LOCATOR SEAL ASSEMBLY PARTS LISTJhonathan MirandaÎncă nu există evaluări

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocument3 paginiSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedÎncă nu există evaluări

- PCK para Limpiar PunzadosDocument19 paginiPCK para Limpiar PunzadosRodolfo RiderÎncă nu există evaluări

- 2021 16.0 TST-2 Service PackerDocument15 pagini2021 16.0 TST-2 Service PackerDhenny FarialÎncă nu există evaluări

- BTU Retreivable PlugDocument1 paginăBTU Retreivable Plugbrunolb1Încă nu există evaluări

- 616-35000 Assembly DrawingDocument1 pagină616-35000 Assembly DrawingAl KautsarÎncă nu există evaluări

- 9.625'' Seal NippleDocument1 pagină9.625'' Seal NippleMohamed Mahmoud Rezk DimoÎncă nu există evaluări

- Catalog - H Hydraulic Setting ToolDocument1 paginăCatalog - H Hydraulic Setting ToolCarlos Alberto Aguilera MendezÎncă nu există evaluări

- Hydro-Mech Bridge Plug ManualDocument7 paginiHydro-Mech Bridge Plug ManualKeshav PujeriÎncă nu există evaluări

- Liner PackersDocument1 paginăLiner PackersMohamed ElabbasyÎncă nu există evaluări

- Permanent PKR Eline/Hydraulic Setting Tool Signature: AdvantagesDocument18 paginiPermanent PKR Eline/Hydraulic Setting Tool Signature: Advantagesjulio RDLRÎncă nu există evaluări

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 paginiC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Model A (O) V-40 Sur-Set™ Check Valve: Flow Control Systems Technical UnitDocument16 paginiModel A (O) V-40 Sur-Set™ Check Valve: Flow Control Systems Technical UnitTamer Hesham AhmedÎncă nu există evaluări

- CHAMP® XHP PackerDocument2 paginiCHAMP® XHP PackerservicemenruÎncă nu există evaluări

- WH6 2005Document19 paginiWH6 2005annÎncă nu există evaluări

- Weatherford Lamb Libya Limited - Casing Exit & Selective ReDocument75 paginiWeatherford Lamb Libya Limited - Casing Exit & Selective ReRicardo Hurtado HernándezÎncă nu există evaluări

- New BDMI L 4.5 HE0Document6 paginiNew BDMI L 4.5 HE0Natanael SaputraÎncă nu există evaluări

- Wire Line SettingDocument19 paginiWire Line SettingNagarjunSHÎncă nu există evaluări

- Bimbar Inflatable PDFDocument36 paginiBimbar Inflatable PDFcarlosdh_03Încă nu există evaluări

- Technical Specification 3.5 CompletionDocument43 paginiTechnical Specification 3.5 Completionbasil ameenÎncă nu există evaluări

- Maximus Product CatalogDocument78 paginiMaximus Product Catalogapi-155731311Încă nu există evaluări

- 15 800 7040 00 00 PLDocument1 pagină15 800 7040 00 00 PLJhonathan MirandaÎncă nu există evaluări

- Baker A-5 SemidisassenblyDocument7 paginiBaker A-5 SemidisassenblyabodolkuhaaÎncă nu există evaluări

- Hydraulic Setting Tool: Simple Operation, High Pressure SettingDocument6 paginiHydraulic Setting Tool: Simple Operation, High Pressure Settinganthony silvaÎncă nu există evaluări

- Half Mule Shoe Guide 88050307Document2 paginiHalf Mule Shoe Guide 88050307satyendraÎncă nu există evaluări

- Hyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ ProfileDocument5 paginiHyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ Profilemsm.ele2009Încă nu există evaluări

- Botil Model BTCN Mechanical Set PackerDocument2 paginiBotil Model BTCN Mechanical Set PackerReivaj JavierÎncă nu există evaluări

- 7 000 X 2.875 HD Retrievable Packer - 1stDocument3 pagini7 000 X 2.875 HD Retrievable Packer - 1stvitortelesÎncă nu există evaluări

- Design Overview: Basic Design and Maintenance InstructionsDocument5 paginiDesign Overview: Basic Design and Maintenance Instructionsazze bouzÎncă nu există evaluări

- RTTS Model 2 Circulating Valves: SectionDocument18 paginiRTTS Model 2 Circulating Valves: SectionMohamed ShafieÎncă nu există evaluări

- FB2 - RB2Document15 paginiFB2 - RB2Sajida QadeerÎncă nu există evaluări

- 9.625x4 Arrow-Pak (265-94)Document3 pagini9.625x4 Arrow-Pak (265-94)Tech AlfaÎncă nu există evaluări

- Schlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"Document1 paginăSchlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"yasirismÎncă nu există evaluări

- Tu-042 - As-Rbp - 5-1.2 inDocument3 paginiTu-042 - As-Rbp - 5-1.2 inDoni KurniawanÎncă nu există evaluări

- Casing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsDocument14 paginiCasing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsJose Antonio Acosta100% (1)

- T-162 1338in Cementing Program (Oct 21,2009)Document24 paginiT-162 1338in Cementing Program (Oct 21,2009)Atom InsideÎncă nu există evaluări

- T-101 D ZoneDocument24 paginiT-101 D ZoneAtom InsideÎncă nu există evaluări

- Well TT 22 CBL VDL GR CCLDocument14 paginiWell TT 22 CBL VDL GR CCLAtom InsideÎncă nu există evaluări

- UTS Well PDFDocument190 paginiUTS Well PDFAtom InsideÎncă nu există evaluări

- Contoh Formulir Pajak PDFDocument16 paginiContoh Formulir Pajak PDFCicillia ArintaÎncă nu există evaluări

- AT For Wizfi360Document66 paginiAT For Wizfi360Sarath SanthoshÎncă nu există evaluări

- Termostato Digital TH1110DV1009 U Honeywell Informacion Del ProductoDocument4 paginiTermostato Digital TH1110DV1009 U Honeywell Informacion Del ProductoHarnold GarnicaÎncă nu există evaluări

- Top 10 Scientists of All Time 1) PythagorasDocument2 paginiTop 10 Scientists of All Time 1) Pythagorassahal yawarÎncă nu există evaluări

- F-SERIES (250 - 550) (6.7L DIESEL) : Electronic Engine Controls Wiring DiagramDocument24 paginiF-SERIES (250 - 550) (6.7L DIESEL) : Electronic Engine Controls Wiring DiagramDiego Lira100% (3)

- UA723Document13 paginiUA723rordenvÎncă nu există evaluări

- Windows Scripting SecretsDocument559 paginiWindows Scripting SecretsA Miguel Simão LealÎncă nu există evaluări

- Introduction To Predictive LearningDocument101 paginiIntroduction To Predictive LearningVivek KumarÎncă nu există evaluări

- Week 11 Lecture 20Document16 paginiWeek 11 Lecture 20Muhammad FaisalÎncă nu există evaluări

- ORACLE9i - SQLDocument113 paginiORACLE9i - SQLmohamed gaaferÎncă nu există evaluări

- Varactor Diode PDFDocument3 paginiVaractor Diode PDFLackith Chandimal HettiarachchiÎncă nu există evaluări

- Westco Model5500 Tubing TongDocument51 paginiWestco Model5500 Tubing Tong000Încă nu există evaluări

- IntroDocument17 paginiIntroRamakrishnaRao SoogooriÎncă nu există evaluări

- Local Search AlgorithmsDocument14 paginiLocal Search AlgorithmsShreyas VaradkarÎncă nu există evaluări

- Pnematic StructureDocument30 paginiPnematic StructureparulÎncă nu există evaluări

- Antipole Tree IndexingDocument16 paginiAntipole Tree IndexingJesus Alberto Arcia HernandezÎncă nu există evaluări

- 2CDS253001R0324Document5 pagini2CDS253001R0324Alma Leon AcostaÎncă nu există evaluări

- 18mat411 MAT-1Document4 pagini18mat411 MAT-1M.A rajaÎncă nu există evaluări

- Basic Parameters:: Wind Load Calculation (X-Direction)Document11 paginiBasic Parameters:: Wind Load Calculation (X-Direction)SuvankarÎncă nu există evaluări

- Siemens MindSphere Whitepaper Tcm27-9395Document26 paginiSiemens MindSphere Whitepaper Tcm27-9395shahramkh59Încă nu există evaluări

- Doubly Reinforced BeamDocument9 paginiDoubly Reinforced BeamBaharulHussainÎncă nu există evaluări

- X X X X X X FX X X: Group A Find The Vertical Asymptotes and Holes of The FollowingDocument9 paginiX X X X X X FX X X: Group A Find The Vertical Asymptotes and Holes of The Followingapi-262707463Încă nu există evaluări

- Renal Physiology:: 1. Renal Blood Flow Is Dependent OnDocument16 paginiRenal Physiology:: 1. Renal Blood Flow Is Dependent OnBlackstarÎncă nu există evaluări

- Field D StarDocument35 paginiField D StarSamgse91Încă nu există evaluări

- Rock DrillDocument76 paginiRock Drillcristian100% (1)

- Tidy-Print Pn-Ad-Tds - EngDocument4 paginiTidy-Print Pn-Ad-Tds - Engtendi soerjanagaraÎncă nu există evaluări

- Training 2021 - APACDocument204 paginiTraining 2021 - APACAlbert Nguyen100% (2)

- Radiation Chemistry: Technetium-99m GeneratorDocument32 paginiRadiation Chemistry: Technetium-99m GeneratorreinpolyÎncă nu există evaluări

- C&R Panel (Without Automation) - Aug, 2016Document73 paginiC&R Panel (Without Automation) - Aug, 2016apsÎncă nu există evaluări

- Designing Backup Solutions For Vmware Vsphere: Technical NoteDocument26 paginiDesigning Backup Solutions For Vmware Vsphere: Technical NoteJorge Luis G RÎncă nu există evaluări

- ChoiceboardDocument3 paginiChoiceboardapi-544591906Încă nu există evaluări