Documente Academic

Documente Profesional

Documente Cultură

Thread Spec ASME B.1.20.1

Încărcat de

Deny Safari0 evaluări0% au considerat acest document util (0 voturi)

488 vizualizări32 paginipipe threads

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentpipe threads

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

488 vizualizări32 paginiThread Spec ASME B.1.20.1

Încărcat de

Deny Safaripipe threads

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 32

AN AMERICAN NATIONAL STANDARD

" PIPE THREADS, GENERAL

PURPOSE (INCH)

ANSI/ASME B1.20.1 - 1983

(REVISION AND REDESIGNATION OF ANS! 2.11968)

SPONSORED AND PUBLISHED BY

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

United Engineering Center 345 East 47th Street New York, N. ¥. 10017

FOREWORD

(This Foreword is not part of American Nations! Standerd, Pipe Threads, General

Purpose (Inch) ANSWASME 81.20 1-1583)

In 1973 American National Standards Committee B2, which had formerly been responsible for pipe thread

standards, was absorbed by ANSI Standards Committee BI and reorganized as subcommittee 20. A com-

plete rewrite of the B2.2-1968 standard on Dryseal Pipe Threads has been completed, with the product

thread data in separate documents from the gaging standards for Dryseal Pipe Threads. The system of aum-

bering, to include metric conversions, is as follows:

ANSI BI.20.3-1976 Dryseal Pipe Threads (Inch)

ANSI BI.20.4-1976 Dryseal Pipe Threads (Metric Translation)

ANSI BI.20.5-1978 Gaging for Dryseal Pipe Threads (Inch)

In preparation, BI.20.6M Gaging for Dryseal Pipe Threads (Metric Translation)

‘A complete rewrite of the B2.1-1968 standard on Pipe Threads (Except Dryseal) was then

‘The system of numbering, to include metric conversions, is as follows:

indertaken.

ANSI/ASME B1.20.1 Pipe Threads, General Purpose (Inch)

In preparation, B1.20.2M Pipe Threads, General Purpose (Metric Translation)

These standards, ANS/ASME: B1,20.1 and B1.20.2M, have product thread dimensions and gaging in the

same document. Thread inspection specifies the use of L, taper thread plug and ring gages similar to

B2.1-1968. In addition, emphasis is given to the requirement that all basic thread design dimensions are to

bbe met within the specified tolerances.

‘The data in this Standard supersede those given in ANSI B2.1-1968.

‘The ANSYASME B1.20.1 was approved by ASME Standards Committce B1 on December 1, 1982 for

publication as an official ANSI standard.

‘The proposed standard was submitted by standards committee BI to the Secretariat and the American

National Standards Institute. It was approved and formally designated as an American National Standard

on February 4, 1983,

ASME STANDARDS COMMITTEE B1

‘Standardization and Unification of Screw Threads

(he foltowing i the roster ofthe Commitee at the time of approval of this Standard)

OFFICERS

. 4 Emanuel, Chalman

i COMMITTEE PERSONNEL

AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA, INC,

. G. Gerber, McDonnell Douglas, St, Louis, Missouth

i H. Boremon, Alternate, Sperry Gyroscope Division, Groat Nock, New York

AMERICAN IRON AND STEEL INSTITUTE

F. Dallas, Svhill Tubular Division, Sharan, Pennsylvania

‘ AMERICAN MEASURING TOOL MANUFACTURERS ASSOCIATION

i 1. Dodge, Pennoyer-Dadge Company, Glendale, California.

4 C. We datho, Alterote, American Messuring Tool Manufacturers Association, Birmingham, Michigan

AMERICAN PIPE FITTINGS ASSOCIATION

i Wi. C. Farol, Stockham Valves and Fittings, Birmingham, Alsbams

DEFENSE INDUSTRIAL SUPPLY CENTER,

( , Schwartz, Defense Industrat Supply Canter, Philadelphia, Pennsyivania

F. 8. Clesarone, Alternate, Defence Indistria! Supply Center, Philadelphia, Pennsylvania

ENGINE MANUFACTURERS ASSOCIATION

| G. A. Ruse, Cummins Engine Company, Columbus, Indiana

\ FARM AND INDUSTRIAL EQUIPMENT INSTITUTE

‘4. F. Nagy, Ford Motor Company, Dearborn, Michigan

INDUSTRIAL FASTENERS INSTITUTE

A. B. Botford, Industrial Fastoners Institute, Cleveland, Ohio

RLM, Harris, Bethichem Stecl Company, Lebanon, Pannsyivania

IK. E. MeCullough, SP Technologies, Inc, Jenkintown, Penneyivania

(C. Medlureay, Russll,Burdsll and Ward Ine., Mentor, Ohio

A. Triling, Holo-Krome Company, West Hartford, Connecticut

. D. Spangler, Alternate, Bethlehem Stoel Company, Lebanon, Pennsylvania

MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTING INDUSTRY

W. C. Farell, Stockham Valves and Fittings, Birmingham, Alabama

METAL CUTTING TOOL INSTITUTE (TAP & DIE DIVISION)

IN. F, Neu, Union/Butertold, Athol, Masschusetts

‘A.D, Shepherd, J, Alternate, Union/Butterfild, Derby Line, Vermont

NATIONAL AUTOMATIC SPRINKLER AND FIRE CONTROL ASSOCIATION, INC.

W. Testa, Grinnll Fire Protection Systems Company, Ine, Providence, Rhode Island

R. P, Fleming, Alternate, National Automatic Sprinkler and Fice Control Aseocation, ne. Patterson, New York

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION

JL. Griffin, Wheatland Tube Company, Whestiand, Pannylvania

4B. Levy, General Electric Company, Schanectady, New York

F, F. Weingruber, Westinghouse Electric Corp, Pitsburah, Penney vena

W. F. Wilford, Alcornate, National Electrial Menutacturers Asrociation, Washington, D.C.

NATIONAL MACHINE TOOL BUILDERS ASSOCIATION

R. J. Sabatos, The Cleveland Twist Drill Company, Cleveland, Ohio

D. R. Stoner, J, Teledyne Landi Machine, Waynesboro, Pennsylvania

NATIONAL SCREW MACHINE PRODUCTS ASSOCIATION

“T. S. Meyer, Fischer Special Manufacturing Company, Cold Spring, Kentucky

H. A. Eichstaed, Alternate, National Sere Machine Products Astociation, Brecksville, Ohio

SOCIETY OF AUTOMOTIVE ENGINEERS

H.W. Elson, General Motors Technical Canter, Waren, Michigan

SOCIETY OF MANUFACTURING ENGINEERS

D. Davidson, MorseHemeo Corp, Holand, Michigan

‘TUBULAR RIVET AND MACHINE INSTITUTE

RLM. Byre, Industry Service Bureau, Ine, White Pine, New York

UNITED STATES DEPARTMENT OF THE AIR FORCE

RP. Stowart, WrightPattercon AFB, Dayton, Ohio

UNITED STATES DEPARTMENT OF THE ARMY

44. Crowley, U.S. Army Material Development and Readiness Command, Alexandre, Visa

F. dk Clas, Watervliet Arsenal, Wateriet, New York

F. L. Jones, alternate, U.S. Army Missle Command, Redstone Arsenal, Alabama

UNITED STATES DEPARTMENT OF DEFENSE

, Schworte, Defense Industrial Supply Center, Philadetphie, Pennsylvani

UNITED STATES DEPARTMENT OF THE NAVY

(. T. Gustalson, Portsmouth Naval Shipyard, Portsmouth, New Homothire

INDIVIDUAL MEMBERS

1G. T. Appleton, Jefferson, Massachusotts

. IN. Badgley, Clark Equipment Company, Battle Creek, Michigan

I. Boshnlsin, PMC Industries, Wiekliffe, Ohio

E. Bour, Sente Monia, California

R. Bread, Mechanical Fasteners and Assembly, Lakewood, Ohio

‘Browning, Southern Gage Company, Erin, Tennesioe

\. Butovic, Air Industries Corp, Garden Grove, California

‘8. Chamerda, The Johnson Gage Company, Bloomfield, Connecticut

F. Gramer, Des Moines, Washington

F. Dickson, Reed Rolled Thread Die Company, Holden, Matsochusatts

B. Donshus, Xerox Corp, Webster, New York

W. Drescher, Lancaster, Pennsylvania

«.

1

wi.

BPRS

Emanuel, Greenfield Tap and Die, Greenisd, Massachusetts

Erickson, Colt Industries, Storing Die Operation, West Hartford, Connecticut

Kanter, The Hanson Whitney Company, Hertford, Connecticut

Lamport, The Ven Keuren Gompany, Watertown, Massachusetts

AL Machel, J, Xerox Corp, Rochester, New York

, Martrson, Watervit, New York

LE. Mazzara, Geometric Tool, New Haven, Connecticut

HG. Muonchingor, Westriy, Rhode Island

Pppepome

. V. Pastore, Raga Beloit Corp, South Bele

Iie

‘MLM, Schuster, H:Shear Corp, Torrance, California

fi ‘A. G. Strang, Boyds, Maryland

L. R. Strang, Caterpillar Tractor Company, Peova,

A. F. Thibodeau, Swanson Tool Manufacturing, Ine., Wert Hartford, Connecticut

Turton, The Bendix Corp., Greenfield,

Maszichusote

PERSONNEL OF SUBCOMMITTEE 81.20 ~ PIPE THREADS

1. N, Badgley, Ghoeman, Clark Equipment Company, Battle Creek, Michigen

WA. Keaton, Vice-Chairman, Genel ldotore Technical Cantar, Warren, Michigan

| J. 8. Hinske, Secretary, Parker Hannifin Corp, Worcester, Massochusetts

{. Banks, Naval Sea System Command, Washington, D.C.

IM, Bibeau, Jamestury Corp, Worcester, Massachusetts

| 4. Browning, Southern Gage Company, Erin, Tennesse

i D. Cadioux, TAW/Greanfield Tap & Die Division, Greenfield, Massachusetts

\ 4. A. Corner, Hydril Technology Contr, H

\ Wi. O. Glinedtins, Belleair, Florida

vston, Tena

WLR. Gechean,J&t S100! Corp., Aliquippa, Pennsylvan

F. Dallas dr, Sawhill Tubular Division, Cyclops Corporation, Sharon, Pennsylvania

1D, Davidson, torse/Hemeo Corp, Holand, Michigan

1. Dodge, Ponnoyer-Dodge Company, Glendale, California

VEC. Fae, J, Stockham Valves & Fittings, Birmingharn, Alabama

LS. Falaheim, The Weatherhead Company, Cleveland, Ohio

A.C. Flanders, Picoma Industrie, Ine, Martine Fery, Ohio

WW. A. Franz, U.S, Stel Cop. Pittsburgh, Pennsylvania

H. D, Gotabers, Alliad Tube & Conduit Carp, Harvey, Ilioois

WE, Hay, The Pipe Machinery Company, Wickliffe, Ohio

I SL. Kanter, The Hanson Whitney Company, Hertford, Connecticut

i G. K. Otten, Wheeling Machine Products Company, Wheeling, West Virgins

s.

a

A. G. Strang, Boyds, Moryland

2

R. 8, Plotrouski, Mack Trucks, Inc. Allentown, Pennsylvani

Ruse, Cummins Engine Company, nc, Columbus, Indiana

. Shehera, J. Litton Unian/Butterild, Derby Line, Vermont

‘Turton, The Bendix Corp, ne, Greealield, Moxeachuratts

CONTENTS

Foreword Sa08

Standards Commitiee Roster

1 Introduction

1.1 Scope coe

12. Thread Designations .

13. Sealing

14 Inspection

15° Appendix

16 Related Standard

2 American National Standard Pipe Thread Form

21 Thread Form... .

22. Angle of Thread i

23° Truncation and Thread Height

3. Specification for General Purpose Taper Pipe Threads, NPT

3.1 Taper Pipe Threads

3.2 Tolerances

4 Specifications for Internal Straight Threads in Pipe Couplings, NPC.

4.1 Straight Pipe Threads in Pipe Couplings

9 Joint Taper Pipe Threads, NPTR

5 Specifications for Ri

5.1 Railing Joints

6 Specifications for Straight Pipe Threads for Mechanical Joints;

NPSM, NPSL, NPSH :

6.1. Straight Pipe Threads

6.2. Free-Fitting Mechanical Joints for Fixtures, NPSM

6.3. Loose-Fitting Mechanical Joints With Locknuts, NPSL.

6.4 Loose-Fitting Mechanical Joints for Hose Coupling, NPSH

7 Gages and Gage Tolerances for American National Standard Pipe Threads

TA Design of Gages

7.2 Classes of Gages

73. Gage Tolerances

74. Relation of Lead and Angle Deviations to Pitch Diameter

Tolerances of Gages

8 Gaging of Taper Pipe Threads G

8.1 Gaging External Taper Threads

8.2 Gaging Internal Taper Threads

83. Gaping Practice

84. Gaging Chamfeted, Countersunk, or Recessed Threads

9 Gaging of Straight Pipe Threads .

9.1 Types of Gages.

9.2 Gage Dimensions

Figures

1 Basic Form of American National Standard Taper Pipe Thread .

2. American National Standard Taper Pipe Threads for Pressure-Tight Joints, NPT

3. American National Standard Taper Pipe Thread Notation

4 NPP Standard Taper Pipe Thread Plug and Ring Gages

5 Suggested Form of Gage Thread

6 Gaging External Taper Threads With Ring Gage

7 Gaging Internal Taper Threads

8 Gaging of Chamfered Threads. -

Tables

1 Limits on Crest and Root Truncation of American National Standard External

and Internal Taper Pipe Threads, NPT

Basic Dimensions of American National Standard Taper Pipe Thread, NPT

Tolerances on Taper, Lead, and Angle of Pipe Threads, NPT.

Dimensions, Internal Straight Threads in Pipe Coupling, NPSC

Dimensions of External and Internal Taper Pipe Threads for Railing Joints, NPT.

Dimensions of External and Internal Straight Pipe Threads for Fixtures, NPSM

Dimensions, External and Internal Straight Pipe Thread for

Locknut Connections, NPSL .

8 Basic Dimensions of Threaded Plug and Ring Gages for National American National

Standard Taper Pipe Threads, NPT

9 Tolerances for American National Standard Working Taper Pipe Thread Plug and

Ring Gages, NPT

10 Diameter Equivalent of Deviation in Hal Included Angle of Thread for

Tools and Gages .

11 Diameter Equivalent of Deviation in Lea for Tools and Gages

‘Appendix

vii

14

4

4

a

1s

12

a

19

20

a

ANSI/ASME 61.20.1-1983

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

1 INTRODUCTION

1.4 Scope

‘This American National Standard covers dimen-

sions and gaging of pipe threads for general purpose

applications.

4.2 Thread Designations

1.2.4. The types of pipe threads included in this

Standard are designated by specifying in sequence

the nominal pipe size,' number of threads per inch

and the thread series symbol as follows:

3/8 ~ 18 NPT

1/8 - 27 NPSC

1/2-14NPTR

1/8 - 27 NPSM

1/8 -27 NPSL.

1-115 NPSH

For left hand threads add LH to the designation,

otherwise right hand threads will be understood. For

example:

3/8 = 18 NPT- Li

1.22 Each of these letters in the symbols has a

definite significance as follows:

N = National (American) Standard

P = Pipe

© = Coupling

S = Straight

M = Mechanical

H = Hose Coupling

R = Railing Fittings

‘where it is necessary to use decimal notation for the size

designation (as when inserting such in a computer or elec:

‘wonic accounting machine) the decimal equivalent of nom

inal pipe size may be substituted for fractional pipe sizes

1.2.3 Coated or Plated Threads. The threaded

product specifications covered in this Standard do

not include an allowance for coatings or plating.

123 Seal

1.3.1 Where pressure-tight joints are required, itis.

intended that taper pipe threads conforming to this,

Standard be made up wrench-tight with a sealant,

To prevent galling on certain piping materials such as

stainless steels, the sealant usually contains a lubricant.

1.32 Pipe threads designed for pressure-tight

joints that may be used without sealing compounds

(Dryseal Threads) are covered in ANSI BI.20.3 (Inch)

and ANSI BI.20.4 (Metric Translation).

1.4 Inspection

A gaging method and tolerances are preseribed in

this Standard to effect a functional inspection of the

hhandtight Z, engagement threads. However, con-

formance to this Standard requires that all basic

design dimensions be met (within applicable toler-

ances) including extension of the thread elements to

provide for wrench-tight makeup. Therefore, addi

tional methods of gaging may be employed to

evaluate conformance to the basic design dimensions.

When additional methods of gaging are employed,

they shall be agreed upon by the supplier and the

purchaser.

1.5 Appendix

Useful and supplementary information which is

not a part of this Standard is presented in the Appen-

dix. Specifically, the Appendix gives Suggested Twist

Drill Diameters for Drilled Hole Sizes for Pipe

Thieads,

1.6 Related Standard

Definitions of terms and symbols for thread di

‘mensions are given in ANSI BI.7, Nomenclature,

Definitions and Letter Symbols for Screw Threads,

op

LE LOZE

Le

Uj

WL

XS

FIG, 1 BASIC FORM OF AMERICAN NATIONAL STANDARD TAPER PIPE THREAD.

PIPE THREADS, GENERAL PURPOSE (INCH) ANSW/ASME 61,20.1-1982,

[AN AMERICAN NATIONAL STANDARD

[21000

isu ae

Sweet emanea | eunmog | et | nog | wr) emuvog

_ wren ‘eran

(4) 2814 40 pI waren i (Uy wonsounay,

14dN ‘SOVSYHL 3dld HAV. TWNUSLNI GNY TWNULXa

GUVANVS TVNOLLVN NVOINAW 40 NOLLWONNEL LOOU GNV 1s3H9NO SLIWIT 1 aTaVL

peasy eusorxg

Prony usesuy

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL. PURPOSE (INCH)

ANSI/ASME 81.20.1-1983

Internat Thread

LLL

Fasc

ZZ

intertrence

External Thread

GENERAL Nor

‘Wen threaded joints are made up wrench tight with lubricant or sealer, i intended thatthe flanks shall bein conto.

FIG. 2. AMERICAN NATIONAL STANDARD TAPER PIPE THREADS FOR PRESSURE-TIGHT JOINTS, NPT

2 AMERICAN NATIONAL STANDARD.

PIPE THREAD FORM

2.1 Thread Form

The form of thread profile specified in this Stan-

dard shall be known as the American National Stan:

dard Pipe Thread Form. The relations as specified

herein, for form of thread and general notation are

shown in Fig. 1

22 Angle of Thread

‘The angle between the sides of the thread is 60

deg when measured in an axial plane. Th line biseot-

ing this angle is perpendicular to the axis

2.3 Truncation and Thread Height

‘The height of the sharp V thread, H, is

H=0.866025p = 0.866025/n

The basic maximum depth of the truncated

thread, ft (Gee Fig. 1), is based on factors enter-

ing into the manufacture of cutting tools and the

‘making of tight joints.

.800p = 0.800)

The crest and root of pipe threads are truncated a

‘minimum of 0.033p. The maximum depth of trunca

tion for the crest and root of these pipe threads will

bbe found in Table 1. The crests and roots of the ex.

temal and internal threads may be truncated either

parallel to the pitch line or parallel to the axis.

‘The sketch in Table 2, giving a sectional view of

this Standard thread form, represents the truncated

thread form by a straight line. However, when closely

examined, the crests and roots of commercially

‘manufactured pipe threads appear slightly rounded.

‘When crests and roots of threading tools or chasers lie

within the limits shown in Table 1, the pipe threads

of products produced by such means are acceptable

on the basis of in-process control.

3 SPECIFICATION FOR GENERAL PURPOSE

‘TAPER PIPE THREADS, NPT

3.1 Taper Pipe Threads

Threads made in accordance with these specifica

tions consist of an external taper and an internal

taper thread, to form the normal type of joint having,

‘general application on pipe and fittings. See Fig, 2.

NPT taper pipe threads are intended to be made

up wrench-tight and with a sealant whenever a pres-

sure-tight joint is required.

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH

Normal wrench

makeup Lp ~L;—>

jae

Plane of nosmat

wwronch take-up

Roterence plana zero

ANSW/ASME 61.20.1-1983

“reed leoath

reed

Plone of vanish point

Z

SS

Gee

FiG.3 AMERICAN NATIONAL STANDARD

‘TAPER PIPE THREAD NOTATION

Sealing is affected by out-of-roundness which is

possible between the wrench-tight mated parts in final

assembly. This will vary depending on the method for

producing the thread in conjunction with the elasticity,

and/or ductility of the mating parts and the resultant

conformance at final assembly,

3.1.1. Thread Designation and Notation, American

National Standard Taper Pipe Threads are designated

in accordance with 1.2.1 as follows:

3/8 - 18. NPT

‘Standard notation applicable to American National

Standard Taper Pipe Threads is shown in Fig. 3.

‘3.1.2 Designation of Plated Threads. The product

specifications of this Standard do not include an

allowance for plating. If plating is desired, it may be

necessary to modify the threads since the same final

gaging requirements must be satisfied for plated and

unplated parts. This may be emphasized by adding

the words AFTER PLATING to the designation, For

‘manufacturing purposes, notes for plated taper pipe

threads may specify the gage limits (turns or threads

engagement) before plating followed by the words

BEFORE PLATING. These should be followed by

the standard gage limits (tums or threads engage

‘ment) after plating and the words AFTER PLATING.

3.1.3 Form of Thread. The form of the thread for

American National Standard Taper Pipe Threads is

that specified in 2.1.

BAA Teper of Thread, The taper of the thread is

1 in 16 or 0.75 in,fft measured on the diameter and

along the axis.

‘2.15 Diameter of Thread. The basic pitch diame-

ters of the taper thread are determined by the follow-

‘ng formulas? based on the outside diameter of the

Pipe and the pitch of the thread:

B= D-(00SD + 1.1) 1/n

=D~ (00D +1.1)p

Ey = Ey +0.0625L,

where

D = outside diameter of pipe

itch diameter of thread at end of pipe or

small end of external thread

E, = pitch diameter of thread at the gaging notch

or large end of internal thread

normal engagement by hand between exter-

nal and internal threads

n= threads per inch

For the Yy-27 and Yy18 sizes, £ approx. =D ~ (0.0SD

9.2277

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

Pied tne

A

ANSH/ASME 81,20.1-1983

tin

v

(oniah dross

(due to chamfer

‘on die)

“Teper of thread

16 measured

RS

aX

KH

th Diam Handiaht Enssoement

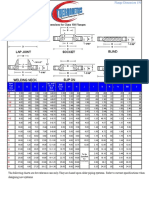

Nominat | 0.0.0f Pach ot | a Boing | Leagan? te an

Pie | Pie | Thronivin. | ‘Threed |'ct extemal | E21? | ag, 3 .

eto a Wr _| Taecd ea) | inch [ Theods | Uerd en

1 2 3 2 6 © >? 3 70 i

te | sis | a o.0370¢| o27i8 | 0160 o2sits | 0261 0.28750

| Mas | oas7o4| 36351 | o1sts 037360 | 02639 | o'3s000

y oso | 18 o9sss6} 0.47739 | 0.2778 ais | 4018 | oso2so

oss | 18 0.08856 | 0.61201 | 0.240 osz701 | 0.4078 | 0.63750

¥ 0.840 “4 0.07143} 0.75843 | 0.320 0.77843 | 0.5337 |} 0.79179

eye a id asriea| oseres | 0339 sass? | 0.5457 | 0175

1 tas | is | onsese| 1.21363 | ooo 123863 | 0.6828 | 25630

1% 1.660 15 | osege| 155713 | 0.420 1558338 | 0.7068 | X60130

ih | 150 | is | assess] 179609 | 0.420 Vaz | 07235 158130

2 as | ou oasea6 | 226002 | 0.436 229627 | 0.7565 231600

a | aes | 8 o.2500| 2.71983 | oss2 aeons | 137s 2.79062

3 3500 | 011500] 334062 | 0.766 338850 | 12000 Sass

3% | 400 | 8 032500| 383750 | 821 3asssr | 12500 3.1362

a 4500 | 8 0.12500) 433438 | O84 a3ena | 13000 562

5 cae o.r2s00| 5.38073 | 0937 sasoa9 | 1.4063 sareea

é seas | 8 0.12500) saasoo | 0358 630597 | 13125 654062

5 tes | 8 o.r2so0| s.a3aso | 1.063 #30003 | 17125 834082

0750 | 8 a.r2s00| 'sasar | 1210 rolsz09 | 119250 vo.ssse2

nao |e 4212500| 125328 | 1360 nasrrar | 21250 va.sese2

4000 | 8 0.12500] 13.7750 | 1562 1asr262 | 2.2500 sis62

e000 | 8 012500] 15.6250 | 12 isarsis | 24500 ts91se2

ve000 | 8 32506 | 1775000 | 2.000 1787500 | 26300 raise

2000 | & a.t2s00) 9.n3730 | 2.15 sarost | 2.8500 9.91562

2400 | 8 a.r2s00| 23.1250 | 2375 2aacons | 32500 poise

NOTES:

(1 The basie dimensions of the American National Standard Taper Pipe Thread are gin in inches to four or five decimal places, While this

implies» greater degre of precision than is ordinarily attinad, these dimensions are the basis of gege dimensions and are go expressed forthe

purpose of eliminating errors in computations,

(2) iso

(2) Aso pitch diameter at gaging notch (handtght

(4) Also tenath of plug gage.

,

rath of thin ring gage end length from goging notch to small end of plug goa.

[AN AMERICAN NATIONAL STANDARD.

PIPE THREADS, GENERAL PURPOSE (INCH) ANSVASME 81.20.1-1980

v

(vanieh threads

‘due to chumnter

on diel

“Taper ofthese

Tin 16 maasired

‘on diameter

Yi,

LL

) 4

1 Le

TABLE2 BASIC DIMENSIONS OF AMERICAN NATIONAL STANDARD TAPER PIPE THREAD, NPT! (CONT'D)

bens: Plane | ova bone

iron Makeup Lana or Nominal Compare

Tos Mae [ome Mekman tra" | any rad | Conn | emit COME] aa | inna |wiel Sam,

Nomina] extenatThresa |_—_!™ (| Seeraat of | inbim! | at Smal

Pipe | tep=Li) | uengtm is) | Blam { thread | Uanath | Diem. | Thess | “Thread | “tnd ot

Sie [ia [Teed | ine [Torna] tes) [im [Toes] “tear | esd’ | t6s) | tn) [100625] Pie io)

1,2 ])ef>i[se|« |v). e|» la || = EJ

the [oro | 273 | omni] 3 | a2sizefoazes| 47 | o3ase| oxa70| oanae7 [ooaves | oooan | o2ne

f° Jonoas | 276 | osm] 3 | 0'3s656 orzss | a7 | oases teas | 027337 [o.ozse3 | ooazat | 03339

Ym fortwo | 313 | oxes7] 3 | 0.46657 Joxs2s | 37 | sous | 02907 | oassss Joossss | oo0347 | 0.4329

4H fouers | 302 | oxesr] 3 | osoreo loses | 3.7 | coos | o.2s67 | aasose foossss | oocsar | o-s676

je Jozrsr | 299 | oztss) 3 | o7asos oze7s | 347 | oss | 02809 | ozezss loasris | ooosss | 0.7013,

a2o61 | 289 | 02103] 3 | osssao jo2476 | 347 | 017935] a4020 | oasate {oasri4 | noosss | sto

1, foaezs | 32s | 02609) 2 | 1.9733 Jo017} 247 | 0984s, 0083) 1.23543 [o.oe9s7 | ooosas | 1.1441

1% |o2s6s | 330 | 02600] 3 | 1'saoaslos07| a7 | v.008s | ols329/ 1'so043 |o.oess7 | oonsas | 1 as76

wis [ososs | 349 | 02609) 3 | 177978 |oa017| 37 | 10282 | 0036) 183040 |o.069s7 | oogsas | 1 7068

2 Jaszes | 269 | ones] 3 | 225272/03017| 47 | 1osea| oseac| 230503 /oossss | oanses | 21985

2 |oasss | 364 | 02500} 2 | 270391 Ja4s37 | 347 | 15712] 087s | 2.77500 0.100000] oor: | 26195

3, |oaseo | 347 | 02500) 2 | 3.32500 oea37 | a7 | t-6337 | 09800 | 240000 |.to0000) o.oo7st | 32406

3% [0.4290 | 343 | 0.2500] 2 | 3.82188 |04337 | 3.47 | 1.5837 | 1.0000 3.90000 | 0.100000| ooorst | 3.2375

4° | 04560 | 365 | 02500] 2 | 43i875|0.337) 347 | 1.7357] 1.0500 | 40000 | 0100000] 00781 | S238

5 |oasss | 375 | 02500] 2 | s.rsis|aess7 | 3.47 | 1.8400] 1.563 | 545300 |o.100000| o.oorei | 5.2907

& —|ossas | 44 | a2s00] 2 | casoe7 lassr | 47 | 113462 | 12625 | 6.52500 [0.100000] aor | east

8 |oass | 5:20 | o2s00] 2 | sarro7|ossy | a7 | 21462|| 14625 | #52500 Joo0000| coorst | 83336

xo fosrso | 572 | a2soo] 2 | 10'52969 Joss7 | a7 | 2.3587 | 116750 [10.5000 |t00000] coors: | 1oeess

12 |oxreso | 612 | 02s00] 2 | r2st7re]oass7 | 347 | 25887 | 1\8750 [12.5000 a100000| oaozst | 128328

140.0,| 0800 | 550 | o2so0} 2 | 1375938 0.4337 | 347 | 26837 | 2.0000 |13:90000 | 0.100000] aaors: | 13.6750

weo.0 |o.s3a0 | 510 | o2soo| 2 | 1748s oss7 | 347 | 28837 | 22000 [15:00 [0 100000] corer | 13662

100.| 08500 | $20 | 02500] 2 | 1773438 ouss7 | 347 | 0837 | 24000 [17-0000 |100000] corer | 12.6300

200.0|0.250 | 80 | 02500] 2 | 1972168 o.ss7) 3.47 | 32637 | 26000 |1530000 | 0.100000] o.00781 | 136373

Moooarso | tan | ozsoo| 2 | seem [oss | dar | aatzr| 3000 [2ssom [osovoo| toorst | sis

(6) The length Lg fom the end of the pipe determines the plano beyond which the thread form is incomplete atthe erst. The next two threeds

are complete atthe root. At this plane the cane formed by the ert ofthe thre intersects the cylinder forming the external surface of the

pine. Ls * La = 20

(6) Given se intormation for use in selecting tap dil. (See Append.

(7) Miliary Specification MIL—P-7108 gies the wench makeup ee theee thresde for sizes 2 and smaller, The £3 dimensions ates follows:

[Nominal pipe size 234 = 2.89609 and size = 3.31719; sizes 2 and smaller ama a above, cl, 16.

(8) Reterence dimension

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE INCH) ANSUASME 81.20.1868

0)

TABLE 2 TOLERANCES ON TAPER, LEAD, AND i

ANGLE OF PIPE THREADS, NPT

Tolan

Taser onPiich Lie | Land in tng | 60 doy Arle

Noninst ‘aia insto ot ettecte | of Theat

Tee | threes Meats | agrees

Sie ee i

7 2 a a @

ha, fe a oh 003 ah

he 18 oh o.003 2 «

hoe “ oh ooo | 2

nit ha | ins th 003! vs

24/2 and targer 8 he 0.0037 Wh

GENERAL NOTE:

For leone on deh of threads Table 1a or lero on farctina si se 3.2.4

Nore

{1) The tleranc onload shal be 20.003 ia/n. on ay size tended to on lective trend length

reser tant in

Pa

TABLE 4 DIMENSIONS, INTERNAL STRAIGHT THREADS IN PIPE COUPLING, NPSC

(Pressure-tight Joints With Lubricant or Sealant)

Nomi | on.

oe oFrien | Toren, | minor Diameter _

Ste ‘oy oo | aim

1 2 2 a 5 6

me | oaos 7 0300 | oavr | oan

& | aso 1% oa | ance | ones

03575 ® os7 osare | osaa2

» | ose “ ons orm | o7ast

% | 1050 " oas ase | o90se

1 is ns 1361 rss | 124s

Me W560 us vss | 157s | tats

ih 1300 us 18 verse | 19305

2 2395 ns 2219 2aeei | 23044

a | ams 8 2ss0 | 27s | 2739

3 3.500 8 aan 33768 | 3.4002

3% | 000 8 am 3am | 33005

4 4300 8 ars asics | 43088

nore:

(1) Attention is called to the fact that the actual pitch diametar of the straight topped hole will be

slightly smller than the value given when goped witha taper plug gage as specified in 9.1.2,

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

3.1.6 Longth of Thread. The basic length of the

effective extemal taper thread L, is determined by

the following formula based on the outside diameter

Of the pipe and the pitch of the thread

(0.80D + 6.8) In

= (0.80D +6.8)p

where

D

outside diameter of pipe

threads per inch

‘This formula determines directly the length of

effective thread which includes two usable threads

slightly incomplete at the crest.

3.4.7 Engagement Between External and Internal

Taper Threads. The normal length of engagement

between external and internal taper threads when

Screwed together handtight is shown in col. 6, Table

2. This length is controlled by the construction and

use of the gages. It is recognized that in special

applications, such as flanges for high pressure work,

longer thread engagement is used, in which case the

pitch diameter (dimension E , Table 2) is maintained

and the pitch diameter Eo at the end of the pipe is

proportionately smaller.

3.1.8 Basic Dimensions. The basic dimensions of

taper pipe threads, derived from the above specifica-

tions, are given in Table 2. All dimensions are given in

inches unless otherwise specified.

3.2 Tolerances

3.2.1 Manufacturing Tolerance on Product. The

maximum allowable deviation in the commercial

product is one tur large or small from gages made to,

the basic dimensions, See 8.2 and 8.3.

3.22 Tolerances on Thread Elements, The permis-

sible deviations in thread elements are given in Table

3. This table is a guide for establishing limits of the

thread elements of taps, dies, arid thread chasers.

Conformance to these limits may be required on

product threads, in which case specifications shall

equire control and checking of thread elements,

‘On pipe fittings and valves (not steel or high grade

alloys used in critical services) for steam pressures

300 tb and below, itis intended that plug and ring

age practices as established in this Standard be used

ANSV/ASME B1.20.1-1983

in conjunction with tooling control of thread cle-

ments, eg., taps and dies, to provide satisfactory

control of functional size. Therefore, no tolerances

con thread elements have been established for this

class.

For service conditions, where more exact checks

fare required, procedures have been developed by

industry to supplement the standard plug and ring

gage method of gaging,

4 SPECIFICATIONS FOR INTERNAL STRAIGHT

‘THREADS IN PIPE COUPLINGS, NPSC

4.1. Straight Pipe Threads in Pipe Couplings

‘Threads in pipe couplings made in accordance

with these specifications are straight (parallel) threads

of the same thread form as the American National

Standard Taper Pipe Thread specified in 2.1. They are

used to form pressure-tight joints when assembled

with an American National Standard external taper

pipe thread and made up wrench-tight with lubricant

or sealant,

4.1.1 Thread Designation. The American National

Standard Coupling Straight Pipe Threads are desig-

nated in accordance with 1.2.1 as follows:

1/8 -27 NPSC

4.1.2 Dimensions and Limits of Size. The dimen-

sions and pitch diameter limits of size are specified in

Table 4. The pitch diameter limits of size correspond

to one and one-half turns large or small of the stan-

dard taper pipe thread. The major and minor di-

ameters vary with the pitch diameter, as the Ameri-

can National Standard Pipe Thread form is main-

tained within the truncation tolerances shown in

Table 1.

5 SPECIFICATIONS FOR RAILING JOINT

‘TAPER PIPE THREADS, NPTR

5.1. Railing Joints

Railing joints that require a rgid mechanical thread

joint may be made with external and internal taper

threads.

The external thread is basically the same as the

American National Standard Taper Pipe Thread,

except that it is shortened to permit the use of the

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

ANSWVASME 81.20.1-1983,

014) 02 payroeet ave supBu9] poor. “Asispu

“Luonoas 29g "6 Brig Peary sold J0dey puepURIS [EUONEN UeOLOWY (2)

‘soumuanuod 40) 80814 (eu2—p

eo |

seo ors | ooo ss5t 7

to | se0 vs | oso seo0e ue

to | seo ove | ovo eure <

90 eo | ove | seo0 s0see ue

evo xo 0 ors | sero 2

tro 3c0 ° aes | ero 4

so seo - ers | sro t

oro wo tee see | aero t

sco | ai | sxo suvo wer | zero %

sto | 980 | sro suo uve | ozeo a

aja |e z t

er ei

preva. | aa

a rune oor

$0 sejweYD or 90199453, yo Buyue soy ad

sony | topiomitt | row

sovnaeg | neucout

(swrop peoruey2ayy)

PLAN ‘SLNIOP ONITIVY HOd SAVAHHA Said H3dVL TYNUBINI ONY TWNUSLX3 JO SNOISNAWIG 5 aTaVL

W

peo

{ede

“pus aun ae pau

ees

lepumis (shy 1unowe MOUs

peo

83

10

[AN AMERICAN NATIONAL STANDARD

He

‘THREADS, GENERAL PURPOSE (INCH)

0.866025

External Thread

peso

ANSITASME 81,20,1-1983

0.541260

Fpy = 0.128000

50 aa

om» | ZN

‘n= 0108280 NN

I

Ieornal Thread

TABLE 6 DIMENSIONS OF EXTERNAL AND INTERNAL STRAIGHT PIPE THREADS FOR FIXTURES, NPSM

(Free Fitting Mechanical Joints)

[ xr! Treed, ln 24 eral Toad ls 28

‘Nom. ‘Threads! | Attow- [ r iain

— wat! | Aloe | air timer | rteh Otmeter | Wino Omer teh Dametr

Size | (0) Maximum | Minimum | Maximum | Minimum | Minimum | Maximum | Minimum! | Maximum

tT?} 3s [~*«]s |e 7 e | s 0 u 2

% [oss] 27 [ooo | 0207 | 039 | 03s | oases | oase oars | oames

& | ose} is 0.0013 | 0.526 | 0.517 0.4903 0.4859 | 0.468 0.4916 0.4974

Hh [ors] ts | ooo | sees | ess | Stace | ost | oes sro | sans

h | sao} 14 0.0015 | 0.823 | 0.813 0.7769 0.7718 | 0.747 0.7784 0.7851

% | 1.050) 14 0.0016 | 1.034 | 1.024 0.9873 0.9820 | 0.958 0.9889 0.9958

7 13S 5 | 0.0017 | 1.293 1.281 1.2369 1.2311 | 1.208 1.2386 1.2462

1s | 1.660) 11.5 0.0018 | 1.638 1.626 1.5816 15756 | 1.546 1.5834 15912

ve | tooo] m3 | ooo | ier | ses | tszos | taiee | t2es | saz | ta30e

2° | 233] 113 | ooors | 2351 | 2359 | 2asea | 22as2 | 2259, aasea | aaoK

2% | 2875] 8 — | 0.0022} 2881 | 2826 | 27600 | 27526 | 2708 2762 | 27720

3, | 3300] 8 | ooo | ater | asa | Saco | sare | 3350 suas | 300

3% | 4000] 8 0.0023 | 3.968 3.953 3.8865 3.8788 | 3.835 3.8888 3.8988

a” | 4500] 8 | ao02s | ase | cast | ase | arr | asas saan | 43sr1

5 | 550] 8 | aooas| ssa | Ssix | sates | Sasso | S308 Saas | S598

6 | 66a] 5 | noo | ssas | csi | esos | sasss | case é'so60 | 6516s

GeNenat nores:

(a) NPSW ehresds ae of Unitied screw thread form to Classes 28/28 tolerances, having the minimum piteh diameter of the intarnal thread

basic and equal to £1 of NPT threads.

(b) The minor diameters of external threads and major diameters of internal threads are those as produced by commercisl straight pipe dis

‘and commercial ground straight pipe taps.

‘The major diameter of the external thread has been calculated on the basis of a truncation of 0.10825, and the minor diameter of the

internal thread hes bean calculated on the bats ofa truncation of 0.21659, t0 provide no interference a

‘a2ged with gages mace in accordance with 9.2.

ore:

rest and root when producti

(1) Column 11 i the some asthe pitch dismeter atthe large end of interna thread, Ey, Basic, (See Table 2, col 8.)

u

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH) ANSIJASME 81.20.1.1883

Stondord fitting

‘vith taper thread

re

“Teper pine

thread

Locknut

Tank floor

‘or wall

Straight loeknut

‘thread

Lock

TABLE7 DIMENSIONS, EXTERNAL AND INTERNAL STRAIGHT PIPE THREAD FOR

LOCKNUT CONNECTIONS, NPSL (Loose Fitting Mechanical Joints)

External Fane internal Fveade

on. : —— :

of ‘Maximum Minimum!

rd arenas | Mami | ten omar | Mim | och Dimer

10) | “isan” | otametor [Waximum | Minimum | Oiemetar | Minimum | Maxim

7 2 3 ‘ 5 ¢ 7 2 3

| oaos | 2 | oa | asso oxez | oases | 02680

Ys 0.540 1 sat 0.5038 0.470 05073 | 0.5125

ys 0.675 18 0.678 0.6409 0.607 0.64de 0.6496

ye | oso | | ose | 07903 oss | osoos | osors

h | oso |e | tase | 0087 axe | tone | Sore

: tas | otis | uate | soe "aos | aes | aa9

Mm | ves | os | tees | toss rss | 16106 | 1187

vA 1,900 WS | 1902 | tsar 4,792 1.8495 1.8576

2 ahs | us | 23% | adie0 anes | aim | ass

he | 2s | a | ae | 279% ase | ago | 28129

3 sso | 8 | 3503 | aa1s8 sau | Sane | S83

3% | 000 | 8 | 00s | 3320 sass | 3om9 | 0306

‘ soo | 8 | 4soz | ates a3 | daze | cars

5 ssa | 8 | soe | sasos saos | saas1 | s.so01

é sas | 8 | sex | éssr2 6asz | 6sas0 | 65567

s | seas | os | seis | asa ase | asast | soe

w | rise | 8 | was | soasae ros77 | 10.6600 | 06017

2 | itso | | intaa | inion rai | ia6ses | 12686

nore

(1 NPSL. theeods ae standard pipe thread form where the pitch diameters ofthe external threads are fixed at 2.5 and 4

turns larger than basic E1, and whore the pitch ameter ofthe internal threads ae Fixed at Sand 65 turn larger than

besie £1, thus proving an allowance equivalent to one turn ofthe standard taper pipe thread.

‘As the American National Standord Straight Pipe Theead form of thread is produced bya single tool, the malor and

‘the minor diameters of the intemal thread and the minor diameter of the axtarnal thread are presumed to vary with

the pitch diameter, The major diameter ofthe external thread is usally determined by the clameter of the pipe, Thees

‘theoretical diameters result from adding the depth of the wuncated thread {0.666025 X pl to the maximum pfteh

sliometers in col. 5, and it should be understood that commercial pipe will not alvays have these maximum major

siameter,

‘The locknut thread is established on the basis of retaining the greatest posible amount of metal thickness between

the bottom ofthe thread and the inside of the pip.

In order that a locknut may fit loosely on the externally threaded pert, an allowance equal to the increase in pitch

diameter per turn i provided, with a tolerance of 1.5 turns for both external and internal threads,

ivy

AN AMERICAN NATIONAL STANDARO

PIPE THREADS, GENERAL PURPOSE (INCH)

larger end of the pipe thread, See Table 5. The di

mensions of these external and internal threads are

shown in Table 5. A recess in the fitting provides a

covering for the last scratch or sharp edges of in

complete threads on the pipe,

5.1.1 Thread Designation. American National

Standard Railing Joint Taper Pipe Threads are desig-

hated in accordance with 1.2.1 as follows.

1/2 -14 NPTR

5.1.2 Form of Thread, The form of the thread is

the same as the form of the American National

Standard Taper Pipe Thiead shown in Fig. |

5.1.3 Tolerances on Thread Elements. The gaging

Of these threads is specified in Tuble 5. The maximum

allowable deviation in the external thread is no turns

large and one turn small. The maximum allowable

deviation in the internal thread is one turn large, no

tums small

6 SPECIFICATIONS FOR STRAIGHT PIPE

‘THREADS FOR MECHANICAL JOINTS;

PSM, NPSL, NPSH

6.1. Straight Pipe Threads

In addition to pressure.tight pipe joints, for which

taper external threads and either taper or straight

internal threads are used, there are mechanical joints

where straight pipe threads are used to advantage on,

both external and internal threads. Three of these

straight pipe thread joints are covered by this Stan:

dard, all of whicle are based on the pitch diameter of

the American National Standard Taper Pipe Thread

at the gaging notch (dimension £, of Table 2) but

hhave various truncations at crest and root as described

below. These three types of joints are as follows:

(@) freesitting mechanical joints for fixtures,

Table 6, both external and internal, NPSM.

(®) loose-fitting mechanical joints with lock:

nuts, Table 7, both external and internal, NPSL.

(©) loose-fitting mechanical joints for hose coupl-

ings (ANSI B2.4), NPSH.

6.1.1 Thread Designations. The above types of

straight pipe threads for mechanical joints are desig-

nated in accordance with 1.2.1 as follows:

13

ANSH/ASME B1.20.1-1989

1/8 - 27 NPSM

1/8 -27 NPSL.

1-115 NPSH

6.1.2 Pitch and Flank Angle. The pitch and flank

angle are the same as the corresponding dimensions of

the taper pipe thread described in Section 3

6.1.3 Diameter of Thread. The basic pitch diame-

ler for both the external and internal straight pipe

threads is equal to the pitch diameter of the Ameri-

can National Standard Taper Pipe Thread at the

gaging notch (dimension £, of Table 2), which is the

same as at the large end of the internal taper pipe

thread.

6.2 Free-Fitting Mechanical Joints for

Fixtures, NPSM_

Pipe is often used for special applications where

there are no internal pressures. Where straight thread

joints are required for mechanical assemblies, straight

pipe threads are often found more suited or con-

venient

‘The dimensions of these threads, a given in Table

6, are for pipe thread connections where reasonably

close fit of the mating parts is desired

6.3 Loose-Fitting Mechanical Joints

With Locknuts, NPSL.

‘The American National Standard External Lock.

nut thread is designed to produce a pipe thread

hhaving the largest diameter that it is possible to cut

‘on standard pipe. Ordinarily Straight Internal Threads

are used with these Straight External Threads, provid-

ing a loose fit. The dimensions of these threads are

given in Table 7. It will be noted that the maximum

major diameter of the external thread is slightly

greater than the nominal outside diameter of the

pipe. The normal manufacturer's variation in pipe

diameter provides for this increase

One application of a taper pipe threed in com.

bination with a locknut thread which has been in use

for some time is that shown in Table 7. It consists of

the nipple threaded joint used to connect standpipes

with the floor or wall of a water supply tank.

Gaging information for these threads is given in

Section 7.

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

jon shows standard design

sizes 2 inch and emaler. Larger

eof sightly diffrent esiens

Ring sioe

FIG. 4 NPT STANDARD TAPER PIPE THREAD

PLUG AND RING GAGES

0.1160

[eee

(Form optional)

ofl,

Roots must clear 0.03819 fat

FIG.5 SUGGESTED FORM OF GAGE THREAD

ANSI/ASME 81.20.1-1963

FIG.6 GAGING EXTERNAL TAPER THREADS

WITH RING GAGE

Basie Size Max. Size Min. Size

FIG.7 GAGING INTERNAL TAPER THREADS.

aging face

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE INCH}

6.4 Loose-Fitting Mechanical Joints

for Hose Couplings, NPSH

Hose coupling joints are ordinarily made with

straight internal and external loose-fitting threads,

There are several standards of hose threads having

various diameters and pitches, one of which is based

fon the American National Standard Pipe Thread. By

the use of this thread series, itis possible to join small,

hhose couplings in sizes % to 4, inclusive, to ends of

standard pipe having American National Standard

External Pipe Threads, using a gasket to seal the joint.

For dimensions and tolerances, see ANSI B2.4.

7 GAGES AND GAGE TOLERANCES

FOR AMERICAN NATIONAL STANDARD

PIPE THREADS

7.1. Design of Gages

Gages for American National Standard Pipe

‘Threads provide a functional check and are of the

standard type as described below. Gages should con:

form to the designs recommended in ANSI Standard

47.1, Gage Blanks.

7.1.4 Standard Type Gages. A set of standard or

basic type gages consists ofa taper-threaded plug gage

and a taper-thteaded ring gage. See Figs. 4 and 5.

‘The plug gages are made to dimensions given in Table

8 with a gaging notch located a distance Ly from the

small end. The £, ring gage has a length equal to

dimension Ly. The roots of the threads on these

szages shall clear 0.0381 width. A sharp V or under-

cut clearance is acceptable, The crests are to be

truncated an amount equal to 0.140p for 27 threads

per inch (tpi), 0.109p for 18 tpi, and 0.100p for 14

‘pi, L1-1/2 tpi and 8 tpi threads (see Fig, 5). In locat-

ing the basic gaging notch, the plane of the notch

should intersect the crest of the gage thread.

‘The ring gage shall be fitted to the plug so that,

when assembled handtight, the gaging notch of the

plug gage will be flush with the large end face of the

ring gage within tolerances as given in Table 9.

Partial end threads shall be removed on both ends

of the ring gage and on the smell end of the plug gage

to fullform profile in order to avoid possible seating

error from bent or malformed feathered edge.

7.1.2 Marking of Gages. Each gage shall be marked

s0 as to indicate clearly the nominal size of pipe,

16

[ANSI/ASME 81.20.1-1989,

threads per inch, and the proper thread series designa-

tion as given in the respective section ofthis Standard.

7.2 Classes of Gages

Gages of the following types may be used to com.

pletely cover gage requirements

(@) master gages used to check working gages.

(©) working gages used to check threads during

‘manufacture and for conformance inspection,

7.2.4 Master Gages. The set of master gages con-

sists of an Li taper threaded plug gage and an Ly

taper threaded ring gage (see Figs. 4 and 5). The plug

gage is made to dimensions specified in Table 8. It is

constructed of hardened steel with a gaging notch

located a distance Ly (Table 2) from the small end

‘The ring gage has a length equal to dimension Ly

specified in Table 8. This ring is fitted to its mating

plug - seating flush at the notch within + 0.002 in

for sizes 1/16 through 2, within £ 0.003 in. for sizes,

2-1/2 through 12, and within + 0.005 in. for sizes 14

and larger, The roots of the threads on these ring

gages shall clear 2 0.0381p flat or may be undercut

beyond a sharp V. The crests of the plug and ring

kage are truncated 0.100p. The set of master gages is

used for checking working gages (see 7.3.2). A

supplementary check by optical means should be

‘made of flank angle and form.

CAUTION: It should be understood that only a

specifically matched set of masters (L4, plug and L

ring) can be expected to mate with each other within

the tolerance specified. There are many characteristics,

or deviations in gage elements that may combine to

cause a significant standoff difference between

‘aster gages which are not specifically matched.

7.2.2 Working Gages. Each set of working gages

consists of an L, taper threaded plug goge and an L

taper threaded ring gage and is used for checking the

product. These gages are made of hardened steel

‘or equivalent material to dimensions given in Table 8.

(See 7.3.2 for tolerance.) In locating the basic notch

of the plug gage the plane of the notch should inter-

sect the erest of the thread.

It is to be noted that these gages are truncated at

the crest so that they bear only on the flanks of the

thread. Thus, although they do not check the crest oF

root truncations specified in Table 1, they are a

satisfactory functional check for the general run of

product. When it is deemed necessary to determine

AN AMERICAN NATIONAL STANDARD

ANSW/ASME 81,20.1-1989

PIPE THREADS, GENERAL PURPOSE (INCH)

eu

y9ede evonounsn axa uodn peng

29s Gut a4 tam Jou aun pE BEB Bro J seu feu GUL. “'Z¥8l JSNY’ Ut UONB SUONUSWYP OF wo} Hau HUET #689 "BLON TWEENS

suse | sstoo0 | souivee | scecoee | caster | vooseer | osticer [eoneerce | aivreez | scsecec | oosevo | | ooove] wore

seve | is.o00 | sousvst| scasvei | casisst| tsocwe | osuecst lames | isesest | suacest | oscro | & | oooeel oor

aoor | tsiooa | susscet] susssct | coste'ct| oosusci | ooostet |seaoect | scusect |seecect | ooscra | & | ooo'si| wost

igi | ssvo0%9 | oszev'st| seeus'si | casiest| sescwst | oscacst [assee'st | oossest | scsre'st | oosero | & | ooosi| “cost

test | isso | esses) sctever | casteet | cazewet | onsecet [eeseeei | esses | szasrei | oosero | s | ooowt| “cost

exci | isio00 | ssvesci| serve | tosseer | isisci | sezeset jeverect | sovorzs| cosiser | oosero | 8 | oseer| zt

aizt | tsio0' | ssuesot | sozorot | zossvot | voocsot | tesesot |searcot | strorot | csecoot | ooseo | 8 | oscar] oF

sso | ieiovo | suai | veose's | zoos | cooore | escer's |ssccve | access [sense | oosero| s | seve] 8

8560 | isuo0% | zzzev9 | verses | coors | vesoso | coors |eneexs | zzoars |seezso | oosero | 3 | sexo | 9

seo | isio0% | vosse's |sruoc's | conus |ezonv's | cxose's |ssiss's | ssees's | seers | oosero css] 5

vewo | 81000 | cacoer | ctiscy | costee |zucars | seveer [estore | sour [esate | oosero wosr| of

tesa | ssooo | sssore |szisve | casice |iseeee | osiewe faessce | coziee |suocee | onset oor | oe

990 | igzoo'o | szsoe'e | cecsre | costes |oseee'e | coovee [esses | seicre | apeze'e ooszi'o Oost &

zepo | tsvo0% | tesusz | acseve | esoere |oteove | eseive |escuee | trseee |aizore | oosero sive |e

sero | ersooo | seseee /annize | ocsuee | ecsere | cossee |ecveee | sinsee | coseer | sesso sue

oewo | evsooo | zreocr | cigeci | oeteer | veecet | cosect |cessei | stoget |oorset | s69900 006"1

cro | srsooo | evses't | zeesrt | octosi |eccest | clusst [raes | scusst |rosiy1 | seasoo 9"

coro | ersooo | zuogict | cussict | oeasci feseece | eorict [zewic | ssseet | rsicet | seae00 siet

see0 | sxv000 | sctrso | usocs0 | seio0 |eseeco | eszaeo |9eeto" | vracot | seston | evtcoo osot

ove'0 | s¥t000 | se0ee0 | se0ic0 | scisco fevecco | cvasco [este | oosero |osoro | trtco0 | oreo

arco | ise000 | toler aszeva | touz90 | 02190 |oscuxo | tocax0 | toaee | sesso sis

suza | creooo | eassvo | acirro | oszoso |estera | eecuvo losicso | estzvo |eteiso | ssss00 ors

sista | eco | seisco [osteo | oooara foseeeo | tsese0 |tcior0 | teseeo |zzseeo | voceoo sovo

oar'0 | tezoow | uvesco | erase | ossaco | etiaeo | siuico |tecoro | score |escero | voceoo sate

comme a | ow a) 6 2 z 2 5 * = elem

w (ar | ay | ea ow of wm | a

ssz90'0) ep wo10N pug (ta) oud vay edt

Peon, na | suse | ews | ‘pug | yon rromenun | 0. | orwon

rasta a | ow ty | ss | taeem a0

o | ssieay w W

sree Ses Bara 10 seep Bury pu ‘ate

enewerg sou fing 30 SeroUrIG YoU

ya 1 sEr0woIG JON

Ad ‘SAVaUHL adid YadV1 GUVONVLS IVNOLLYN NVOIYSIY TYNOLLYN

YOd S3DVD ONIY GNV ONId G3QV3YHL JO SNOISNAWIG Disa 8.3T8VL

"

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

whether or not such truncations are within the limits

specified, or particulary to see that maximum trunca

tion is not exceeded, it is necessary to make further

inspection. For this inspection, optics or optical

projection is suggested.

7.3 Gage Tolerances

In the manufacture of gages, variations from basic

dimensions are unavoidable, Furthermore, gages will

wear in use. In order to fix the maximum allowable

variations of gages, tolerances have been established.

See Table 9 and 7.3.2.

7.3.1 Master Gage Tolerances. The set of master

gages should be made to the basic dimensions as

accurately as possible, but in no case shall the eum-

lative deviation exceed one-half of the total eum-

ulative tolerance specified in cols. 13 and 14 of Table

9. Each master gage should be accompanied by 2

record of the measurements of all elements of the

thread and the standoff of master plug to master

fing (large end of ring gage to basic notch of plug

age).

7.3.2 Working Gage Tolerances, All gages applied

to the product thread, whether in manufacture or

inspection, are designated as working gages. All work-

ing gages should be made to the basic dimensions

specified in Table 8 and within tolerances specified

in Table 9. The maximum wear on a working gage

shall not be more than the equivalent of one-quarter

tum from its original dimensions.

7.4 Relation of Lead and Angle Deviations to Piteh

Diameter Tolerances of Gages

When it is necessary to compute from measure:

ments the decimal part of a turn that a gage varies

from the basic dimensions, Tables 10 and 11 should

be used. Table 10 gives the correction in diameter for

angle deviations and Table 11 gives the correction in

diameter for lead deviations. These corrections are

always added to the pitch diameter in tho case of

external threads and subtracted in the case of internal

threads regardless of whether the lead or angle devia

tions are either plus or minus.

‘The diameter equivalent for lead and sngle devia

tions plus the pitch diameter deviation multiplied by

16 gives the longitudinal deviation from basic at the

gaging notch. This longitudinal deviation divided by

the pitch equals the decimal part of a turn that the

‘gage varies from basic at the gaging notch.

ANSW/ASME B1.20.1-1983

8 GAGING OF TAPER PIPE THREADS

8.1. Gaging External Tapor Threads

In gaging external taper threads, the /., ring gege,

Fig, 6, is screwed handtight on the pipe or external

thread. The thread is within the permissible tolerance

when the gaging face of the working ring gage is not

‘more than one turn, large or small, from being flush

with the end of the thread, as indicated in Fig. 6.

8.2 Gaging Internal Taper Threads

In gaging internal taper threads, the J. plug gage,

Fig, 4, is screwed handtight into the fitting or coup-

ling. The thread is within the permissible tolerance

when the gaging notch of the working plug gage is

not more than 1 turn, large or small, from being Mush,

with the end of the thread, as indicated in Fig. 7.

8.3 Gaging Practice

8.3.1 Procautions. In gaging pipe threads it is

‘common practice to tap or rap the part to assure

proper seating of the gage in or on the product thread.

However, it is first necessary to clean both the gage

and the product threads so that they are feee of chips,

burs, abrasives, or other foreign materials.

8.3.2 Supplemental Gaging. Gaging of both in-

ternal and external threads by use of the Z plug and

ring gages, illustrated by Figs. 6 and 7, serves to

assure conformance to the L. elements of the design

dimensions, However, conformance to this Standard

requires that all basic design dimensions be met

within applicable tolerances including extension of

the thread clements to provide for wrench-tight make-

up. Therefore, in controlling manufacturing practices

for as otherwise required, additional methods of

measuring or gaging may be employed to supplement

L, gaging,

8.4 Gaging Chamfered, Countersunk, or

Recessed Threads

‘The reference point for gaging internal product

threads depends upon the chamfer diameter, When

the internal chamfer diameter exceeds the major

diameter of the intemal thread, the reference point is

the last thread seratch on the chamfer cone. See

Fig. 88. Otherwise, when the internal chamfer

diameter does not exceed the major diameter of the

internal thread, the reference point is the end of the

[AN AMERICAN NATIONAL STANDARD

ANSITASME 81.20.1-198

PIPE THREADS, GENERAL PURPOSE INCH)

ooo + pue

ran ananet £0

‘snenautZ 0 #8218 30 L00'0 - Pur 000'0 + #4

j #08 20} 2000'S wynmn aubrpueY parqusse uaye Syd 8

‘S810N TURNED

seo [iceovo | sozove | oxooa Jozooe | si000 | o1ov0 | ov ‘s000'0 |

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- AGA Report No. 11 Revised Coriolis Meter GuidelinesDocument7 paginiAGA Report No. 11 Revised Coriolis Meter GuidelineselijbbÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 paginiEmerson-Valve Sizing Calculations (Traditional Method)iqtorresÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- EN Operating Instructions VEGAPULS 64 Two Wire 4 20 Ma HARTDocument96 paginiEN Operating Instructions VEGAPULS 64 Two Wire 4 20 Ma HARTDeny SafariÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- How To Calibrate VEGA LT PDFDocument4 paginiHow To Calibrate VEGA LT PDFDeny SafariÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Loopsense As7240 - An Addressable Fire Alarm Control Panel: FeaturesDocument2 paginiLoopsense As7240 - An Addressable Fire Alarm Control Panel: FeaturesDeny SafariÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- ASME - Wake Frequency CalculationDocument7 paginiASME - Wake Frequency CalculationpsaayoÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- T Rec G.652 201611 I!!pdf e PDFDocument28 paginiT Rec G.652 201611 I!!pdf e PDFrajaramghoshÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 8 - HVAC Load CalculationDocument16 pagini8 - HVAC Load CalculationSenghy MaoÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Air Condition Size Calculator (1.1.17)Document3 paginiAir Condition Size Calculator (1.1.17)Deny SafariÎncă nu există evaluări

- 2700 Catalog SectionDocument37 pagini2700 Catalog SectionIebe SeventynineÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 03 Electrical PDFDocument13 pagini03 Electrical PDFDeny SafariÎncă nu există evaluări

- Bettis EHO ESD ActuatorDocument12 paginiBettis EHO ESD ActuatorNazim SalehÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- NEC Article 250Document42 paginiNEC Article 250unknown_3100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 2 - 3 - 4-Wire RTD MeasurementDocument9 pagini2 - 3 - 4-Wire RTD MeasurementtotovasiÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- API Catalog EN PDFDocument56 paginiAPI Catalog EN PDFDarioPioliÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Loopsense As7240 - An Addressable Fire Alarm Control Panel: FeaturesDocument2 paginiLoopsense As7240 - An Addressable Fire Alarm Control Panel: FeaturesDeny SafariÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- How To Do GroundingDocument12 paginiHow To Do Groundingnch1225Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Aga 3 Part 2Document80 paginiAga 3 Part 2adactivator100% (1)

- @practical Guide To Electrical Grounding, 1st Edition, 1999Document131 pagini@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Grounding System Design and PlanningDocument29 paginiGrounding System Design and PlanningKordofanÎncă nu există evaluări

- Class 150 Flanges PDFDocument2 paginiClass 150 Flanges PDFDeny SafariÎncă nu există evaluări

- UNM Grounding and Bonding SpecificationDocument9 paginiUNM Grounding and Bonding SpecificationDeny SafariÎncă nu există evaluări

- Cable Trench - UCIManual PDFDocument48 paginiCable Trench - UCIManual PDFDeny SafariÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- My GuideDocument222 paginiMy Guideeng_mahmoud3000Încă nu există evaluări

- Valve Actuators Technical Specs PDFDocument11 paginiValve Actuators Technical Specs PDFDeny Safari0% (1)

- Calidus 201 Micro Gas Chromatograph Fal003Document2 paginiCalidus 201 Micro Gas Chromatograph Fal003Deny SafariÎncă nu există evaluări

- Industrial Bimetallic Thermometers for Temperature Measurement and MonitoringDocument4 paginiIndustrial Bimetallic Thermometers for Temperature Measurement and MonitoringDeny SafariÎncă nu există evaluări

- Grounding Equipment: Catalog 3000 March 2013Document32 paginiGrounding Equipment: Catalog 3000 March 2013Deny SafariÎncă nu există evaluări

- Folle ToDocument8 paginiFolle ToSaku-Jessy CamposÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)