Documente Academic

Documente Profesional

Documente Cultură

NPTEL - Chemical - Mass Transfer Operation 1 - Humidification and Cooling Tower Principles

Încărcat de

sherilyn pagarintanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NPTEL - Chemical - Mass Transfer Operation 1 - Humidification and Cooling Tower Principles

Încărcat de

sherilyn pagarintanDrepturi de autor:

Formate disponibile

NPTEL Chemical Mass Transfer Operation 1

MODULE 6

HUMIDIFICATION AND AIR CONDITIONING

LECTURE NO. 3

6.3 Humidification and dehumidification operations and design

calculations

Humidification operations: In this operation, water transfers from liquid phase

to gas phase. Hence, moisture content of air increases. Air with particular

moisture content is useful for drying of a solid under controlled condition.

Dehumidification operations: It is the reverse phenomena of humidification. A

portion of water vapor from moist warm air is condensed by contacting cold water

in air conditioning.

6.4 Cooling tower principle and operation

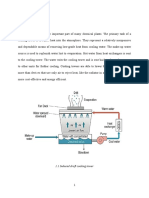

A cooling tower is a special type of heat exchanger in which the warm water and

the air are brought in direct contact for evaporative cooling. It provides a very

good contact of air and water in terms of the contact area and mass transfer co-

efficient of water vapor while keeping air pressure drop low.

Enthalpy of air is lower than enthalpy of water. Sensible heat and latent heat

transfer take place from water drop to surrounding air. Schematic of heat transfer

from water drop to surrounding air is presented in Figure 6.3.

Joint initiative of IITs and IISc Funded by MHRD Page 1 of 5

NPTEL Chemical Mass Transfer Operation 1

Heat transfer Heat transfer

Interfacial film

Water drop at Air temperature at

temperature Tw Tw

Heat transfer Heat transfer

Figure 6.3: Schematic of heat transfer from water drop to surrounding air.

Thus, cooling is accomplished by sensible heat transfer from water to air and

evaporation of a small portion of water. A generalized cooling tower system is

shown in Figure 6.4. The hot water which is coming from heat exchanger is

sprayed at the top of the cooling tower. Air enters through the louvers at the two

opposite walls of the cooling tower. During cooling process of water, around 2%

water is evaporated. Make water is used to compensate the water loss due to

evaporation. Blowdown is there to drain a part of water containing solid deposit.

The exit cold water from the cooling tower is used in the heat exchanger or other

unit operation.

Joint initiative of IITs and IISc Funded by MHRD Page 2 of 5

NPTEL Chemical Mass Transfer Operation 1

Water cooling tower Humid air Hot water

Heat

exchanger

Air Air

Make-up Cold water

water

Pump

Blowdown

Figure 6.4: Generalized cooling tower system.

Factors govern the operation of cooling tower

i. The dry-bulb and wet-bulb temperatures of air

ii. Temperature of warm water

iii. The efficiency of contact between air and water in terms of volumetric mass

transfer coefficient ( k y/ a )

iv. Contact time between air and water

v. The uniformity of the distribution of the phases within the tower

vi. Air pressure drop

vii. Desired temperature of cooled water

Joint initiative of IITs and IISc Funded by MHRD Page 3 of 5

NPTEL Chemical Mass Transfer Operation 1

6.5 Types of equipment

Classification of Cooling Towers

Based on air draft Based on air flow pattern

Atmospheric Natural draft Mechanical draft Cross-flow Counter-flow

Induced draft Forced draft

(A) Atmospheric Towers

It is a big rectangular chamber with two opposite louvered walls. Tower is

packed with a suitable tower fill. Atmospheric air enters the tower through

louvers driven by its own velocity. Direction and velocity of wind greatly influence

its performance. Figure 6.5 shows the schematic of the atmospheric cooling

tower.

Hot air out

Hot water in

Louvers

Air in

Air in

Louvers

Cold water out

Figure 6.5: Schematic of atmospheric cooling tower.

Joint initiative of IITs and IISc Funded by MHRD Page 4 of 5

NPTEL Chemical Mass Transfer Operation 1

(B) Natural Draft Towers

A natural draft cooling tower has a large reinforced concrete shell of hyperbolic

shape (also called hyperbolic tower). Natural flow of air occurs through the

tower; hence it is called natural draft (refer Figure 6.6).

Factors responsible for creating natural draft

(a) A rise in temperature and humidity of air in the column reduces its density

(b) Wind velocity at the tower bottom

Fan is used to enhance the air flow rate in fan assisted natural draft tower. The

typical diameter of tower is 150 m and capacity is 5,00,000 gallon/minute.

Hot air out

Concrete shell wall

Drift eliminator

Hot water in

Packing material

Air in

Air in

Cold water out

Figure 6.6: Schematic of natural draft tower.

Why hyperbolic shape?

(i) More packing materials can be placed at the bottom

(ii) The entering air gets smoothly directed towards the centre

(iii) Greater structural strength and stability

Joint initiative of IITs and IISc Funded by MHRD Page 5 of 5

S-ar putea să vă placă și

- Atom WorksheetsDocument4 paginiAtom Worksheetsapi-271960049Încă nu există evaluări

- Cooling Tower WebinarDocument17 paginiCooling Tower Webinariftekhar ahmedÎncă nu există evaluări

- Cooling TowerDocument10 paginiCooling TowerKeshav Rao100% (1)

- Cooling TowersDocument11 paginiCooling TowersSlim Kat Nkosi0% (2)

- Cooling Tower AshraeDocument18 paginiCooling Tower AshraeMAITREE JHAÎncă nu există evaluări

- Plate and Frame Filter Press ExperimentsDocument13 paginiPlate and Frame Filter Press Experimentshazwani75% (4)

- Cooling Tower ProjectDocument50 paginiCooling Tower ProjectRahul Wavdekar100% (1)

- Cooling Towers Design and Operation ConsiderationsDocument10 paginiCooling Towers Design and Operation ConsiderationsLiu YangtzeÎncă nu există evaluări

- Cooling Tower REPORTDocument25 paginiCooling Tower REPORTSaroj KumarÎncă nu există evaluări

- Cooling TowersDocument40 paginiCooling Towers1000 Subscribers Without a Video100% (2)

- Back to Basics Cooling Towers GuideDocument4 paginiBack to Basics Cooling Towers GuideWalter J Naspirán Castañeda100% (1)

- Water Cooling TowerDocument13 paginiWater Cooling TowerArlene Joy PasquinÎncă nu există evaluări

- DEP 39011012 - Inf - 2018-02 - A01Document67 paginiDEP 39011012 - Inf - 2018-02 - A01g_325899365Încă nu există evaluări

- Design Philosophy of Cooling TowerDocument34 paginiDesign Philosophy of Cooling Towerdinesh100% (2)

- Cooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalDocument21 paginiCooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalMegha LakhaniÎncă nu există evaluări

- Cooling Tower Water CalculationsDocument11 paginiCooling Tower Water CalculationsShesadri ChakrabartyÎncă nu există evaluări

- Cooling Tower Basics Calculation Formulas - Cooling Tower EfficiencyDocument9 paginiCooling Tower Basics Calculation Formulas - Cooling Tower EfficiencySantosh JayasavalÎncă nu există evaluări

- Cooling Towers - Downloaded SkillsDocument22 paginiCooling Towers - Downloaded SkillsVuthpalachaitanya KrishnaÎncă nu există evaluări

- Cooling TowersDocument35 paginiCooling TowersSingaravelu MariappanÎncă nu există evaluări

- Cooling Tower LabDocument33 paginiCooling Tower Labkeckstand100% (2)

- CFD SimulationDocument39 paginiCFD SimulationSambhav JainÎncă nu există evaluări

- Clinical Chemistry - Theory, Analysis, CorrelationDocument344 paginiClinical Chemistry - Theory, Analysis, Correlationaristides.quinteroÎncă nu există evaluări

- Lec3 PDFDocument5 paginiLec3 PDFVenkatesh VenkyÎncă nu există evaluări

- Mass Transfer Operations - 1: Humidification and Cooling Tower DesignDocument5 paginiMass Transfer Operations - 1: Humidification and Cooling Tower DesignAnand kesanakurtiÎncă nu există evaluări

- Lec1 MergedDocument12 paginiLec1 MergedShuyabahmed PatilÎncă nu există evaluări

- MT Cooling TowerDocument4 paginiMT Cooling TowerRajat SonkarÎncă nu există evaluări

- Design and Analysis of Cooling TowerDocument6 paginiDesign and Analysis of Cooling TowerNIKHIL soniÎncă nu există evaluări

- 09 Heat Rejection SystemsDocument14 pagini09 Heat Rejection Systemsscarpredator5Încă nu există evaluări

- Design and Performance Analysis of a Cooling Tower for an Adhesive FactoryDocument7 paginiDesign and Performance Analysis of a Cooling Tower for an Adhesive FactoryMaan Raj SinghÎncă nu există evaluări

- Design and Performance Evaluation of A Cooling Tower Based On Different ParametersDocument18 paginiDesign and Performance Evaluation of A Cooling Tower Based On Different ParametersSabrinaÎncă nu există evaluări

- Experiment 7 Cooling TowerDocument9 paginiExperiment 7 Cooling TowerRicky Jay0% (1)

- 10 1016@j Solener 2020 04 083Document9 pagini10 1016@j Solener 2020 04 083Sirine SaidiÎncă nu există evaluări

- 04-Lecture (August 31)Document16 pagini04-Lecture (August 31)Goura Sundar TripathyÎncă nu există evaluări

- Humidification and Air Conditioning: (A) Mechanical Draft Towers: Forced Draft Towers and Induced Draft TowersDocument4 paginiHumidification and Air Conditioning: (A) Mechanical Draft Towers: Forced Draft Towers and Induced Draft TowersAnand kesanakurtiÎncă nu există evaluări

- Split Cooling ProjectDocument43 paginiSplit Cooling ProjectVivek Kumar SinghÎncă nu există evaluări

- IJETR021301Document12 paginiIJETR021301erpublicationÎncă nu există evaluări

- Dean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDocument40 paginiDean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDean Paul100% (1)

- Cht313a WK6Document10 paginiCht313a WK6Ivan Dwight DescallarÎncă nu există evaluări

- Chapter Nine Cooling TowerDocument10 paginiChapter Nine Cooling Towerحيدر محمدÎncă nu există evaluări

- ChE 153Document19 paginiChE 153Joyce EdrozoÎncă nu există evaluări

- Experimental Investigation of The Performance CharacteristicsDocument8 paginiExperimental Investigation of The Performance CharacteristicsFernandoÎncă nu există evaluări

- Cooling TowerDocument9 paginiCooling TowerMd. Osman AliÎncă nu există evaluări

- Transpiration Cooling Using Liquid Water: American Institute of Aeronautics and Astronautics 1Document14 paginiTranspiration Cooling Using Liquid Water: American Institute of Aeronautics and Astronautics 1Ihsan SalimÎncă nu există evaluări

- Cooling Towers-MT (SM)Document6 paginiCooling Towers-MT (SM)Ritik ChaturvediÎncă nu există evaluări

- Assignment # 2: Subject Submitted To Submitted by TopicDocument8 paginiAssignment # 2: Subject Submitted To Submitted by TopicSania SaeedÎncă nu există evaluări

- 3, Cooling Tower, 021170037Document14 pagini3, Cooling Tower, 021170037balluzessaÎncă nu există evaluări

- Desalination: M. Deziani, Kh. Rahmani, S.J. Mirrezaei Roudaki, M. KordlooDocument6 paginiDesalination: M. Deziani, Kh. Rahmani, S.J. Mirrezaei Roudaki, M. KordlooMustafa KaddouraÎncă nu există evaluări

- Circuiting of Industrial Evaporators Under Frosting Conditions (Aljuwayhel Et Al, 2007)Document11 paginiCircuiting of Industrial Evaporators Under Frosting Conditions (Aljuwayhel Et Al, 2007)Alessio DeOsimoÎncă nu există evaluări

- Gilani-Poshtiri2017 Article ThermalDesignOfTwo-stageEvaporDocument20 paginiGilani-Poshtiri2017 Article ThermalDesignOfTwo-stageEvaporFelipe BarriosÎncă nu există evaluări

- Effects of Discharge Recirculation in Cooling Towers On Energy Efficiency and Visible Plume Potenial of Chilling PlantsDocument8 paginiEffects of Discharge Recirculation in Cooling Towers On Energy Efficiency and Visible Plume Potenial of Chilling PlantsSimoncarter LawÎncă nu există evaluări

- Forced Draft Cooling Tower ExperimentDocument28 paginiForced Draft Cooling Tower ExperimentIbrahim DanladiÎncă nu există evaluări

- CEP Aug 2009 - Cooling Towers Part 1 Siting - Selecting and SizingDocument4 paginiCEP Aug 2009 - Cooling Towers Part 1 Siting - Selecting and SizingMohamed Mamdouh AbdelHameedÎncă nu există evaluări

- Koeltorenboekje Engels Zonder LogoDocument32 paginiKoeltorenboekje Engels Zonder Logoanup_nairÎncă nu există evaluări

- PO Box 1702 11111 W. 8 Ave Unit C Bailey, CO 80421 Lakewood, CO 80215 PH: 303.816.7075 FX: 303.838.9651Document4 paginiPO Box 1702 11111 W. 8 Ave Unit C Bailey, CO 80421 Lakewood, CO 80215 PH: 303.816.7075 FX: 303.838.9651hemantÎncă nu există evaluări

- Cooling Towers: Fig. Temperature Relationship Between Water and Air in Counterflow Cooling TowerDocument20 paginiCooling Towers: Fig. Temperature Relationship Between Water and Air in Counterflow Cooling Towereddie eddÎncă nu există evaluări

- Humidification - Postlab FINAL PDFDocument24 paginiHumidification - Postlab FINAL PDFJames Matthew LimpinÎncă nu există evaluări

- CFDDocument34 paginiCFDSambhav JainÎncă nu există evaluări

- Performance and Analysis of An Evaporative Cooling System A Review PDFDocument9 paginiPerformance and Analysis of An Evaporative Cooling System A Review PDF011 BARANI KUMAR KÎncă nu există evaluări

- Cooling Tower PresentationDocument90 paginiCooling Tower Presentationnermeen ahmedÎncă nu există evaluări

- The Effects of Evaporative Cooling in Tropical Climate: KeywordsDocument6 paginiThe Effects of Evaporative Cooling in Tropical Climate: Keywordspaween saetaeÎncă nu există evaluări

- Comparative Analysis of Forced Draft Cooling Tower Using Two Design Methods A ReviewDocument4 paginiComparative Analysis of Forced Draft Cooling Tower Using Two Design Methods A ReviewEditor IJTSRDÎncă nu există evaluări

- Lee 2013Document7 paginiLee 2013Marga CenizaÎncă nu există evaluări

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationDe la EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationÎncă nu există evaluări

- Rangkuman Lanjutan SmithDocument2 paginiRangkuman Lanjutan Smithsherilyn pagarintanÎncă nu există evaluări

- Bhopal Case AnalysisDocument28 paginiBhopal Case Analysissherilyn pagarintanÎncă nu există evaluări

- Subject 7. Equipment Sizing and Costing OCW PDFDocument30 paginiSubject 7. Equipment Sizing and Costing OCW PDFhamzashafiq1100% (1)

- BP Statistical Review of World Energy 2016 Indonesia Insights PDFDocument1 paginăBP Statistical Review of World Energy 2016 Indonesia Insights PDFsherilyn pagarintanÎncă nu există evaluări

- Catalysts 06 00134Document15 paginiCatalysts 06 00134sherilyn pagarintanÎncă nu există evaluări

- Data Pengamatan Modul Plate and FrameDocument2 paginiData Pengamatan Modul Plate and Framesherilyn pagarintanÎncă nu există evaluări

- Steam TablesDocument16 paginiSteam TablesSantosh KumarÎncă nu există evaluări

- Jadwal Semester 6Document1 paginăJadwal Semester 6sherilyn pagarintanÎncă nu există evaluări

- Literatur Modul 5 - Kesetimbangan FasaDocument18 paginiLiteratur Modul 5 - Kesetimbangan Fasasherilyn pagarintanÎncă nu există evaluări

- Jadwal Semester 6Document1 paginăJadwal Semester 6sherilyn pagarintanÎncă nu există evaluări

- Perhitungan PFDocument26 paginiPerhitungan PFsherilyn pagarintanÎncă nu există evaluări

- Data Pengamatan Modul Plate and FrameDocument2 paginiData Pengamatan Modul Plate and Framesherilyn pagarintanÎncă nu există evaluări

- Antibiotics and Their Types PDFDocument6 paginiAntibiotics and Their Types PDFsherilyn pagarintanÎncă nu există evaluări

- Non Renewable EnergyDocument28 paginiNon Renewable EnergyTariq KhanÎncă nu există evaluări

- Monoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneDocument5 paginiMonoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneMonarch DigitalÎncă nu există evaluări

- Wolkite University Museum Technique Group AssignmentDocument23 paginiWolkite University Museum Technique Group AssignmentNatnael SisayÎncă nu există evaluări

- ThermodynamicsDocument12 paginiThermodynamicsWasif RazzaqÎncă nu există evaluări

- Parent Consent Petition Tutorialclass PDC 2Document8 paginiParent Consent Petition Tutorialclass PDC 2John Bryan AldovinoÎncă nu există evaluări

- Reasons to Replace Expired Fire ExtinguishersDocument3 paginiReasons to Replace Expired Fire ExtinguishersswapnilmanwtkarÎncă nu există evaluări

- Afa Reviewer ADocument28 paginiAfa Reviewer AJane CastroÎncă nu există evaluări

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 paginiFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuÎncă nu există evaluări

- A Seminar Report OnDocument1 paginăA Seminar Report Onu10ch019Încă nu există evaluări

- Enhanced Hybrid Science 6 Quarter1 Module 1 Week1Document10 paginiEnhanced Hybrid Science 6 Quarter1 Module 1 Week1KATHLENE CORPUS100% (1)

- Psma411-Prelim ReviewerDocument82 paginiPsma411-Prelim ReviewerRebekah EquizÎncă nu există evaluări

- Ideal Vapor Compression Refrigeration CycleDocument9 paginiIdeal Vapor Compression Refrigeration CycleStephanie ParkÎncă nu există evaluări

- MECANIQUE - Construction Practice Onshore SteelDocument54 paginiMECANIQUE - Construction Practice Onshore SteelYaser ShabasyÎncă nu există evaluări

- June 2017 (v1) QP - Paper 6 CIE Biology IGCSEDocument12 paginiJune 2017 (v1) QP - Paper 6 CIE Biology IGCSEbandana dekaÎncă nu există evaluări

- API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Document5 paginiAPI Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Luis Ernesto Marin JaimesÎncă nu există evaluări

- Recycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Document20 paginiRecycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Vijaykumar SharmaÎncă nu există evaluări

- Solubility and Distribution PhenomenaDocument89 paginiSolubility and Distribution Phenomenadesekar sejati100% (2)

- The Effect of Different Alkalinity Levels On Litopenaeus Vannamei Reared With Bio Oc Technology (BFT)Document17 paginiThe Effect of Different Alkalinity Levels On Litopenaeus Vannamei Reared With Bio Oc Technology (BFT)Manu MorpheusÎncă nu există evaluări

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument2 paginiDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelÎncă nu există evaluări

- OLEDreport PDFDocument26 paginiOLEDreport PDFStanimir YordanovÎncă nu există evaluări

- Response Problems Crystal DefectsDocument1 paginăResponse Problems Crystal DefectsYustinus LazuardiÎncă nu există evaluări

- Quantitative Analysis of Carbohydrates I - Lab 4Document27 paginiQuantitative Analysis of Carbohydrates I - Lab 4Noriko Medoruma0% (3)

- Fulltext ClorometaDocument9 paginiFulltext ClorometakarkamalusÎncă nu există evaluări

- Year 8 Science End of Term 1 Test: AnswerDocument11 paginiYear 8 Science End of Term 1 Test: Answerchan myaeÎncă nu există evaluări

- Figure 1: Coordinate of Plant LocationDocument11 paginiFigure 1: Coordinate of Plant LocationJonathon John100% (1)

- Coal Conversion StatisticsDocument2 paginiCoal Conversion StatisticsPaulo BarraÎncă nu există evaluări