Documente Academic

Documente Profesional

Documente Cultură

Operations Management 2010 April (2006 Ad)

Încărcat de

VDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Operations Management 2010 April (2006 Ad)

Încărcat de

VDrepturi de autor:

Formate disponibile

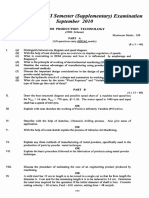

BTS (C) VIII 10 001 Q

B. Tech Degree VIII Semester Examination, April 2010

ME 801 OPERATIONS MANAGEMENT

(2006 Scheme)

Time: 3 Hours Maximum Marks: 100

PART A

(Answer ALL questions)

(8 x 5 = 40)

I. (a) Explain algorithm for finding critical path.

Compare CPM and PERT.

What is "Product Life Cycle".

Explain "Bin Card System".

Describe "Gantt Chart".

What are the functions of Despatch.

What are the principles of material handing.

(h) What is "Depreciation"

PART B

(All questions carry EQUAL marks)

(15 x 4 = 60)

II. Draw the PERT network and calculate project completion time. The following

informations are available.

Predecessor AB C DE F GH I J K

activities

Successor D B G G I I G -

L

activities F H H K K

Duration 9 7 9 4 3 3 12 10 16

8 l0 6

(week)

OR

II' The precedence relationship with Node numbers of a maintenance job are given as follows:

(i) Draw the arrow diagram and show the critical path (ii) indicate the slack times

for jobs (3, 5) and (7, 8) (ie.) for 'd' and

Job Node Estimated

Number D uration

(Days)

a (1, 2) 2

b (2, 3) 3

c (2, 4) 4

d (3, 5) 5

e (3, 6) 10

f (4, 6) 6

g (4, 7) 3

h (5, 8) 8

k (6, 8) 7

1 (7, 8) 3

(Turn Over)

2

Iv. Write notes on: (i) Interchangeability (ii) Standardisation

(iii)

Product design

OR

A concern is engaged in casting of carburetors. It's demand from the automobile

industries per year is 50,000. The cost of set up is Rs.10001-, There are ten workers

engaged, each on wage rate of Rs. 15/- per day. The overhead cost is Rs.100/- per day.

The daily production capacity is 200/-. The material cost for each carburetor is Rs.101-,

The annual rate of depreciation, insurance, taxes and storage cost, etc. is 20% of unit

cost. The supply should be instantaneous and no shortages are permitted.

Find: (i) The economic lot size (ii) The number of runs

(iii) Duration of each run

VI. Determine an optimum sequence to process the various types of fan blades each day

from the following information so as to minimize the total elapsed time.

Type of fan Number to be Processing time on

Blade Processed in each Machine A Machine B

day (Minutes) (Minutes)

1 4 4 8

2 6 12 6

3 5 14 16

4 2 20 22

5 4 8 10

6 3 18 2

Also workout the total elapsed time for an optimum square. What is the total idle

time on Machine A and on Machine B.

OR

We have five jobs each of which must go through three machines A, B and C in the

order A, B, C. Processing time in hours are given. Determine a sequence for the five

jobs that will minimize the total elapsed time. Find also the idle time for machine A, B

and C.

Job Processing Time

Ai Bi Ci

1 16 10 8

2 20 12 18

3 12 4 16

4 14 6 12

5 22 8 10

Explain the factors to be considered for plant location.

What are the different types of plant layouts. Explain any two in detail.

OR

Differentiate between preventive maintenance and breakdown maintenance.

How can we find the optimum period for replacement? Show graphical representation.

***

S-ar putea să vă placă și

- Belt DriveDocument14 paginiBelt DriveSumit VakhariaÎncă nu există evaluări

- c4611 SampleDocument4 paginic4611 SampleeburkiewÎncă nu există evaluări

- Operations Management 2011 Sept (2006 Ad)Document3 paginiOperations Management 2011 Sept (2006 Ad)VÎncă nu există evaluări

- Cochin University of Science and TechnologyDocument1 paginăCochin University of Science and TechnologyVÎncă nu există evaluări

- Operations Management 2011 Sept (2006 Ad)Document3 paginiOperations Management 2011 Sept (2006 Ad)VÎncă nu există evaluări

- Production Technology 2010 Sept (2006 Ad)Document1 paginăProduction Technology 2010 Sept (2006 Ad)VÎncă nu există evaluări

- CUSATDocument73 paginiCUSATAJIN ELIAS ALEXÎncă nu există evaluări

- Operations Management 2012 April (2006 Ad)Document2 paginiOperations Management 2012 April (2006 Ad)VÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Whiskey FinalDocument13 paginiWhiskey FinalElijahRosejuneGumapacAmoyÎncă nu există evaluări

- MII-U2-Actividad 4. Práctica de La GramáticaDocument1 paginăMII-U2-Actividad 4. Práctica de La GramáticaCESARÎncă nu există evaluări

- How I Have Experienced The 2020: LockdownDocument3 paginiHow I Have Experienced The 2020: LockdownГеоргий КузнецовÎncă nu există evaluări

- Salesforce - Service Cloud Consultant.v2021!11!08.q122Document35 paginiSalesforce - Service Cloud Consultant.v2021!11!08.q122Parveen KaurÎncă nu există evaluări

- AcadinfoDocument10 paginiAcadinfoYumi LingÎncă nu există evaluări

- B. Rivera ST., Tinajeros Malabon CityDocument24 paginiB. Rivera ST., Tinajeros Malabon CityAdrian Carl BarbinÎncă nu există evaluări

- Taqwa (Pıety) Beıng Conscıous of Maıntaınıng Allah's PleasureDocument1 paginăTaqwa (Pıety) Beıng Conscıous of Maıntaınıng Allah's PleasuretunaÎncă nu există evaluări

- Ephesians 5.32-33Document2 paginiEphesians 5.32-33Blaine RogersÎncă nu există evaluări

- 22ba093 - Souvick SahaDocument12 pagini22ba093 - Souvick SahaSouvickÎncă nu există evaluări

- Undiscovered Places in MaharashtraDocument1 paginăUndiscovered Places in MaharashtraNikita mishraÎncă nu există evaluări

- Jacques Maritain - Man and The State-University of Chicago Press (1966)Document230 paginiJacques Maritain - Man and The State-University of Chicago Press (1966)Gabriel Viana Silveira100% (1)

- 12 Business Combination Pt2 PDFDocument1 pagină12 Business Combination Pt2 PDFRiselle Ann SanchezÎncă nu există evaluări

- Complete ES1 2023 Vol1Document334 paginiComplete ES1 2023 Vol1Chandu SeekalaÎncă nu există evaluări

- Process Recording Template 1Document5 paginiProcess Recording Template 1api-584340241Încă nu există evaluări

- The Effect of Celebrity Endorsement On Customer Usage Behavior in The Case of Dashen Bank - Copy (Repaired)Document78 paginiThe Effect of Celebrity Endorsement On Customer Usage Behavior in The Case of Dashen Bank - Copy (Repaired)Eyuael SolomonÎncă nu există evaluări

- Causes of UnemploymentDocument7 paginiCauses of UnemploymentBishwaranjan RoyÎncă nu există evaluări

- Module - No. 7 CGP G12. - Name of AuthorsDocument77 paginiModule - No. 7 CGP G12. - Name of AuthorsJericson San Jose100% (1)

- Mechanisms: For Tabletop RoleplayingDocument15 paginiMechanisms: For Tabletop RoleplayinglaniÎncă nu există evaluări

- Income Tax CalculatorDocument11 paginiIncome Tax Calculatorsaty_76Încă nu există evaluări

- Soal SemesterDocument5 paginiSoal SemesterWayan HamalÎncă nu există evaluări

- Bagabag National High School Instructional Modules in FABM 1Document2 paginiBagabag National High School Instructional Modules in FABM 1marissa casareno almueteÎncă nu există evaluări

- 154 - 2 - Passive Voice ExercisesDocument9 pagini154 - 2 - Passive Voice ExercisesSerbescuÎncă nu există evaluări

- What Is Ecocroticism - GlotfeltyDocument3 paginiWhat Is Ecocroticism - GlotfeltyUmut AlıntaşÎncă nu există evaluări

- Finals Week 12 Joint Arrangements - ACTG341 Advanced Financial Accounting and Reporting 1Document6 paginiFinals Week 12 Joint Arrangements - ACTG341 Advanced Financial Accounting and Reporting 1Marilou Arcillas PanisalesÎncă nu există evaluări

- Goldenway Merchandising Corporation vs. Equitable PCI Bank Case DigestDocument1 paginăGoldenway Merchandising Corporation vs. Equitable PCI Bank Case DigestTopher Oliva100% (1)

- Computer Science and Engineering: Seminar Report On Mass Media byDocument17 paginiComputer Science and Engineering: Seminar Report On Mass Media byJohnny ThomasÎncă nu există evaluări

- Professional Cloud Architect Journey PDFDocument1 paginăProfessional Cloud Architect Journey PDFPraphulla RayalaÎncă nu există evaluări

- BPHC HRSA-23-025 (H8H) FY 2023 Ending HIV Epidemic - FinalDocument44 paginiBPHC HRSA-23-025 (H8H) FY 2023 Ending HIV Epidemic - FinalTuhin DeyÎncă nu există evaluări

- ISA UPANISHAD, Translated With Notes by Swami LokeswaranandaDocument24 paginiISA UPANISHAD, Translated With Notes by Swami LokeswaranandaEstudante da Vedanta100% (4)

- General Sir Arthur Cotton R E His Life and Work Lady Hope 1000598480Document656 paginiGeneral Sir Arthur Cotton R E His Life and Work Lady Hope 1000598480rajk_onlineÎncă nu există evaluări