Documente Academic

Documente Profesional

Documente Cultură

PRN004

Încărcat de

bey0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări2 paginiThis document summarizes the results of a welding procedure qualification test. It tested the gas metal arc welding process using short circuit and globular transfer modes. The test used a single-vee groove weld on SA106 Grade B steel with ER70S-2 filler metal. Tensile and guided bend tests met the requirements. Hardness surveys found the base metal was 150 BHN, heat-affected zone was 138 BHN, and weld metal was 155 BHN. The welder and laboratory certified that the tests and records complied with ASME Code requirements.

Descriere originală:

PRN004

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document summarizes the results of a welding procedure qualification test. It tested the gas metal arc welding process using short circuit and globular transfer modes. The test used a single-vee groove weld on SA106 Grade B steel with ER70S-2 filler metal. Tensile and guided bend tests met the requirements. Hardness surveys found the base metal was 150 BHN, heat-affected zone was 138 BHN, and weld metal was 155 BHN. The welder and laboratory certified that the tests and records complied with ASME Code requirements.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări2 paginiPRN004

Încărcat de

beyThis document summarizes the results of a welding procedure qualification test. It tested the gas metal arc welding process using short circuit and globular transfer modes. The test used a single-vee groove weld on SA106 Grade B steel with ER70S-2 filler metal. Tensile and guided bend tests met the requirements. Hardness surveys found the base metal was 150 BHN, heat-affected zone was 138 BHN, and weld metal was 155 BHN. The welder and laboratory certified that the tests and records complied with ASME Code requirements.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

PRN004

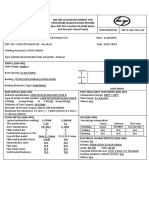

Company Name: The Shaw Group, Inc./ B. F. Shaw, Inc.

Procedure Qualification Record No.: 12673 Date: September 21, 1990

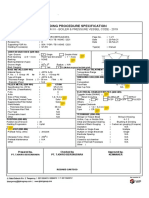

WPS No.: 102, 105, 1.402

Welding Process(es) GMAW

Types (Manual, Automatic, Semi-Auto) Semi-automatic

JOINTS (QW-402)

SINGLE VEE GROOVE

70 DEGREE INCLUDED ANGLE

5/32 GAP

1/16 LAND

Groove Design of Test Coupon

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec.: SA106 Temperature: None

Type or Grade: B Time:

P-No.: 1 to P-No.: 1 Other:

Thickness of test coupon: .280

Diameter of test coupon: 6 NPS

Other: The deposition of each pass did not exceed .

FILLER METALS (QW-404) GAS (QW-408)

Process: GMAW GMAW

SFA Specification: 5.18 5.18 Percent CFH

AWS Classification: ER70S-2 ER70S-2 Gas(es) Composition Flow

Filler Metal F-No.: 6 6 (Mixture) Rate

Weld Metal A-No.: 1 1 Shielding Argon/CO2 75/25 40

Size of Filler Metal: .035 .035 Trailing None None None

Other: Note 1 & 2 Note 1 & 3 Backing None None None

Weld Metal Thickness: .0625 .2175

Root Pass Fill & Cap Passes

NOTES: ELECTRICAL CHARACTERISTICS (QW-409)

1. Supplemental filler metal or powdered filler metal Current: DC Polarity: EP

were not used. AMPS: Root Pass: 140-150* Fill & Cap Passes: 170-180**

2. Short Circuit Transfer Mode Volts: Root Pass: 15-18 * Fill & Cap Passes: 20-22 **

3. Globular Transfer Mode Tungsten Electrode Size: Not applicable this WPS

Transfer Mode: N/A

Other: *Short Circuiting Mode ** Globular Mode

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Groove: 5G Travel Speed: Manual

Weld Progression: Uphill: Fill & Cap String or Weave Bead: Weave

Downhill: Root Pass

Other: Oscillation: Not applicable this WPS

PREHEAT (QW-406) Multipass/Single Pass (per side): Multipass

o o

Preheat Temp.: 50 F Interpass Temp: 500 F Single or Multiple Electrodes: Single

Other: Other:

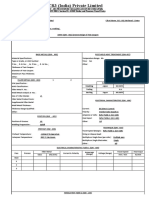

PQR No.: 12673 (PRN004)

QW-462.1(b)

Tensile Test (QW-150)

Ultimate Ultimate Type of Failure &

Specimen Width Thickness Total Load Unit Stress Location

No. (Inches) (Inches) Area lb psi

T1 .748 .234 .175 12,150 69,500 Ductile-Base

T2 .745 .237 .176 12,850 73,000 Ductile-Base

Guided-Bend Tests (QW-160)

Type and Figure No. Result

QW-462.3 (a) Root Bend No. 1 Satisfactory (QW 163)

QW-462.3 (a) Root Bend No. 2 Satisfactory (QW 163)

QW-462.3 (a) Face Bend No. 1 Satisfactory (QW 163)

QW-462.3 (a) Face Bend No. 2 Satisfactory (QW 163)

Toughness Tests (QW-170)

Specimen Notch Specimen Size Notch Test Impact Lateral Exp.

No. Location Type Temp. Values % Shear Mils

Fillet-Weld Test (QW-180)

Result Satisfactory: Yes ______ No _____ Penetration into Parent Metal: Yes _______ No _______

Macro-Results:

Other Tests

Type of Test: Brinell Hardness Survey: Base Metal: 150 BHN, HAZ: 138 BHN, Weld Metal: 155 BHN

Deposit Analysis:

Other:

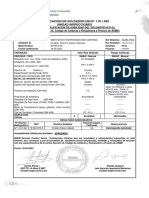

Welders Name: M. Bailey Clock No.: Stamp No.: P8

Test Conducted By: Scientific Testing Laboratories, Inc. Laboratory Test No.: 12673

We certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Code.

Manufacturer: The Shaw Group, Inc./B.F. Shaw, Inc.

Date: April 7, 2000 By: ________________________________________

S-ar putea să vă placă și

- PRN005Document2 paginiPRN005beyÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 paginiBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyÎncă nu există evaluări

- Transducer Handbook: User's Directory of Electrical TransducersDe la EverandTransducer Handbook: User's Directory of Electrical TransducersÎncă nu există evaluări

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 paginiJOINTS (QW-402) : Groove Design of Test CouponbeyÎncă nu există evaluări

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 paginiJOINTS (QW-402) : Groove Design of Test CouponbeyÎncă nu există evaluări

- PQR FormatDocument2 paginiPQR FormatBE GÎncă nu există evaluări

- Procedure Qualification RecordDocument6 paginiProcedure Qualification RecordGaurang PandyaÎncă nu există evaluări

- WPS&PQR For PipeDocument5 paginiWPS&PQR For PipeKAMALÎncă nu există evaluări

- Aic Asf PQR 133Document3 paginiAic Asf PQR 133AHMED MEDANYÎncă nu există evaluări

- QW483Document2 paginiQW483Sc TanÎncă nu există evaluări

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 paginiWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- 1 5 1Document5 pagini1 5 1daemsalÎncă nu există evaluări

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 paginiQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Încă nu există evaluări

- PQR With-PwhtDocument2 paginiPQR With-PwhtKarthikÎncă nu există evaluări

- PQR ForDocument3 paginiPQR ForAkash Singh TomarÎncă nu există evaluări

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 paginiQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghÎncă nu există evaluări

- PQR GmawDocument4 paginiPQR GmawEr Sumant Kumar Singh0% (1)

- Procedure Qualification Record PQRDocument3 paginiProcedure Qualification Record PQRNMBaihakiARÎncă nu există evaluări

- Swathi Industries: JOINT (QW 402)Document10 paginiSwathi Industries: JOINT (QW 402)Mustu AkolawalaÎncă nu există evaluări

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pagini(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaÎncă nu există evaluări

- Procedure Qualification Record (PQR)Document3 paginiProcedure Qualification Record (PQR)surjithkocherilÎncă nu există evaluări

- WPQ FormatDocument8 paginiWPQ FormatsanjaykumarmauryaÎncă nu există evaluări

- Gta+sma PQRDocument3 paginiGta+sma PQRRahul MoottolikandyÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriÎncă nu există evaluări

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 paginiWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanÎncă nu există evaluări

- Bdde PQR CS 001Document2 paginiBdde PQR CS 001mainur mechanical engineer0% (1)

- Mechanical Engineering M.Abdul GhoziDocument4 paginiMechanical Engineering M.Abdul GhoziRizaldy PhoenksÎncă nu există evaluări

- PQR TipsDocument2 paginiPQR TipsWaqas WaqasÎncă nu există evaluări

- WPS 10Document2 paginiWPS 10Arab WeldersÎncă nu există evaluări

- Wps Format Asme Sec - IxDocument2 paginiWps Format Asme Sec - IxDeepu ChandranÎncă nu există evaluări

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 paginiAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1Încă nu există evaluări

- WPS, PQR, WPQ PoojaDocument10 paginiWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- PQR 005-50-NLG PWHT (Icas)Document2 paginiPQR 005-50-NLG PWHT (Icas)Atilio BarriosÎncă nu există evaluări

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 paginiWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberÎncă nu există evaluări

- 37507022-WPS-PQR-SS-316 LDocument5 pagini37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 paginiWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanÎncă nu există evaluări

- WPS 03 GtawDocument3 paginiWPS 03 GtawBiswajit DeyÎncă nu există evaluări

- 2005-05 - WPS & PQR C5Document6 pagini2005-05 - WPS & PQR C5misthahÎncă nu există evaluări

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Document1 paginăWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenÎncă nu există evaluări

- PQR Editable SampleDocument2 paginiPQR Editable SampleKoya ThangalÎncă nu există evaluări

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 paginiAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposÎncă nu există evaluări

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 paginiNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalÎncă nu există evaluări

- Daewoo E & C: Welding Procedure Specification (WPS)Document2 paginiDaewoo E & C: Welding Procedure Specification (WPS)Jarus YdenapÎncă nu există evaluări

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 paginiWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSÎncă nu există evaluări

- Welding Procedure SpecificationDocument27 paginiWelding Procedure SpecificationGopakumar K100% (2)

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 paginăTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnÎncă nu există evaluări

- WPQ WeldCanada PDFDocument1 paginăWPQ WeldCanada PDFAhmad DanielÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedÎncă nu există evaluări

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 paginiMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozÎncă nu există evaluări

- PQR FormatDocument2 paginiPQR Formatravi0009880% (5)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 paginiWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPQ 양식 김정균 (DSHI Rev.0)Document5 paginiWPQ 양식 김정균 (DSHI Rev.0)이훈Încă nu există evaluări

- 1.911.032 WPQ Smaw Astm A36Document1 pagină1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaÎncă nu există evaluări

- WPS PQR Procedure PDFDocument31 paginiWPS PQR Procedure PDFsudeesh kumarÎncă nu există evaluări

- WPS PQR ProcedureDocument31 paginiWPS PQR Proceduresudeesh kumarÎncă nu există evaluări

- SampleDocument5 paginiSample이훈Încă nu există evaluări

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 paginiWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanÎncă nu există evaluări

- Aic Asf PQR 0122Document2 paginiAic Asf PQR 0122AHMED MEDANYÎncă nu există evaluări

- Pipeline & Piping ScheduleDocument12 paginiPipeline & Piping SchedulebeyÎncă nu există evaluări

- Well Test Interpreta TionDocument6 paginiWell Test Interpreta TionbeyÎncă nu există evaluări

- 4 Wti Wellsite ValidationDocument6 pagini4 Wti Wellsite ValidationbeyÎncă nu există evaluări

- Bilad 2018 01 21Document25 paginiBilad 2018 01 21beyÎncă nu există evaluări

- Flare Ignition ProcedureDocument4 paginiFlare Ignition ProcedurebeyÎncă nu există evaluări

- Engineering Data Book: Gas Processors Suppliers AssociationDocument30 paginiEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- PRN List For Volume 1-113001Document1 paginăPRN List For Volume 1-113001beyÎncă nu există evaluări

- Introduction To Drilling: School of Hassi MessaoudDocument210 paginiIntroduction To Drilling: School of Hassi MessaoudbeyÎncă nu există evaluări

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 paginăPipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyÎncă nu există evaluări

- Table of Contents-Rev. 07Document4 paginiTable of Contents-Rev. 07beyÎncă nu există evaluări

- Piping DesignDocument89 paginiPiping Designbey100% (2)

- PRC-0008 CurrentDocument50 paginiPRC-0008 CurrentbeyÎncă nu există evaluări

- GENREV11Document14 paginiGENREV11beyÎncă nu există evaluări

- Wps Model 2 PDFDocument17 paginiWps Model 2 PDFbeyÎncă nu există evaluări

- 104 Rev 2Document2 pagini104 Rev 2beyÎncă nu există evaluări

- 403 Rev 2Document2 pagini403 Rev 2beyÎncă nu există evaluări

- Sonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationDocument2 paginiSonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationbeyÎncă nu există evaluări

- David Sacks Resume February 16 2015Document1 paginăDavid Sacks Resume February 16 2015api-279280948Încă nu există evaluări

- Kimberly Jimenez Resume 10Document2 paginiKimberly Jimenez Resume 10kimberlymjÎncă nu există evaluări

- IAU Logbook Core 6weeksDocument7 paginiIAU Logbook Core 6weeksbajariaaÎncă nu există evaluări

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Document296 paginiBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatÎncă nu există evaluări

- Cesars WayDocument20 paginiCesars WayToni TursićÎncă nu există evaluări

- Research Paper OutlineDocument2 paginiResearch Paper Outlineapi-270769683Încă nu există evaluări

- CHAPTER 2 (C) Innovation in EntrepreneurDocument36 paginiCHAPTER 2 (C) Innovation in EntrepreneurHuiLingÎncă nu există evaluări

- Chemistry Previos Papaer 313Document19 paginiChemistry Previos Papaer 313Ashu GuptaÎncă nu există evaluări

- Contents of HvacDocument2 paginiContents of Hvaclijo johnÎncă nu există evaluări

- Adolescents and Career DevelopmentDocument10 paginiAdolescents and Career DevelopmentMasrijah MasirÎncă nu există evaluări

- PCNSE DemoDocument11 paginiPCNSE DemodezaxxlÎncă nu există evaluări

- High School Physics Rutherford Atom Lesson 27Document4 paginiHigh School Physics Rutherford Atom Lesson 27John JohnsonÎncă nu există evaluări

- Firststep To AlaskaDocument28 paginiFirststep To AlaskaBarbara NelsonÎncă nu există evaluări

- Alumni Homecoming ScriptDocument2 paginiAlumni Homecoming ScriptMeliza Casipit100% (1)

- DbmsDocument5 paginiDbmsRohit KushwahaÎncă nu există evaluări

- Lay Planning TypesDocument1 paginăLay Planning TypesGaurav Shakya100% (1)

- Primefaces Users Guide 3 5cDocument497 paginiPrimefaces Users Guide 3 5calvarolucasÎncă nu există evaluări

- The Names of Allah and Their ReflectionsDocument98 paginiThe Names of Allah and Their ReflectionsSuleyman HldÎncă nu există evaluări

- Store Docket - Wood PeckerDocument89 paginiStore Docket - Wood PeckerRakesh KumarÎncă nu există evaluări

- Application of SPACE MatrixDocument11 paginiApplication of SPACE Matrixdecker444975% (4)

- BROMINE Safety Handbook - Web FinalDocument110 paginiBROMINE Safety Handbook - Web Finalmonil panchalÎncă nu există evaluări

- Dr. Alberto A. Jumao-As JRDocument46 paginiDr. Alberto A. Jumao-As JRClinton Mazo100% (1)

- Grand Chapter Mentor ProgramDocument13 paginiGrand Chapter Mentor ProgramJulius Wright100% (1)

- 2012 Karshaniya YavaguDocument4 pagini2012 Karshaniya YavaguRANJEET SAWANTÎncă nu există evaluări

- Solow 5e Web SolutionsDocument58 paginiSolow 5e Web SolutionsOscar VelezÎncă nu există evaluări

- VRF-SLB013-EN - 0805115 - Catalogo Ingles 2015 PDFDocument50 paginiVRF-SLB013-EN - 0805115 - Catalogo Ingles 2015 PDFJhon Lewis PinoÎncă nu există evaluări

- Answer KeyDocument4 paginiAnswer KeyLouina YnciertoÎncă nu există evaluări

- Organic Food Business in India A Survey of CompaniDocument19 paginiOrganic Food Business in India A Survey of CompaniShravan KemturÎncă nu există evaluări

- Sketch NotesDocument32 paginiSketch NotesFilipe Rovarotto100% (8)