Documente Academic

Documente Profesional

Documente Cultură

Keystone Fig. 60 Butterfly Valve

Încărcat de

Carlos GutierrezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Keystone Fig. 60 Butterfly Valve

Încărcat de

Carlos GutierrezDrepturi de autor:

Formate disponibile

Keystone Butterfly Valves - Series 60

2" to 24"

60W - Wafer style resilient seated butterfly valve

60L - Lugged style resilient seated butterfly valve

Cartridge Seat Design

Features and Benefits

Suitable for high pressure and full

vacuum service due to the use of

a cartridge seat design.

Triple function cartridge seat isolates

the body and stem from the media,

provides positive drop-tight shut-off

of line media at full rated pressure

and provides a flange seal, eliminating

the need for flange gaskets.

Full rated unidirectional dead-end

service is achieved by utilizing a

unique patented lip in the lug body.

Strong disc-to-stem connection

and elimination of exposed pins

or bolts is achieved through a

rectangular drive.

Ability to install the valve with the disc

in the closed position eliminates the

risk of damage to the valve during

installation.

Maximum flow and rangeabililty

is achieved with the use of a

streamlined disc.

Stems are blowout-proof stems as

a standard.

Longer seat life with low operating

torques is ensured by utilizing upper

and lower stem bearings.

Need for costly brackets is eliminated

due to the ability to direct mount

actuation onto the valve top-plate.

General Application Technical Data

Ideally suited for many industrial Size Range: 2" to 24" wafer and

applications such as food and beverage, lugged styles

pulp and paper, chemical, mining, water

Pressure Rating: 2" to 12" 250 psi

treatment, power, and automotive where

14" to 24" 200 psi

a heavy-duty resilient seated butterfly

valve is required. Available in a wide Teflon seat or

variety of body, disc and seat materials elastomer covered disc

to fit a wide variety of media 2" to 12" 150 psi

applications.

Dead End Rating: Full rated in preferred

direction of flow

Flange Standard: ASME Class 125/150

Designed to comply with MSS-SP-67 and API 609 (may be shell tested to spec on request).

Keystone is either a trademark or registered trademark of Tyco International Services AG or its affiliates

in the United States and/or other countries. All other brand names, product names, or trademarks

belong to their respective holders.

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026-US-0904

Keystone Butterfly Valves - Series 60

2" to 24"

Specifications

6

5

Materials Notes

Part Standard Material Material Specifications 1. 14" and larger Wafer style available in Cast

Iron Body only.

1. Body Cast Iron1 ASTM A126 Class B

2. 14" and larger Lug style available in Ductile

Ductile Iron (2" to 12") ASTM A395 Grade 60/40/18 Iron Body only.

Ductile Iron2 (14" to 24" Lug style) ASTM A536 Grade 65/45/12 3. Offered in 2" to 6" only. These bodies come

316 Stainless Steel3 ASTM A351 CF8M standard with a vented shaft and food grade

seats.

2. Disc Ductile Iron/Nickel Plated ASTM A536 Grade 65/45/12

4. 316 Stainless Steel Stem available in 2" to

Aluminum Bronze ASTM B148 C95400

12" only.

316 Stainless Steel ASTM A351 CF8M

5. Valves with 316 SS bodies are provided with

EPDM Coated (2" to 12") two additional bearings in the lower stem

NBR Coated (2" to 12") journal.

3. Stem 416 Stainless Steel (standard) ASTM A582 UNS S41600 Cond. A 6. Teflon is a registered trademark of E.I.

duPont de Nemours & Company.

316 Stainless Steel (optional)4 ASTM A276 UNS S31600 Cond. A

4. Seat EPDM Food Grade (-20F 250F) 7. Gar-Fil is a registered trademark of Garlock

Bearings, Inc.

NBR (0F 180F)

Fluoroelastomer (0F 300F)

Teflon (-20F 250F) (2" to 12")

5. Bearing5 Teflon Gar-Fil (2" to 24")

6. Pin Carbon Steel

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

2

Keystone Butterfly Valves - Series 60

2" to 24"

Specifications

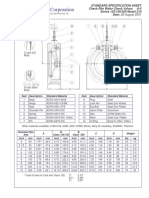

Series 60W Series 60L

Dimensions (inches)

Adapt.

Size B C1 C2 D E F G H J L M N P Q* Key Code

2" 5.09 5.75 4.69 1.63 4.00 1.25 0.56 0.37 0.406 3.00 3.25 5/8-11 4.75 1.41 - BAB

21/2" 5.81 6.25 - 1.75 4.00 1.25 0.56 0.37 0.406 3.00 3.25 5/8-11 5.50 1.82 - BAB

3" 6.25 6.50 4.87 1.75 4.00 1.25 0.56 0.37 0.406 3.00 3.25 5/8-11 6.00 2.62 - BAB

4" 7.81 7.25 6.00 2.00 4.00 1.25 0.63 0.43 0.406 3.00 3.25 5/8-11 7.50 3.62 - BAC

5" 8.75 7.75 - 2.13 4.00 1.25 0.75 0.50 0.406 3.00 3.25 3/4-10 8.50 4.67 - BAD

6" 9.75 8.38 6.50 2.14 4.00 1.25 0.75 0.50 0.406 3.00 3.25 3/4-10 9.50 5.68 - BAD

8" 12.00 9.62 - 2.35 6.00 1.25 0.87 0.63 0.562 5.00 - 3/4-10 11.75 7.54 - CAE

10" 14.50 11.00 - 2.63 6.00 2.00 1.12 - 0.562 5.00 - 7/8-9 14.25 9.65 1/4 x 1/4 CAF

12" 17.50 12.50 - 3.00 6.00 2.00 1.37 - 0.562 5.00 - 7/8-9 17.00 11.49 5/16 x 5/16 CAG

14" 19.50 13.25 - 3.06 6.00 3.00 1.37 - 0.531 5.00 - 1-8 18.75 12.97 5/16 x 5/16 CAG

16" 22.06 14.75 - 4.01 6.00 3.00 1.63 - 0.531 5.00 - 1-8 21.25 14.85 3/8 x 3/8 CAH

18" 23.44 15.75 - 4.48 6.75 3.00 1.63 - 0.531 5.00 - 11/8-7 22.75 16.76 3/8 x 3/8 CAH

20" 25.68 16.25 - 4.99 6.75 4.25 1.88 - 0.812 6.50 - 11/8-7 25.00 18.72 1/2 x 3/8 DAJ

24" 30.06 19.12 - 6.00 8.00 4.25 1.88 - 0.812 6.50 - 11/4-7 29.50 22.59 1/2 x 3/8 DAJ

C1 Dimensions apply to Cast Iron and Ductile Iron bodies ONLY.

C2 Dimensions apply to Stainless Steel bodies ONLY.

Q* Dimension is the minimum allowable pipe or flange inside diameter at the centered body face

to protect the disc sealing edge against damage when opening the valve.

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

3

Keystone Butterfly Valves - Series 60

2" to 24"

Valve Sizing

Rate of flow through a valve depends flow of water in gallons per minute characteristics are shown in the same

upon the pressure drop. The most (GPM) with a 1 psi pressure drop manner with Cvs at the various disc

common method of presenting this through the valve. The higher the Cv, openings. Tabulated below are the Cvs

information is by Cv. The Cv is the valve the greater the flow and the better the for the Series 60 Butterfly Valve.

coefficient of flow and represents the control characteristics. Throttling

Cv Chart (Water @ 70F, Specific Gravity = 1.00)

Valve Disc position (Degrees Open)

Size 25 30 40 50 60 70 80 90

2" 3 7 19 36 63 84 115 120

21/2" 4 10 24 47 78 113 182 194

3" 14 21 45 84 133 203 382 430

4" 30 52 100 165 270 420 703 830

5" 85 130 210 345 525 825 1,350 1,500

6" 165 225 360 570 820 1,260 1,875 1,980

8" 210 300 480 780 1,320 2,280 3,780 3,870

10" 405 575 850 1,200 1,900 3,300 6,100 6,450

12" 550 750 1,200 1,875 2,850 5,025 9,300 9,800

14" 650 825 1,500 2,300 3,500 6,200 9,700 10,500

16" 800 1,000 1,850 2,900 4,600 7,500 10,600 13,500

18" 1,100 1,400 2,450 3,800 5,000 9,700 13,850 18,000

20" 1,400 1,650 3,050 4,800 7,400 12,500 17,750 23,000

24" 2,000 2,400 4,200 6,600 10,500 17,000 23,000 31,000

Torque Data

Torque is the rotary effort required to Breakaway torque at 70F Note: These values are valid for water

operate a valve. This turning force in a Breakaway torque is the total of the and lubricating fluids only at 70F. Since

butterfly valve is determined by three torques resulting from bearing friction torques are greatly increased for dry and

factors the friction of the disc and seat and disc/seat interference friction at a nonlubricating fluids and temperature

due to interference for sealing, bearing given pressure differential. Listed below variations, contact your Keystone

friction, and fluid dynamic torque. are torques to open and close the valve representative for accurate values in

at pressures shown in wet services these applications.

(normal conditions).

Breakaway torque in inch pounds for wet service applications/standard disc

Line Size

Pressure 2 21/2 3 4 5 6 8 10 12 14 16 18 20 24

50 85 126 180 355 562 918 1,440 2,466 3,510 5,200 6,900 9,000 11,000 16,000

100 108 153 207 414 652 1,035 1,692 3,010 4,140 6,000 8,000 10,500 14,000 21,000

150 126 175 256 472 715 1,152 1,922 3,550 5,616 7,500 9,500 12,000 15,200 28,000

200 144 198 297 531 787 1,269 2,205 4,095 7,686 8,550 10,750 13,500 17,600 33,700

250 162 221 339 590 869 1,386 2,476 4,660 10,556 - - - - -

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

4

Keystone Butterfly Valves - Series 60

2" to 24"

Materials Description

Seats Special Valve Seats Hypalon Rated for temperatures 0F

Food Grade EPDM Rated for EPDM Rated for temperatures -20F to 225F. Hypalon is the DuPont Dow

temperatures -20F to 250F. Service to 250F. EPDM is an abbreviation of a Elastomers trademark for chlorosulfo-

conditions are equivalent to those compound called Ethylene Propylene nated polyethylene. Hypalon is resistant

recommended for regular EPDM Diene Monomer. It is also commonly to most chemicals and greases and is

including applications where Food called EPT, Nordel, and EPR. EPDM is particularly unaffected by aqueous salt

Grade is required. used extensively in the HVAC (Heating, solutions, alcohols, weak and concen-

Ventilation, Air Conditioning) industry due trated alkalies, and concentrated sulfuric

NBR Rated for temperatures 0F to acid. It is not recommended for gasoline,

to its resistance to polar compounds such

180F. NBR is also commonly identified jet fuels, ketones, or chlorinated

as water, phosphate esters, ketones,

as BUNA-N, Nitrile, or Hycar. It is an solvents. Hypalon has excellent

alcohols, and glycols.The EPDM

excellent general purpose elastomer abrasion resistance and is unaffected by

material is also applicable for handling

suitable for use with air, water as well prolonged immersion in water.

concentrated sulfuric acid, 20% sodium

as most petroleum oils and greases,

hypochlorite (bleach), chlorinated water

automotive gasolines (except those Disc Coatings

for swimming pools, and other alkaline

which have additives), alcohols and PVDF Coated Disc Rated for

solutions. EPDM is not resistant to

glycols, L-P gases, propane and butane, temperatures -20F to 275F.

hydrocarbon solvents and oils,

fuel oils and many other fluids. It also Polyvinylidene fluoride also known as

chlorinated hydrocarbons, turpentine,

exhibits good abrasion resistance, and Kynar is a strong, tough fluoroplastic

or any other petroleum based oils.

excellent resistance to compression set. material that is particularly suited to

White Neoprene Rated for corrosion resistant applications in severe

Viton Rated for temperatures 0F

temperatures 0F to 180F. Neoprene environments. The coating has a high

to 300F. Viton is a DuPont Dow

has excellent resistance to alcohols, degree of mechanical strength, and is

Elastomers trademark. Fluorel is

glycols, dilute mineral acids, concentra- chemically resistant to most acids and

Dyneons trademark for the equivalent

ted caustics, and aqueous salt solutions. bases over a broad temperature range.

fluorocarbon elastomer. This material

White Neoprene is generally used in (min. thickness 20 mils).

offers higher temperature resistance

sanitary applications, and although it

and outstanding chemical resistance. EPDM Coated Disc Rated for

is slightly inferior to BUNA-N in oil

It is resistant to hydrocarbon products temperatures -20F to 250F. EPDM

resistance, it is markedly better than most

and mineral acids, both diluted and coated disc provides excellent wear and

elastomers in these applications.

concentrated solutions. However, it is abrasion characteristics for use in highly

never to be used in steam applications Black Neoprene Rated for abrasive environments. The EPDM

and is relatively poor in water service. temperatures 0F to 180F. Neoprene elastomer also provides the disc with

offers excellent physical properties chemical resistance for handling certain

Teflon Rated for temperatures -20F

where resistance to alcohols, glycols, acids, esters, ketones and all types of

to 250F. The Teflon liner overlays

dilute mineral acids, concentrated water service where normal metal discs

silicone which is bonded to a rigid

caustics, aqueous salt solutions, and cannot be used due to chemical and/or

phenolic ring on the outside seat

mild abrasion resistance is required. The abrasive conditions. The EPDM coated

perimeter. Teflon extends over the seat

black grade provides better abrasion discs are not recommended for use in

faces and outside flange seal diameter,

and oil resistance than the white grade hydrocarbon solvents and oils,

completely covering the EPDM layer of

Neoprene, and although it is slightly chlorinated hydrocarbons, turpentine, or

the seat which provides the resilience for

inferior to BUNA-N in oil resistance, it any other petroleum based oils. Other

sealing valve stems and the closed disc.

provides excellent service in water/oil, rubber materials available upon request.

air/oil services.

Notes

A. Phenolic reinforced seats standard on Fluorel is a registered trademark of Dyneon, a

2" to 24" 3M company.

B. Letter identification of phenolic reinforced Hycar is a registered trademark of Noveon, Inc.

liners on I.D. of liner is: Hypalon and Viton are registered trademarks

NB = NBR of DuPont Dow Elastomers.

EM = Food-Grade EPDM

CF = White Neoprene Nordel is a trademark of The Dow Chemical

EP = EPDM Company.

FK = Viton Kynar is a registered trademark of Elf Atochem

CR = Black Neoprene North America, Inc.

CS = Hypalon

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

5

Keystone Butterfly Valves - Series 60

2" to 24"

Valve Weights

Wafer Body (lbs)

Valve Size: 2 2.5 3 4 5 6 8 10 12 14 16 18 20 24

Bare Stem 5 6 7 17 19 29 36 58 87 140 177 222 347 465

Lever OP 10 11 12 22 24 34 41 63 92 - - - - -

Gear OP 14 15 19 24 30 32 62 84 130 164 201 246 371 535

Lug Body (lbs)

Valve Size: 2 2.5 3 4 5 6 8 10 12 14 16 18 20 24

Bare Stem 8 10 11 15 27 31 44 64 120 156 226 266 412 495

Lever OP 13 15 16 20 32 36 49 69 125 - - - - -

Gear OP 17 19 20 27 40 44 79 115 163 180 250 290 436 565

Material Specifications - ASTM References

Part Material Specs

Body Cast Iron A126 Class B

Ductile Iron (2" 12") A395 Grade 60/40/18

Ductile Iron (14" 24" Lug) A536 Grade 65/45/12

Stainless Steel A351 Grade CF8M

Disc Ductile Iron A236 Grade 65/45/12

Stainless Steel A351 Grade CF8M

Aluminum Bronze B148 UNS C945000

Stem 416 SS A582 Type 416

316 SS A276 Type 316 Cond. A

Bearings Teflon Gar-Fil

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

6

Keystone Butterfly Valves - Series 60

2" to 24"

Series 60 Ordering Information

Example: 040 60 L C A S 2 U 1

a 4" lug style with cast iron body, aluminum

bronze U/C disc, 416 SS shaft and NBR seat

with handle 040 60L CAS2 U 1

Size

020 2" 100 10"

025 21/2" 120 12"

030 3" 140 14"

040 4" 160 16"

050 5" 180 18"

060 6" 200 20"

080 8" 240 24"

Series

60

Body Style

W Wafer

L Lug

Body Material

C Cast Iron (14" and larger wafer style available only in Cast Iron)

D Ductile Iron (14" and larger lug style available only in Ductile Iron)

S Stainless Steel (available only in 2" to 6" sizes)

X Other

Disc Material

S 316 Stainless Steel (2" to 12" valves with 316 SS Disc are available only with 316 SS Stem)

A Aluminum Bronze

D Ductile Iron ENP

E EPDM coated

N NBR coated

X Other

Stem Material

S 416 Stainless Steel (standard)

P 316 Stainless Steel (optional; available only in 2" to 12" sizes)

X Other

Seat Material

1 EPDM (Food Grade) 6 Black Neoprene

2 NBR 7 Teflon

3 Viton 8 EPDM

4 Black Hypalon X Other

5 White Neoprene

Special

U U/C

S Silicone-free

C Sanitary Service (available only with Stainless Steel Body)

X Other

Actuation

0 None 4 Pneumatic Direct Acting

1 10 Position Handles 5 Pneumatic Spring Return

2 Gear 6 Electric

3 Chain Wheel X Other

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

7

Keystone Butterfly Valves - Series 60

2" to 24"

Additional Keystone Products

Keystone K-LOK ANSI rated high Keystone Figure 106 large diameter

performance valves are available in butterfly valves are offered in sizes 24"

ASME 150 and ASME 300 pressure through 48" for your larger diameter

classes. They are available in a variety valve requirements.

of trims to meet your higher pressure

higher temperature requirements.

Keystone

Tyco Flow Control offers a complete MRP Pneumatic Rack

line of actuation and controls to meet all and Pinion Actuators

your automation needs. This allows us

to supply a complete package for single

source responsibility.

Keystone

EPI2 Electric Actuator

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services.

Individuals using this data sheet must exercise their independent judgment in evaluating product selection and determining product appropriateness for their particular purpose and system requirements. TFC MAKES NO

REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR DAMAGES (OF ANY KIND OR NATURE, INCLUDING

INCIDENTAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and Patents Pending in the U.S. and foreign countries. Tyco

reserves the right to change product designs and specifications without notice. All registered trademarks are the property of their respective owners. Printed in the USA.

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0026

8

S-ar putea să vă placă și

- Grinnell Series 8000Document8 paginiGrinnell Series 8000Sergio Gana GonzalezÎncă nu există evaluări

- Tyco Grinnell Resilient Seat ButterflyDocument8 paginiTyco Grinnell Resilient Seat ButterflySergio Gana GonzalezÎncă nu există evaluări

- V - CuchillaDocument8 paginiV - Cuchillaalex95591Încă nu există evaluări

- Bray Válvula GuillotinaDocument8 paginiBray Válvula Guillotinajuniortrader05Încă nu există evaluări

- BTFY Keystone Ar1 Ar2Document4 paginiBTFY Keystone Ar1 Ar2tali011971Încă nu există evaluări

- Your Global Flow Control Partner: International Product ProfileDocument16 paginiYour Global Flow Control Partner: International Product ProfileKevin EsquivelÎncă nu există evaluări

- Series 59 Full Port Ball ValveDocument4 paginiSeries 59 Full Port Ball Valvekyeong cheol leeÎncă nu există evaluări

- Series 20-21 SS Butterfly ValvesDocument2 paginiSeries 20-21 SS Butterfly ValvesQuangNgocÎncă nu există evaluări

- EN V6007 S762 KnifeGate Web 20220706Document8 paginiEN V6007 S762 KnifeGate Web 20220706password2002Încă nu există evaluări

- Bray Valves Profile I-5000 EL Profile 10 2015 LRDocument17 paginiBray Valves Profile I-5000 EL Profile 10 2015 LRChandravadanÎncă nu există evaluări

- Dossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Document212 paginiDossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Bureau VeritasÎncă nu există evaluări

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 paginiBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaÎncă nu există evaluări

- Control Valves Two PortDocument16 paginiControl Valves Two Portwendelreis19746883100% (1)

- Catálogo Mariposas PRATT USADocument12 paginiCatálogo Mariposas PRATT USAAlex Javier Garzon OrduñaÎncă nu există evaluări

- Bray-B-1008 ProdProfile 06 07 2016Document13 paginiBray-B-1008 ProdProfile 06 07 2016Osvaldo Junges BomfimÎncă nu există evaluări

- Rotary Control Valve: K-MaxDocument12 paginiRotary Control Valve: K-MaxBrLuxy1952Încă nu există evaluări

- Rotary Control Valve: K-MaxDocument12 paginiRotary Control Valve: K-MaxBrLuxy1952Încă nu există evaluări

- Aop Trunnion Ball Valves BrochureDocument28 paginiAop Trunnion Ball Valves BrochureEsteban LobatoÎncă nu există evaluări

- Breather Valve 94020-3HDocument8 paginiBreather Valve 94020-3Hbuzz cmkyÎncă nu există evaluări

- Conservation Vent (Pressure & Vacuum)Document8 paginiConservation Vent (Pressure & Vacuum)SudhirÎncă nu există evaluări

- 98H Series Backpressure/Relief Valves: Industrial RegulatorsDocument4 pagini98H Series Backpressure/Relief Valves: Industrial RegulatorsDaniel ReyÎncă nu există evaluări

- L&T - Triple OffsetDocument16 paginiL&T - Triple OffsetTasneemÎncă nu există evaluări

- Hygienic Butterfly Valves f250 f251 Wafer Suedmo Brochure enDocument6 paginiHygienic Butterfly Valves f250 f251 Wafer Suedmo Brochure enSincro AutomatizacionesÎncă nu există evaluări

- 437 - Control Valve For General ApplicationsDocument16 pagini437 - Control Valve For General ApplicationsWahyu TryÎncă nu există evaluări

- Flowserve Argus FK76M Technical Bulletin Arenbr0015 EnaqDocument92 paginiFlowserve Argus FK76M Technical Bulletin Arenbr0015 Enaqsonalpanchal7Încă nu există evaluări

- High-efficiency pressure relief ventDocument5 paginiHigh-efficiency pressure relief ventjithin.rjn4055Încă nu există evaluări

- Pressure Range - 200 To 1480 PSIG: PurposeDocument2 paginiPressure Range - 200 To 1480 PSIG: Purposesunil601Încă nu există evaluări

- Ap 03 101Document36 paginiAp 03 101TariqÎncă nu există evaluări

- Spirax StrainerDocument4 paginiSpirax StrainerVrajesh ChoksiÎncă nu există evaluări

- S&P Overview - VGSP1014 - R0Document6 paginiS&P Overview - VGSP1014 - R0nicolasgonzÎncă nu există evaluări

- L&T Double Block and Bleed Plug ValvesDocument12 paginiL&T Double Block and Bleed Plug Valvesvijay10484Încă nu există evaluări

- Combination Conservation Vent & Flame Arrester: FeaturesDocument6 paginiCombination Conservation Vent & Flame Arrester: FeaturesCarlos Andrés BeltránÎncă nu există evaluări

- VB-02 - Bola CS CL600 SW (Apollo 83B-240)Document4 paginiVB-02 - Bola CS CL600 SW (Apollo 83B-240)joseÎncă nu există evaluări

- Pratt Hpseriesbfv Brof13263 Update v2Document12 paginiPratt Hpseriesbfv Brof13263 Update v2Onkar DograÎncă nu există evaluări

- Ball Valve Bv3Document45 paginiBall Valve Bv3JULIO CESAR PINEDA GUTIERREZÎncă nu există evaluări

- Vc d v Kea Kfa Kla Spira Trol Ti d413 03Document8 paginiVc d v Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiÎncă nu există evaluări

- DeZURIK Valve Selection GuideDocument18 paginiDeZURIK Valve Selection GuideJosé Manuel GonzálezÎncă nu există evaluări

- 10 00 1 (Valve Selection Guide)Document18 pagini10 00 1 (Valve Selection Guide)Zahid MehmoodÎncă nu există evaluări

- Spring Loaded Conservation VentDocument5 paginiSpring Loaded Conservation VentMustafa PardawalaÎncă nu există evaluări

- Premier Valves Product SelectorDocument12 paginiPremier Valves Product Selectorneelkant sharmaÎncă nu există evaluări

- Premier Valves Product SelectorDocument8 paginiPremier Valves Product SelectortcsÎncă nu există evaluări

- Brochure Isolation Valves Product Overview en en 5253576Document36 paginiBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RÎncă nu există evaluări

- Keystone K-Lok 360-370 Data SheetDocument12 paginiKeystone K-Lok 360-370 Data SheetMnttoMecÎncă nu există evaluări

- WKM DynaSeal 370D4 PDFDocument40 paginiWKM DynaSeal 370D4 PDFAlfredo MedinaÎncă nu există evaluări

- PASCAL Check Valves CatalogueDocument19 paginiPASCAL Check Valves Cataloguecrys100% (1)

- Hoke 1700 SeriesDocument38 paginiHoke 1700 SeriesOceanexÎncă nu există evaluări

- Pigging Products: Safe and Effi Cient PiggingDocument16 paginiPigging Products: Safe and Effi Cient PiggingAnonymous qhVGVpÎncă nu există evaluări

- Check Valve MS PDFDocument4 paginiCheck Valve MS PDFazeazeazeÎncă nu există evaluări

- Dual-Plate High Performance Wafer Check Valves, API 594: CatalogueDocument11 paginiDual-Plate High Performance Wafer Check Valves, API 594: Cataloguejun dongÎncă nu există evaluări

- Valves, Fittings and Tubing: Medium and High Pressure Condensed CatalogDocument20 paginiValves, Fittings and Tubing: Medium and High Pressure Condensed CatalogEnrique AssmannÎncă nu există evaluări

- ACA0291 GBDocument12 paginiACA0291 GBJosé Mariano ContrerasÎncă nu există evaluări

- Latest structural steel materials updateDocument3 paginiLatest structural steel materials updatejworder100% (1)

- The F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveDocument4 paginiThe F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveCapacitacion TodocatÎncă nu există evaluări

- High Performance Butterfly ValvesDocument8 paginiHigh Performance Butterfly ValvesTejas JasaniÎncă nu există evaluări

- Norm Ex ValvesDocument6 paginiNorm Ex Valvesapi-3712612Încă nu există evaluări

- Dezurik Valve Selection PDFDocument28 paginiDezurik Valve Selection PDFnoklit15100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Attachment 1 - API 650 Sections 7 and 8Document17 paginiAttachment 1 - API 650 Sections 7 and 8Carlos GutierrezÎncă nu există evaluări

- TritopDocument11 paginiTritopgaps1986Încă nu există evaluări

- EulaDocument2 paginiEulaKukuh DialosaÎncă nu există evaluări

- BETE EngineeringInformationDocument9 paginiBETE EngineeringInformationCarlos GutierrezÎncă nu există evaluări

- Clamp Mount MixersDocument1 paginăClamp Mount MixersCarlos GutierrezÎncă nu există evaluări

- ReadmeDocument1 paginăReadmeCarlos GutierrezÎncă nu există evaluări

- Ads-18-2005-Ca - Cge-Contrato U Orden de Compra o de ServicioDocument2 paginiAds-18-2005-Ca - Cge-Contrato U Orden de Compra o de ServicioCarlos GutierrezÎncă nu există evaluări

- BoquillasDocument127 paginiBoquillasDiegx OchoaÎncă nu există evaluări

- PVC & Mil of Lime Hdpe y CsDocument60 paginiPVC & Mil of Lime Hdpe y CsCarlos GutierrezÎncă nu există evaluări

- API 650 Des PDFDocument13 paginiAPI 650 Des PDFDhakshina K100% (1)

- C2quick PDFDocument54 paginiC2quick PDFCarlos Gutierrez100% (1)

- Dust Control Nozzle Selection PDFDocument4 paginiDust Control Nozzle Selection PDFsyamsudin2006Încă nu există evaluări

- Ameron Iso-14692 Muy BuenoDocument11 paginiAmeron Iso-14692 Muy BuenoCarlos GutierrezÎncă nu există evaluări

- Info99e6-Definition of TermsDocument2 paginiInfo99e6-Definition of TermsCarlos GutierrezÎncă nu există evaluări

- HDPE FittingsApril2012Document110 paginiHDPE FittingsApril2012Carlos GutierrezÎncă nu există evaluări

- Valve Specification Sheet for Ritepro CorporationDocument2 paginiValve Specification Sheet for Ritepro CorporationCarlos GutierrezÎncă nu există evaluări

- Experience MinebackfillDocument5 paginiExperience MinebackfillCarlos Gutierrez0% (1)

- Info02e5 Safety ValveDocument2 paginiInfo02e5 Safety ValveCarlos GutierrezÎncă nu există evaluări

- TM - 1050 - Resil - 2010-08 RESILIENT SEATED BUTTERFLY VALVES PDFDocument21 paginiTM - 1050 - Resil - 2010-08 RESILIENT SEATED BUTTERFLY VALVES PDFCarlos GutierrezÎncă nu există evaluări

- FRP Above Ground Installation ManualDocument32 paginiFRP Above Ground Installation ManualCarlos GutierrezÎncă nu există evaluări

- HDPE For Storage TanksDocument38 paginiHDPE For Storage TanksCarlos GutierrezÎncă nu există evaluări

- Info01e1-Piston Pumps-Rio Capim+IncoDocument2 paginiInfo01e1-Piston Pumps-Rio Capim+IncoCarlos GutierrezÎncă nu există evaluări

- Tuberia Astm A53Document2 paginiTuberia Astm A53Carlos GutierrezÎncă nu există evaluări

- A5 210 PDFDocument2 paginiA5 210 PDFCarlos GutierrezÎncă nu există evaluări

- 04 6 200 5Document1 pagină04 6 200 5Carlos GutierrezÎncă nu există evaluări

- G - Catalogo General Rite PDFDocument11 paginiG - Catalogo General Rite PDFCarlos GutierrezÎncă nu există evaluări

- 04 6 200 5Document1 pagină04 6 200 5Carlos GutierrezÎncă nu există evaluări

- 5 - ChecksizeDocument26 pagini5 - ChecksizeCarlos GutierrezÎncă nu există evaluări

- Install and maintain Check Rite wafer check valvesDocument18 paginiInstall and maintain Check Rite wafer check valvesRoman Arango Herrera0% (1)

- An Introduction To Software DevelopmentDocument19 paginiAn Introduction To Software Developmentsanjeewani wimalarathneÎncă nu există evaluări

- Using Accelerometers in A Data Acquisition SystemDocument10 paginiUsing Accelerometers in A Data Acquisition SystemueidaqÎncă nu există evaluări

- ACE Personal Trainer Manual Chapter 13Document59 paginiACE Personal Trainer Manual Chapter 13Đạt NguyễnÎncă nu există evaluări

- TPS6 LecturePowerPoint 11.1 DT 043018Document62 paginiTPS6 LecturePowerPoint 11.1 DT 043018Isabelle TorresÎncă nu există evaluări

- Service: Audi A6 2011 Audi A7 Sportback 2011Document160 paginiService: Audi A6 2011 Audi A7 Sportback 2011Javier SerranoÎncă nu există evaluări

- Addams Family Character BreakdownDocument2 paginiAddams Family Character BreakdowngabreÎncă nu există evaluări

- Eye Floaters Cure - Natural Treatment For Eye FloatersDocument34 paginiEye Floaters Cure - Natural Treatment For Eye FloatersVilluri Venkata Kannaapparao50% (2)

- Persian Songs (Vol.1) - Erotic PoetryDocument26 paginiPersian Songs (Vol.1) - Erotic PoetrygamahucherÎncă nu există evaluări

- System ThinkingDocument18 paginiSystem Thinkingpptam50% (2)

- Journal Pre-Proof: Crop ProtectionDocument34 paginiJournal Pre-Proof: Crop ProtectionKenan YılmazÎncă nu există evaluări

- HandwritingDocument25 paginiHandwritingajeshtnÎncă nu există evaluări

- Vacuum Pump Manual (English)Document12 paginiVacuum Pump Manual (English)nguyen lam An100% (1)

- 列印|單字總是背不住?教你輕鬆記憶法! (How to Memorize Vocabulary Perfectly With Minimal Effort) - VoiceTube《看影片學英語》Document4 pagini列印|單字總是背不住?教你輕鬆記憶法! (How to Memorize Vocabulary Perfectly With Minimal Effort) - VoiceTube《看影片學英語》John LamÎncă nu există evaluări

- Sap Press Integrating EWM in SAP S4HANADocument25 paginiSap Press Integrating EWM in SAP S4HANASuvendu BishoyiÎncă nu există evaluări

- Underground Cable FaultDocument8 paginiUnderground Cable FaultMohammad IrfanÎncă nu există evaluări

- A LITTLE CHEMISTRY Chapter 2-1 and 2-2Document5 paginiA LITTLE CHEMISTRY Chapter 2-1 and 2-2Lexi MasseyÎncă nu există evaluări

- Pe Unit2Document2 paginiPe Unit2srikaanth06Încă nu există evaluări

- Schedule-of-rates-MI 2014-15Document151 paginiSchedule-of-rates-MI 2014-15Vinisha RaoÎncă nu există evaluări

- 2022 Australian Grand Prix - Race Director's Event NotesDocument5 pagini2022 Australian Grand Prix - Race Director's Event NotesEduard De Ribot SanchezÎncă nu există evaluări

- Malunggay cooking oil substituteDocument5 paginiMalunggay cooking oil substitutebaba112Încă nu există evaluări

- 33 - The Passive Acoustic Effect of Turbo-CompressorsDocument10 pagini33 - The Passive Acoustic Effect of Turbo-CompressorsSindhu R ShekharÎncă nu există evaluări

- Aits 2223 PT III Jeea Paper 1Document15 paginiAits 2223 PT III Jeea Paper 1Suvrajyoti TaraphdarÎncă nu există evaluări

- Name CompilationDocument490 paginiName CompilationMark Taylor100% (1)

- Life Orientation September 2022 EngDocument9 paginiLife Orientation September 2022 EngTondaniÎncă nu există evaluări

- Bulletin 13.9.22Document4 paginiBulletin 13.9.22dbq088sÎncă nu există evaluări

- Essay 'Why Alice Remain Popular?'Document3 paginiEssay 'Why Alice Remain Popular?'Syamil AdzmanÎncă nu există evaluări

- 1950's or The Golden Age of TechnologyDocument15 pagini1950's or The Golden Age of TechnologyFausta ŽurauskaitėÎncă nu există evaluări

- 7310 Installation InstructionsDocument2 pagini7310 Installation InstructionsmohamedÎncă nu există evaluări

- HST.582J / 6.555J / 16.456J Biomedical Signal and Image ProcessingDocument23 paginiHST.582J / 6.555J / 16.456J Biomedical Signal and Image ProcessingEduardo AlvarezÎncă nu există evaluări

- Doctrina PNP Mayer LotDocument23 paginiDoctrina PNP Mayer LotWilson Francisco Saldarriaga CruzÎncă nu există evaluări